Pros and applicability

When this drill first appeared, it was used exclusively for making blind holes in soft and hard woods. Today it is also successfully used when working with materials such as chipboard, fiberboard, MDF, etc.

The most successful and large-scale application is recorded in the production of furniture, for example:

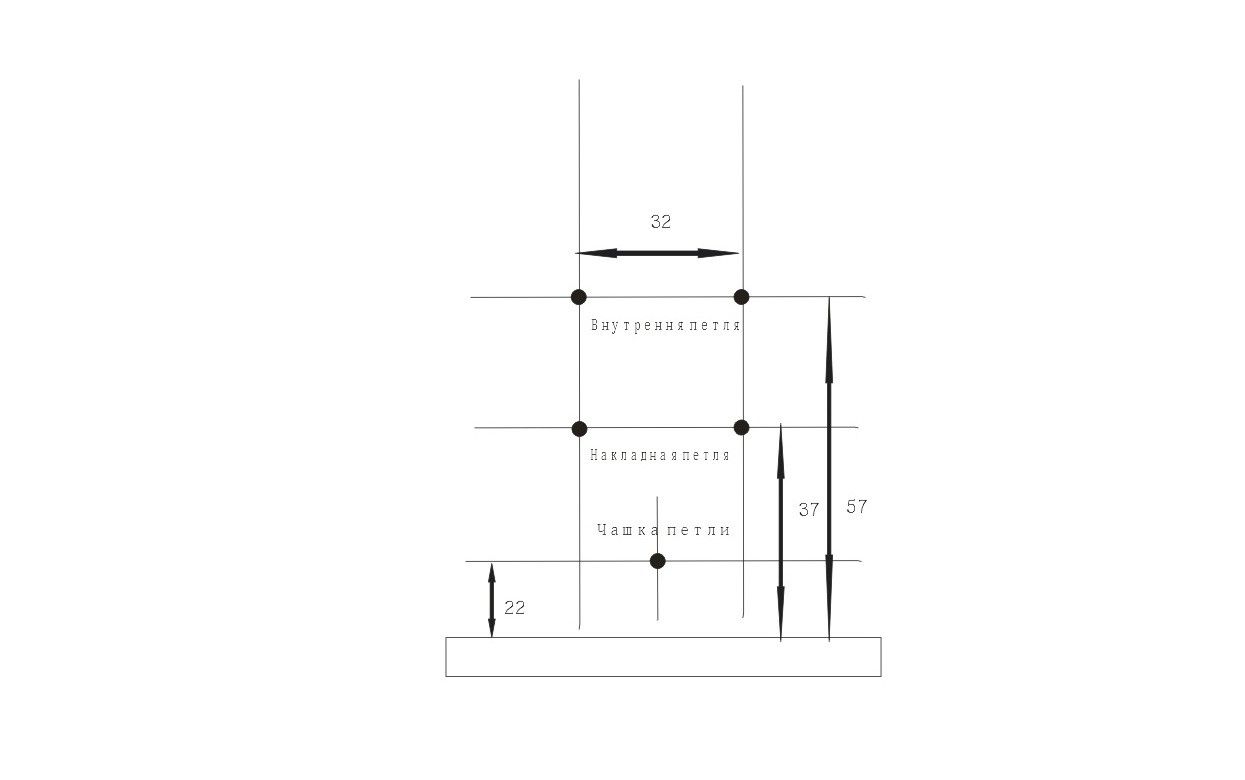

- For making holes for door hinges, interior locks and eccentric ties.

- It is also used if it is necessary to obtain high-quality deep holes with absolutely even edges when drilling.

No less successful is the use of Forstner's wood drill in other works, for example, when installing sockets, switches, installing mortise locks and window openings.

As for the objective advantages, these include:

- Superior performance.

- Due to the centering head, the fineness of the process and the speed of drilling holes are significantly increased.

- The Forstner drill has a large number of modifications in terms of parameters, so that holes can be drilled with a wide variety of diameters.

- Finally, it is the only drill that drills with maximum precision to the specified dimensions and with absolute precision.

General information about the Forstner device

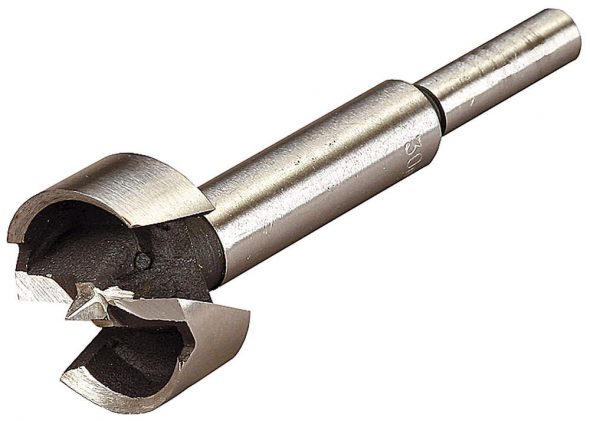

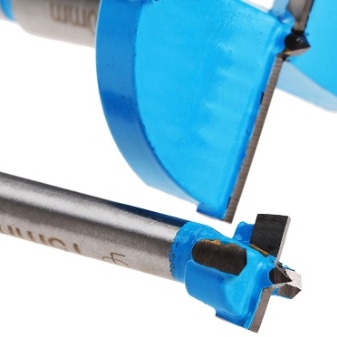

Forstner's drill for furniture hinges is a complex configuration device that has several varieties. But at the heart of all of them there is one center point, a transverse incisor and two located on the rim.

There are three main types of drills on sale for installing furniture hinges:

- Original design, milled and finished by hand

- Cast head, adapted for fully machine production

- Cast-in with welded-in HSS cutters

In terms of cost, these three types also differ radically - the most expensive are representatives of the first type, and the most budgetary ones are the third. The quality can be both consistently high (for the Forstner drills made according to the first type), and rather mediocre. in any case, this device is not too cheap and when buying it, you need to carry out a thorough visual inspection for the quality of workmanship (no surface defects, chips, even and symmetrical sharpening, accurate welding and hardening).

Main standard sizes and working diameters of the device

All variants of the device have a fairly wide range of diameters. The furniture hinge drill with a diameter of 35 mm is in great demand. Two other slightly less popular diameters are 26 and 40 mm. The length of the shank may vary depending on the manufacturer, but it, most often, is a standard 10-12 cm hexagon for modern drills and screwdrivers.

The shank can be chemically engraved not only with the manufacturer's logo and drill size marking, but also with a special immersion depth scale. Sometimes a removable immersion limiter may be included. It is a metal disc in diameter 4-6 mm larger than the outer diameter of the drill. The stop is attached to the shank using a screw screwed into its sleeve.

The process of working with Forstner's device

With a Forstner drill, the process of cutting a hole is greatly simplified. There are two possible options here:

- Without depth gauge. If the device does not have it, then you need to proceed as follows - poke a hole in the center with a tap, place a center point in it. Next, start drilling at medium speed. Taking frequent breaks to control depth.It is necessary at this time to apply the loop cup and see if it fits. In addition, breaks will prevent the drill from overheating and setting fire to the wood.

- With a limiter. In this case, the work is simplified. The main thing is to correctly set the immersion depth of the device. Marking on the shank or using a vernier caliper will help.

When setting the depth for the Forstner adaptation, the size of the central point must be taken into account. Most often it is 2 to 4 mm long. If you forget about it, then you can spoil the front surface of the part - the facade of the furniture.

In general, before starting work with real pieces of furniture, it is worth practicing several times with unnecessary pieces of material of the same thickness and composition. This will greatly facilitate the work.

When working with the device, try to observe the uniformity of its rotation and maintain its perpendicular position in relation to the surface of the part. To avoid chips on it, you can first stick a piece of masking tape to the drilling site. Once the recess is made, it will be easy to remove and the edges will be free of burrs.

Species overview

Various versions of Forstner's drill are produced today by both domestic and European manufacturers - a wide range of their products is presented on the Russian market. Many companies are trying to improve the design of the drill for ease of use, so on sale you can find models with a drill depth stop, which can be either fixed or adjustable. In addition, models that can be sharpened by machine are very popular. In such a drill, the cutting edge of the rim on the back of the cutters has a special cut.

Forstner's drill bits are also subject to modifications, depending on their type of model, they are divided into two main groups.

With carbide cutters

The design feature of such a tool is that some modifications have cutters to which sharpened elements made of high hardness carbon steel alloys are soldered. Such cutting edges significantly increase the cost of the tool, but these costs are justified by the efficiency of the work and the long service life of the drill.

With toothed rims

The design of the drill on the cutters has a serration located along the entire annular cutting rim. The advantage of such a tool is that during operation, the drill itself and the surface of the workpiece to be machined are less exposed to overheating. In addition, all modern Forstner drills with a diameter of more than 25 mm are available with teeth.

Instrument characteristics

Materials for making

The present, patented in the century before last, the drill is made of carbon steel. Other, non-original types of Forstner cutters, are made of high-speed (alloy) steel HSS, which has good performance at high cutting speeds and low cost.

Normal steel becomes softer when overheated and the incisors lose their sharpness. High speed steel is highly resistant to overheating. Some manufacturers apply a special coating based on titanium nitride to reduce overheating due to active work on the cutting part of the drill. This protection method is quite effective.

Rotational speed

There are several important recommendations for performing work with Forstner drills:

- When working, drills of large diameters quickly overheat, and therefore the rotation speed should be set lower.

- Performing work at low speed does not affect the quality in any way, it simply decreases productivity, but at the same time, good safety of the tool is ensured.

- On the packaging of all models of these cutters, the maximum permissible speed is always indicated, which must not be exceeded.

Sharpening features

During the operation of the cutters, the sharpness of their cutters gradually decreases and periodically it is necessary to sharpen, which is performed according to certain rules:

- The outer edge can only be sharpened from the inside to maintain the bezel size. The annular edge is sharpened with a round file, the rim with teeth is triangular.

- To sharpen the internal incisors, a file or a belt-type sharpener with fine notches is used, as well as a sharpening stone (fine-grained). Only the front sides of the incisors can be sharpened, and burrs can be removed from the back with a fine-grained stone.

- Fine-grained whetstones are used to refine the edges of the cutters and the central point.

Confirmation

The most common type of fastener is the confirmation. It is also the easiest to use. With its help, it is easier and faster to assemble furniture than using other types of furniture screed. Especially if during assembly you have to drill holes for fasteners yourself. With the help of a confirmation, two parts are connected at an angle of 90 degrees.

Increase

Fig. 1.

In order to pull off the two parts, you need to drill two holes. One is in one part, with a diameter equal to the diameter of the confirmation head, the other, at the end of the second part, of a smaller diameter equal to the diameter of the threaded part.

As a rule, drills with a diameter of 6 and 5 mm are used for this, respectively. However, there is a combo drill available for simultaneous drilling of holes. It is very convenient. There is no need to constantly rearrange the drills or use two drills at the same time.

Increase

Fig. 2.

Confirmate is a universal fastener, but it has some drawbacks and application features.

Confirmate should be applied simultaneously with the use of dowels. A dowel is a wooden rod with a diameter of 6-8 mm and a length of 20-30 mm (pictured below, next to the confirmation). The dowel acts as a guide and does not allow parts to move during tightening.

Increase

Fig. 3.

Despite the fact that furniture assembled with the use of Confiramate can be assembled or disassembled, furniture made of laminated chipboard does not tolerate this very well. As a rule, after one disassembly, the furniture screed already does not hold well.

Wrap the confirmat carefully. The best option by hand or with a screwdriver at low speed

Otherwise, the confirmation thread turns into a drill, which breaks the hole.

Increase

Fig. 4.

In order to drown the hat into the body of the piece of furniture, you should use a key and do it carefully, otherwise there is a possibility of thread breaking. Sometimes it is necessary to pre-make a ciconing

Confirmation refers to "visible" fasteners. Those. unlike other types of fasteners, it remains visible, so it is necessary to use special plugs or stickers to hide the fasteners.

Increase

Fig. 5.

Increase

Fig. 6.

Fig. 6.