Where to begin?

At first glance, creating a wardrobe with your own hands seems like a heavy and unbearable burden, but it is not. You just need to know what it is for, where to put it and what to store. The design of any wardrobe, first of all, begins with a drawing of a piece of furniture.

If a person does not have special drawing skills, then you can turn to the World Wide Web. On the Internet, everyone can find a special program designed for this case.

Before starting work, you need to pay attention to the size of the wardrobe, the size of the room where the piece of furniture will be placed

When working on a project drawing, special attention must be paid to two details:

- what kind of plinth is placed in the room. In the case of designing a wardrobe from one wall to another, it will not work to move the object close to it. Then you need to either create a cabinet with bevels of vertical edges, or disassemble the skirting board itself;

- what density the chipboard will be. If there are no long bookshelves in the cabinet, the thickness of the material will start from 16 mm.

When working on a drawing (especially for those types that are built under the ceiling of the room), one must not forget that the collection of furniture takes place in a lying position and only then the cabinet is raised and placed. In this case, the diagonal of the cabinet should be several centimeters lower, otherwise, when the cabinet is lifted, it will simply rest against the ceiling.

Following the above instructions, now everyone will understand that developing a drawing, for example, a wardrobe with your own hands, does not constitute special skills.

Step-by-step instructions for creating a unique piece of furniture

- choice of location;

- drawing development;

- creating a frame, collecting it;

- installation of a doorway;

- installation of auxiliary parts (shelves);

- use of paints and varnishes - varnishing, impregnation (if necessary) and final painting;

- installation of handles for doors.

Decorating

Before implementing the plan for decorative finishing, you need to clearly decide on the style of the new piece of furniture, determine the way it will be clad. There are several techniques for decorating chipboard cabinets. Consider painting and wrapping.

Paint

The most reliable and thorough finishing method is painting. It is very easy to implement and inexpensive. Chipboards are treated with acrylic, alkyd, spray or ordinary paint on wood.

The most reliable and thorough finishing method is painting. It is very easy to implement and inexpensive. Chipboards are treated with acrylic, alkyd, spray or ordinary paint on wood.

Reference. Acrylic spray paint adheres better than regular spray paint. The treated surfaces are uniformly colored and smooth.

Chipboard coloring is carried out in stages:

- Level and dedust the work surface.

- Degrease and apply a primer.

- Existing chips are filled with putty and rubbed.

- Apply one or two more layers of primer.

- The surfaces are painted with the selected paint.

You can decorate the wardrobe with a stencil with fancy multi-colored or monochromatic patterns and symbols.

Cover with foil

Self-adhesive foil will add originality and style to the wardrobe. The film must harmoniously fit into the interior design. But such a coating will not last long.

Self-adhesive foil will add originality and style to the wardrobe. The film must harmoniously fit into the interior design. But such a coating will not last long.

To complete the work you will need:

- primer;

- solvent;

- soft tissue;

- knife and scissors;

- roller;

- sanding paper.

The chipboard is glued with a film according to the given algorithm:

- Measurements.

- Cutting the material in the required amount for surface decoration.

- Removing the protective layer from the film.

- Pasting the furniture panel with a prepared cut.

Important! In the process of using a self-adhesive film, the surface of the product is treated with a primer to improve the adhesion of both planes.

To prevent creases from forming, the plane is smoothed with a roller. Start from the edge where the material is applied.

For processing large areas, you can use a different method of wrapping with foil. It is based on a solution of water and soap. Remove the protective layer from the material and place it on the floor. With a spray, a soap solution is applied to the adhesive layer of the film and applied to the surface. If you wish, you can do the gluing with a film together with painting.

Upon completion of the work, the final design of the cabinet is performed - they install mirrors, equip lighting and other functional elements.

If you are considering the option of making cabinets from other materials, we recommend that you consider furniture board, cardboard and drywall.

Varieties of cabinet models

Wardrobes are among the main pieces of furniture, without which it is difficult to imagine even the most minimalistic furnishings. The perception of the entire interior of the room largely depends on the appearance of these overall structures.

Cabinets come in various types

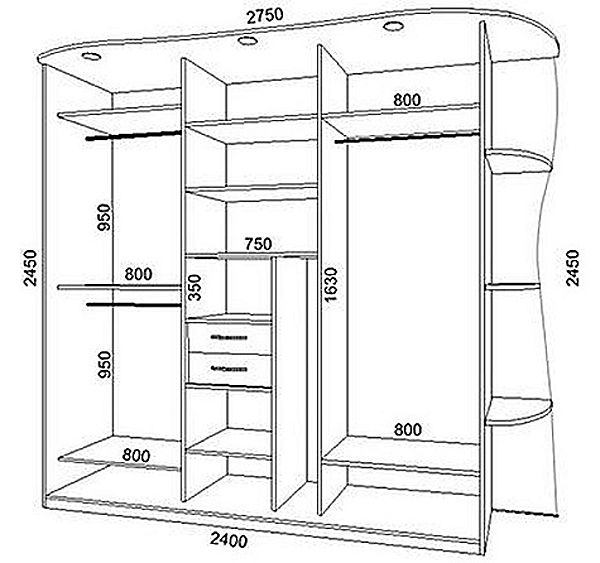

Two main types of products are used, depending on the door opening system (options for their drawings are presented).

-

Swing. This type of construction, used for a long time, and today, in different situations, is often uncontested.

-

Wardrobes. Furniture items that are equipped with sliding doors that open in one plane are very functional. No additional space is required to open them, thus optimizing space. This moment is especially important in small rooms, for example, in the corridor. It is most convenient to install such products in niches.

Depending on the installation method, there are three main types of cabinets.

-

Built-in. In such models, which become part of the interior and do not clutter up the space, any surfaces in the room can serve as a structural element of the cabinet: floor, ceiling, walls and niches. One of the advantages is the substantial savings in materials. A big plus of the structures installed up to the ceiling is the absence of dust accumulations at the top, which saves effort on cleaning. However, it is not possible to move the built-in construct. The entire decoration of the room will largely be determined by the location of the cabinet, and it will not work to change it.

-

Partially embedded. These models are usually also installed at the full height of the room. They differ from built-in ones in that only instead of part of the parts they use walls, floor or ceiling. Moving such a cabinet is also quite difficult.

-

Hull. The free-standing structure, consisting of sides, back wall, bottom, top and flaps, can be installed anywhere in the room and just as easily, if necessary, moved to a new place. Usually there is a gap between the top of the cabinet and the ceiling, with the result that the top surface becomes a "dust collector".

Cabinets can be linear, that is, installed in a straight line, corner or even radius.

Spherical wardrobe

They can differ in depth, internal filling and number of sashes.

The main materials used for the manufacture of structures are wood, chipboard, fiberboard, MDF, plywood, glass and plastic. Metal models can also be found in industrial premises or offices.

Metal cabinet for office

Recommendations for work

As you can see, assembling the cabinet is a fairly simple process that any householder can do. The main thing in this case is accuracy when taking measurements and the presence of several tools usually available at home: a saw, a screwdriver, a grinder (it can be replaced with ordinary sandpaper), a protractor, a level and a tape measure with a pencil.

Table.Accessories and fixtures that may be needed in the manufacture of the product.

| Name | Image |

|---|---|

| Self-tapping screws | |

| Confirmates | |

| Hooks | |

| Furniture dowels | |

| Corners | |

| Slides for drawers | |

| Clothes bar with fastening | |

| Sash guide system | |

| Hinges (if a swing structure is installed) | |

| Decorative caps for attachment points | |

| Drawer and door handles |

In addition to the devices presented, modern types of fittings can also be used: systems of smooth and silent closing, devices that allow you to open the boxes with a slight hand pressure (in this case, there is no need to install handles on the boxes), etc.

To make the edges of chipboard, which is most often used for the production of cabinets, attractive, several types of furniture edges are produced: paper (melamine-impregnated), acrylic, PVC, ABS plastic or veneer. The easiest way is to apply a melamine edging. This requires only an iron. But it also serves less than its counterparts.

The most important element in wardrobes is a sliding system. You should not save on it. Poor quality products can quickly deteriorate. To date, there are many models on the market that differ in the type of guides

Whichever device is chosen, it is recommended to pay attention to the material from which it is made

It is best to purchase aluminum systems

They are durable and can handle stress easily.

You can cut the material yourself, but if there are not so many furniture making skills, it is better to entrust this work to professionals.

When drilling holes, it is important to observe clear geometry, otherwise visible asymmetry, even masked by plugs, can spoil the appearance of the cabinet.

With a responsible approach to business, labor costs and time spent will be embodied in a reliable and functional design, which will take into account all the individual wishes of the owner.

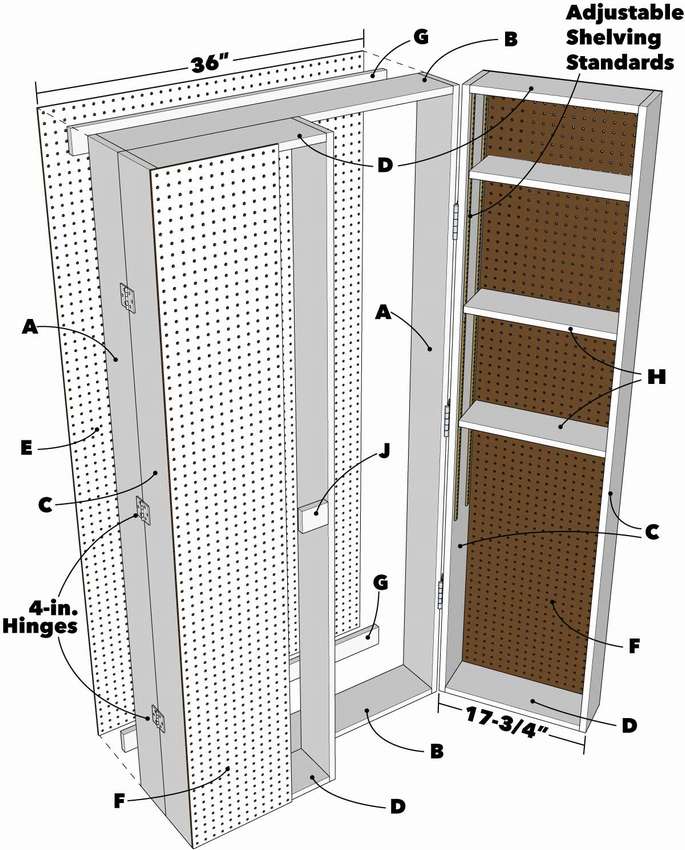

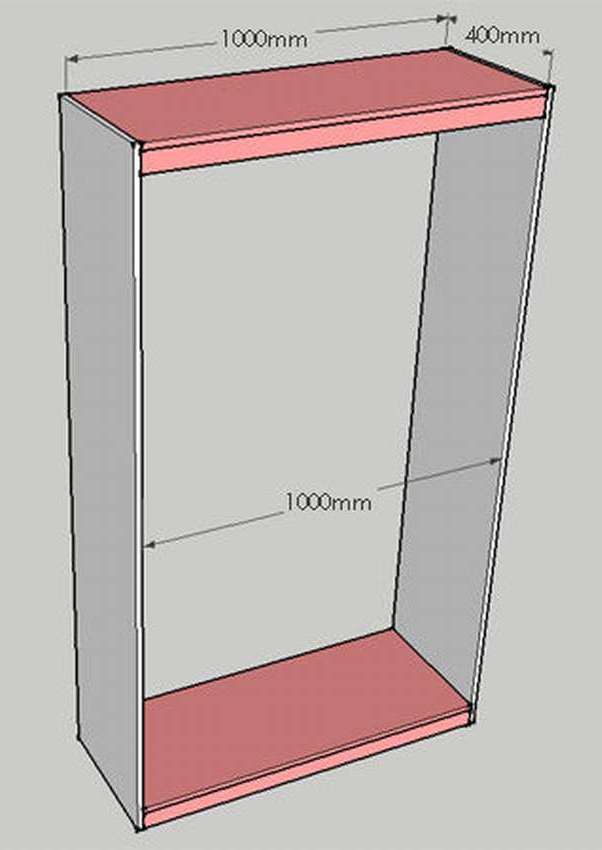

Wall cabinet with shelves

Another example of how to make a do-it-yourself hinged kitchen cabinet. Unlike other presented designs, this cabinet has double doors. The general rule of thumb is that the door should always be taller than the width. You also need to add a center vertical strip to close the gap between the double doors. To work, you need boards, plywood, and two sets of doors.

First, secure the sidewalls with pin holes on the inside for the adjustable shelves - much easier to do at first. Drill holes for the face frames. For taller shelves, simply trim the sides up. For deep shelves, the plywood width needs to be adjusted.

Attach the rear support strip at the top of the cabinet. When you hang the cabinet, screw this board into the studs on the wall. For additional support, you can add a second support at the bottom of the cabinet.

The back is not structural, but covers the interior, so it cannot be used for hanging. Use glue and nails for fastening.

The bezel attaches flush at the top and bottom, but extends the sides of the cabinet, so leave some wiggle room when setting up the cabinets. Finally, install the shelves and secure the doors.

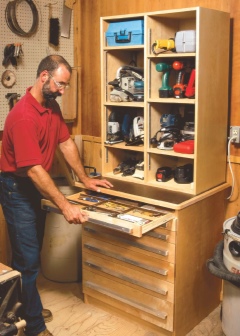

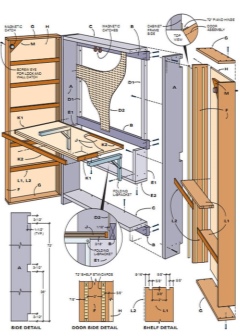

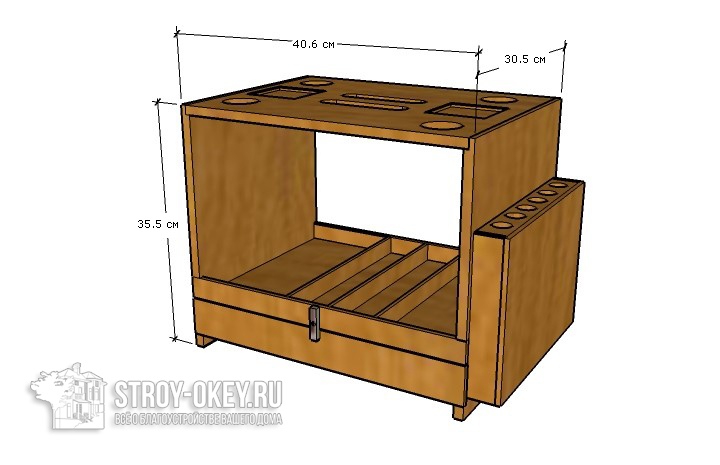

Step-by-step assembly of the tool cabinet

Wood is a vulnerable material, therefore, before starting work, wooden parts are treated with a special solution against fungi and bacteria. Also, the tree needs to be coated with a primer.

Before assembling the structure, you need to carefully study its scheme.

You need to assemble such furniture according to the instructions, paying attention to the smallest details, because the safety of the future product depends on it.

Before assembly, the floor is checked for evenness, and if the surface is not even enough, it must be straightened. Only then does the installation of the cabinet begin.

The assembly of such a structure for tools is done in this way:

First, the back wall is installed, which is often made of hardboard.

Then they make a frame and check it for strength and stability. After that, the internal filling of such furniture begins. Holes must be drilled on the parts, into which the shelves are attached using self-tapping screws.

A rod is attached to special flanges. Later, drawers and drawers are inserted into the product.

The final stage of work is the installation of door leaves

Particular attention must be paid to the installation of a mirrored door.

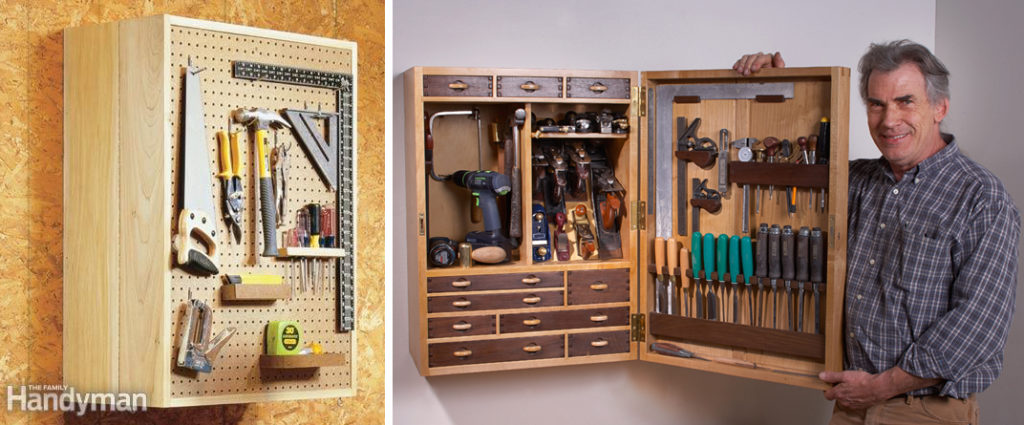

Tool box - a modern organizer for workers of different professions (95 photos)

It would seem: much simpler - a toolbox, what can be special here. However, this is only the initial impression of a person who has not encountered this problem in real life.

The toolbox should be not so much roomy as practical, provide easy access, allow you to store not only the tools themselves, but also consumables or accessories that will help you need it in everyday work.

Its design must be strong enough to serve faithfully for many years. In this article, we will focus on all the implicit criteria for choosing a tool box, consider issues related to the design features and help you understand all the variety of products on the market.

If you look at the price lists of companies offering goods for craftsmen, while paying attention to the presented photos of tool boxes, even the most sophisticated craftsman will note the variety of all kinds of designs of different sizes, capacities and made of different materials.

How not to get lost in this variety and choose exactly what you need, while saving your family budget and getting the best combination of price and quality - read about this in this article.

If we use an organizer to store business papers and documents in everyday life, then a tool needs its own case - a special tool box. It is possible to divide the tool boxes into professional and universal, which are most often used in the household.

Our grandfathers generally made a toolbox with their own hands, but today there is no need for this - you can always find on sale what you need and at a very reasonable price. Naturally, those who like to do everything with their own hands have the right to prove themselves here and collect an original case that meets all individual requirements.

- Professional boxes are generally made for specific sets of tools, which depend on the type of activity.

Naturally, in this case, you can distribute the contents in the most optimal way, provide for everything that is required: from special fasteners for specific devices and tools, to boxes for consumables and spare parts.

All tool boxes are divided into two types:

Container-type box. This design usually has an opening top. There are several compartments inside, separated by a partition. The design includes separate lockable drawers.

Container structures are more versatile, spacious and easy to operate, but they are inferior in terms of ease of access to boxes of the "case" type.

Internal partitions are also made of wood or plastic. The covers are suspended on hinges; it is necessary to provide a lock that will protect against accidental opening.

- The finished box is painted or sheathed with an improvised and suitable material, both outside and inside.

In the selection process, first of all, look at the material from which the body is made.

Plastic tool boxes are lightweight, easy to use and repair. For all that, they do not withstand mechanical stress and stress very well.

Stronger and more durable metal toolboxes made of aluminum, its alloys or steel. With a greater mass, they are more durable, however, they require periodic maintenance: restoration of paintwork, cleaning from rust and traces of corrosion. Among other things, metal boxes are more expensive.

Remember practicality: the drawer should provide free access to the entire tool. It must have a sufficiently reliable case, protect the contents from moisture, dust and external influences.

It is not always convenient when there are too many compartments and drawers inside: you can get lost in them and search for what you need for a long time.

Pay your attention to the hinges and the lock - as practice shows, it is these elements that most often break.