How to choose?

There are some important aspects to consider before purchasing drills. First, decide what material the model will be used for, because each individual variety is used to drill only certain surfaces.

Specimens for concrete and metal have greater strength and hardness. Woodworking products are less stable and wear-resistant.

Also, before purchasing, look at the dimensions of the drills. In this case, the dimensions must correspond to the dimensions of the surfaces to be drilled. In addition, the choice will depend on which hole you want to make.

See what material the drills are made of. The most common and reliable options are tools made from different types of steel. They are particularly durable. It is also best to select samples with a protective coating that will prevent them from possible corrosion on the surface.

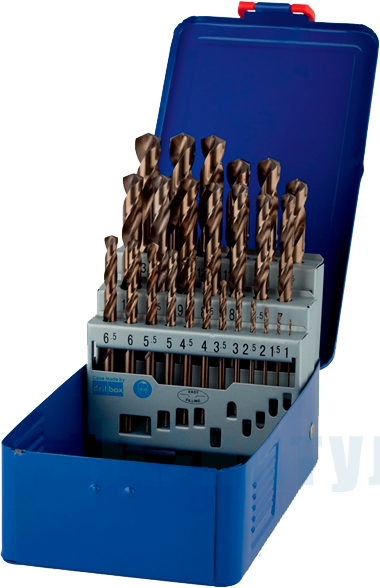

If you often use drills during construction work, then it is better for you to immediately purchase a set with such devices. Typically, these kits contain samples of different sizes and designed for drilling in different materials.

Carefully review the working part of the products before purchasing. It should not even have minor irregularities or scuffs. Such defects can affect the quality of work, make the grooves uneven or spoil the material.

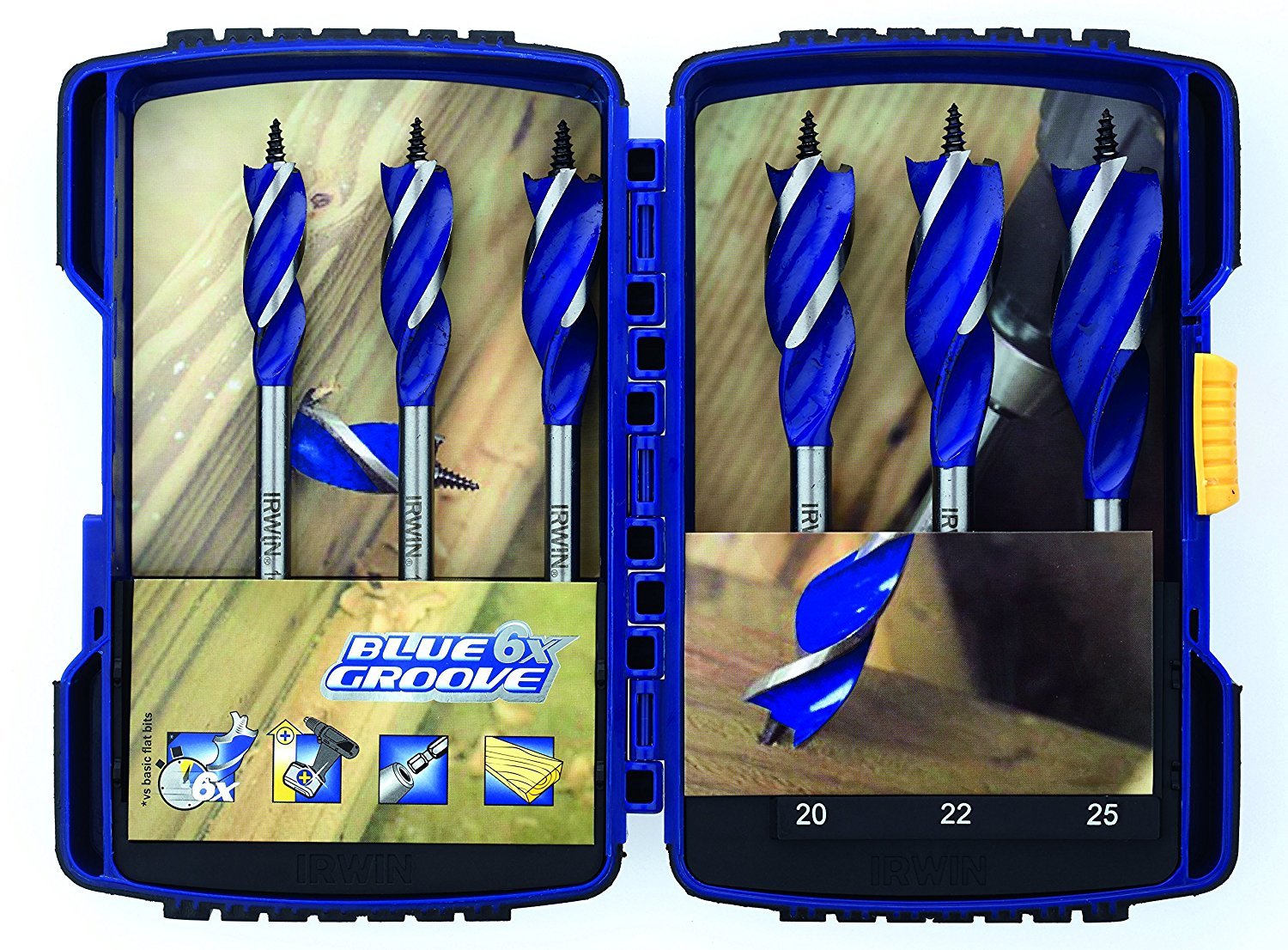

For an overview of the Irwin Blue Groove series drills, see the following video.

Assortment overview

Today in hardware stores you can find a large number of drills from the Irwin manufacturing company.

Wood. Irwin's wood drills are part of the innovative Blue Groove series. The models in this collection are designed for ultra fast drilling. They are much more powerful than standard tools. These samples have replaced the old Speedbor drills. The new parts come with a special patented blade that allows you to make the deepest hole possible in a short time. In addition, the metal rod of the new products has a greater length in comparison with the outdated models. They are equipped with a special parabolic groove, which makes it possible to machine surfaces without leaving a large amount of chips.

In addition to the above models, the Irwin manufacturing company also produces diamond drills for processing ceramic products. These varieties are used to create holes in hard and soft tiles.

These attachments should only be used for hammerless drilling.

It is also necessary that the rotation occurs at an angle of 45 degrees - this will avoid slipping during operation. When the depression begins to form gradually, the device is slowly raised vertically.

The diamond tool does not need to be pressed or physically applied while drilling - it must work independently. Sharp sharpening of the product allows the cutting part to be restored over time.