Selection Tips

To make the right choice of rescue harness, the following factors should be considered.

What kind of high-rise work will be carried out with the help of this insurance, how high is the degree of danger. Accordingly, the higher the risk, the stronger and more complex the belay system should be.

For long-term work in one position, you need to select a harness with special additional seats or more comfortable wide loops.

The fire-resistant and intrinsically safe harness is used for extinguishing fires and for working in enclosed explosive spaces. In this case, non-combustible material is necessarily used to make the leash.

When buying a rescue harness, you must have a state certificate and instructions for use.

There is a certain size range of harnesses

It is very important that the rescue kit fits snugly around the shoulders, waist and legs of the worker.

Inspection frequency of harnesses

by order of the Ministry of Health and Social Development of Russia dated 01.06.2009 No. 290n (hereinafter - Order of the Ministry of Health and Social Development of Russia No. 290n). The specified Intersectoral Rules entered into force in February 2010. At the same time, by order of the Ministry of Health and Social Development of Russia No. 290n, the Resolution of the Ministry of Labor of Russia No. 51 of December 18, 1998 was declared invalid.

5.3 GOSTR 50849-96 "Construction safety belts. General technical conditions. Test methods ”periodic tests are carried out by a manufacturer or a specialized laboratory on samples of the same design, randomly selected from batches that have passed acceptance tests, at least once a year.

Description and requirements

The mounting belt looks like a wide waist belt, the outer part of which is made of hard synthetic material, and the inner part is equipped with a soft elastic lining (sash).

Mandatory elements of the mounting belt:

- buckle - for tight fastening in size;

- sash - a wide soft lining on the inside, necessary for greater comfort during long work, as well as so that the hard belt of the belt does not cut into the skin;

- fasteners (rings) - for attaching harness elements, belay;

- safety halyard - a tape or rope made of polymer material, steel (depending on environmental conditions), it can be removable or built-in.

For convenience, some belts are equipped with pockets and sockets for a tool, a fall indicator.

GOST defines the dimensions of belts and their elements:

- The back support is made at least 100 mm wide in the area corresponding to the lower back, the front part of such a belt is at least 43 mm. The mounting belt without back support is made from 80 mm thick.

- The mounting belt is produced as standard with a waist circumference of 640 to 1500 mm in three sizes. On request, custom-made belts should be made for precise fit - for particularly small or large sizes.

- The weight of the strap-less belt is up to 2.1 kg, the strap-up belt - up to 3 kg.

And also the products must meet the following requirements:

- belts and shoulder straps should provide for the possibility of precise adjustment, while they should be comfortable, not interfere with movements;

- fabric elements are made of durable synthetic materials, stitched with synthetic threads, the use of leather as a less durable material is not allowed;

- as standard, belts are designed for operation at temperatures from -40 to +50 degrees Celsius;

- metal elements and fasteners must have an anti-corrosion coating, must be reliable, without the risk of spontaneous opening and unfastening;

- each belt must withstand high breaking and static loads exceeding the weight of a person, providing a margin of safety in any extreme situation;

- the seam is made with a bright, contrasting thread so that it is easy to control its integrity.

Terms of testing harnesses

Restraining and safety systems and their components US I, US II, US I a, CC II, SUS II, UPR I, UPR II D; E; F, SPR II D; F; Zh1; Zh2, SUPR II F, Zhu, G4 PASSPORT AND INSTRUCTIONS FOR USE Restraint and safety systems are used as means of individual protection of a person from falling from a height when working on overhead power transmission and communication lines, oil rigs, electrical and nuclear power plants, in confined spaces, wells, trenches and other high-rise structures in various climatic conditions at ambient temperatures from - 40 ° C to + 50 ° C. Restraint systems (SS) are designed to prevent free fall, as well as to perform the functions of holding and supporting the worker at a given height and are not intended to be used as safety systems. The lanyard, harness and shock absorber can be components of US, CC and SUS, which are produced by the manufacturer both as part of the above systems, or separately.

The system or its components are considered to have passed the test if they have retained their bearing capacity and no damage has occurred. The product (tag or token) is marked with the date of the test by a method that ensures its safety and readability until the next tests.

Safety harness test

Below is an excerpt from the GOST. Buying a stand for testing safety harnesses, you get equipment that fully complies with all technical conditions and regulatory documents. Testing of harnesses is carried out independently, without the involvement of third-party organizations. The test is carried out at a special stand, YOUR, certified employee. For this type of test, a dummy specially made for this purpose is used.

In addition to the instructions for use, it should be indicated which element of the harness attachment should be used in the fall arrest system in accordance with EN 363 or in the restraint system in accordance with GOST R 12.4.205. The operating instructions must contain all the information necessary for the correct donning of the full body harness.

Views

The key role of the rescue harness in the harness is that it:

- holds;

- positions;

- insures.

That is, it allows the high-altitude operator to be in a safe, reliably suspended state at a height, so that at the same time he has the opportunity to be clearly fixed in the desired position and move in any direction necessary for work.

The rescue system can differ in various additional details, depending on what kind of work it is intended for. For example, if it is required to be in a sitting position for work, then, accordingly, the safety equipment is supplied with a special seat. A wide sash can also be attached to the belt, which reduces pressure on the back.

For especially dangerous work, when more reliable belay is required, the harness is five-point, that is, it is supplied with additional anchor rings in front, at the level of the solar plexus and at the belt. More professional universal rescue harnesses for working with power lines, in oil and gas tanks, as well as for employees of the Ministry of Emergency Situations, are already equipped with six attachment points.

For workers who are involved in rescue mountain operations and industrial mountaineering, special multifunctional mountaineering leashes have been created. Such equipment is marked with a marker of the international standard EIAA and EN.

There is also the Samospas rope and descent system, with its help you can evacuate people from all kinds of structures and buildings in case of any accident or fire. Such rescue-height kits can be used both by the victims themselves and with the help of rescuers.

Frequency of Inspection or Testing of Full Body Harnesses

However, it should be remembered: a safety harness is not an absolute guarantor of human safety - methods of protecting human life and health should be used in a comprehensive manner, safety requirements must be strictly observed, the qualifications of a specialist must correspond to a high level. The harness can be used not only for professional high-altitude work of any kind (installation, fire fighting, emergency response, etc.), but also for hiking, rock climbing and mountaineering. The main function of the safety equipment is both to prevent unauthorized descent and to stop a person from falling from a height.

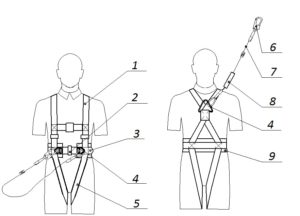

Before use, the harness is put on: the belt is located at the waist, leg loops and shoulder straps - on the corresponding parts of the body.

The dorsal position is adjusted and the shoulder strap is tightened.

The shoulder straps are attached to the belt with buckles and carabiners.

The testing of the safety harness is carried out under the conditions specified by the manufacturer: it is important to observe the recommended temperature conditions and to exclude the possibility of damage to individual units and elements by chemically aggressive substances and piercing-cutting objects.

Is it necessary to test harnesses according to the new rules lawyer's answer 2020

It is shown in the table. Type of work What to indicate and foresee in the PPR Works with the probability of cargo falling from a height when moving them with a crane, containerization means and containers for moving piece and bulk materials, concrete and mortar, taking into account the nature of the cargo being moved and the convenience of its delivery to the place of work; methods of slinging, ensuring the supply of elements to a position corresponding to or close to the design; devices (pyramids, cassettes) for stable storage of structural elements; the procedure and methods for storing products, materials, equipment; methods of final fixing of structures; methods of temporarily securing the dismantled elements during the dismantling of buildings and structures;

Before use, the harness is put on: the belt is located at the waist, leg loops and shoulder straps - on the corresponding parts of the body. The dorsal position is adjusted and the shoulder strap is tightened. The shoulder straps are attached to the belt with buckles and carabiners.

Other types of harnesses described in other European standards, such as EN 358, EN 813 or EN 1497, can be integrated into a full body harness. Fall arrest systems are described in EN 363, dated and undated references to European standards are used in this standard.

This Work Plan for Work at Height (hereinafter referred to as the Work Plan) establishes a general procedure for organizing and carrying out all types of work at height in order to ensure the safety of workers performing these work and persons in the area of these work.

The procedure for passing periodic inspections of PPE from falling from a height

Seat belt system for the whole body "(EN 361: 2002" Personal protective equipment against falls from a height - Full body harnesses "). When applying this standard, it is recommended to use, instead of the reference European standards, the corresponding national standards of the Russian Federation, information about which is given in Appendix B.

These straps are connected to each other by durable adjustable buckles. On the back, sides, at the intersection of the bands, there are special anchor points with metal rings.A safety rope is attached to them, which actually keeps it from falling, or slows it down.

Safety harnesses-check

According to the requirements of labor protection in the Russian Federation, a company engaged in high-altitude hazardous work must provide reliable protection for employees. Safety harnesses provide additional safety, insure employees, taking into account the special working conditions. The enterprise should conduct testing of this equipment, its results must be recorded on the pages of a special journal.

- If deformations, cuts, stretching of materials are found, do not use the system.

- Periodic checks of equipment are carried out once every 12 months, about which there must be a corresponding record.

- The service life is determined by the passport period, often 5 years from the date of issue.

Primary requirements

The main task performed by the safety system is to stop the worker's body at the moment of falling from a height, as well as to prevent an unexpected sudden descent down. The requirements for belay devices are as follows.

- An understandable and convenient use of an individual safety system, where the worker adjusts the dimensions for himself independently, is able to provide not only quick preparation for the start of work, but also helps to quickly navigate in the event of any emergency situation.

- The harness must be made of a durable and lightweight material that has been pre-tested and can support several times the weight of a person.

In order for the harness to provide reliable protection during work, before putting on the safety system on yourself, you need to carefully inspect it and check it for integrity. Each belt must be labeled with the size, date, and system strength test number.

Safety harness test report example

You receive printed products numbered, laced and prepared for binding with a seal in accordance with the current regulatory documents: The cost of lacing and binding is 39 rubles. Page numbering starts from the title page to the last page of the magazine.

Before putting into operation and every 6 months during operation, the consumer should be tested with a static load: a belt sling without a shock absorber - with a weight of 700 kg; a belt sling with a shock absorber - with a weight of 400 kg (while the shock absorber is not tested); a buckle with a belt - with a weight of 300 kg.

How belts are tested

The life and health of workers depends on the quality of equipment, therefore it is strictly controlled.

The tests are carried out:

- before commissioning;

- regularly in the prescribed manner.

During these tests, the belts are tested for static and dynamic loading.

To check for static load, one of the tests is used:

- a load of the required mass is suspended from the leash with the help of fasteners for 5 minutes;

- the harness is fixed to a dummy or test beam, its attachment to a fixed support is fixed, then the dummy or beam is subjected to the specified load for 5 minutes.

In dynamic tests, a person's fall from a height is simulated. For this, a dummy or rigid weight of 100 kg is used from a height equal to two lengths of the sling. If the belt does not break at the same time, its elements also do not break or deform, the dummy does not fall - then the equipment is considered to have passed the test successfully. The corresponding marking is put on it.

If the product does not pass the test, it is rejected.

In addition to acceptance and type tests, safety belts must also undergo periodic checks. According to the new rules (from 2015), the frequency of such inspections and their methodology is established by the manufacturer, but they must be carried out at least once a year.

Periodic testing should be carried out by the manufacturer or a certified laboratory. The company operating the protective equipment itself cannot test them, but its duty is to send PPE for inspection on time.