Types of hillers

All such devices are divided into 3 main groups. It makes no sense to consider (and design) propeller-type models. Firstly, not everyone can make them with their own hands. Secondly (and this is the most important thing), such hillers are suitable for working together only with expensive walk-behind tractors with 2 forward gears. For the processing of garden plots or adjoining territories, such units are extremely rarely purchased.

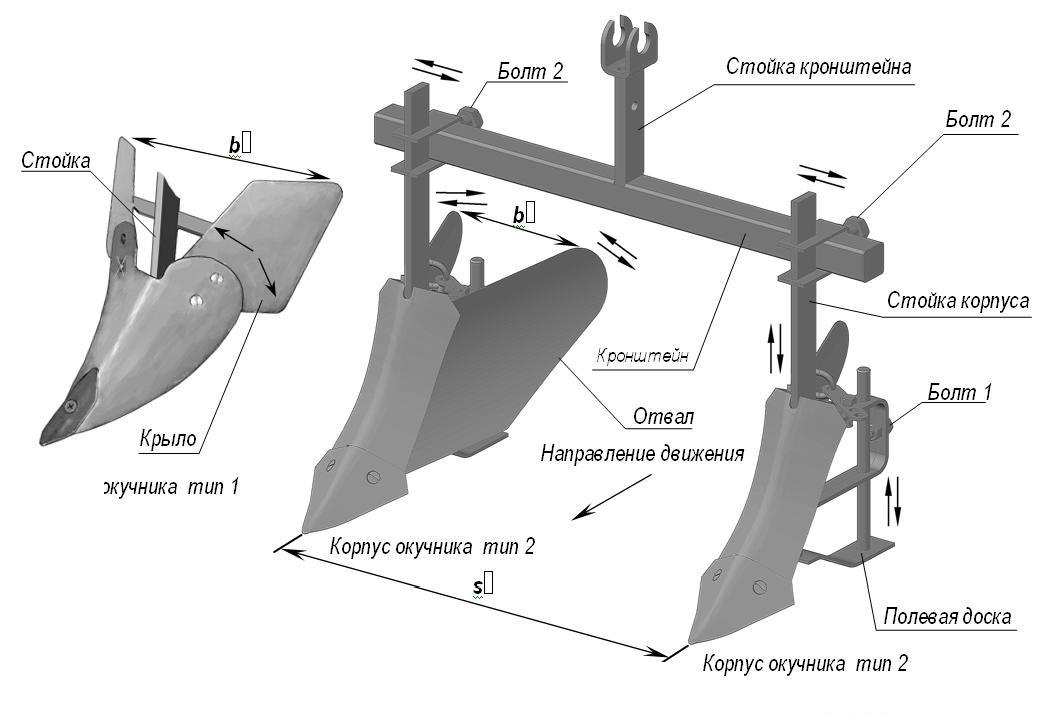

Hiller lister

The simplest option is an unregulated model. The figure shows its shape and recommended metal thickness.

Despite the fact that this hiller will not be able to make a "clean" drive between the rows at a time (the earth will partially crumble into the furrow), it is these devices that are in greatest demand among private traders.

Manufacturing features

As already noted, it is necessary to select sheet metal with a thickness of within 2.5 mm. Less - there is a risk of deformation during operation. If you take a thicker iron, then the hiller will turn out to be quite heavy. And it is difficult to work with it, and the walk-behind tractor (depending on the power) may not "pull".

The marking of a metal sample is made for the manufacture of structural elements of the hiller. When assembling it with your own hands, the following parameters are recommended for the "halves":

The resulting parts are fastened by welding, and the seam is processed.

Making a rack is also not difficult. To fix such a hiller, a pipe length of 12 is enough.

The model is adjustable and universal. By spreading (shifting) the wings, you can use such a hiller to process areas with different parameters of the row spacing. The complexity of operation is that such devices are attached only to walk-behind tractors, the power of which is not less than 4 "horses". You won't be able to work with "weaker" models.

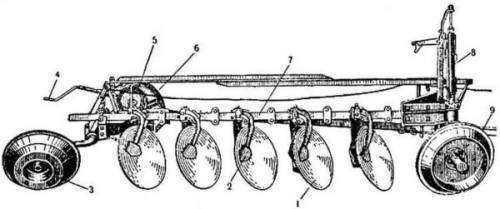

Disk hiller

This option is considered more successful. It is generally accepted that the hiller is needed only for processing plots with planted potatoes. This is not entirely true. The disc mechanism is great for hilling a number of other plantings, therefore, when used in a small area where various crops are planted, it is advisable to make just such a hiller with your own hands.

- It is much easier to work with such devices, and the load on the walk-behind tractor is significantly reduced. Disc models can be used with smaller units, which are most common in the private sector. The ability to adjust the distance between the working elements allows you to process areas with any plantings.

Manufacturing features

For discs, you can use iron within 2 mm. The main condition is their absolute symmetry. So that they do not fall into the ground during the operation of the hiller, it is necessary to process the edges. With your own hands, this is done quite simply. Either a wire is welded around the circumference of the discs, or the edges are slightly bent. Alternatively, use plowshares from a used seeder or something similar. Someone even uses lids from large-sized pots (these are found at public catering facilities).

When installing all moving parts of the hiller, it is more advisable to use bearings rather than bushings. With such a mechanism, the processing of any soil will go much easier.

The design shown in the figure allows you to easily adjust the distance between the discs. You can change their position by reinstalling the latches (B).

The diagrams are quite detailed, so any additional explanations are hardly required.

The final "fine-tuning" of the hiller is carried out after its practical use. Only then it will become clear, for example, at what angle the discs should be set, as well as a number of other nuances.

The reader himself can change something in the presented drawings, modify individual elements. But the author assembled these structures with his own hands, tested it himself, and they showed quite good performance. For a small plot of land, such hillers are quite enough.

DIY manual plow. Housings

According to the number of bodies, plows are single-body, double-body and multi-body. The body consists of several parts:

- rack;

- working surface - share and blade;

- field board.

Body with share and blade

The share and the blade are the working surface - this part is responsible for the quality and type of plowing. The soil layer is trimmed with a share, along which it rises to the dump. Here the soil crumbles and turns over. The degree of seam rotation depends on the shape of the dump. A field board is attached to the bottom of the case. Its task is to prevent the plow from moving towards the already plowed area.

If you are going to make a plow with your own hands, you need to choose a design taking into account the type of soil you are going to work with. Plow bodies are:

- Dump. For plowing with full or partial rotation of the seam. Such plows promote soil formation (grown plants are cut off, laid on the bottom of the furrow, where they rot), enrich the soil with oxygen (due to loosening).

- cultural - it is used for long-cultivated land, it crumbles the soil well, wraps it up to a medium degree;

- semi-screw moldboard bodies are used for cultivating virgin lands, plowing heavily turfed soil, it wraps the soil well, moderately crumbles it (models with an elongated feather wrap the layer completely);

- screw - good for cultivating virgin lands - the layer is completely wrapped;

Types of plow bodies

Moldless. Used in arid climates to retain moisture and in regions with a risk of wind erosion.

Cutout. Suitable for soils with a small plow horizon. The lower part only loosens, not rising outward, the upper part is removed and thrown into the previous furrow, in which the podzolic layer loosened during the previous pass lies.

With a soil deepener. They are used mainly on marginal lands. The subsoiler loosens the podzolic layer, which contributes to an increase in the thickness of the fertile layer.

With a retractable chisel. They are used on clays, loams, soil with a lot of stones. The chisel, fixed on the tine in front of the share, prevents damage to the cutting edge. As the grind progresses, the chisel is pushed forward - for this there are special holes on it.

Disc tractor plow

Disk. With its help, waterlogged soils are cultivated, it is also good with a large number of roots.

Methods for planting potatoes with a walk-behind tractor

When the site is prepared, you can proceed directly to planting potatoes. With the help of a walk-behind tractor, you can plant a crop in different ways:

- Semi-automated method. A hiller is installed on the walk-behind tractor, which allows you to form and then sprinkle the furrow with a layer of soil. The seed potatoes are stacked by hand.

- Automated method. All processes are carried out by a walk-behind tractor using a special mounted potato planter.

- Planting potatoes with a walk-behind tractor under the plow.

The choice of the method depends on the equipment supplied with the walk-behind tractor and the area of the treated area. To understand the difference, let's take a closer look at the features of each of these methods.

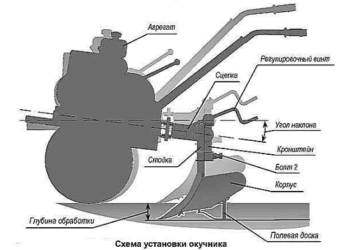

Planting potatoes with a walk-behind tractor with a hiller

If potatoes are planted in a small area, then a hiller is most often used, which is attached to a walk-behind tractor.The purpose of this device is to raise the ground by creating a furrow and forming ridges on either side of the walkway.

With the help of a walk-behind tractor, furrows are formed for planting potatoes

There are several types of hillers:

- regular, with a fixed width of capture (lister);

- normal, with an adjustable width of capture;

- disk.

The first two are very similar in appearance and resemble a knife of two curved wings joined together at the front and spread apart at the back. The difference lies in their functional features.

Fixed width hiller

This hiller is rather primitive and does not allow adjusting the row spacing. It is not very suitable for planting potatoes, since the working grip of such a device is only 20-30 cm. It is more appropriate to use it for planting vegetables that do not require a significant distance between the rows.

The non-adjustable hiller is more suitable for marking beds with narrow row spacings

Riser with adjustable working width

The second version of the hiller is the most popular among gardeners. The design of this attachment allows you to adjust the working width of the soil. Therefore, it is possible to set the desired row spacing. However, an adjustable hiller also has a number of disadvantages:

- To use it, you need a more powerful and heavier walk-behind tractor (with a capacity of at least 4 liters. From. And weighing more than 30 kg).

- The performance of this equipment is slightly lower, since when working with it, part of the soil from the ridges can crumble back into the furrow.

- With an increase in the distance between the dumps, the load on the walk-behind tractor increases and the fuel consumption increases.

Adjustment of the furrow width of the hiller allows you to change the row spacing

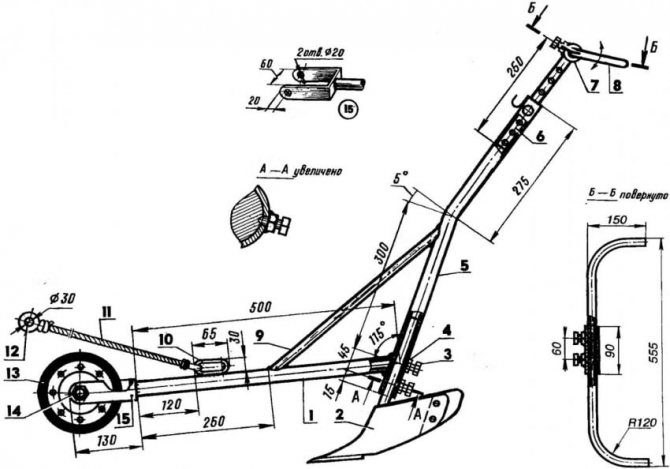

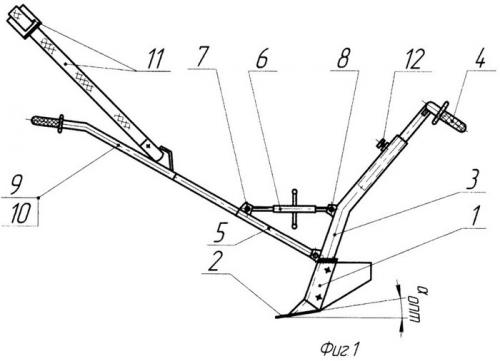

Do-it-yourself manual plow for planting potatoes. Planting plow

A hand plow will help to plant potatoes without a shovel. To make it with your own hands, you will have to make some effort. But they are worth spending, since the device turns out to be universal - the plow is used not only for planting potato beds, but also for the subsequent hilling of bushes and loosening the row spacing.

Since hollow pipes and sheet metal are used in the manufacture of the structure, you will need welding equipment, a gas burner or blowtorch, and a grinder.

To create a universal method of planting potatoes, follow the following algorithm:

- a meter-long pipe with a diameter of 2.5 cm is filled with sand and closed with plugs;

- bent at an angle of 10-15 degrees at a distance of 30 cm from the edge, using a blowtorch; get a rack, in the drawing indicated by the number 3;

- removing the plugs, pour out the sand (it is only needed for a neat bend of the pipe);

- a double-mold working element with a cutting knife is formed from pieces of metal and fixed from the bottom of the rack with bolts, for which holes are pre-drilled in the pipe;

- the control handle 4 is inserted into the pipe from above and fixed with the bolt 12; there should be several holes on the handle to make a telescopic retractable system;

- the front link 5 is shaped as indicated in the drawing and welded to the strut; positions 9, 10 indicate the presence of a horny handle;

- With brackets 7 and 8, a lanyard 6 is attached to the rod and the riser, which allows you to adjust the level of attack of the knife.

Manual plow with pull

For convenient plow control, a strong neck-axillary tape can be attached at the base of the traction arms (position 11). It will allow the leading worker to evenly distribute his efforts when driving with the plow over the area.

How to make a tiller with your own hands

How to make a do-it-yourself potato hiller? To do this, we need the following tools:

- hollow plumbing pipes: length - 10 cm, with a diameter of 1 inch;

- another similar pipe, but with a diameter of 3/4 inch;

- sheet steel 1-2 mm .;

- lanyard or steel plate;

- pipe bender or gas burner;

- welding tool;

- grinders.

This is an approximate list of tools, depending on what type of tiller you want to make, it can vary.

It will be possible to adjust the device in several ways:

- Height. Due to the telescopic mechanism in the center. A smaller pipe will be mounted in the pipe of the central pillar, which will act as a rear thrust. This design is very comfortable to use, because it can adapt to any person's height.

- Change the angle of attack by tilting the center post to the ground. We get this opportunity if we change the angle between the front link and the vertical strut. If your design does not have a lanyard, then you can change the angle by changing the position of the plate.

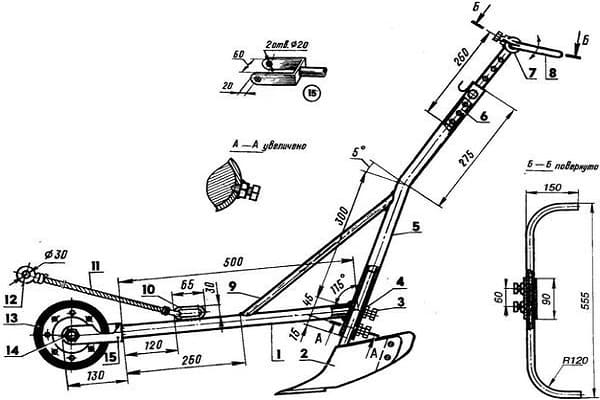

We begin to make a hand-made homemade potato hiller with vertical racks

We take the pipe 10 cm and measure from the end about 4 cm.At this distance we should make a slight bend. Approximately 15 degrees. The most comfortable and easiest way to do this is with a pipe bender - a tool specially designed for this. Of course, not everyone has such a device, so we will tell you about a more affordable way to complete this stage.

We fill the pipe tightly with sand or earth - which is freely available. We insert the plugs so that the whole mixture does not spill out. Using a blowtorch or any other heating element, we make the bend we need. Due to the fact that there is a mixture of sand or earth inside the pipe, it will not bend and retain its ideal parameters.

Moving on to the manufacture of traction

A rear link is built into the homemade manual potato ridger. It has the shape of the letter "Pe". In our design, it will be of the following dimensions: 5 cm wide and 2 cm long. Note that if you change this value for one mechanism, you must do the same for the others. In the center of the fork we attach a pipe 3 cm long, vertically. Then we will insert it into the vertical rod.

In the center of the fork we attach a pipe 3 cm long, vertically. Then we will insert it into the vertical rod.

We now need to bend the 3/4 diameter pipe. This can be done in the way already discussed above. If you have other options, you can use them. In this case, the main thing is one result.

Let's take care of the ability to change the height. We make a hole at the top and in the vertical part of the mechanism. And now, by changing the bolt, we can adjust the height. So, a person of any height will be comfortable working with the tool.

We made the rear pull, now we need to move on to making the front. It is made in the form of a fork, like the rear link, it differs only in size. The handles should be of such length that the person can comfortably stand between the handles.

For ease of use, we will add an elastic strap that can be worn on the shoulders and chest. This design will reduce stress on the hands and retain the strength of the operator.

Dimensions: handles - 6 cm, vertical part - 7 cm. On the vertical part of the fork, at its end, you need to make a hole, with which it can be fixed to the rack.

Let's move on to adjusting the angle of attack. The best option is a lanyard.

We count 3 cm from the bottom of the vertical post and mount a corner 25x25 cm in this place.We count from the position of the fork 0.3 cm and then do the same. And we repeat the procedure to the upright over our first corner.

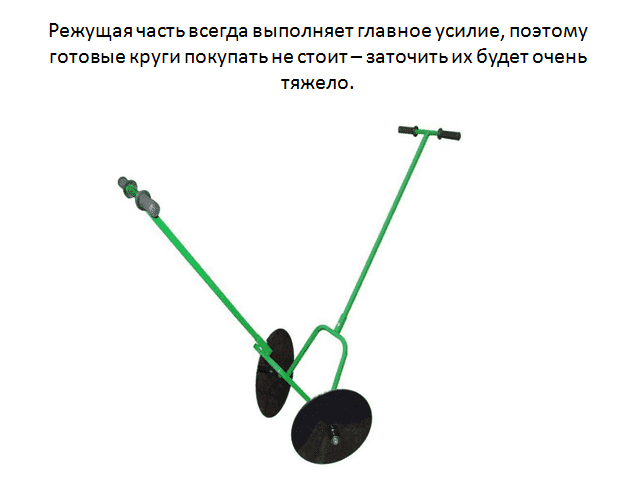

The last step is a pruning knife

It is this mechanism that takes all the load and reduces the resistance in the soil during operation.

Choose carbon steel for your knife. You need to cut the arrows and sharpen them at a 45 degree angle. Such parameters allow our mechanism to remain sharp and fully cope with its tasks.

Now you need to start welding the knife to the bottom end of the vertical rack. Our handmade DIY potato ridger is now ready!

Manual hiller for potatoes.Homemade manual bicycle hiller

It is very difficult to huddle potatoes and beds with your own hands, however, a homemade hiller greatly simplifies the life of a farmer. The scheme for creating an aggregate is very simple.

Operating principle

The key part of the manual hiller is the cultivator or plow. It is he who will do what is done manually with a hoe or a hoe - to plow the soil. This plow, with the help of its sharp end ("nose"), slightly digs into the soil and distributes it to the sides of itself, covering the potato rows with earth.

If a self-made model from a bicycle acts as a hiller, then the cultivator will be fixed on its frame. By slightly changing the structure of the unit, grabbing the steering wheel, you can control the device, directing it in the right direction. The very same movement of the hiller is carried out at the expense of a single wheel in the front of the frame.

More concisely, you can summarize the essence of the work of a manual hiller with the following algorithm:

- the cultivator crashes into the ground;

- the controller with the help of the steering wheel directs the hiller in the right direction and moves it forward;

- the movement is carried out at the expense of the existing wheel.

What is needed to create a hiller?

First of all, you need certain equipment and materials:

- unnecessary bike frame (always with a handlebar and one wheel 26-28 inches);

- fixtures for welding;

- wrenches for nuts and bolts (if the cultivator will be screwed to the mount).

At the same time, you need a little patience and the ability to work with the welding machine.

Preliminary actions

To begin with, a bicycle frame is prepared: a handlebar, a saddle, pedals, the rear wheel is removed. The second wheel is disassembled and cleaned - only a metal rim is needed.

The metal rim fits better into the soil, which gives the hiller much more stability and maneuverability than with rubber. It will become much easier to operate such a unit.

The process of creating a hiller

The manufacturing process can be divided into 5 stages:

- The rear wheel mount is trimmed so that there is only a "triangle" from the bike frame in the end.

- The cultivator will be placed instead of the wheel, it must be fixed there.

- Screw on or weld on the cultivator. This should be done with high quality, because this part of the hiller will be the greatest load.

If the cultivator is screwed on, then tighten the nuts as tight as possible, otherwise the manual hiller will not last even a couple of days. This is where both wrenches come to the rescue: for bolts and nuts. Wielding them at the same time, it will be possible to firmly and permanently fix the parts.

- Further, the cultivator extension is regulated (how far / close it is). This is done for the sake of convenience during the hilling process, so as not to stumble over the blades of the cultivator.

- The handlebars removed in advance are twisted tightly in place of the saddle.

Creation of a cultivator section

Building a basic cultivator is pretty straightforward. In fact, this is the same plow. Two plates are attached near the base, which form an angle directed forward (towards the wheel). During the movement of the hiller, the plates will divide the soil into 2 parts and spud the potato rows with the raised soil.

However, you should adhere to the following requirements for this part:

- the total width of the blades should be 2/3 of the row spacing of potato bushes;

- the cultivator should go 10-15 cm under the ground;

- the angle of the blades should be close to 90 degrees - this way they will perfectly pick up the soil.

After carrying out the full range of work, you should get a full-fledged manual hiller, ideally doing its job in the course of growing potatoes.

To get acquainted with the device in more detail and understand how to properly make such a homemade hiller, you can see the following

Useful Tips

If you manage the hiller together, the hilling process will be greatly simplified and the efficiency of the work done will significantly increase.To work with a manual tiller in pairs, you need to attach a regular belt to the front of the unit.

Any weight can be attached to the back. This improves the penetration into the ground, which, again, increases the efficiency of the work. But at the same time, it will be more difficult for such a unit to move forward due to the increase in mass.

From a bicycle wheel and a fork

If there is a front bicycle fork and a wheel for it, then you can create a hiller using the following technology:

- 2 pipes must be welded at an obtuse angle;

- a handlebar from a bicycle is attached to a long pipe (it would be wiser to weld it so that it does not fall off during operation);

- a cultivator is attached / welded to the junction of both pipes, below.

The final result of the work will be similar to this:

It is much easier to create such a hiller than the one mentioned earlier. However, different types of aggregates should be used for different purposes.

DIY manual hiller for potatoes

Some vegetable growers do not want to spend money to purchase such a device and therefore try to make a manual hiller on their own.

Before starting work, you need to prepare all the materials and necessary tools. To create a structure, you will need the following:

- sheet traction with a thickness of 2-3 mm, with the help of which the dumps will be made;

- one hollow tube at least one meter long for the manufacture of rear and front thrust;

- meter water pipe, which will be needed when creating a vertical rack;

- steel plate or lanyard for connecting the upright to the front link;

- gas burner for heating metal products in the places of their bends;

- grinder for working with joints;

- welding machine.

Also, in order to create a hiller on your own, you need a drawing where the correct location of all components will be depicted. Of course, you can make a product without the help of a drawing. However, it is more likely that such a hiller will be of poor quality and will quickly break down.

Making a vertical stand

It is necessary to make a potato hiller from a vertical stand, which is considered the basis of the entire structure. For this, a pipe is prepared with a length of about a meter.

To create a high-quality rack, the pipe will have to be bent 10–20 degrees forward at a distance of 300–400 mm from the beginning of the structure. A special device is used to bend metal pipes - a pipe bender. However, not everyone has the opportunity to use it and have to do everything with their own hands. To bend a metal pipe yourself, you will have to:

pour river sand into the pipe cavity;

install plugs on the edges of the structure that will hold the sand;

the place where the pipe should bend should be heated with a soldering machine;

carefully bend the pipe at the heating point.

Some people try to repeat the above steps, but without using sand. However, without sand between the walls of the vertical pipe, its shape deforms due to heating and therefore it will not be able to maintain its original cross-section.

We make front and rear rods

For the rear and front linkages, you will need a ¾ ”pipe. It will have to be bent in the same way as the pipe when creating a vertical post. When the product is bent, several holes are made in it at the top and bottom, where the plug will be installed. The holes created will be needed in the future to change the height of the rack.

When making the front fork, you need to take into account the height of a person who will work with a hand-made disc tiller for potatoes made by yourself. Therefore, the front link is designed so that its forks are at least 60 cm long. To connect the fork to the upright, holes are drilled for large screws.

Double-mold plow

Making a manual plow for hilling potatoes is quite simple. For this, two metal plates with a thickness of at least 3-4 mm are prepared.They should have small semicircular curves to make it easier to loosen the ground. A self-made plow is attached to a vertical rack. For a more reliable fastening of the structure, a welding machine is used.

Undercut knife

At the very end, a pruning knife is created for the manual potato disc hiller. This part of the structure is made of carbon steel, from which a knife of the required length and diameter is cut. Having cut the product, it will have to be sharpened exactly at an angle of 40-45 degrees to create a sharp blade. When the knife is ready, it is welded to the upper half of the vertical rack and the welding seams are grinded with a grinder.

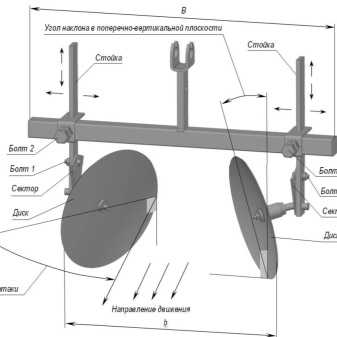

Device and purpose

Structurally, the disc hiller is presented in the form of a frame equipped with two wheels, with spherical discs suspended from it. The angles of rotation of the discs are regulated by means of two screw lanyards, which move the discs around a vertically located axis. Moreover, the angles of attack for both discs must be exactly the same. Otherwise, the hiller will start to move aside and cut the bushes. The distance between the discs is regulated by the movement of the stands, and can be from 35 to 70 cm.

The height of the earthen ridge is regulated by bringing the discs closer together, changing the angle of inclination and deepening. So, when the disks move apart, the height of the ridge decreases, and when they approach, it increases. A walk-behind tractor is usually used as a traction for disc hillers, although work with mini-tractors and cultivators is also allowed.

The scope of application of the hiller is not limited to hilling potatoes. It can be used to process plantations of beans, asparagus and corn, as well as use it as a weeding machine. Thanks to the sliding design, which allows the adjustment of the working width of the land, it is possible to process plantings with any frequency of furrow arrangement. However, the hiller is used not only for hilling and weeding.

With its help, spring cultivation of the land is carried out before planting crops and the soil is prepared for winter after the last harvest.

In addition, it is necessary to focus on the disc model even in cases where it is necessary to cut furrows for planting plants or cover them with a layer of earth after planting seeds. For such work, it is better to choose a model with a furrow cutter - a special wedge-shaped device located on the frame and designed for cutting furrows