Photo of mini drills

We also recommend viewing:

- The best woodworking machines for home use

- Review of the best types of drilling machines

- Knitting gun for fittings

- How to choose a soldering iron for polypropylene pipes

- TOP best miter saws

- How to choose a good circular saw

- Review of the best electric planers

- How to choose an electric riveter

- An overview of the most reliable chain saws

- The best handheld wood milling cutters

- Electric type construction stapler

- Best electric spray guns

- The best grinders

- Which cordless screwdriver is better to choose

- Rating of the best blowers

- How to choose a renovator

- How to choose electric metal shears

- Which building hair dryer is better to choose

- Review of the best glue guns

- Rating of the best impact drills

- TOP-best jigsaws of 2018

- Review of the best drills of 2018

- TOP best engravers

- Best cordless screwdrivers

- The best grinders

- How to choose a good electric hawk

- Review of the best models of electric trimmers

- Which construction vacuum cleaner to choose

- DIY power tool repair

- Review of the best soldering irons for home

- Review of the best rock drills in terms of reliability

- The best polishing machines

- Best Reciprocating Saws

- How to choose a good jackhammer

- Best screwdrivers of 2018

- Review of the best wall chasers

- How to choose a good impact wrench

Help the site, share on social networks

Types of hand planers

Planers are also classified according to the type of wood processing: flat or curly.

For flat machining:

- simple single plane. The design has one straight blade and a sole with rounded edges, for high-quality processing without visible marks. This is one of the universal planers used for leveling and finishing the workpiece;

- a miter planer is a small tool with a sole rounded at the ends. From the name it is clear that it is used to process the ends. Also used in the final sanding of wood. Mostly supplied with a chipbreaker. There are models with a straight or oblique knife;

- A jointer is a popular type of woodworking tool. It has an elongated body. Used to align edges and planes. Allows to process products with a large area. High-quality alignment is carried out using a sharp knife. In the process of processing the product, first there are abrupt chips. If a solid tape begins to come out, then the surface of the part is completely leveled;

- semi-jointer. Smaller than a jointer in size. Used for processing small parts;

- sherhebel has a narrow sole and a rounded knife. The iron is installed at an angle of 45 degrees to the body. In the process, it removes a thick layer of wood. It is usually used for primary rough processing, since roughness remains on the surface during the process;

- The double knife plow (or grinder) consists of a double knife with a chip breaker. The blade is at a 50 degree angle to the sole. Used in fine finishes to achieve a smooth finish;

- roughing planers - a tool for processing drywall edges. The sole looks like a grater, made of hardened steel. The body is made of reinforced plastic, steel or silumin;

- The zinubel has a serrated blade that creates a grooved surface in the process. Such processing is the best option for bonding the material, as it gives the best adhesion of the parts. Often used when planing hard wood.

- zenzubel - a plane with a narrow block, on which a blade in the form of a blade is fixed. Iron can be with a straight or oblique end. When processed along and across the fibers, a smooth surface is obtained. With this tool, you can create folds, grooves, rectangular cuts, and also clean out quarters;

- The cantenhobel has an interesting shape of the edge of the blade - in the form of a trapezoid. Some models have two knives. Performs the following functions: processes edges, ends, easily copes with chamfering. You can process wood, plastic, drywall;

- the tongue and groove consists of several plates, bolted together. A blade is attached to one block, the other is a guide. Using a tongue and groove, you can easily create a good longitudinal groove of different depths. The design has a stop that can be adjusted depending on the required distance from the edge of the groove to the edge;

- Federgubel - a special plow with a special blade, with a slot in the middle. With the help of it, a longitudinal protrusion is made along the edge of the workpiece;

- kalevka has several soles and a replaceable blade with a figured end. Used for decorative processing of photo frames, cornices and other wooden products;

- The falzebel has a wide stepped body. It copes well with grooving, stripping a quarter. Since the body is wide, you can create identical grooves without marking. For vertical processing of a quarter, a side cutter is placed;

- staple. With the help of it, rounded edges are made. The blade and body are concave and rounded;

- humpback - a plane with a semicircular sole, it can be concave or convex. A sharp knife is attached to the center of the body. The sole can be metal or wood. On some models it is possible to change the degree of bending of the case. Due to this, the part can be made both concave and curved;

- the fillet resembles a humpback in appearance; it also has a convex sole. With the help of it, semicircular notches and recesses are made. Available in different widths. It depends on what kind of notch you get;

- small planes are used in small works: inlays, restoration, for removing small chamfers, when correcting minor errors. Usually, professional carpenters work with this tool, since beginners often make mistakes or simply cannot cope with the equipment.

milling cutter

Choice of electric planers

The main list of operations performed by an electrical appliance includes: surface pretreatment (planing), machining to size, fitting, edge processing. In addition, the availability of additional devices also expands the list of functions of the electric plane.

In the process of choosing the model you need, we pay close attention to the following points:

- sole. Just as with the mechanical planer, a flat sole will provide you with a smooth planed wood. This is the backbone of the basics. When choosing a model, give preference to soles with grooves, they are more comfortable to work with. The stability of the tool directly depends on the thickness and length of this element;

- handles. The electric planer is not the easiest and most maneuverable tool, therefore, it is easier to move it across the board area using two handles. If you apply great effort with pressure on the front, then the chips will be noticeably thicker;

- knives. Removable knives of modern models of power tools are double-sided. For different manufacturers, materials can be hardened steel, tungsten and carbide. Depending on the material, the knives should be carefully aligned with each other.

- protective devices. All existing models from different manufacturers are equally carefully provided with protective devices. Remember that this is a traumatic tool. In the electric version of the tool, contact of fingers with knives is excluded;

- additional equipment.You can purchase the necessary parts for the base model. For example, knives for roughing wood.

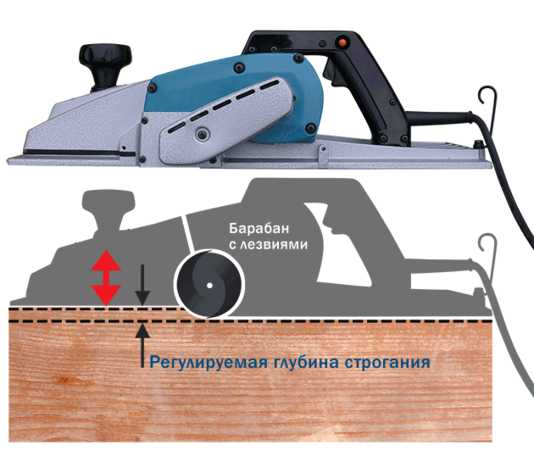

Principle of operation

The forefoot of the sole slides over the rough surface and can be adjusted in height to determine the depth of cut and the size of the chips. The rear part, therefore, already moves along the planed board. Adjusting the cutting depth is easy. Do not forget, when working on this tool, move it smoothly at the same speed, an indicator of correct operation will be the identical shavings that you will remove from the wooden part.

Hand planer selection options

The device of a hand tool is simple, but problems arise when buying.

Let's figure out how to choose a plane yourself:

The first step is to decide on the material with which you will work. For our category of tools, this is either classic wood, or drywall and similar materials.

There are two types of devices for working with gypsum boards:

- rough - for adjusting the edges of the sheets;

- edging - for the formation of chamfers.

At home, with small amounts of work, instead of both types, you can get by with a hand cutter, but for production it is better to purchase a specialized model.

To choose a tool for wood, it is worth finding out what kind of planers there are for working on this material.

When leveling a surface, in most cases, 3 types of tools are used:

- sherhebel - large mechanical for primary processing, removes thick shavings;

- after the initial planing, the surface is processed with a single plane with one blade;

- the final processing is carried out with a double plane, except for the main knife, which has a chip breaker.

These three types of tools do not replace each other, but complement each other. It's a good idea to have everything in a home workshop.

For precise processing of large surfaces, a variety called a jointer is used. It is necessarily equipped with a chipbreaker, and its length is 2-3 times the size of a conventional model.

Our review also mentions the model of a cross-cut planer - it is designed for planing the ends of workpieces.

There are also a large number of models for curly cutting (humpback, zenzubel, groove, etc.), but today they are practically superseded by a power tool.

With regard to the quality of workmanship, when buying any model, you should pay attention to the sole. It should be flat and smooth.

Also appreciate the quality and sharpening of the knife, but it is not difficult to re-sharpen or replace it altogether.

It is rational to make a choice by manufacturer. Our review includes models of brands: ZUBR, matrix, Sparta, STANLEY, STAYER, MTX.

The cost of a tool in most cases directly determines its consumer properties. Quality materials are expensive. Also included in the final price is the depreciation of the good equipment on which the plane was produced and the remuneration of the skilled worker.

Types and purpose of engravers

In appearance, the tool resembles a straight grinder, the main elements of which are: motor, gearbox, shaft, housing. Principle of operation: by pressing the start key, the electric motor is started, rotational movements are transmitted through the gearbox to the spindle, which sets the working equipment in motion.

Engravers are:

- electric - they operate from a stationary network;

- rechargeable - lithium-ion batteries are used as a power source;

- with a flexible shaft - a hose of different lengths with a steel cable inside, which is mounted between the equipment and the spindle. It functions as an extension cord, making your work more comfortable. The tool can be held with one hand, like a regular pencil, and can be applied to the surface with patterns, inscriptions, and decorative processing;

- laser - desktop, floor electric machines, which are solid-state (allow you to process metal) and gas (used to work with any materials, including natural leather, glass).

Correct use of the engraver

- allocation of free space on the countertop;

- installation of a powerful lamp to illuminate small parts;

- covering the surface with a cloth or thick paper, because during the cutting process, chips and dust are formed;

- preparation of wood tape, felt-tip pen, pencil for transferring the drawing. Sticky paper tape will allow you to attach the sketch to the surface, after removing it there are no streaks.

Important! Before applying the pattern, the metal, plastic, glass surface must be treated with alcohol or solvent. The pattern is applied to the wood with a pencil.

- preparation of working equipment - the instructions for the model describe the purpose of each of them and the possibility of processing a particular material;

- the installation of the suspension allows you to minimize vibration and cutting error. It must not interfere with the flexible shaft;

- it is recommended for novice craftsmen to choose the minimum number of revolutions - they will be able to get a neat and clear pattern, lines of the same depth;

- the drawing is first traced along the contour, after which small elements are drawn;

- at the final stage, the pattern is polished with a soft felt nozzle, which allows you to remove all irregularities from the surface.

- before connecting to the network, the network cable is checked for integrity;

- use special glasses to protect eyes from dust and sparks;

- when the nozzle is jammed, pull it out before disconnecting the device from the electrical network or disconnecting the battery;

- if the plastic case is very hot, the device should be allowed to rest for a while. Due to the lack of an air cooling system, this must be done frequently. This will prevent overheating of the motor and the failure of the engraver. The optimal working and cooling time is indicated in the instructions;

- when purchasing consumables, you should make sure that they are suitable for the characteristics of the model.

Daily care

Thoroughly clean the air vents on the chassis as they allow air to cool the engine. When cutting, grinding PVC, glass or wood, the holes become littered with debris and dust, which negatively affects the productivity of the engraver and leads to its premature failure. Cleaning should be done with a dry soft cloth. By following these simple rules, you will be able to use the tool for a long time and get a high-quality work result.

More about the electric plane

Definition

An electric planer is a woodworking tool powered by electrical energy. Unlike a traditional planer, which has a blade in its lower part, which removes a layer of wood, if you press on the workpiece with a tool and slide it in a direction away from you, an electric plane cuts material due to a drum with blades rotating in a certain direction.

Varieties

Electric planers are of several types.

Depending on the ability to move, they are of two types:

When working with them, this type of tools is held in the hands and their movement is also guided by the hands.

They represent a metal table with an electric motor and one or more drums with blades attached to it. In addition to them on such a table, as a rule, there are adjustable guides for more precise movement of the workpiece. The plane itself does not move during operation - they move the workpiece being processed.

1-Manual planer 2-Stationary planer

Depending on the type of power supply, electric planers are divided into:

They operate on a 220 V household power supply.

They are powered by replaceable batteries.

1-Network planer 2-Battery planer

Expert opinion

Vasily Kuznetsov

In the case of an electric plane, it is better to choose a network one. The fact is that this tool requires a fairly large consumption of electricity, which leads to a rapid drain on the battery charge. Of course, a cordless tool is in some way autonomous and can be taken anywhere, but its operation time from one battery will be only one to two hours, which is very short.

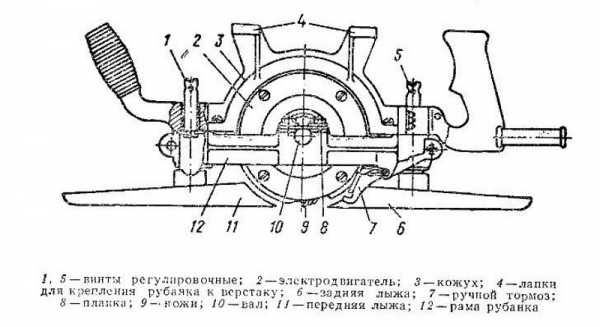

Constructive device

The electric hand planer consists of the following parts:

- The body is a casing (most often plastic) designed to protect the tool parts from mechanical damage.

- The handle is an element for holding the tool in the hands during work (as a rule, there are two handles on electric planers - for the right and left hands).

- Control Button - Turns on the power supply to the engine.

- Rotational speed regulator - is a variable resistor that allows you to select the desired rotation speed of the drum with blades.

- Electric motor - located inside the housing and drives the drum with blades.

- Belt drive - a belt made of polymer material that transfers rotational energy from the electric motor to the drum.

- A drum is a cylindrical metal part with blades attached to it, which performs the function of processing wood.

- Lower platform. It is a flat metal plate with a cutout for the drum and acts as a guide that allows you to smoothly work the wood, and also balances the center of gravity of the tool, moving it to the lower part of the planer.

- Channel for removal of shavings. A special channel is usually placed next to the drums for the removal of chips. When working with an electric plane, there are quite a lot of them, so if they are not removed, they can clog the drum or the inside of the tool body.

The design of a stationary electric planer is somewhat different.

It consists of:

- Metal table.

- Electric motor.

- Belt drive.

- One or more drums with blades.

- Guide, ensuring the movement of the workpiece in the desired direction.

How to choose?

Wood craftsmen often wonder which planer is best for use at home and at work.

When buying a tool, you should pay attention to the following features

- Sole. It should be characterized by evenness, absence of damage, chips, drops.

- The blade in the planer must be properly fixed, and there must be no backlash. The best material for making an element is hardened steel. The edges must not be damaged during sharpening.

- Lever. It must be selected in accordance with your palm. It should be comfortable for the master to work with the plane. It is not worth buying a high quality tool that is inconvenient to use.

- Manufacturer. According to experts, planers are considered the best, which were made in Soviet times, since they are characterized by high quality workmanship and good characteristics of the knife. Such modern brands of planers as Stanley, Sigma, Zubr, Irwin, Sparta, Bailey, Handyman have proven themselves well. According to consumer reviews, Indian tool manufacturer Groz should not be preferred as it can be inconvenient and of poor quality.

- Body material. The choice of metal or wood is up to the master himself. Often consumers choose wooden planers, but they are not so easy to find.

A hand planer is a fairly popular tool today, so many manufacturers produce it. This device can have a different purpose, quality, and functionality. Before buying a planer, you should decide on the purpose of the purchase, as well as the functions that the tool will have to perform.

An overview of the Enkor RE-780/82 electric plane is presented in the following video.

Figured planing

Planers classified in this category are designed for processing grooves, projections, edges.

Zenzubeli

With their help, quarters are selected and cleaned, rectangular cuts, grooves, folds are formed, perpendicular elements of the workpieces are rounded. The chisel cutter is made in the form of a blade with a straight or oblique cutting edge, it depends on how the knife is fixed in relation to the sole. The oblique blade has two cutting edges, both sharpening is applied to them. Tooth teeth are used where a dovetail groove needs to be formed. Even processing across the grain gives a perfectly smooth surface.

It is better to start choosing a quarter with a falzgebel, and use a zenzubel for finishing work.

Cantenhobeli

This is an edge picker used for chamfering, processing ends, edges, bringing to specified dimensions.

The main difference between the cantenhobel and other planers is the trapezoidal shape of the blade.

Some models can be equipped with two cutting elements. Depending on the position of the knife, you can cut along the edge at an angle. In this case, a fold is formed for the future joining of two parts, gaps are excluded.

Tongue and groove

With their help, a longitudinal groove is selected. The groove consists of two blocks connected by screws. One of them serves as a guide, the second serves as a mount for the blade. With an adjustable stop, the edge of the groove can be set at the desired distance from the edge. Due to the stop protrusion, the penetration occurs to the required parameters, while the blade does not bend.

Federgubeli

The figured end planer is designed to form a longitudinal protrusion along the edge of the workpiece. This is provided by a blade with a central opening. After passing along the edge, a ridge remains. It fits into the groove. As a result, two parts are connected.

Kalevki

Equipped with a replaceable blade with a shaped cutting edge. They have a multi-stage sole. The tool is most often used for the manufacture of decorative parts: cornices, baguettes, and other wooden elements.

Falzgebeli

Needed to select a groove along the edge of the workpiece without preliminary marking. Includes multi-step outsole. The wide last helps to form grooves of the same size. If it is necessary to process the vertical wall of the quarter, an additional side cutter is installed on the rebate.

Staples

Designed for rounding the edges of parts. These planers have a blade, the edge of which is provided with a semicircular recess. There is a concave sole. When processing the edge of rectangular ends of parts, the knife removes the chips in such a way that the edge takes on a rounded shape.

Durable mini planer MTX 879055 for drywall

The mini-plane for processing drywall sheet edges is designed and manufactured in Germany. The body is made of reinforced nylon, which allows achieving a combination of mechanical strength with a low weight - 277 g.

The two trapezoidal cutting blades are made of 45 carbon tool steel - strong but not prone to brittleness. One blade is set to cut at 45 degrees, the other at 22.5. Their depth can be adjusted separately.

Settings are available for drywall thickness of 9.5 mm, 12.5 mm and for thicker sheets of 15+ mm. The lateral position of the web is also adjusted. The handle is made in the form of a bead on the body.

Recommended for forming edges and chamfers on drywall, wood and laminated plastics. Suitable for both an experienced and a novice craftsman in production.

The owners note the traditional German quality of the instrument and the thoughtfulness of the design. Many people think that a length of 25 cm is optimal. A shorter model will take a long time to work, and an elongated one is not always convenient.

The best professional electric planers

Professional means more powerful. But not only in terms of performance and capabilities, but also in terms of electricity consumption.Therefore, more often professional models of electric planers are bought by representatives of small and medium-sized businesses. An expensive tool must be the breadwinner. The best electric planers have superior functionality and excellent quality. Among them are the following models.

Makita KP312S

The considerable size and impressive weight of the Makita KP312S do not prevent it from being highly productive and easy to use. A powerful 2200W motor spins the drum at a speed of 12 thousand revolutions per minute. A sharp swivel knife removes 15 centimeters of the product's width in one pass. At the same time, it can be immersed by 3.5 mm. If the target width is 312 mm, then the slice thickness will be 1.5 mm. The planing depth can be adjusted directly during the process.

The clever electronic filling of the planer will qualitatively balance all operations. It is especially valuable that the tireless assistant is able to work non-stop and deliver significant quantities of processed material. Electronic motor braking stops the knife instantly. This not only improves safety, but also saves working time.

Dignity

- Easy replacement of cutting parts;

- Effective dust extraction system;

- Guide roller;

- Ergonomic handles;

- Uniquely durable body;

- Cable length 10 meters.

disadvantages

Weight 19 kg.

The double insulation is made in compliance with European standards. The Makita KP312S electric planer can even be connected to ungrounded power outlets.

Mafell MHU82 T-MAX set

Mafell specializes in the production of small series of electrical joinery equipment. Every product, including the Mafell MHU82 T-MAX set, is state of the art. At first glance, the model does not differ in special power, only 800W. Standard planing width 82 mm, depth 3 mm, 12000 drum revolutions.

But it has its own flavor. Thus, the Mafell MHU82 T-MAX set has a universal motor and a built-in swarf removal pipe. This makes the planer especially useful for folding doors, decorating parts and cutting out quarters. After processing wood and materials, the surface is smooth, like a mirror. There is a possibility of stationary fastening.

Dignity

- Quarter sampling depth 22 mm;

- Outsole material cast aluminum;

- Pendulum protective casing;

- Breaker lock button;

- Convenient vacuum cleaner adapter;

- Weight 3.4 kg.

disadvantages

- RPM is not regulated;

- No soft start and no overload protection.

Minor shortcomings of the model are compensated for by half the price in comparison with analogues.

Festool PL 205 E

If serious carpentry or joinery work is ahead, the Festool PL 205 E professional electric planer will do just like no other. 2000 watts of power help to cope with wood of any hardness, with non-standard materials. With such a plane, you can take on any object.

In addition to processing large surfaces, the model specializes in smoothing cut edges on beams. Thanks to the wedge-shaped groove in the sole, it makes bevels of the upper parts of the rafters. The operation is specific, since it usually takes place in an open area. Your work will be successful with the Festool PL 205 E electric plane.

Dignity

- Planing width 205 mm;

- Two double sided trimetallic planing cutters;

- Idling speed 13500;

- Smooth start;

- Overload protection;

- Maintaining speed under load.

disadvantages

High price.

Guaranteed German quality costs a lot. But such tools serve for a long time and reliably.