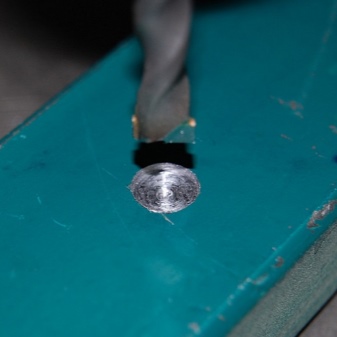

Drill sharpening for spot welding

In the process of resistance welding, the metal is compacted, therefore it is rather difficult to drill it out. Drills must be made of strong high-speed steel and have a special sharpening.

For through drilling. If you plan to scroll through the parts, you can use a conventional taper sharpened drill. The diameter is selected 1-2 mm wider than the welded spot.

For drilling one piece. They have an almost flat sharpening, in the center of the drill there is a ledge - a leash. It is designed for centering and looks like a small drill. The leash can be narrow - suitable for working with thin sheet metal, and wide - suitable for working with thick metal. The diameter is selected according to the diameter of the point or slightly wider.

Core drills. They consist of a cutting part, a guide driver and a shank. The cutting head can be made of soft material with carbide taps. The inner diameter of the crown should be 1 mm wider than the point. The peculiarity of working with a crown is that it does not drill out the material of the point, but selects the metal of the part around it.

It is quite difficult to repeat the shape of sharpening yourself in a garage environment.

It is important not to spoil the leash or overheat the metal. You will need a calibrated sharpening machine and a jig

An experienced turner can sharpen a drill on a conventional machine, but the drill will not perform as well.

Interesting: Carbide inserts - advantages, classification

Peculiarities

The spot welding drill is used to remove a permanent welded joint. Such a cutter allows you to perform accurate reaming of the welding point, without causing significant damage to the surface of the part by such actions. Often, a tool with a diameter of 8 mm is used for drilling. You can find such a drilling tool in specialized retail outlets, but its cost can be quite high. However, the purchased drill will pay off your costs, making it much easier to remove parts connected by spot welding.

The main advantages of a cutter for removing spot weld fixtures.

- It is possible to carry out welding drilling work without first forming a depression in the welding point, that is, without punching. This feature of the drill is convenient, as it saves a lot of time and effort.

- You can work with a drill for a long time, carrying out sequential drilling of several welding points in a row at once. Even when heated, the drill does not lose its properties.

- The service life of the tool is quite long, since this product is made from high-strength steel grades and has the ability to multiple sharpening cycles.

- After reaming the weld points, the dismantled part remains saved for reuse. In addition, the surface of the second workpiece, to which the dismantled part was attached, is not damaged, and it can again be used for its intended purpose.

The tool for dismantling welding points is made of alloy steel with the addition of titanium spraying. There are 2 types of such tools available: with one working side or double-sided. Drill diameters are different - they can be 6, 8 and 10 mm. The choice of the drill diameter depends on the size of the weld point to be drilled. In this case, an additional up to 1.5 mm is added to the diameter of the drilling object.

By its structure, the drilling tool has 3 main parts.

- Core area.The height of this part must be selected in such a way that it exceeds the thickness of the part by 2 mm.

- Cutting part. To strengthen this area, titanium spraying is applied to the metal, which greatly strengthens the drill, extends its wear resistance and allows the tool to work regardless of its heating.

- Mounting area. This part is for attaching the drilling tool to the electric drill holder.

By visual signs, it is quite simple to distinguish a tool designed for dismantling welding points from other drilling counterparts - the tool axis has a tapered shape, with an angle of 90 °, while the working end part of the drill is flat.

How to work?

At first glance, the simple technology of using a tool designed for dismantling welding points has several features. Experts adhere to the following rules in their work.

- An electric drill is used for work, which has the ability to adjust the speed of rotation.

- Drilling work must not be carried out at high speed, since the tool pin may be broken due to the heavy load.

- To carry out the drilling process, the drill is set to the drilling point in a strictly perpendicular position. Any deviations during work are unacceptable, as this can damage the surface of the drilled part.

Before starting drilling work, the work surface must be prepared. They do it as follows.

- The surface is cleaned of dirt and a layer of paint - this will significantly improve the quality of the work result and reduce the likelihood that the tool will come off during drilling. Cleaning is performed using sandpaper.

- Although the drill can be used without first punching the drilling area, for convenience, this procedure is sometimes performed using a separate punch for this purpose.

Before starting work, it is necessary to inspect all welding points and determine which tool diameter will need to be used for drilling.

When the preparatory work is completed, you can start drilling. To do this, the drilling tool is placed in the chuck of an electric drill and, after pointing the working part of the tool to the welding point, pressing the drill tightly, they begin to drill, starting at low speed

During the drilling process, it is important to take your time and make sure that you do not drill through the metal part. After the end of the process of drilling the points of the welded attachment, the next step will be to separate one part from another.

It should be borne in mind that the cutter does not completely drill through the weld point, as a conventional drill does, its principle of operation is different - it drills in a circle in the area of the weld point and allows you to separate the part from the base. After the parts are separated, the remaining metal from the welding is cut off with a grinder or a cut-off grinding disc, and in some - especially difficult - cases, a chisel with a hammer is used to separate parts

If it is necessary to drill the front of the welding attachment, use a drill, which has a peculiar cone-shaped protrusion in the form of a spout, with which the center of the drill is held in the desired position. In this case, the sharpening of the drill itself is flat.

Another effective way to dismantle welding points is to use a small crown with sharpened teeth. This device has in its design a spring-loaded centering stop that acts as a limiter. It can be adjusted using a special setting. The crown during operation removes only the area of the weld point, while not affecting excess parts of the metal of the part.

Other ways to remove spot welding

There are several ways to remove weld spots in hard-to-reach places.They can be used in conjunction with drilling, if getting to the point is problematic.

- Cutting down. A sharp chisel is installed between the parts, the point is cut off with sharp blows. Parts are deformed, so additional editing will be required. The process can be facilitated with a pneumatic chisel or perforator.

- Grinding. The metal of the point is selected with an abrasive wheel until a clear outline of the joint appears. The method requires accuracy, since there is a risk of damage to the part.

- Cutting out. This requires a plasma cutting machine. They can carefully cut through the points, and weld the holes.

Depending on the goals facing the wizard and the ease of use, you can apply any of the proposed methods. Each case is unique. you should trust your experience and intuition.

Advantages of the spot welding drill

With regard to alternative methods for removing spot welded joints, the use of a specialized drill has several advantages.

- No need for a variety of preparatory procedures. The drilling process starts immediately without punching, etc.

- Ability to delete several connections in a row without pauses.

- If you have the equipment with which you can sharpen the drill, its service life is very long.

- In the process of drilling, the second sheet of metal is not damaged, this allows the removed part to be used in the future for its main purpose.

A large number of different products, devices, car parts, etc. are interconnected by non-detachable methods (bolts, nuts, screws, etc.), namely by means of spot welding. Accordingly, it is quite problematic to remove it without damaging it using a variety of methods. With the help of a welding drill, this procedure is as easy as shelling pears. It is worth noting that, despite the rather narrow specialization of the drill, absolutely any drill is suitable for its use. However, it is best to use equipment that allows you to adjust the operating power. Of course, the product will not be able to perform all the work for the master, so if the part is subsequently used again, then the work requires increased accuracy.

How to prepare the area for drilling?

To work with the car body as easy as possible, you should remove the sealing compound, paint, and all additional coatings from its surface - this allows you to quite well observe the points where the welded work was carried out. It is worth noting that professional workers in workshops dealing with vehicle bodies do not always remove the paint itself. It is enough for them to lightly clean the spot welded areas with sanding paper or an angle grinder - this is quite enough to get a good view of the welded area.

Drilling process

Detaching a body part consists of several logical steps:

- Preparation. It is worth removing all elastic bands, moldings, linings. The entire edge of the joint must be visible. We clean the edge with sandpaper - so all the points will be visible. If necessary, use a narrow sharp chisel to remove sealant, putty or paint build-up.

- Punching points. Using a sharp core with neat strokes, mark the center of the drilling. The punched points will help keep the center in place and prevent the drill from breaking at the start.

- Drilling. With a sharp nose, the drill is installed in the center of the weld point in the intended recess. It is necessary to drill out spot welding at low speeds, hold the drill firmly with both hands - the parts are uneven, and the edges of the tool always try to touch the metal protrusions.

- Detaching surfaces. As a rule, parts after drilling continue to adhere to paint, sealant, or un-drilled areas.Prying with a flat thin chisel will help to detach, it also cuts out undrilled areas.

How to prepare a site for drilling

When considering such a technology, it should be borne in mind that the final result largely depends on the quality of surface preparation. The features of this technology include the following points:

- It is recommended to core the hole to be drilled. You can use a screwdriver for this.

- By cleaning the surface from various contaminants, you can significantly improve the quality of the work being done.

If you do not carry out preliminary surface preparation, then there is a possibility of the rod popping out. If the angle of the load is changed, the bar may break. In addition, with a fairly large contact area, the tool used can overheat.

Outcome

It should be noted that today plasma cutting is used for the drilled hole. It can be used to burn through any thickness of a structural part made of iron.

This is a rather expensive service, which is why it is used in rare and extremely necessary situations. Many craftsmen who work with bodies still use spot welding.

Thanks to the appropriate drills, the work becomes easy, not costly in terms of finance, time and effort, pays off due to its properties and functions. In addition, it is necessary to emphasize that such drills need regular sharpening using a special design.