What material should the rivet be of

Rivets are usually taken from the same material as the parts to be joined - this avoids electrochemical corrosion

Pay attention to the strength characteristics. But, as a rule, when connecting aluminum parts, the strength of aluminum hardware is sufficient

In general, rivets are made from the following metals:

steel:

- ordinary - grades St2, St3, St10;

- corrosion-resistant Х18Н9Т;

- galvanized;

When connecting copper parts, the installation of brass and copper is permissible. Aluminum is bonded with aluminum alloys. Steel sheets - corresponding grades of steel rivets. There are also mixed hardware - from two different metals (chemically non-conflicting). Most often, there are aluminum-steel.

For the installation of facade elements, slopes, ebbs, metal tiles and profiled sheets, blind rivets made of galvanized painted steel are usually used. Coloring - in tone with the details.

How do you find the perfect rivet for your production?

- The thickness of the materials to be bonded. The rivet must be selected in such a way that the clamping range corresponds to the thickness of the materials to be fastened. Some rivets are designed for a wide range of fastener thicknesses, which simplifies installation and reduces the number of fastener items stored in stock. Such rivets are called multi-clamp rivets.

- Hole size. The hole is made in advance and the more precisely it matches the diameter of the rivet, the more reliable the connection will be, although most modern rivets are not very sensitive to the shape of the hole. Allowed to use on holes with irregularities, etc.

- Rivet strength. If the connection is subjected to high shear or tensile stresses, a rivet of the appropriate strength must be selected.

- Corrosion resistance. The blind rivets presented in our catalog are designed to provide various levels of corrosion resistance. If the requirements for this parameter are high, we recommend choosing reliable stainless steel rivets. Additional corrosion resistance is provided by special coatings using non-ferrous metals.

- Uniform load distribution. This parameter must be taken into account when bonding thin sheet or fragile materials. Rivets with a wide rim allow to ensure the most even distribution of the load on the material and exclude damage from both the front and back sides.

Species overview

Pneumatic riveters come in different types. For example, pneumohydraulic or simply hydraulic is used for large threaded rivets in industry. Such options carry out the fastening of parts with high clamping force. Mostly used in mechanical engineering.

The AIRKRAFT hydraulic pneumatic riveter is designed to work with aluminum and stainless steel rivets. Performs professional riveting in a continuous process. The design is equipped with a double air intake, which allows for both right and left hand operation. There is a special container with a rim to protect the user's eyes and keep the workplace clean. This design is designed to minimize hand fatigue.

A muffler is provided, and a special tip design has been created to avoid rivet loss. There is also an oil filling hole. For work, you must use an air hose with a diameter of 8-10 mm. During riveting, there is an air consumption of 0.7 liters per unit.The power is 220 Hm. Stroke length - 14 mm.

Also, pneumatic rivets can differ in their purpose and performance, they can be used to install blind rivets, threaded rivets or nut rivets. The Taurus-1 model of pneumohydraulic rivet drawing tool has a light weight (1.3 kg), the air consumption is 1 liter per rivet with a working stroke of 15 mm. The rivet will be held in any position thanks to a special switchable suction system. The receiver uses compressed air to install it and eject the tear-off rods.

A pressure relief safety valve is also provided. During operation, there is minimal vibration and noise level, the weight distribution is optimal. There is a retractable gimbal holder. The model is equipped with a handle with a rubber insert. The blind riveter carries out work on the installation of blind rivets. The main advantage of this type is the low price of consumables. Rivets of this type cover the hole of the workpiece well.

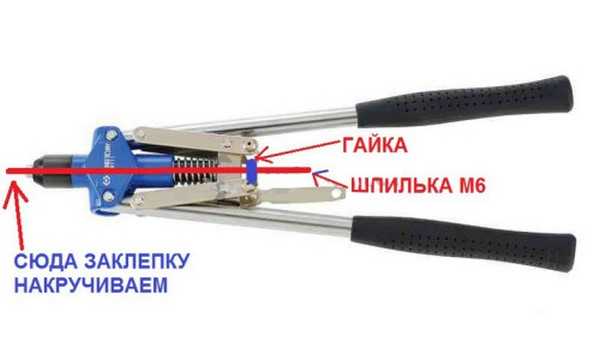

The threaded version works a little differently, it is designed for threaded rivets. This type is a shallow tube, at one end of which there is an internal thread, and the other side is flaring, like a blind nut. A stud is screwed into the thread. Pulling towards itself, the thin metal between the thread and the flaring is crumpled, as a result of which it firmly compresses the parts to be joined. These connections are highly durable, but the cost of such rivets is much higher than the previous version.

There are also universal pneumatic guns that work with rivets and threaded types at the same time. The set includes replaceable heads and instructions. The JTC reinforced pneumatic riveter has the following dimensions: length - 260 mm, width - 90 mm, height - 325 mm, weight - 2 kg. Air connection size is 1/4 PT. The tool is designed to work with rivets made of aluminum and stainless steel.

Easy and simple operation is guaranteed by the two-component handle. The working part is made of chrome vanadium steel, due to which the tool has a long service life. To increase productivity, you can work with two hands. This model belongs to the professional and industrial class. The quality of the products is confirmed by an international certificate.

How to choose?

When choosing a riveter, it is important to pay attention to a number of important points.

- Appointment of the tool. For the home, you should choose the simplest options - for aluminum rivets, even a one-hand option or an "accordion" is suitable. For steel and stainless steel, it is better to purchase two-handed manual models. Professional equipment for riveting metal of different thicknesses is required only for those who are engaged in production, repair and construction.

- Features of fasteners. For example, for a drywall profile, a conventional one-hand lever-type cutter is suitable. For Molly dowels and for anchors of this type, select similar models. For semi-hollow rivets, you need a pulling tool that is simple and straightforward to use.

- Manufacturing material. It must be tool steel of sufficient thickness. This point is especially important for professional use. Silumin and aluminum options are not even worth considering.

- Head type. If you have to carry out work in different conditions, it is better to immediately choose a model with a rotary mechanism. For not too frequent installation of rivets at home, you can get by with a simple straight or angled option.

- Equipment. The wider it is, the less you will have to buy additional accessories in the end. In addition, the tool must have the necessary mounting keys and other devices to facilitate the work of the master.

- Weight and power. A quality riveter is always quite heavy, its weight is close to 1 kg or more.The most powerful models are pneumatic, electric corded ones are inferior to them, but such performance is required only when the tool is used in-line. If this is not required, it is better to choose a manual option or a drill adapter.

These are the main criteria that can be followed when choosing a riveter for use in a home workshop.

general description

More recently, the principle by which the connection was made using rivets had a huge number of shortcomings and subtleties, which excluded the possibility of its implementation at home.

First of all, riveting had a huge number of very different technological difficulties, in addition, the connection of this type was very laborious.

It was necessary to exert great physical exertion in order to install the appropriate rivet in the right place.

These and many other drawbacks made the riveted connection, which is characterized by a fairly high reliability, not popular.

It should be noted that at home in those days, the riveting tool was not only inconvenient to use, but also unsafe.

Of course, engineers from different countries of the world were constantly working on this problem, and as a result of their work, a manual-type riveter was born, which has a compact size, and most importantly, allows you to make a reliable connection with minimal physical effort.

Video:

The device of such a hand-held tool is quite simple, in addition, it is very simple to use it for the corresponding work.

This versatile tool allows the connection to be accessed directly to both sides at the same time, with no additional support required.

The only thing that is required when working with a hand-type riveter is to drill a hole in metal blanks for installing a rivet, after which it remains only to fix it with the appropriate tool.

All the work is quite simple, and everyone can do it without any problems. It should be noted that the price of such a versatile and convenient tool is within reach.

What is riveting

The mechanical connection of parts using a series of rivets is called a riveting, and the connection itself is a riveted seam. It is used where it is inconvenient to weld parts or where non-weldable materials are connected. Not only metals are riveted, thus they connect parts in clothes, accessories, etc. But there it is more of a finish than a loaded connection. So further we will talk about riveting in construction or home improvement. In principle, instead of riveting, you can use a screw connection, but bolts and nuts are more expensive, and their installation takes more time.

Advertisement

This is what a riveted joint looks like

If we talk about installing fences made of profiled sheet, rivets are more reliable, since they can only be removed by reaming the fasteners. When installing screws or self-tapping screws, they can be unscrewed and carried away both metal and hardware. In some cases, riveting is more convenient when installing a roof from corrugated board or metal. On the roof, the installation of screw connections is problematic and time-consuming. And with rivets, and with a good tool, you can do it in an hour or even less.

The most common use in the personal household

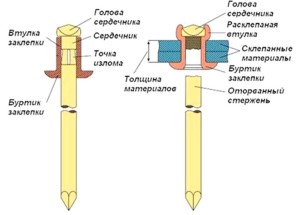

How are parts connected with rivets? The rivet is inserted into the prepared through hole. It has a head that rests against the material and the rod. During the riveting process, the end of the rod is flattened, changing its shape under the influence of force. Therefore, plastic metals are used for these hardware.

Photo of electric rivets

We also recommend viewing:

- The best woodworking machines for home use

- Review of the best types of drilling machines

- Knitting gun for fittings

- How to choose a soldering iron for polypropylene pipes

- TOP best miter saws

- How to choose a good circular saw

- Review of the best electric planers

- An overview of the most reliable chain saws

- The best handheld wood milling cutters

- Electric type construction stapler

- Best electric spray guns

- The best grinders

- Which cordless screwdriver is better to choose

- Rating of the best blowers

- How to choose a renovator

- How to choose electric metal shears

- Which building hair dryer is better to choose

- Review of the best glue guns

- Rating of the best impact drills

- How to choose a mini drill

- TOP-best jigsaws of 2018

- Review of the best drills of 2018

- TOP best engravers

- Best cordless screwdrivers

- The best grinders

- How to choose a good electric hawk

- Review of the best models of electric trimmers

- Which construction vacuum cleaner to choose

- DIY power tool repair

- Review of the best soldering irons for home

- Review of the best rock drills in terms of reliability

- The best polishing machines

- Best Reciprocating Saws

- How to choose a good jackhammer

- Best screwdrivers of 2018

- Review of the best wall chasers

- How to choose a good impact wrench

Help the site, share on social networks

How to rivet a rivet without a riveter?

There are old "old-fashioned" methods of installing and removing rivets, if there is no special tool-pistol at hand. How to rivet a rivet without a rivet is known to many experienced craftsmen. This method is used if there are several connections in the work, since it will require physical efforts and tools: a rivet, a drill or screwdriver, a screw, nuts (simple or connecting), a wide washer.

- Holes must be drilled in the parts to be connected.

- Insert rivets into them.

- Screw one union nut onto the screw. Instead, you can use 2-3 simple ones.

- Install the washer.

- Screw the screw into the rivet.

- Use a screwdriver to tighten the screw, pulling out the hidden rivet element.

- Unscrew the screw.

How the device works

Working with a manual riveter is very simple, and you do not need to have any specific knowledge for this. First of all, you need to properly purchase the instrument itself.

In this case, its price should not be the determining factor. It is better to choose a well-known brand tool with good strength and high reliability.

After the manual type riveter is purchased, you should mark the places for the holes on the surface of the fastened elements.

This should be done so that, without fail, after making a hole on different sheets, the holes themselves coincide.

Then a rivet of a suitable diameter is inserted directly into the hole itself and the tool handle is gently squeezed. When using a hand-type riveter, several different presses will need to be done.

When the riveter is given a force, the rivet shaft will gradually begin to stretch, and the sleeve, on the contrary, will flatten out.

If you look at the rivet from the back side after flattening it, you can see quite wide petals.

As a result, on one side of the material to be fastened, there will be a head of the rivet itself, and on the other, flattened petals.

After the rod is fully retracted, it will be necessary to carefully bite off all the resulting excess with nippers.

The video, which is posted below, describes in detail how to independently work with a manual riveter.

Video:

When buying a hand tool, price should not be the determining factor. As a rule, low quality handheld models at a low cost provide poor connection quality, and besides, they quickly fail.

Currently, hand riveters, both pull-out and threaded, can be purchased in almost all specialized stores, where they are presented in a wide range.

You should also pay attention to the quality of the rivets themselves, as well as to the material from which they are made.

What is a riveter and how does it work

Riveters or riveters are devices for setting rivets. There are special tools for different types of fasteners. There are separate for pulling, screw rivets. There are also universal models, but they belong to the group of a professional tool, respectively, they cost respectably.

One use case

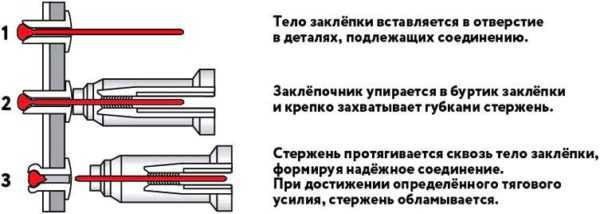

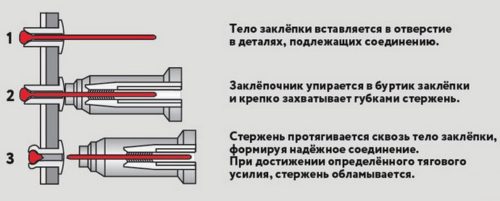

To choose the right riveter, it is advisable to understand how it works. Regardless of the type of rivets with which the unit works, the principle of riveting is always the same: the device flares the second (far) part of the rivet, forming a closing head. Only the flaring method can differ:

-

When installing blind rivets, the rod is grasped and pulled by the sponges. At the end of the rod there is a ball that rests on the edge of the rivet body and crushes it. When a certain effort is reached, the rod breaks off.

- The installation of screw rivets is different. The inside of the hollow body is threaded. A screw of a suitable diameter is screwed into this hardware. When twisting, it begins to tighten the rivet edge, due to which the plastic metal is expanded (see video below).

-

When installing hollow rivets (piston rivets), a flaring with a cone-shaped nozzle takes place. Piston rivets are used in unloaded places, but more often not in a construction site, but for finishing or when joining parts made of leather, fabric, etc.

In general, the process is clear. As you can see, the only differences are that in one case it is necessary to pull the rod, in the other - to turn the screw, in the third - the conical nozzle is pressed

When choosing the type of rivets, note that the tool for extraction is inexpensive, but for screw rivets it usually costs a lot. This basically limits the use of screw rivets.

Well, and the fact that they are hollow - leaking.

Species overview

The development of manual mechanical riveters went in several main directions, the general requirement was to apply physical efforts to the power mechanism to form a strong connection.

By the type of rivets used

The evolution of rivets paralleled the evolution of rivets, which led to the emergence of fundamentally different tools. Traditionally, rivets are made from steel, copper or aluminum. The use of different metals requires different efforts and different designs of rivets. Joining with simple copper or aluminum rivets could be made with a hammer, and the same could be done with steel rivets. However, in the conditions of a home workshop or garage, such a seemingly simple operation often turned out to be almost impracticable.

Another thing is the use of steel blind rivets. For blind rivets, a manual mechanical riveter is sufficient. The development of a lever-ratchet mechanism made it possible to develop a tool for steel rivets. The tool for threaded rivets is slightly different. Working with such a device, in contrast to pulling rivets, takes more time, however, the connection is more durable.

By the number of handles

Manual riveters were divided into the so-called two-handed and one-handed, depending on how many hands are involved in the operation. A two-handed riveter produces a very significant force. Such a tool can be used for long-term work, since it distributes the load quite evenly, and thanks to the long handles and lever mechanism, it allows you to do with relatively little physical effort

Some models for the installation of hollow rivets are equipped with a special container for collecting broken pins, which is especially important for industrial work. However, this type of tool also has a drawback, with its help you can work only by providing free access to the junction

This problem can be solved by a one-hand riveting machine - the so-called "pistol". The force on the ratchet is transmitted from one hand by compressing the movable and fixed handles. When installing thin and short rivets, one movement is enough, however, more often you still have to do several squeezes of the handles before the rivet rolls over and the pin breaks off. Such a tool can be used to install a small number of rivets, since the length of the handles still requires quite a lot of physical effort.

However, the small size allows the use of a one-handed tool where it is impossible to place a two-handed one. In addition, some models are equipped with a swivel head, which significantly expands the range of their application. Most of the models have a reinforced body fixedly connected to one of the handles, which allows the tool to be used successfully for many years. Professionals have in their arsenal both two-handed and one-handed tools that allow them to quickly and efficiently rivet any parts and materials.

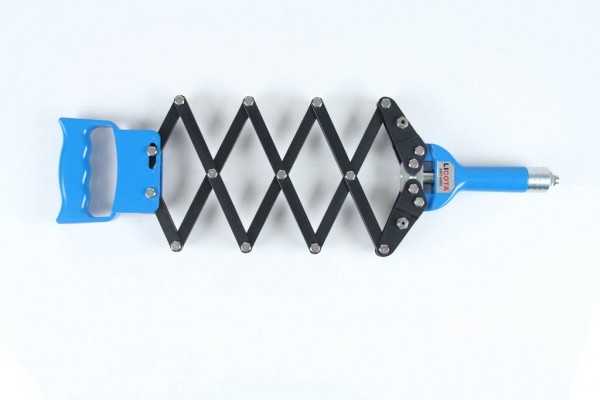

A separate species is the "accordion" riveting machine, aka "frog". It can also be classified as one-handed instrument. The force on the mechanism is transmitted from the compressible linkage system. With the help of such a riveting machine, large diameter rivets can be used quite effectively.

What are riveters and their scope

Riveters come in many different types. Let's try to understand this variety of models and classify them.

To begin with, let's say that the tool is designed for pull-type and threaded rivets. There are two categories of tools available: for industrial and domestic use. A professional tool allows you to create more force and, accordingly, work with rivets made of harder metals. Household tools are used for soft metal rivets (copper, aluminum). By design and method of creating effort, the following types are distinguished:

- With one handle. By moving one handle of the tool, force is created, the second handle remains stationary. The mounting head is fixed at its end.

- "Scissors" - the effort is created by bringing two handles together. This design allows you to create significant pressure compared to the previous one.

- "Harmony" - is a hybrid of the above models, the effort is created by pressing the control handle.

By the type of drive, they are distinguished:

- pneumatic drive;

- manual drive;

- drive from the electrical network;

- battery drive;

- pneumohydraulic.

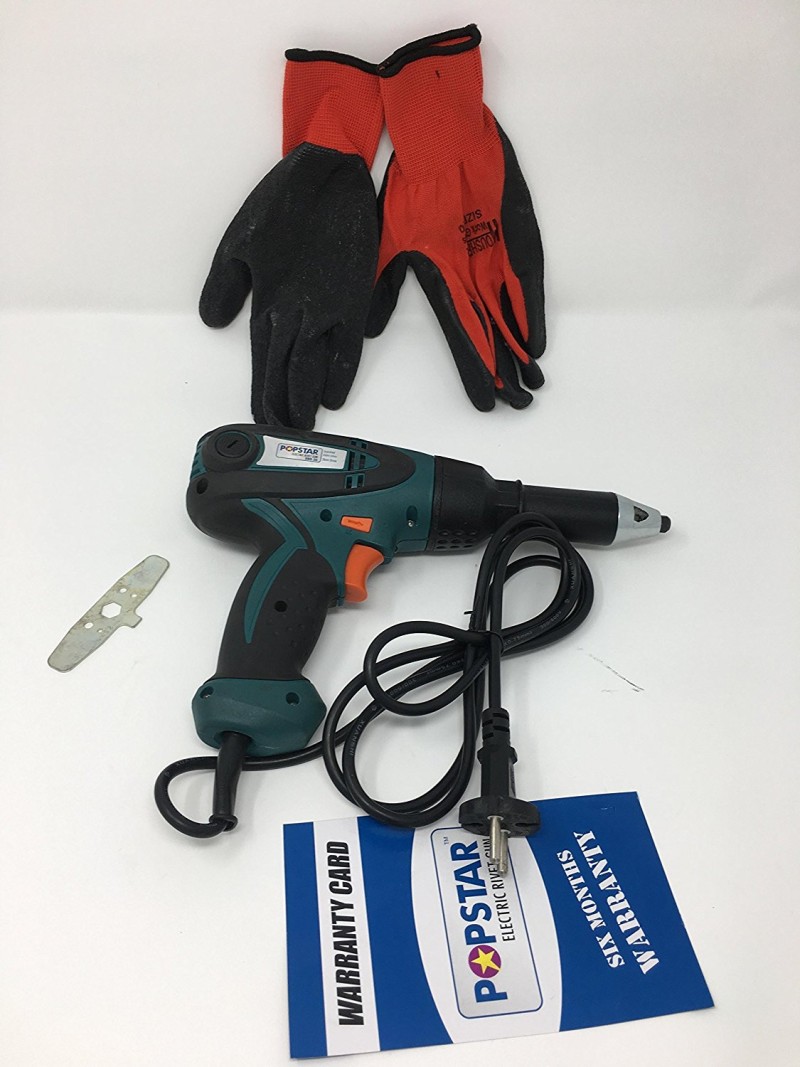

Electric pull-out riveter

This type of rivets will be very useful for you if you need to install a large number of blind rivets, but there is a small problem: there is no compressed air supply. This tool is powered by 220 V and is not as mobile as a cordless riveter. However, it also costs much less than a battery one, since a battery is an expensive pleasure. These models differ in lower weight.

Cordless riveter

These riveters are expensive compared to mains powered rivets. The battery must be constantly recharged. Since it has a significant weight, the instrument will be heavier than its network counterpart. It must be used in those places where there is no opportunity to connect to the mains.

Electric Riveter for Threaded Rivets

The difference between this type of tool and a pull tool is that the hinge is retracted by twisting the thread in the pipe-shaped part of the rivet. The head is fixed by tightening the handle. This method is rarely used and is mainly needed for fixing parts of small thickness. Complete with a riveter, you can also purchase attachments of various diameters.

Let's take a look at some of the models on the market today:

- Model GesipaAccubird 220V. Works with steel, aluminum, stainless steel. The weight of the device is 2.45 kg. Length - 265 mm. The body is made of impact-resistant plastic. Cord length - 2.4 m. The device is designed to work with blind rivets no more than 5 mm. The kit includes a container for the disposal of used rods.

- BraloTR-1000 model. This model is pneumohydraulic and works with threaded rivets. Rivet material - aluminum, steel, stainless steel. Tool length - 275 mm, weight - 2.2 kg. The delivery set includes accessories for mounting M4-8 rivets.

- AirPro HR-707. It is a hand held blind rivet riveter. Works with steel, stainless steel, aluminum, copper. Its length is 250 mm. It weighs 0.6 kg. It is necessary to work with it with one hand. Because of this feature, it is not suitable for a large amount of work. The delivery also includes a set of attachments for mounting rivets with a diameter of 3.2–4.8 mm.

Manual or electric

All types of riveters are manual and mechanized; in the latter, the source of driving force can be electricity, hydraulics or compressed air.

Hand riveters work very well on site. They are comfortable enough for frequent and short-term use. There are three tool classes for rivets of different thicknesses:

- One-handed for rods up to 1.5 mm.

- Two-handed with lateral handles for rods from 1.5 to 3.5 mm.

- Two-handed with elongated longitudinal handles with a rod thickness of more than 3.5 mm.

Electric and battery riveters should be used on large volumes of work: 150-200 rivets, even for a trained hand, is a very serious load. If in professional activity you often have to use this type of fastener, the electric tool will pay for itself many times over, moreover, the component parts of the mechanism in it live 5-6 times longer than in a manual one.

Description of the tool and its types

The riveter is a type of tool based on the same principle as the gun. It is used to connect structural elements and their parts with a thickness of no more than 1 cm.

When using such a mechanical pistol, the joints of the parts are most often created from the inside. The manual riveter is a lever version of the pistol, in the design of which two main elements can be distinguished:

- Lever system that provides the necessary force when connecting the elements of the products.

- Spring mechanism required to pull the rivet inward.

Manufacturers produce two types of manual rivets - pull-out and threaded.

Exhaust type

This type of tool provides the connection of parts by means of a pulling force, through which the rivet is fixed. When the lever of the gun exerts force, the rivet shank begins to retract into its tubular part, expanding the rivet head. Outside, the rivet head is also flattened, and as a result, a fairly strong connection of the parts is obtained.

Threaded rivets

Riveters of this type work on a similar principle with a few exceptions. Here the ball is drawn into the working part due to the rotation of the thread in the tubular part of the rivet. In other words, the connection of the elements is carried out by fixing the head by twisting the handle.This method of fixing the elements of parts is less common, it is mainly used to connect parts of small thickness.

As a rule, the riveting tool is sold with a set of bits of various diameters.

Depending on the type of drive used, riveters can be classified into several main groups:

- pneumohydraulic;

- rechargeable;

- electrical;

- mechanical (manual);

- pneumatic.

More often than others in the household sphere, devices with a mechanical drive are used. Manufacturers produce them in two versions: the first involves the connection of parts with one hand, and the second - due to the force exerted by two hands.

The principle of joining parts with one hand is also the basis for the work of the manual riveter known as the "accordion".

Manual riveters can be purchased at various prices depending on several factors - drive type, model, connection method and manufacturer. Devices from well-known brands are more expensive than products from unknown manufacturers.

Cordless, pneumohydraulic and electrical tool modifications can also be considered expensive when compared to manual riveting machines. This can be explained by the use of a more complex structure in them. Most often, such devices are used in industrial production.

Popular brands

At the moment, a fairly wide selection of models of both household and professional models of electric riveting equipment is presented in the corresponding market segment. On the one hand, this allows you to choose the most suitable option in each specific case. However, some may have some problems with this variety. The current ratings of the most popular brands and models can come to the rescue. So, now the following well-known brands can be distinguished.

Time-Proof is a manufacturer from the Middle Kingdom, specializing in the production of rivets. The model range of this brand, along with pneumohydraulic and reinforced hand tools, includes, for example, an electric riveting machine TAS-500 with unique performance indicators.

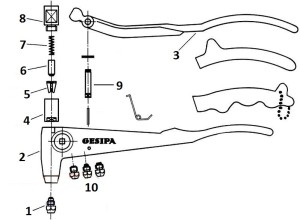

In addition to all those already listed, it is worth paying attention to the riveting equipment of the Gesipa brand. The German company specializes in the development and production of professional equipment for the installation of blind rivets, as well as the hardware products themselves

How does a manual riveter work?

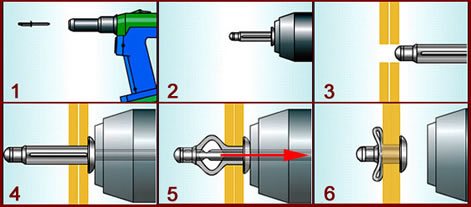

To understand the process, you need to see the rivet at work. The diagram shows its main elements:

A rivet sleeve is placed in the prepared hole. The tool is put on the core and abuts against the rivet collar. The fixed rod is pulled out of the bushing, riveting the top of the bushing.

When the riveting is completed and the core head is firmly seated in the riveted bushing, the rod comes off. Riveted materials are connected only by a bushing.

IMPORTANT! The material describes a mechanical blind riveter. There are hydraulic, pneumatic and electrical attachments.

However, they are not used in everyday life.

The principle of operation of the tool itself and its structure will also be considered in the diagram.

- the head (1) is put on the core of the rivet installed in the hole;

- the body (2) acts as a lower handle and a thrust bed;

- the upper handle (3), resting on the frame with the help of the axis (9), is a power lever;

- when squeezing the handles, the working sleeve (4) compresses the collet jaws (5), tightly fixing the rivet rod;

- continuing to move, the collet mechanism pulls the rod out of the rivet sleeve, forming a riveted ring;

- when the handles are unclenched, the tapered bushing (6), under the action of the spring (7), unclenches the cams, allowing the collet mechanism to take its original lower position;

- cover (8) is a spring stop, can be removed to service the collet mechanism;

- for the convenience of the operator, removable heads (10) are stored in the body for different diameters of rivets.

We looked at how the riveter works. In this case, you need to understand how to choose the right connecting elements.