Garden digging devices

But just the other day, under a drizzling rain, I decided to transplant old raspberry bushes to a new place for rejuvenation. For these purposes, I took that very shovel and dug holes for new bushes. But with digging up the old ones, I had to tinker.

But that was not the problem. After some time of intensive work, the shovel cracked. At first I thought that I had cracked, as usual, the handle, but when I cleaned the shovel from clods of earth, a crack was revealed that went through almost the entire central part.

I had to say goodbye to the Chinese "rail steel".

After such a failure at the dacha, I decided to go over new alternative inventions again. I already wrote about some of them, but this time I decided to insert videos with reviews of the capabilities of these hand tools, so to speak, in action, for clarification. As the saying goes, it's better to see once than not read it once.

Garden ripper "Mole"

This is perhaps the most famous invention of recent years. We have already written about the mole shovel on the site. So you can read in more detail about the device and technology of digging there. In the meantime, I advise you to watch the video "Mole" in action, at least three times the gain in time and quality.

But they already wrote to me that this invention is far from suitable for all types of soil, and besides, the weight of the device is not for everyone. This design has many variations that were invented by inventors from different regions of Russia.

But not all of them, unfortunately, are suitable for digging oily loam or sod.

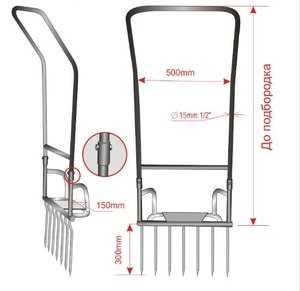

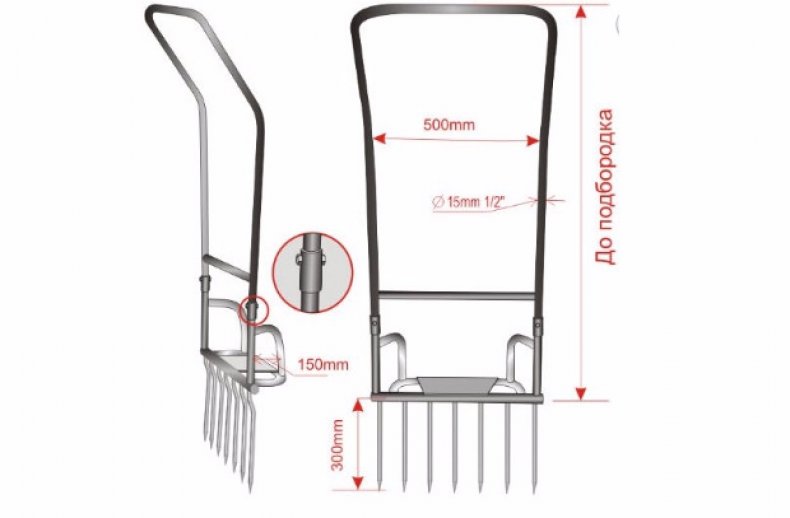

Fork with support

Another device from the same series as "Mole", "Excavator" and "Plowman". In essence, these are also extended and hardened forks, but in this case also with support. Convenient for the elderly. Loosening occurs. Also suitable for digging up potatoes.

Shovel with rudder

So I called, with your permission, this outlandish implementation of the invention for digging the soil. More precisely a dump. The handle is complemented by a bicycle handlebar, and the soil part itself is off-center.

explains everything in detail. The ground, as you can see from the video, is dry sandy and can be easily taken even with a hoe. Only now, will this structure withstand the oily moist chernozem? We write your ideas, advice, recommendations.

Another flat cutter with a wheel

The wide blade of the flat cutter is based on a frame with a bicycle wheel. Suitable for shallow soil tillage, cutting weeds and loosening the ground. However, you will not be able to dig up the beds with such a wheel.

Another plane cutter, but not Fokina

In the late 1980s, my parents had a flat cutter that they used to weed potatoes. Various home inventors continue to create the same design. Again, I would like to note that the plane cutter is suitable mainly for weeding and loosening the soil, and not for digging under the garden bed.

Shovel-flat-cutter "Genius"

The unusual combination of two seemingly incompatible devices in one instrument made it possible to create a very useful instrument. However, it seems to me that there is no need to expect performance from it.

Tornado

No, this is not a deadly wind, but an unusual structure that can also plow a garden. But for a full-fledged digging, it is still not suitable. Although the authors of this video

At the end of the article, I would like to inform you that the choice of new technology, even manual, must be approached wisely, carefully studying and trying for strength with your own hands the tools that you are going to purchase.It is also worth noting that the quality of the materials from which modern hand tools are made for working in the country leaves much to be desired. Aren't you ashamed, gentlemen, manufacturers?

P. S. This year I am doing the following experiment. I buy an "Excavator", a steel bayonet shovel (a shovel made of metal of unknown origin could not stand it, read about it at the very beginning of the article) and Fokin's large plane cutter. Throughout the season I will use these devices in full force, and at the end I will report the results.

There is a lot of work in the garden and in the garden, but the most exhausting one is digging the land, cultivating it and removing weeds. They begin to dig ahead of time, in small sections, since the load is too large.

The miracle of a shovel will help to reduce the complexity several times and at the same time speed up the process at least twice. This relatively inexpensive and uncomplicated tool really works, even on difficult soils.

Instructions - how to make an Archimedes shovel

For an Archimedean shovel, you can use almost any bayonet shovel, but the author recommends taking a lightweight shovel with holes. Dirt sticks to it less, because of the holes it is lighter than an ordinary shovel. In addition, it loosens the soil better. However, it also requires improvement. Several holes need to be made in it (explanations in the video).

Next, you need to trim the foot lever on both sides. A bevel is made at one end with a length of 180 mm. At the edge, the thickness of the bar is about 10 mm. An inset is made on the back of the cut and a small piece of cutting is glued into it with Titanium glue. The result is a heel. Note: the heel in the construction of the shovel is needed to adjust the angle of the ground tilting, it does not allow the ground to fall on its feet, gives a vector to the explosion (soil dump) forward, helps to create an explosive funnel. From the opposite end of the bar, the length is about 80 mm. The thickness of the end of the segment is half the diameter of the cutting. The foot lever is ready.

The foot lever is driven into a bayonet shovel to a depth of 150 mm. Fastened with screws and bolt. The bolt is designed to prevent the lever from breaking. We make a through hole in the wood along the previously marked holes in the bayonet.

Putting together a large handle with a handle and a bracket - the only original part. It is made of 1.5mm thick steel. Has several holes with a diameter of 6.2 mm. Stretching between the upper holes 190 mm, between the lower ones - 100 mm. Along the axis of symmetry there are two mounting holes. The bottom hole is 15 mm from the bottom edge, the second hole is 85 mm from the bottom edge. Development height - 150 mm. Stretching up to the hole - 135 mm. In the central part, the height is 110 mm. The total width is 220 mm. In the lower narrow part - 150 mm. By bending a blank made from a template, a ready-made bracket is obtained. It is assembled on a shovel using two bolted connections. The author seriously offers an alternative option for making a papier-mâché bracket. To increase the strength, at least two layers of cotton should be placed between the layers of paper. The total thickness of the layers is required at least 5 mm. The result is a very rigid and sturdy construction. In order to strengthen the walls of the holes for the axis of rotation, washers are glued between the paper. The papier-mâché bracket has one advantage: with a fairly high strength, it weighs 250 grams less than an iron one.

How to make a bracket

See how the author makes the bracket. But, if you want to make one shovel for yourself, then you can make, as he says, easier. Bend the workpiece directly on the handle. That is, in place, you need to make two fastening holes strictly on the axis of the handle with the same dimensions as on the steel reamer of the bracket. Fasten the reamer on the handle with bolts and M6 nuts through wide washers and bend it impactfully on a large locksmith's vice using a heavy hammer. The reamer will bend around the handle - the bracket is ready.

When the Archimedean shovel is ready, you need to check: when lowering the finished shovel with a bayonet, the levers should not diverge.

disadvantages

The gardeners did not find any significant "flaws" in the miracle structures for digging the land, but no one would argue with objective facts:

- The "working" grip of the ripper shovels can reach 40 cm, which means that in the area where the seedlings are planted close to each other, it is a useless tool;

- it will not be possible to dig a deep hole with a loosening or digging device (the invention of Father Gennady);

- advanced models are difficult to repair in the event of breakdowns, as they are made of a large number of parts.

The fewer elements, rotating mechanisms, bolted joints are provided in the device, the easier it is in routine maintenance and repair. Therefore, it is better to start making homemade shovels with a careful selection of the drawing, which involves the use of a small number of simple elements. For pointed rods on panels, shanks, handles, you need to select durable, corrosion-resistant materials. The ideal option in this case is stainless steel. A metal pipe is suitable for the handle; you can also make a bar and an emphasis from it.

3 Cons of the Miracle Shovel - What to Consider

Such a super-shovel cannot be used for digging a vegetable garden, only for loosening. At the same time, the working width reduces maneuverability, which can become a hindrance in tight spaces between landings. While an ordinary bayonet shovel can be easily thrown over your shoulder and moved to the other end of the site to work on the next plot, things are a little more complicated with a toothed tool. The fact is that earthen miracle forks, equipped with stops, have a very significant weight, which creates inconvenience when carrying and transporting in general. And the dimensions of this tool are quite large. Some models require the operator to be heavy enough to sink the tines completely into the ground when pushing down on the footrest.

Another drawback is the complexity of maintenance and repair. The edge of a bayonet is much easier to sharpen than a couple of dozen long rod-shaped teeth. Moving joints should be regularly lubricated, cleaned of trapped earth. The repair of the miracle shovel is also quite difficult. In the event of a joint breakage, a suitable bushing must be selected. Teeth can bend over stones or even break off the frame. Therefore, tool manufacturers recommend to loosen only the soil sufficiently moistened by precipitation or artificially. It is not recommended to work with very hard, caked clay and rocky ground.

The main structural elements of the miracle shovel

In addition to the option that is shown above (under the name "Tornado", "Excavator" or "Plowman"), there are several more options for the designs of the miracle shovel under different names.

This design also has working and support forks, but does not have a front stop. Therefore, it is less bulky, weighs a little less. But the front stop provides increased stability when working. And the drag weight is not that important.

The handle is attached to the working forks, the back stop is welded to the comb of the second forks. Both of these structures are movably interconnected (even door hinges can be used).

Ripper miracle shovel for easy tillage

The photo shows one of the implementations, which is made on the basis of a corner and a round pipe. When working, they drive the pins into the ground by pressing on the crossbar, and not on the stop, as in most models.

The Digger version is essentially a wide forks with a stop for easier eversion and a high, powerful handle.

The peculiarity of this design is the stop and the adjustable handle. It is fixed with two bolts, matched to the height of the working person.

The emphasis is not stationary, but movable. It is fixed to the frame. When the pins are immersed in the ground, they press on it with their foot, then, without removing the leg, they turn it out by pressing the handle of the pitchfork out of the ground.

Digger in action

How to make a miracle digger, see the next video.

This design of the miracle shovel is slightly different from the previous one. The stops in it are rounded, the handle is arched, but the basis of the structure is the same. Some drawback - there is no way to adjust the handle, but otherwise everything is the same - a movable stop and working forks.

Two options called "Legkokop". The simplest ripper for the garden, garden and cottage

It is difficult to say whether this variation is better or worse. It would be possible to evaluate only by comparing the work of both copies on the same site.

The miracle shovel performs not only its direct functions - digging the earth, it also loosens and breaks clods of earth. The design consists of two strips with pins. They are movably connected to each other. Sometimes the device can consist of one such bar.

Some manufacturers produce models that have a backgauge. Such a shovel is designed to facilitate labor when digging dense, heavy soil. So what a miracle shovel more like a double pitchfork.

The main advantages of the miracle of a shovel include the fact that it is capable of performing several functions:

- Loosens the soil;

- Breaks up large clods of earth;

- Pulls out the roots of any weeds without leaving them in the ground;

- Easily digs potatoes, beets and other root vegetables.

The principle of operation of this device is not complicated. To describe it in general terms, it will look like this: a conventional pitchfork, mounted on the back stop, loosen the ground by means of the force that a person transfers manually to the tool, pressing on the handle.

At this time, the second fork teeth, located opposite and entering the lock, break up large lumps of soil in the process of loosening. As a result, the earth is well dug up and loosened.

The ripper is equipped with a front stop that provides good stability to the entire mechanism. Looking at the work of the miracle of a shovel, it can be compared to scissors that cut and grind piles of earth. This eliminates the need for cultivating the land with a garden rake.

The miracle shovel is an indispensable tool for gardeners and gardeners. It is especially good to use it when digging large areas, since with the help of this tool of labor, the work process can be accelerated several times.

Watch the video! Miracle shovel, which one to choose

What are the features

She became a real gift to all diggers and plowmen. After all, any summer resident-gardener knows that the most difficult physical labor is associated with digging up the earth. For planting potatoes, we all pay with pain in the back, arms and legs. An Orthodox monk made his own version of the traditional bayonet shovel, he claims that it is a pleasure to dig with it, it even helps to plant potatoes.

In the process of digging a garden, you have to bend over each time, pressing the shovel into the ground with force, and then, straining all your muscles, lift not only a heavy shovel, but also the earth on it. Of course, my back hurts from such work. The shovel "Vyatsky Plowman" allows you to work without stress. This is its main advantage, therefore it is called a "shovel for the lazy", or more precisely, for the weak, because any pensioner with it can become a digger.

It is not symmetrical, you can work with it only with one foot - the left, but there is no problem with that, you can make a tool under the right foot. In the upper part, the inventor installed a bicycle handlebar, so that you can hold the shovel with both hands at chest level. The most important thing: you do not need to lift the ground, it turns over exactly as a result of the pivoting movement of the hands.

With such a shovel, labor productivity can be increased several times. It is successfully used for digging a garden and planting potatoes, but you can also dig a ditch.

Various tool options

There are fixtures that, although arranged in a similar way, have important design differences. Further on they are described in more detail.

Soil cultivator without front stop

There is no front stop in this type of design. The clod breaking grid is made without a front bar. This slightly reduces the weight of the mole ripper shovel. However, since there is no need to lift the shovel off the ground during operation, this does not provide a significant advantage.

Soil cultivator without front stop

Digger

This option differs from the classic one in that it does not have a front grill. The tool handle is also made in a different way.

The digger consists of the following parts:

- It uses a pen made in the shape of the letter "T". Therefore, in the process of work, the shovel is not held as usual. Hold the instrument by the horizontal bars with your hands. This helps to increase the force of pressure on the soil when working. In addition, such a handle is usually made of metal. It can slide up or down. After finding a comfortable position, the handle is bolted.

- The pitchfork is attached to the handle at two ends, and not at the central part, as in the classic version.

- A stop attached to the back of the tool is more powerful than usual.

The disadvantage of this design is that soil crushing is not provided.

Digger

Easycop

This option can be considered the simplest design. For her, a rectangular metal frame had to be invented, to which a pitchfork was attached, looking down. The stop, made rectangular, is attached horizontally. The front grill is missing.

On a note. Despite its simple design, this kind of miracle shovel is an effective digging tool.

Archimedes' shovel

It bears little resemblance to the classic version. The difference, in particular, is that here, for digging, not a pitchfork, but a bayonet shovel is used. However, the inventor applied a similar principle here: the rule of leverage. This is an invention of Vladimir Kolybelin from the city of Kovrov, Vladimir region.

The Archimedes' shovel is arranged in this way:

- It has two shafts: long and short.

- The tool blade is attached to a short shaft.

- All parts are connected in one piece by the bracket. With its help, a short shaft with a shovel in the middle is connected to a long handle and can be rotated.

When working, the tool is stuck into the ground, the long handle is slightly shifted forward. Then they step on the short part, and, taking into account the law of the lever and the length of the arm, the shovel will lift the ground.

Important! Although the arhimedova shovel saves effort compared to conventional tools, it is difficult to use on heavy clay soils

Archimedes' shovel

Advantages and disadvantages

An electric snow shovel has its pros and cons. They must be taken into account when choosing a product between a manual and a self-propelled snow blower.

Device advantages:

- Relative lightness and small size. The design is simplified as much as possible, due to the absence of a tank and a number of other additional elements. Even with a weight of 6-7 kg, the mass is almost not felt. The compactness of the electric shovel allows it to be used for clearing snow even in small rooms without any difficulties with storage.

- Reliability and long service life. Modern snow clearing machines are equipped with overheating protection, which extends the life of the motor. The electric motors of the snow blowers are equipped with double insulated windings, which provide additional protection against water and reduce the risk of breakage. The electric shovel motor is unpretentious and capable of operating for a long time without the need for expensive maintenance.

- Low noise level. The electric motor of the snow blower makes almost no noise, which does not require the installation of an additional noise-insulating housing. This factor further facilitates the construction.

- Environmental friendliness. Electropath motors are environmentally friendly. In the process of their work, carbon dioxide, carbon monoxide or other harmful elements are not emitted.

- Ease of use.Electric snow cleaners don't need to add oil or buy gasoline. In addition, the start-up process is simplified here. All that is required is to charge the battery on time or insert the plug into the outlet.

- Low price. Unlike self-propelled snowblowers, electric shovels have a lower price, but they do the job just as efficiently.

Disadvantages of an electropath:

Lack of power. Often, manual snow blowers are equipped with motors up to 2 kW, which is enough for domestic purposes, but not enough for professional work. In the latter case, a gasoline or diesel snow cleaner is more suitable.

Poor mobility. Electric shovels powered from the mains are "tied" to 220 V sockets, which forces you to stay near power sources or use extension cords. This is not a problem for cleaning the area near an office or a country house, but difficulties can arise in remote areas. The problem is solved if you give preference to a shovel on a battery.

Difficulty throwing out frozen snow. Structurally, electric shovels are designed for cleaning fresh and still loose snow. If it thawed, and later became covered with an ice crust, difficulties arise, and the motor may overheat.

Relatively small snow throwing range

When buying, it is important to look at what distance the snow mass is thrown. Here it is necessary to proceed from the characteristics of the territory and the proximity to other people's sites.

POPULAR WITH READERS: LED lamp flashing: causes and remedies

Electro-shovels are not a self-propelled mechanism, therefore their control requires some labor. But this does not cause difficulties even for people with minimal physical training. The question of control is further simplified if the device is provided with wheels.

Principle of operation

The job is to push the shovel's bucket (blade) into the ground and turn over the earth layer by turning the handles to the right. The earth in a neatly cut layer turns over and lies on the right. The back remains straight, there is no need to bend, a bayonet is stuck into the ground, thanks to this, the blade of the shovel enters the soil under the weight of the leg. On light soil, you can work with only hands. The spine performs only a rotational movement, without the use of force with the help of a lever, work is done to cut, take out and turn over the layer of earth.

It is possible to plant potatoes with this "magic digger" as with a plow. It is necessary to dig one furrow (stepping back), put potatoes in it, and when digging the second furrow, an even and accurate burial occurs. Moreover, fertilizer can be placed in the second furrow and bury it, passing the next furrow. With a bucket width of 30 cm, you get a very even planting of potatoes, where there will be 60 cm between the bushes.

Advantages

The indisputable advantage of "Vyatsky Plowman" is its high labor productivity and the absence of stress on the spine when digging a vegetable garden. With its help, an excavator can dig a trench, and a summer resident can easily and quickly dig up a vegetable garden. This miracle digger can handle when digging up virgin soil. It is especially good to use it in light sandy soil, then you don't even have to loosen it.

It is interesting that this miracle shovel can be made with his own hands. There are drawings on the Internet, made by a resident of the Dnipropetrovsk region to help everyone. It can be made almost from scrap metal. You will need such simple materials:

- stainless steel pipe;

- stainless steel shovel blade (better cold-rolled);

- pin;

- bicycle wheel.

With the help of these drawings, a do-it-yourself shovel for the lazy can be made taking into account the height of a person. The horizontal handle should be at chest level so you don't have to raise or lower your arms. Although today you can buy a ready-made digger for any leg to choose from. It is in demand, which means that the production can be entrusted to professionals, and you will not have to understand the drawings!

The advantages of the new structures are that working with them does not require a lot of time and physical effort.

In addition, they are convenient in that:

- labor productivity increases 3-4 times;

- no need to bend over to the ground;

- there is no need to strain the muscles of the back when the shovel moves upward along with the clod of earth (when the ground is damp, it is even harder to do this);

- due to the rotational movement of the digging or loosening main element, only the hands are strained, pressing on the handles, which are attached to the handle.

When buying, you need to pay attention to how much a person's weight is designed for a miracle shovel. For example, the classic options can be used by people no lighter than 80 kg, since the devices are quite bulky, it is difficult to move them on the surface.

But the construction "Plowman" is suitable for gardeners weighing 60 kg and more. Father Gennady's shovel is much lighter than complex configurations, so a person who freely holds it in his hands will not be difficult to carry out garden work, regardless of his weight category.

Instructions for making a miracle shovel with drawings

Before you start making your own miracle shovel, you need to turn your attention to the main structural features of such a tool. In most models, the forks are mounted movably on a forward, horizontally located frame, supplemented by a stop at the rear (in some cases, the frame is replaced with a slide slightly curved upward)

Between the teeth, counter-directed rods are passed, which are more like a rake.

The tool can have two handles, but in most cases it is a regular handle, like a shovel or the same forks. However, not in all cases a wooden handle is used, since such a lever can easily break (the teeth often cling to the roots). Instead of the handle, a metal pipe (for example, aluminum) can be installed. If the wooden handle breaks in the nest of the garden tool, at its very base, then it will be quite difficult to remove the piece, and the only way out is to try to drill it out.

There are also more simplified models, the design of which includes only the frame, which, along the way, is an emphasis (located behind the working part). The teeth are fixed directly to the front bar, at the ends of which there are fasteners for the other two handles. This version of the miracle shovel is most often made at home.

Did you know? In the old days, a standard wooden shovel (or, as it was also called, “blade”) had a width of 6-14 vershoks and a length of 8-16 vershoks, and this with a total length with a handle of 1½ — 1¾ arshins. In Russia, all shovels and blades were hewn mainly from aspen, sometimes from linden or birch, and even less often from oak or maple.

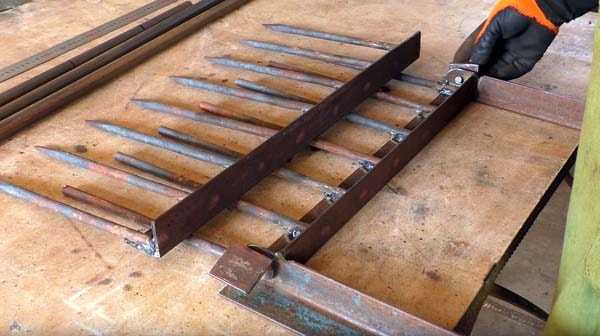

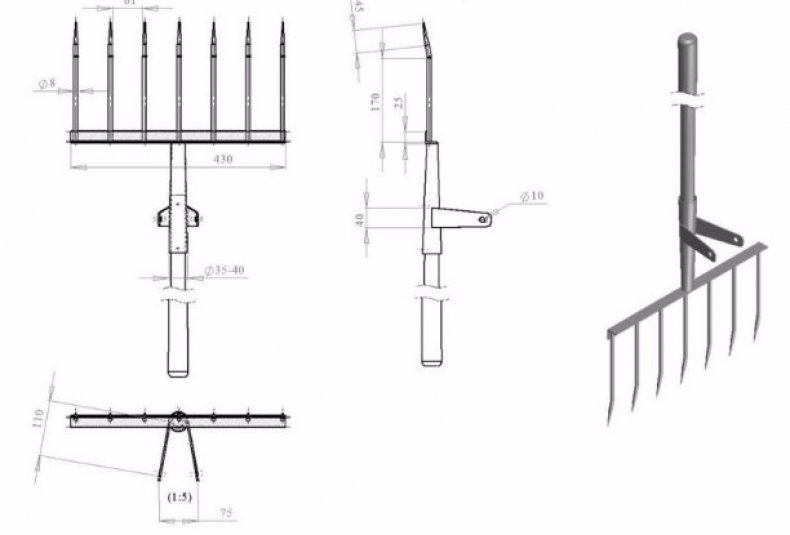

When making a miracle shovel on your own, first of all, it is necessary to create bayonets, for which the reinforcement prepared in advance is cut into pieces of the required length. The ends of these segments are sharpened on one side at an angle of 30 °, although if the soil in your area is soft, then the bevel angle can be reduced to 15 ° (although this will lead to frequent dullness of the cutting part).

Having the required bayonets on hand, you can proceed to creating a supporting bar, for which a part of a square pipe is cut off. It is also worth preparing a round hollow pipe, which will play the role of a handle in the future. All elements are welded according to the drawings below.

How to make a DIY super shovel

Manufacturers of tools for the garden and garden have long adopted such a tool and produce it on an industrial scale. Nevertheless, you can find such a shovel everywhere, and if it is found in a store, then its cost will be very high.

At the same time, you can assemble such a tool with your own hands, using available tools. And even if some materials need to be bought, the cost of the shovel will still be below market value.

To make such a digger with your own hands, you will need the following materials:

- a metal pipe with a diameter of 20-25 mm will be used for the manufacture of the supporting frame;

- a two-meter piece of steel pipe with a diameter of 4 cm;

- a sheet of steel with a size of 20x20 cm and a thickness of 2 mm;

- fittings or round rods with a cross section of 1 cm - 2 meters, they will be needed to make a rake.

To assemble and fasten all parts of the shovel, you will need tools - a welding machine, a grinder with a disc for metal and a drill with drills. The manufacturing process takes place in the following sequence.

- Carrying frame manufacturing. To make such a frame with your own hands, use a round steel pipe with a cross section of 2 cm.You can take a square pipe with a cross section of 2x2 cm.The pipe can be bent in the form of an arc or connect separate pipe sections in the shape of the letter A. The size of the frame should be 46x80 cm.

- Installation of bars. Another tube is welded across the frame. Holes with a diameter of 8 mm are drilled in diameter at a distance of 5 cm and an angle of 20 degrees. You can increase the distance between the bars up to 10 cm if the soil in the garden is light and fertile. Rods 20 cm long each are inserted into the holes and welded using a welding machine. The rods must be pre-sharpened at a 30 degree angle to facilitate penetration into the soil. Also, to make digging with a shovel easier, the teeth made from reinforcement need to be slightly bent. Another row of teeth must be installed opposite the welded teeth. To do this, a piece of iron pipe is welded to the frame, and another row of reinforcement rods is welded to it.

- Installation of support under the foot. To the upper part of the frame, a T-shaped leg rest is welded at an angle of 120 degrees. To fasten the support and the rake, you must use the metal ears.

- Then a piece of pipe with a diameter of 6 cm or more is welded to the structure to install the handle into it.

After fastening all parts with a welding machine, the tool can be used.

Any gardener can make such a digger, the main thing is to have the necessary materials. With the help of such a hand-made shovel, the processing of the garden will be much faster and better.

In addition, thanks to the forks, which form the basis of the structure, the weeds in the soil will not be cut off, but will be pulled out of it using the tines. This allows you to remove weeds from the root, while reducing the possibility of their germination.

How to make it yourself

You can make such a shovel yourself, but for this you need to be able to work with metal, for example, perform welding. This section will tell you how to make a miracle shovel with your own hands, about the drawings and dimensions for making it.

Materials (edit)

The main part of the structure is made of metal. To do this, you can take a profiled pipe or corner. The thickness should be approximately 30 mm. In the latter case, the steel used is important, it should not be thinner than 3 mm.

Important! The teeth should be made of high quality steel. Suitable forks derived from forks or those made on the basis of an automobile spring

It is recommended that there are 6 to 8 teeth.

The handle can be made of wood or metal pipe.

Dimensions (edit)

The width of the working part is usually from 60 to 80 cm. If you make more, then this practically does not add productivity. The recommended length of the pins is 22 to 30 cm.

The length of the handle is made according to the height. It will be convenient if it reaches the shoulder.

Blueprints

The figure below shows one of the options for how to make a shovel.

In accordance with this diagram, it is possible to make your own instrument.

The miracle shovel greatly facilitates the work of digging up the site. You can do it yourself. If possible, it makes sense to purchase a high-quality commercial model.

Not everyone knows how to do the miracle of a shovel with their own hands, but almost all summer residents and gardeners, owners of backyard plots know how difficult it is to dig up a garden. This procedure will be greatly simplified if you know how to make a miracle shovel with your own hands. It is worth noting that such a device is far from the only one in the arsenal of summer residents, there are others, however, it is this device that can significantly reduce the time for digging up the site, save energy when working "in the field".

A miracle shovel is necessary for digging up a site in spring and autumn, before planting plants in gardening and dacha works.

The latter is especially important, since everyone who has come across such a job knows how difficult it is to complete it. After all, intensive digging of the garden is not only difficult and tiring, but also detrimental to health.

A homemade tool performs much better the functions of an ordinary shovel and, according to the owners of this device, they can quickly and efficiently dig up the required piece of land.

Which shovel is best for digging land in the garden and vegetable garden

Ordinary shovel

If the digger is traveling with a large vehicle, the long Fiskars shovel will do the trick. In terms of dimensions, it is not limited, in terms of ergonomics, it is the most it. And the inclination of the bayonet to the handle, and the bend of the handle - everything works for convenience.

He can also advise the Fiskars telescopic shovel - for shallow purposes it may not be completely laid out. And if you need to remove the top layer from a large area - move it forward and onto the mines.

Folding paddles

The thing is useful as an addition to the main shovel. Or as a last chance shovel. But digging for her all day is an occupation worthy of Sisyphus. A lot of effort with little result. Unless you can take such a paddle to hunt for coins on the beach in addition to a scuba or even without it.

Read also: Tesoro Tejon: detailed analysis of a metal detector, customer reviews, videos from the cop and finds

Fiskars ergo mobile

This shovel is now out of production, it was replaced by the most popular among diggers Fiskars Ergo Solid - sapper. With the same dimensions - 800 mm in length - the sapper has a welded attachment of the handle, and the bayonet has become a little narrower and acquired a more pointed shape.