General information

The Forstner drill is very different from the popular and familiar to everyone spiral models. It is more correct to even select it as an end mill, because its cutting edge is at the end. This important feature helps to make blind holes of huge diameter with high-quality centering according to preliminary marking. This precision is achieved by the centering head of the fixture.

A perfectly sharpened drill bit can guarantee a clean finish on the inside of the hole. This type of device is distinguished by high performance, and a long service life, subject to the rules of work. The tool is easy to use and can be used with full success both in standard special machines and in hand-held electric devices. At the moment, the Forstner drill has been improved by the presence of very strong insert parts in the form of a cutting edge. This helped to extend the term of its use several times.

A perfectly sharpened drill bit can guarantee a clean finish on the inside of the hole. This type of device is distinguished by high performance, and a long service life, subject to the rules of work. The tool is easy to use and can be used with full success both in standard special machines and in hand-held electric devices. At the moment, the Forstner drill has been improved by the presence of very strong insert parts in the form of a cutting edge. This helped to extend the term of its use several times.

Advantages

This tool, in comparison with other designs, has two big advantages: the cleanliness of the processed surface and the ability to perfectly hold a certain direction. This is possible even on overlapping parts or when the diameters of the holes extend beyond the edges of the workpiece.

Cut quality of the sidewalls is achieved by cutting the fibers around the circumference even before the main cutting edge touches them. This helps to avoid chipping and scuffing of the material outside the required diameter.

The second plus is due to the fact that the direction is held not by the centering tip, but by the lateral annular special edge and the entire cylindrical plane of the working surface. After the start of material sampling, the drill is firmly held in the created hole.

Briefly about the size

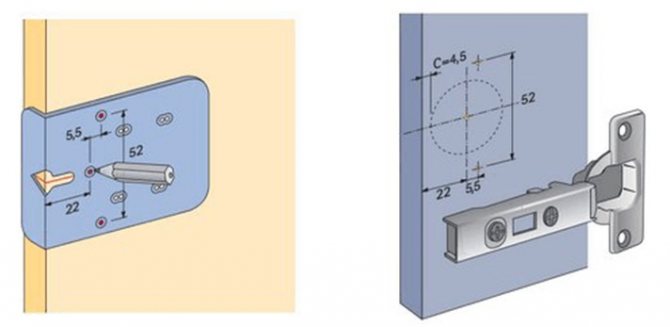

The holes in the furniture product are needed in order to fit the bowl of the furniture hinge inside, fix and ensure a reliable connection between the canvas and the fittings.

The diameter of the special drill used is selected based on the size of the purchased and used furniture hinge. Most often on sale you can find bowls of loops with a diameter of 26, 35 and 40 millimeters. Moreover, in the overwhelming majority of cases, manufacturers of furniture accessories use a diameter of exactly 35 mm. It is universal in size, optimal for most types of standard furniture where hinges are required. But since there are also non-standard solutions, special hinges are also sold for them. And for these hinges, you can purchase the corresponding cutters.

No special skills are required for insertion. But experience, even the slightest, will not be superfluous.

In addition, I would like to remind you of a set of tools for a furniture maker, which are considered basic and most essential. It is definitely worth including a hinge cutter or just a Forstner drill in this set.

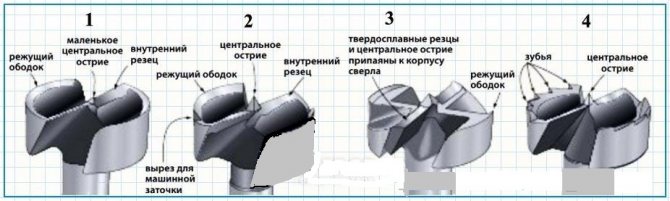

Design features

The drill itself is shaped like a milling cutter with an extended tip. Has a cylindrical head. The working part of the tool consists of a short centering point and two main cutting edges (knives) located diametrically to each other. The resulting chips are removed by two chip removers. The centering point provides the ability to position the drill in the center of the future hole. The outer cutting edge is interrupted in two places by the main blades. The peripheral edges when drilling create the sidewalls, and the chip removers create the bottom of the holes.

The profile of the drill resembles the letter "Z" (when mirrored it looks like the letter "S").A selective cutting edge is placed on the transverse jumper, and along the entire circumference of the drill there is a scoring edge that acts as a limiter and holds the tool in the required diameter. The drilling direction is maintained by the rim and not by the center point.

Forstner drills are made from carbon steel using the turning method. This allows you to maintain a significant wall thickness of the drill, which reduces overheating of the tool during operation and achieve greater tool life of the cutting edges. Considering the material of manufacture, it is possible to fully justify the relatively high cost of the Forstner drill in relation to its counterparts.

Choice of cutters

Which cutters are better to buy - expensive real ones or cheap non-original ones? The choice depends on how often you need to use them in your work. In a workshop where a permanent production of furniture products is planned, you will have to use this tool quite often. Moreover, you will need cutters of different sizes. It is unprofitable to purchase expensive tools only for your household needs.

Which cutters are better to buy - expensive real ones or cheap non-original ones? The choice depends on how often you need to use them in your work. In a workshop where a permanent production of furniture products is planned, you will have to use this tool quite often. Moreover, you will need cutters of different sizes. It is unprofitable to purchase expensive tools only for your household needs.

With active use, it is better to choose original products in order to ensure continuous operation and at the same time keep the tool in good condition for a long time. The high price will pay off over time.

For rare use, it is better to buy a set of 6-7 cutters of common sizes (including a 35 mm Forstner drill), the price of which will correspond to one expensive original copy. With this set, you can perform many types of work where you need to create holes of different sizes. With the help of these tools, you can create a furniture set with your own hands or simply replace new fittings that require the manufacture of high-quality holes.

Design features

The Forstner drill has:

- Centering tip.

- Cutting edges in the amount of 2 pieces.

If you look closely, you can see that the cutter is similar in profile to the Latin letter Z. The principle of drilling is in the choice of wood cutting edges, and accuracy is ensured by a special tip limiter.

OLYMPUS DIGITAL CAMERA

OLYMPUS DIGITAL CAMERA

When drilling holes, the Forstner drill is characterized by such a positive quality as chip ejection, as a result of which the cutter never gets jammed, unlike other analogues.

Various metals are used for manufacturing, but most often high-speed steel, since only it is able to withstand the heating that occurs during the drilling process.

Recently, some manufacturers are introducing an interesting addition in the form of carbide taps, titanium spraying or toothing. Thanks to these innovations:

- The quality of drilling is improved.

- The probability of metal overheating and, accordingly, darkening of the wood is practically excluded.

- The speed of work is increased without losing the purity of processing.

Operating rules

They are designed to make work easier and prevent injuries:

- The drill must be accurately positioned. For this, the centering point is pressed into the wood until it touches the outer edge. The nozzle works at low rpm up to 1800. Drilling should be started at a minimum rotation speed of 800 rpm;

- The working speed is directly related to the hole diameter. The larger it is, the less speed it needs to be drilled. This helps to maintain the optimum temperature on the working part of the tool;

- The Forster drill can be equipped with a depth stop. This is a useful option designed to fix the depth of the cut, as well as increase safety measures during work;

- Sometimes the thickness of the material does not allow full use of the functionality of the tool. If the sheet of wood is too thin, the centering tip can punch through it, then two drills are used. The first sets the direction of movement. The second has a sharpened point. With its help, the required hole thickness is selected.

Selection rules

You can choose the right drill-milling cutter for use if you take into account all the significant points.

- Country of origin and brand. Inexpensive products from China do not always justify the hopes placed on them - they quickly become dull, break, bend. More reliable options are produced by companies from the USA, Germany, and Russia. Market leaders include Metabo, Hawera, Ruko.

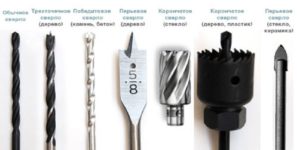

- Material of manufacture, availability of coating. For metal work, carbide steel options are used, the most durable and productive, with or without coating. Other drills are more suitable for processing wood and composite materials, chipboard and fibreboard. They are made from high speed tool steel.

- Tail type. It directly determines the compatibility of the instrument. For a drill, hammer drill, options with a hexagonal or cylindrical tip are best suited. In addition, the length of this part is important. It must correspond to the parameters of the hand and power tool on which the accessory will be installed.

- Dimensions. The diameter of the drill-cutter is indicated by the manufacturer in millimeters. This parameter is always determined by the dimensions of the working part.

- Milling element type. It determines which holes can be obtained after processing. And the angle of its sharpening is also important.

All these factors help to select high-quality and reliable drills-milling cutters for performing work on metal or wood. Combined instruments help to simplify and reduce the number of operations, eliminating the need to change the tip. Refusing to change bits, choosing the right combination product, you can get the result no worse than when performing work using special milling equipment.

The following video talks about drill bits.

How to drill a concrete wall?

1. Conventional drills are not suitable for concrete. It is better to use solid carbide drills, for example, winder. Such drills for concrete have at the ends special brazed inserts made of carbide material (mainly a mixture of tungsten carbide and cobalt in a ratio of 10 to 90%). Carbide tips are easily recognizable - they have the shape of a kind of "house".

2. If the holes are planned to be few and they are relatively narrow, then at home you can use a drill with

shock loading function. An impact drill at home is suitable for holes in concrete with a diameter of no more than 12-13 mm, otherwise it is better to take a more expensive hammer drill. As for a conventional drill ("hammerless"), it is advisable to use it for concrete only as a last resort, if you do not have other working tools at hand.

3. The hammer drill is suitable for any drilling in concrete - it is more effective due to its “crushing” function, although it is more expensive than a hammer drill. In the hammer drill, the rotation of the drill is combined with its reciprocating movement, which makes the drilling work much faster. The hammer drill is good when a lot of drilling work is foreseen (for example, when you need to fasten the lathing to the ceiling or walls). Keep in mind that a hammer drill is more powerful than a drill. Therefore, for example, for foam concrete (aerated concrete), it is not suitable, as it will completely "collapse" the wall. And when drilling ordinary concrete with a perforator, do not overdo it - make sure that the plaster does not fall off.

4. For the hammer drill, special drills ("SDS Plus" and "SDS-Max") of various diameters are used - from 4-5 mm to 7-8 cm. future dowels, and just in case "plus or minus" a couple of neighboring sizes.

5. In addition to drilling with a hammer drill and hammer drill, there is another way - the so-called diamond drilling. Only for this option you need special drilling rigs and diamond drills.This type of concrete drilling is very expensive, and, as a rule, a team of master repairmen is hired for it. Diamond drilling is used in the case when a lot of repair work on drilling a concrete base is planned, or large holes or longitudinal grooves are needed (for example, when laying communications in a wall or floor). The advantage of this method is that after the drilling rig there is no dust left - it supplies water to the hole, washing away the dust and cooling the drill.