Application features

Listen to the advice of professionals regarding the purchase of motoblock devices with hubs.

- When ordering for your unit of hub parts, do not forget to send data about the type and model of equipment, as well as about the wheels - for example, the so-called eighth hub will fit to wheel 8.

- Usually, when buying a fully equipped walk-behind tractor, there is also one set of hub elements. Purchase an additional 1-2 at once - this will increase the comfort of working with various attachments, you do not have to change or rearrange the hubs when changing additional elements.

- If there are pneumatic wheels in the purchased set, the presence of hub elements is mandatory.

For more information on hubs for motoblocks, see the video below.

How to make it yourself?

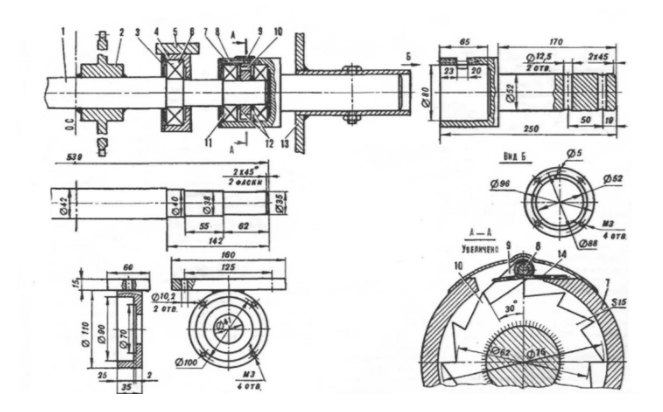

If you have drawings, these parts are easy to make yourself.

First of all, take care of the quality of the material from which you will make these elements. The best option is high-strength steel, because the hubs will constantly work under serious stress. Next, you must grind the part on a lathe according to the dimensions indicated in the drawing. Of course, you can use a simplified option - grind the flange and connect it by welding to a pipe or metal profile.

After you have made the part, install it on the tiller and check how it works. But do not give maximum load to a freshly made part - there is a high probability of its deformation. Test your device on level ground with a few turns and turns at minimum to medium speed. After such a peculiar lapping of parts, you can safely use the walk-behind tractor for work on your personal plot.

Purpose and varieties

The presence of such an important part as the hub can significantly improve the maneuverability of your machine, the quality of soil cultivation and other agricultural operations. There are 2 types of hubs for walk-behind tractor wheels

There are 2 types of hubs for motoblock wheels.

- Simple or common. Such parts are characterized by simplicity of design and rather low efficiency - they can only slightly improve the maneuverability of the unit, as a result of which they are gradually losing popularity.

- Differential. Suitable for almost all models of motoblocks, as a result of which they are also called universal. Parts with a differential are necessary for models in which the design of the wheels is not provided for unlocking and the turning and turning maneuvers of the unit are difficult. The same type of part with bearings serves to improve the maneuverability of the wheeled units.

The diameter and cross-sectional shape of these parts can be different:

- round;

- hexagonal - 32 and 24 mm (there are also parts with a diameter of 23 mm);

- sliding.

Round hubs can be of different diameters - 24 mm, 30 mm, etc., depending on the brand and model of the device, for the wheels (lugs) of which they are intended.

The cross-sectional shape of the hexagonal hub parts, as the name logically suggests, is a regular hexagon - hexagon. Their purpose is a smoother transmission of torque to the wheelset of the walk-behind tractor and to facilitate the performance of turning maneuvers.

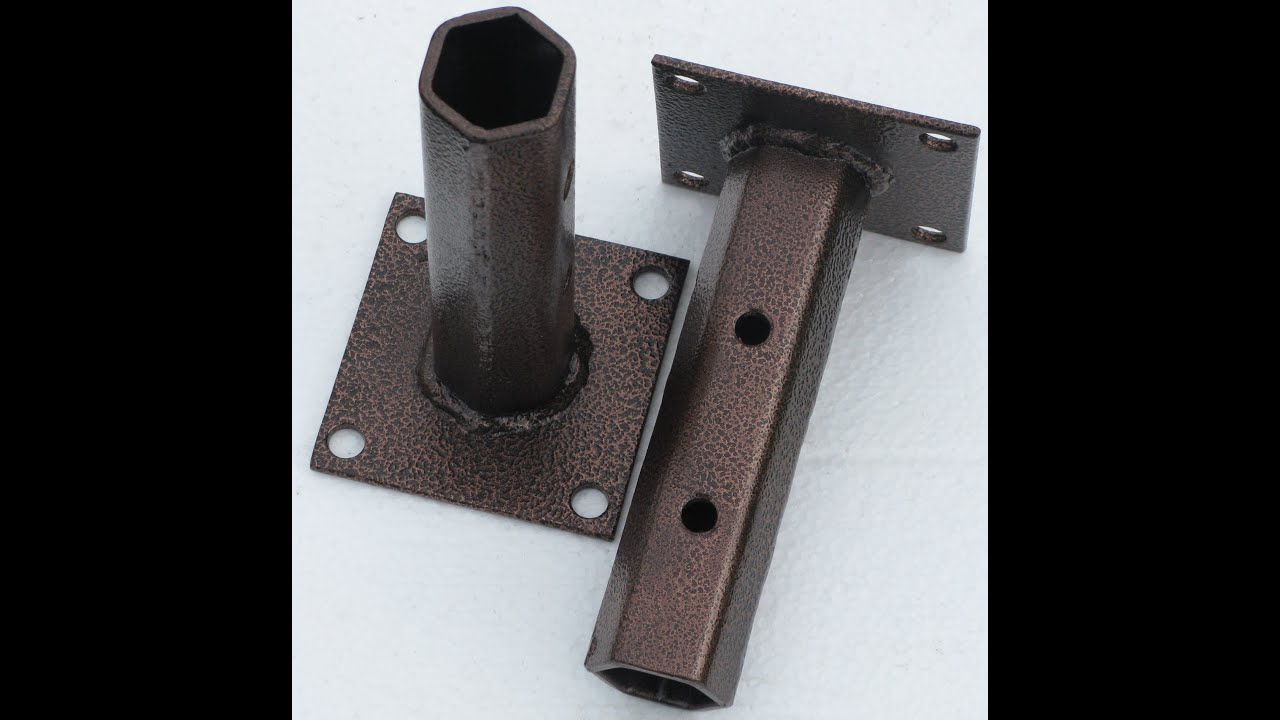

There are 2-piece sliding hub elements that fit into each other.Their purpose is the same as for other similar elements, plus they allow you to adjust the track width. This is done by moving the outer tube along the inner tube. To fix the required distance, special holes are provided into which fasteners are inserted.

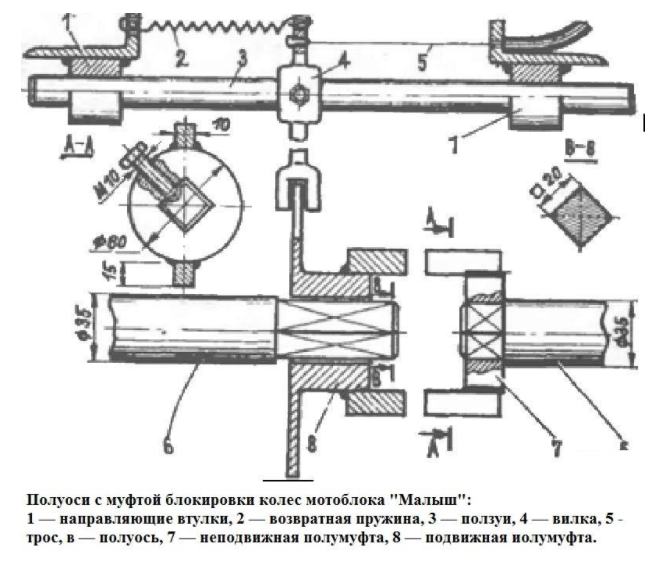

Also, semi-differential hub elements can be distinguished in an almost separate form. Their operation is based on the principle of transferring torque from the axle to the hub part by means of projections on these elements. The wheelset is not rigidly connected, which allows you to make a turning maneuver without a power reserve, practically in place.

For trailers, special reinforced hubs are produced - the so-called Zhiguli hubs. They are usually made from suitable grades of cast iron or steel.

The length and weight of parts can vary significantly.