Circular drill device

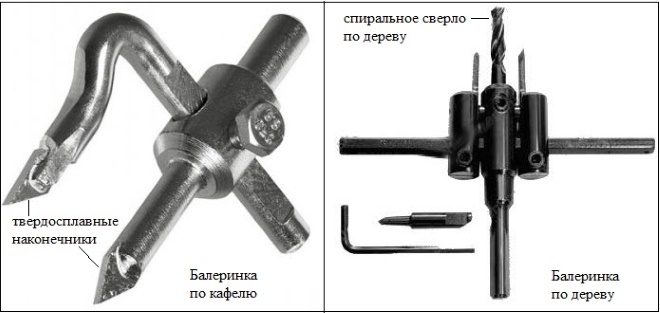

Drill-ballerina for wood is made of carbon, tool, alloy steels, which are not suitable for processing hard materials: metal, tiles, porcelain stoneware. But they easily cut drywall and plastic.

Drill-ballerina for wood is made of carbon, tool, alloy steels, which are not suitable for processing hard materials: metal, tiles, porcelain stoneware. But they easily cut drywall and plastic.

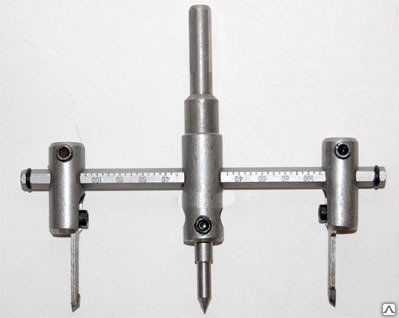

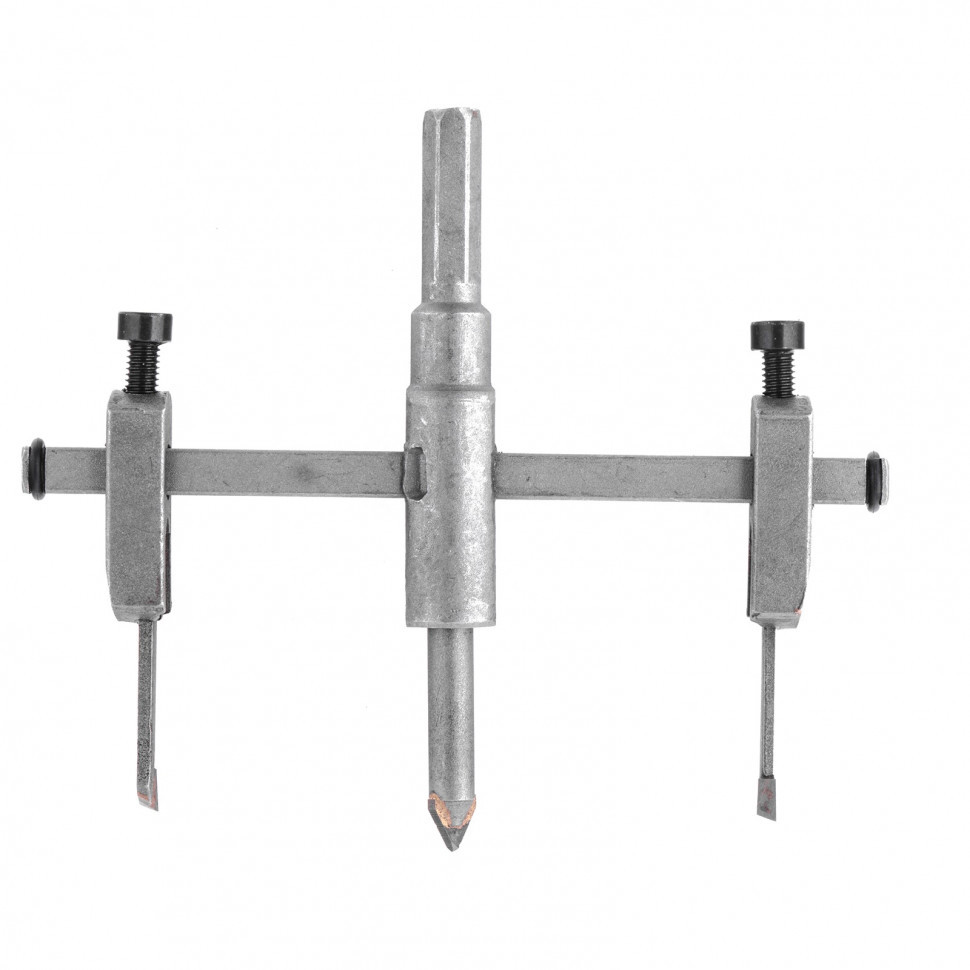

The two-incised ballerina looks like an ordinary compass. But the design is much more complicated. Bracket and cylindrical shank are made in one piece. The bracket has two holes. A center drill is installed in one. A barbell is installed in the second. Both are fastened with screws.

To set the required diameter, the cutters move along the bar. It has a vernier scale on it. The tool holders are also fixed with screws. The incisors are knife-shaped. The oblique edge of the cutter should be directed in the direction of rotation, clockwise.

If the drill becomes blunt during operation, it can be easily replaced. If the cutters are dull, then, having the skills of working on a sharpening machine, they can be refueled. The shank of the structure is fixed in the chuck of an electric drill. It is worth remembering that the small power of the power tool may not be enough to work as a ballerina, unlike drills for metal.

How to drill a large hole in a tile

The need to drill large-diameter holes in the tile arises when preparing a place for installing pipes and other plumbing communications, as well as for installing electrical outlets. To drill such holes in the tile, special tools are used, which can be a tubular drill, a ballerina drill on a tile, etc.

The ballerina, with which you can create holes of various diameters in the tile, somewhat resembles in its design an adjustable feather drill used for working with wood products. The ballerina works according to the principle of a compass: a central drill serves to center her, and a working cutter, which can move along a special bracket, cuts a hole of the required diameter on the surface of the tile. By adjusting the position of the cutter, it is possible to obtain holes with a diameter in the range of 30–90 mm.

Drilling a hole with a ballerina

At the same time, the ballerina is unproductive, since it is possible to work with her only at low drill speeds. Moreover, such a tool is not very convenient to use, since it is rather difficult to hold it in one position.

More effective (but also expensive) is a circular drill for tiles, which is often called tubular. Its cutting part can be coated with diamond or tungsten carbide spraying.

Drilling the tile with a tubular drill without a center begins at low speeds, slightly deviating the drill from the vertical position

When using a tubular drill, a number of rules should be followed:

- perform drilling at a rotation speed not exceeding 500 rpm;

- intensively cool the tool during processing;

- use the tool only on a stationary drilling machine, if not provided in its design.

DIY making

When there is no device at hand that can cut a circle out of wood material or other, then you can try to make it yourself. To do this, you need a collet holder and a set of the desired size of feather drills. A collet is a clamping mechanism that is used to clamp a rotating cutting tool. It can be made from a bolt, the diameter of which depends on the brace chuck, machine tool or drill.The head of the bolt must be cut off, and cut crosswise from the side of the thread.

When there is no device at hand that can cut a circle out of wood material or other, then you can try to make it yourself. To do this, you need a collet holder and a set of the desired size of feather drills. A collet is a clamping mechanism that is used to clamp a rotating cutting tool. It can be made from a bolt, the diameter of which depends on the brace chuck, machine tool or drill.The head of the bolt must be cut off, and cut crosswise from the side of the thread.

The center drill is ground to the taper and the cutting drill to the wedge. In this case, the end of the center drill should be 3-5 mm longer.

The drill is held by two nuts: one is a clamping nut, the other is a guide. If holes with a constant radius are cut, the drill can be welded to the holder.

Device and principle of operation

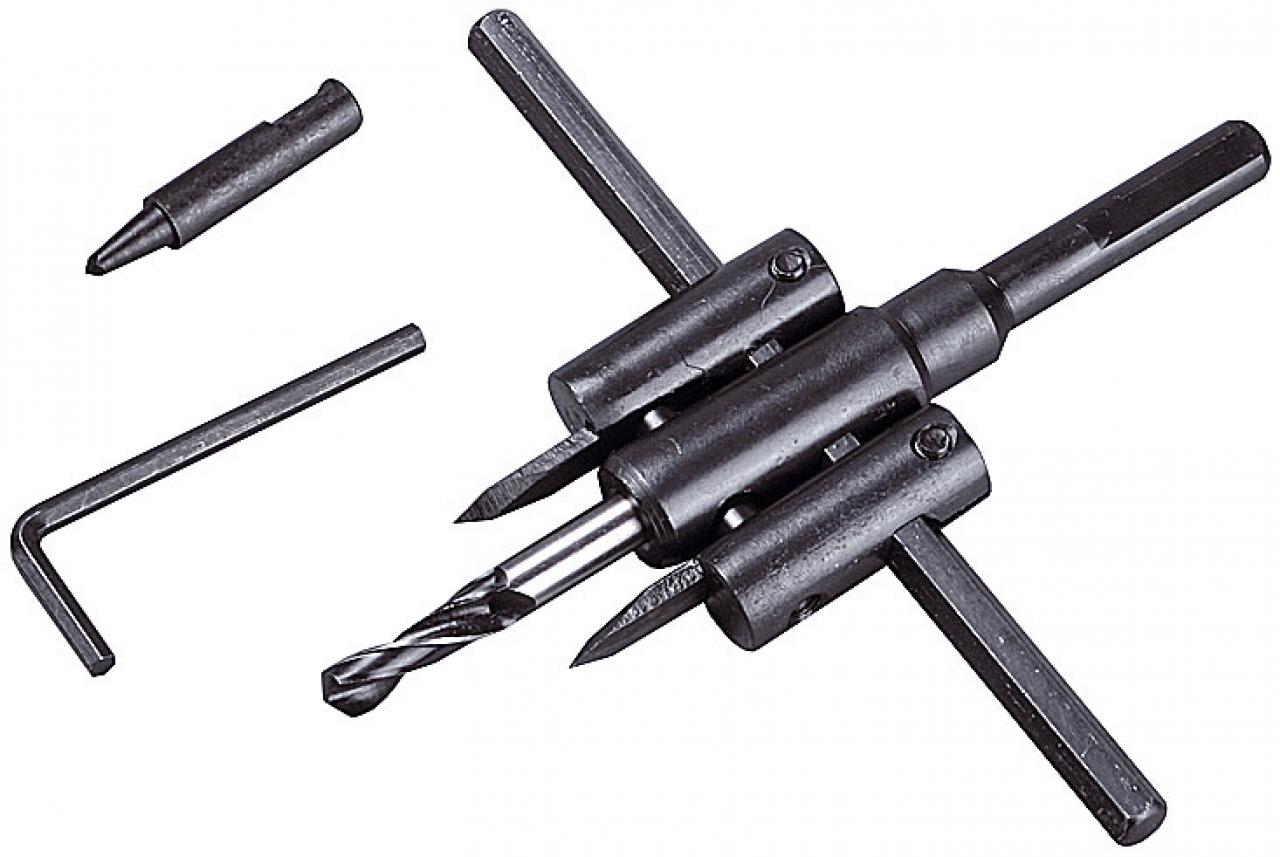

The construction of a circular drill is quite simple and basically consists of three parts:

- drill, responsible for centering the fixture;

- a fixing rod of a certain length, on which the cutting elements are installed;

- cutters equipped with a device for attaching them to a rod, their number ranges from one to three.

This design is used on single and double cutter models. If there are three cutting elements, then in this case the cutters are fixed on a circular disc, and move along the slots to change the radius. Additionally, some models can be equipped with a protective cover that protects the working person from flying shavings or sawdust. It also protects the worker from being hit by shrapnel when the device is destroyed.

Now let's see how to drill. With a central drill, you need to drill at a predetermined point. If the materials are strong, for example, iron, tiles or laminate, then it is better to first mark the drilling site with a conventional drill. This is done for convenience, so that the "ballerina" does not slip on the surface and does not scratch the top layer.

Next, we cut the path of the radius we need.

Again, here you need to pay attention to the material in which the holes are drilled. If this is a tile, then to prevent damage to the facade surface, you need to drill at a low speed and lubricate the tile with water or machine oil.

This will prevent damage to the tiles and the scattering of fragments. Tile panels must be laid on a flat surface, otherwise they will crack with effort.

If the tile is already attached to the walls or floor, then you only need to cut through it, and then change the "ballerina" for a drill for concrete. When drilling laminate or veneer, it is difficult to pass the top layer, but it goes further easier. There are no special instructions for wood, iron, plastic and drywall. The last step is to remove the cut objects.

In addition to the basic instructions, there are a few additional nuances.

- in no case should you put pressure on the tool, lean on it with your whole body: this can damage the device and split the material in which the hole is made;

- you can not use "hammer" or "perforating" modes, only drilling;

- no need to let the "ballerina" overheat: high temperatures may deteriorate the coating of the incisors;

- if drilling is slow, then you should add revolutions.

To save your health when working with a device for drilling circular holes, you need to follow some simple rules:

- before starting work, you need to check whether all components of the device are securely fixed;

- wear goggles or a mask to protect your eyes;

- clothes should not contribute to getting into rotating elements;

- if possible, it is imperative to install a protective grill on the "ballerina".

Varieties of the instrument

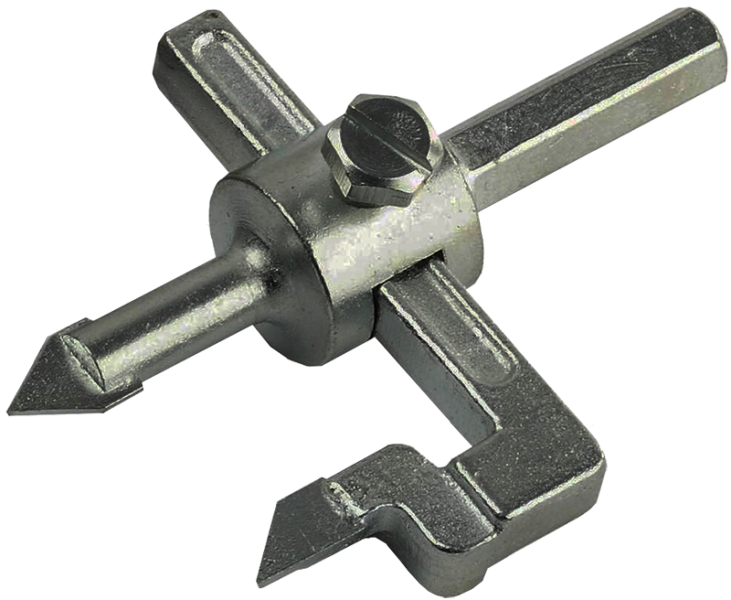

In addition to the classic double-cut circular drill, there are single- and three-cut models. In the design of a single-cutter drill, the cutting part is directly attached to the rod. The cutter and centering lance are equipped with carbide inserts. They make it easier for the ballerina to work on tiles.

In addition to the classic double-cut circular drill, there are single- and three-cut models. In the design of a single-cutter drill, the cutting part is directly attached to the rod. The cutter and centering lance are equipped with carbide inserts. They make it easier for the ballerina to work on tiles.

In three-cutter models, the cutters are mounted on a circular platform with grooves. The cutters move along these slots. They have a scale. The correct size allows you to cut more accurately and quickly.

Currently, some models are equipped with a plastic protective grill. It improves work efficiency and convenience.

The ballerina for metal is equipped with carbide plates with a sharpening cut-off turning tool. A large cutting force dictates the use of stationary or portable radial drilling machines. Basically, the holes are cut out in galvanized sheet, the thickness of which does not exceed one millimeter.

Features of working with the tool

The principle of working with a circular drill is simple. A hole is drilled with a centering drill, and then the cutters are included in the work. They gradually make a narrow groove, gradually cutting through the material in a circle to the full depth.

The materials used in working with the ballerina are various: wood, fiberboard, chipboard, MDF, drywall, plastic. One common point - the thickness of the part should be no more than 15-20 millimeters. This parameter is limited by the length of the cutters. Usually the manufacturer indicates the maximum drilling depth on the packaging. When trying to drill thicker material, problems with ragged edges may occur.

Runout is typical for single-cut tools. This is caused by the lack of balancing in relation to the longitudinal axis of the drilling. Runout will be felt especially when cutting large diameter holes. Cut holes with a drill at low to medium speeds. When working on a drilling machine, such problems do not arise.

Also, inconvenience during work can be delivered by a laminated or veneered surface. After passing through the decorative layer, drilling proceeds without problems.

A feature of the circular drill can be considered the ability to adjust the diameter. The distance between the incisors can be set on a scale on the bar or more precisely using a vernier caliper. This is convenient if you need to make a hole without gaps for a pipe or a round piece.

The spacing of the cutters from the center can be adjusted separately. It is necessary to position the cutting parts as accurately as possible. This will eliminate unnecessary effort during work and extend the life of the tool.

How to choose the right one and what to look for

Choosing a quality circular drill is easy enough

The main thing is to know the main points to which you should pay attention first of all, but also not to lose sight of the little things.

Construction, a very important point: a ballerina on a tree comes with one chisel or two or more. For frequent use, it is better to purchase an option with two or three cutting elements. It is easier to work with such devices and the quality of the processing performed will be at an acceptable level.

The possibility of replacing individual parts will not be superfluous. Inexpensive circular drills can have a one-piece shank with a fixed center drill and rod.

Metal, strength and ability to withstand working loads depend on its quality. A quality tool is made from high-strength steel or alloys. Shank and tool holders are machine-shaped. The rod is usually stamped and made of the same metal.

Low-cost options often use soft metals or alloys that can be brittle. Under load, parts can deform or collapse. Such a tool will not last long and it will also be difficult to achieve accuracy from it.

Workmanship, the main feature is the absence of backlash and distortions. All parts must fit together and securely fastened with fixing screws.

The markings of the bar of a high-quality ballerina are stamped. Sometimes the divisions are highlighted with bright paint for better visibility.

Cutters, high-quality cutting elements are made of hardened tool steel. On the holders, they are fastened with rivets or using soldering. Solid cutters with holders (made of the same metal) quickly become dull and are not durable.

The manufacturer, when choosing any tool and consumables, preference should be given to well-known and long-proven brands and brands.The most common are Topfix, Stayer, Irwin, Strum.

Buying an adjustable rotary drill for home use, or drilling multiple holes if necessary, pays off. This eliminates the need to purchase an expensive tool that may only be needed a few times.

Criterias of choice

Before choosing a "ballerina", you need to know its main advantages over other devices for cutting large holes, be it crowns, jigsaws, etc.

Pluses of circular devices of the adjustable type:

- the ability to replace the central drill or lateral incisors at any time;

- structural reliability;

- if necessary, cutting elements can be sharpened;

- adjustable hole width.

Now let's look at the parameters that you need to pay attention to when buying.

- Reliability. It is unlikely that you can determine this criterion visually, so it would be better to check the quality certificates for products from the seller. Most likely, they will not be for a low-quality product.

- Workmanship. Before purchasing, you need to carefully examine the device for the presence of shells, chips and other flaws. The incisors must be well and accurately sharpened. If the drill is very long, check if it is even. Usually these defects are visible immediately and by eye.

- Package. High-quality products from well-known manufacturers usually have bright and solid packaging. There will be no grammatical errors in the text. None of the famous brands can afford to package their products somehow.

- Price. Cost can also be considered an indicator of quality. Inexpensive models last a very short time.

Famous brands care about their reputation, and their products will meet all quality criteria. Therefore, it is better to contact authorized dealers so that the money is not wasted.

The next video tells about the ballerina drill.

What is a ballerina

The cutting tool, commonly referred to as a ballerina, has a more professional name - “circular adjustable drill with incisors”. The drill is located in the center of the tool and is used to center the hole. The radius of the circle, which will be described by the cutters, is counted from the centerline of this drill.

To equip ballerinas, drills of the first or auger type are used, since the conical tool does not cope well with ceramic materials and can slide off their surface. This slippage can result in damage to both the tool itself and the tile surface.

The ballerina on the tile differs from the nozzle designed for drilling holes in wood materials

Application of special drills

Special drills for ceramic tiles are used when a small diameter hole is required. As such a tool, if it is required to make only a few holes in the tile, you can use a regular drill for wood, sharpening it sharper, but a drill for metal work, equipped with victorious solders, is better for these purposes. The resources of the latter, if provided with high-quality cooling, will be enough to make more holes.

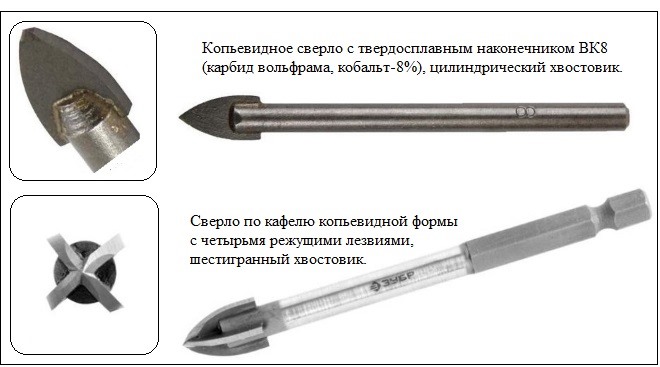

Of the inexpensive ceramic drills, with which it is convenient to create holes for dowel fasteners, spear-type tools should be distinguished. With one such drill, which can be up to 12 mm in diameter, you can create up to five holes in a tile. When using this tool, it should be borne in mind that it is possible to drill tiles with it only at low drill speeds.

Varieties of spear drills for tiles and ceramics

You can also drill the tiles for the placement of the dowel fasteners using drills equipped with carbide inserts and gear cutters. The latter differ from ordinary carbide-type drills in that their cutting inserts have one-sided and sharper sharpening. The disadvantages of using such tools are that it is quite difficult to obtain a high-quality result with their help, and before drilling the center of the future hole must be punched.

More convenient to use is the pen tile drilling tool. The advantages of such a drill are that before using it, it is not required to perform preliminary punching of the tile, and it is much easier to aim it at the center of the future hole. With the help of tiling drills, the cutting part of which is made in the form of a feather, it is possible to make holes with a diameter of up to 30 mm.

The most expensive, but also distinguished by the greatest resource of work, are spear-shaped drills, on the cutting part of which diamond spraying is applied. It is advisable to purchase such expensive and reliable drills when a large amount of work is to be done with their help.

Tubular diamond drills for tiles

Experts advise adhering to the following recommendations when drilling holes in the tile for placing dowel fasteners.

- After the tile already attached to the concrete wall has been drilled to its full thickness, the tile drill should be replaced with a concrete tool. In this case, a drill or perforator can be put into percussion mode. This approach can significantly extend the life of a drill designed for work on tiles only.

- To prevent the tiles, fixed on a concrete base, from accidentally damaging when driving in the dowel, the hole in it must be of a larger diameter than in concrete.

- In order to drill a hole in the seam between two tiles without damaging them, you should choose a tool whose diameter is less than the width of such a seam.

- When hammering in the dowel, you must act very carefully so as not to accidentally damage the surface of the tile.

Where and which drill is best to buy?

As for drills for tiles of foreign production, the domestic market is mainly represented by American, Polish and German models. Their price is much higher than domestic ones, and the packaging is more beautiful. In terms of quality, they differ little from Russian ones. Therefore, overpaying is not at all necessary. A separate price category is the so-called "professional" tile drills. Not everyone can afford them. But it is also very easy and convenient to work with them. Their appearance is also simply amazing. The soldering of the plates is performed with the highest degree of accuracy and precision, the joints are almost invisible. The tip is sharpened in such a way that it is simply impossible to repeat it at home. In addition, these tiles differ from ordinary drills in that they have a fixed service life, during which they cannot become blunt. After its expiration, the drill loses its "professional" status and, after sharpening at home, can be used as usual.

Specifications

For the manufacture of the device, carbon steel is used. It is an alloy of carbon with iron. The amount of carbon determines the strength of the tool, the ability to resist stress. For greater wear resistance, less sensitivity to overheating and deformation, some manufacturers add chromium, silicon, tungsten, vanadium, molybdenum to the alloy. For example, the P6M5 marking indicates that the steel from which the cutter or drill can be made contains 6% tungsten, 5% molybdenum, this increases the strength.

For the manufacture of the device, carbon steel is used. It is an alloy of carbon with iron. The amount of carbon determines the strength of the tool, the ability to resist stress. For greater wear resistance, less sensitivity to overheating and deformation, some manufacturers add chromium, silicon, tungsten, vanadium, molybdenum to the alloy. For example, the P6M5 marking indicates that the steel from which the cutter or drill can be made contains 6% tungsten, 5% molybdenum, this increases the strength.

The drill bit can be tipped with carbide for durability and longer life.Such devices give a cutting depth of 30 mm, and without soldering - 25 mm.

Rotations from 1000 rpm to 1400 rpm will be comfortable for the operation of the tool.

The ballerina, depending on the functional accessory, makes holes, the radius of which is in the range from 20 to 150 mm, while the diameter of the cut circle will be 2 times larger. For example, using a table-top drilling machine or a drill, a ballerina for metal allows you to cut or drill holes in metal with a radius of 22 to 105 mm. The thickness of the material to be processed must be up to 14 mm. The material can be steel, cast iron, brass, bronze, aluminum.

How is the tile cutting process performed?

There is a certain algorithm that should be followed when using a tool for drilling holes in tiles, such as a ballerina.

- First of all, on the front side of the tile, you need to mark the center of the future hole, for which you can use a regular core.

- The cutter or cutters of the ballerina, which will carry out the main work on cutting the material, are installed and fixed at the required distance from the axis of the central drill.

- It is advisable to lubricate the part of the tile on which the cut will be made with machine oil. In this case, you should check that it does not fall into the center of the circle, which can lead to the drill slipping.

- The drill, located and rotating in the center of the future hole in the tile, must pass through its surface before the incisors, therefore, it must have a greater length than their protruding part.

- The tile in which the hole is made with the help of a ballerina must be rigidly fixed on a flat surface of a wooden board or drywall. Conventional clamps can be used to provide this fixation.

- The hole is drilled at low tool speeds, while it is desirable to constantly water the groove forming on the tile with machine oil.

- After the cut in the tile is made more than half of its thickness, and the central drill has passed through the material to be processed, the product is turned over and a similar processing is performed on its reverse side.

- The tile on the reverse side is drilled to the end, and the edge of the resulting hole, which may not turn out to be too even, is processed with a file, emery cloth or a grinder.

Despite the fact that the holes obtained with the help of a ballerina differ in not very even edges, it is quite reasonable to use it to perform not too voluminous work. In addition, the uneven edges of the holes will later be hidden by the outer panels of electrical outlets and other decorative elements.

Peculiarities

The main feature of the "ballerina" drill (its full name sounds more than impressive - "adjustable type circular drill with incisors") is the ability to change the diameter of the cut circle. The distance between the cutting elements can be adjusted using the auxiliary scale on the mounting bar. If maximum accuracy is required, then here you have to use a caliper. This is quite convenient when it becomes necessary to make a hole for a pipe or other round piece without backlash.

The second distinguishing feature is the number of incisors. It can be from one to three and the quality of processing the edges of the cut holes depends on this. If you have purchased an adjustable drill with one cutting element, then you need to be prepared for the fact that the tool will "hit". Vibration increases with an increase in the diameter of the cut hole: the larger it is, the higher the runout. This is due to the fact that there is no balancing about the longitudinal axis.

Drill metal characteristics

The drilling process is the mechanical and physical impact of the drill, therefore the raw material from which it is made must have such properties as:

- Strength. This will allow drilling into thick layers of wood.

- Fatigue strength. It characterizes the ability of a drill to withstand cyclic loads in contact with wood.

- Plastic. Allows you to carry out operations to prepare the drill for work.

- Hardness. Determines the durability of the metal.

- Heat resistance. Retains the mechanical properties of the drill when heated at high drilling speeds.

- Corrosion resistant. Possibility of drilling raw wood.

We are sure that the article on what are the drill bits for drilling in concrete for a rotary hammer will be useful to you.