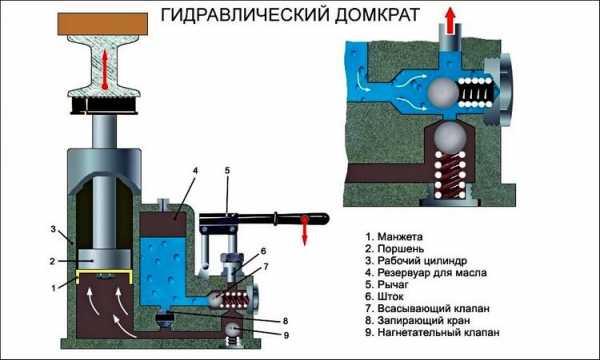

Bottle (hydraulic) jack

The most popular model today. It is a vertical metal body on a massive square base, inside of which there is a hydraulic drive, similar to that which drives a rolling jack.

The device is located under the load, after which the operator inserts a lever into the valve and starts pumping fluid into the working cylinder, gradually raising the working piston with the platform.

Jacks are widely used in all sorts of enterprises, during construction and installation work, in industry, workshops and services, as well as by drivers of cars and trucks. It has the following advantages: huge carrying capacity (for professional models up to 200 tons!), Compact dimensions, reliability and stability, tightness and impact resistance, low price.

Disadvantages: lifting height, which does not allow using the jack in cases where the load is too close to the ground, the need for additional maintenance of the hydraulic drive (cleaning the cylinders, changing the oil), storage and transportation only in an upright position.

Conclusion: suitable for all types of lifting work, as well as for owners of vehicles with high ground clearance.

Bottle hydraulic jack 50 t "Inforce"

One of the most popular models of joint Russian-Chinese production. Combines the best characteristics of lifting capacity, lifting height and smooth running; resistant to uneven surfaces and corrosion resistant thanks to a special protective coating on the body.

It can be used both as a stand-alone mechanism and as a more complex system, for example, a hydraulic press. Price - 6145 rubles. The firm's warranty is 12 months.

- Carrying capacity - 50 t

- Lift height - 480 mm

- Pick-up height - 300 mm

- Working stroke - 180 mm

- Base dimensions - 176 * 225 mm

- Weight - 32.2 kg

Jack 50 tons hydraulic "BelAK"

Russian jack, without which no construction site can do. Housing made of high-strength structural steel with protective paintwork; wide base provides stability against vibration. Comes with a case with a removable handle for easy carrying of the device in an upright position. Price - 3917 rubles. Manufacturer's warranty - 12 months.

- Carrying capacity - 50 t

- Lift height - 365 mm

- Pick-up height - 230 mm

- Working stroke - 135 mm

- Base dimensions - 180 * 150 mm

- Weight - 18 kg

Bottle jack 50 tons "Stels"

A heavy duty jack that is ideal for off-road use thanks to its special base design. Stainless steel body; complete tightness of the moving parts of the mechanism. Supplied with several removable platform covers and a carrying handle. Price - 5037 rubles. The warranty is 12 months.

| № | Useful information |

|---|---|

| 1 | Carrying capacity - 50 |

| 2 | Lifting height - 356 m |

| 3 | Pick-up height - 236 m |

| 4 | Working stroke - 120 m |

| 5 | Base dimensions - 240 * 260 m |

| 6 | Weight - 26.47 kg |

How to choose a quality tool: comparison of manufacturers and models

Diamond Jack

Diamond Jack

Before buying a rhombic car jack, the right decision would be to read reviews and tips for choosing. When faced with this topic for the first time, it is easy to stumble upon a low-quality product, but using the correct information, it will be easy to determine which diamond jack will not only work effectively in tandem with a car, but also last as long as possible.

Among the simple mechanical jacks, you can find both domestic and foreign production. Know-name products are often found, but this is not particularly worth trusting, because there are no quality guarantees, except for the seller's assurances.

Jacks from the Kaluga Turbine Works have proven themselves well in the domestic market. They are distinguished by their high stability and reliability.The handle of the jack is equipped with a ratchet, which will facilitate the lifting process.

Jacks made by Kraft, Sorokin, Zubr will also be a good choice.

How to choose?

Choosing a rolling car jack is not as easy as it might seem at first glance. First you need to understand where and in what conditions this tool will be used. It should be remembered that rolling devices need a solid and even surface, if there is none, then this type of jack will not work. When you have decided on the type and capacity of the jack, you need to choose its minimum and maximum height. With each new generation of cars, they are getting lower, so it is better to choose devices with a low profile of 90 or 100 mm. The maximum lift must be higher than the vehicle's suspension travel.

The next important fact when choosing a jack is its length in working order.

This value is important for those who work with these devices in a small garage. The jack must be installed strictly perpendicular to the car, your lifting device must fit between the car and the wall

Under no circumstances should the lift be installed diagonally to the machine. This is due to the fact that during lifting, the jack passes slightly forward (under the machine). If you start to lift the car with the jack standing obliquely, then its support wheels (not designed for such a load direction) may break.

When choosing a rolling jack, be sure to inspect it for defects in the o-ring around the stem. The seal must be clean, free of cracks, and seated at the same distance around the entire perimeter. The device must be free of oil stains. It is best to purchase such a tool in a specialized store with a good long-term reputation. In such establishments, experienced consultants will not only help you make the final choice, but will also give a guarantee for the purchased product. Ask the staff for a quality certificate for the purchased products, this will protect you from buying a low-quality product or from a fake.

You can find out how to make a hydraulic trolley jack with your own hands in the next video.

Design and types of screw jacks

The bodies of heavy vehicles are held in the required position, the most powerful springs are squeezed, steel pipes move through the ground. The design of the screw devices is simple, they are distinguished by their reliability.

By the type of force application, screw products are divided into the following:

- manual;

- equipped with an electric drive.

By design:

- Hydraulic.

- Screw.

- Rack and pinion.

- Pneumatic.

Screw jacks are simple and powerful mechanisms. Their principle of operation is to convert the twisting moment into translational movement. The main elements of these devices are a pair of "screw-nut" and a worm-type gearbox.

The gearbox supplies a twisting moment to the nut, where it, having converted into a translational movement, lifts the load. In a more advanced modification - jacks with a ball screw (ball screw), additional balls or rollers are added to the screw-nut pair.

The addition of additional elements makes it possible to increase the efficiency of such a device by reducing the frictional resistance, to increase the operating time and the speed of lifting the load. However, the cost of such a mechanism is slightly higher than that of a conventional screw device.

Screw and ball screw mechanisms have their own advantages. First, a screw jack was developed. Then, when it became necessary to lift loads with an increasing mass, devices were invented based on a group of electric jacks.

Installation of a group of such products, operating simultaneously and synchronously, makes it possible to lift loads of large mass, carrying them into motion by means of a symmetrical transmission.

Peculiarities

A modern rhombic jack with a lifting capacity of 2 tons allows you to raise a car or motorcycle to a height of 0.5 m. Models of this type of jack are usually supplied with the car.

Car owners note the following advantages of rhombic lifting mechanisms:

- simple in execution;

- relatively lightweight;

- rarely need some kind of repair;

- but if there are any problems, they can be easily repaired.

Oil does not flow out of the classic rhombic jack, as there is simply no oil in this device. Therefore, this option is better than the hydraulic counterpart. There are also no working chambers, which are available in portable pneumatic models, so it will not work to pierce anything. The supporting surface of this design is quite reliable.

But with all this, disadvantages should be noted:

- relatively high price;

- the need to spend your own muscle strength;

- insufficient working stroke.

The design of the rhombic jack is simple. The key property of the rhombus is symmetry. When the size of one diagonal changes, the second becomes larger, and the total length of the perimeter does not change. One diagonal can be adjusted using a threaded axle. When it is twisted, the two nearest corners are pulled together, and the two far ones diverge. This creates a lifting effect.

Screw jack

The word "screw" has already sounded above when describing ancient jacks - modern screw models have not gone too far from them, except that they have reduced in weight and dimensions, and also do not require the efforts of several people. The design is extremely simple - a rhombic engine, which contracts when rotating a steel screw passing through it; rotation is provided by the working handle.

With this jack, you can raise a passenger car - for changing a wheel, for example - but only on a flat surface, since the base area of the device is extremely small. Thus, the advantages include low price, compact dimensions and ease of use; of the minuses - a serious expenditure of time and physical strength with a low carrying capacity.

Conclusion: ideal for car owners who have physical strength and do not have a lot of money.

Rack mechanical jacks

The design of such jacks for a car is a platform on which a rack and a movable mechanism with teeth are fixed. There is a support heel (foot) on it, which raises the car to the required height. This device is set in motion by rotating the handle or moving the lever. This type of lifting mechanisms does not require large expenditures of human physical strength. In addition, rack and pinion jacks can be used as a winch mechanism: the car can be moved not only back and forth, but also sideways. Thanks to the peculiarities of this lifting mechanism, the driver has the ability to carry out the curb of the wheels.

The features of rack and pinion jacks include their considerable carrying capacity, which can reach 3000 kg. In addition, this device can lift a car to a height of over 1 m.This feature will certainly be appreciated by SUV owners, who sometimes find it difficult to cope with wheel slip on a difficult-to-pass road section, for example, heavy mud after rain. To use this mechanism, additional fixation of the supporting part and the provided places at the bottom of the car for lifting it are required.

Peculiarities

A screw jack is a mechanical structure that is used to lift or move loads.Bottle-type screw jacks are very convenient and are in demand among drivers of various types of transport.

In the event of a malfunction, these types can be repaired by yourself. They have a low cost, designed for lifting small loads. They have a small footprint, provide reliable operation, but you must always monitor the threaded connection.

For a detailed overview of the pocket bottle jack, see below.

The principle of operation of such devices is to rotate the handle, a screw emerges from the support part, which subsequently transmits a circular motion to the support nut. Thanks to this scheme, the load is lifted to the desired height.

Disadvantages in work

The disadvantages include a small minimum pickup and significant effort at the beginning of work, a low ability to lift a load. The screw rhombic jack has a height restriction for lifting gravity, while in low-power devices, the support area is small.

Constant monitoring of the state of the thread is required, since turns with a small pitch often fail. Despite such disadvantages, motorists tend to favor mechanical rhombic devices, the cost of the mechanism plays a role.

The cost of similar models differs and depends on the brand, manufacturer and material of structural parts. The price for rhombic lifting devices ranges from 450 to 1,500 rubles.

What criteria should be considered when choosing a jack

How to choose a jack for personal use and what characteristics need to be considered? You have probably seen different types of jacks. For example, rolling, diamond or hydraulic. Before we decide which jack to choose the best for your car, let's look at the criteria that need to be considered. The main technical characteristics that affect the correct choice of a jack for a car are:

Maximum lifting capacity. In this regard, before buying a jack, you should take into account not only the weight of the machine, but also add about 500 kg, taking into account the transported cargo.

- Maximum lift height level. This criterion is no less important, since it determines how high you can lift the car from the ground level.

- With low vehicle ground clearance, the working height of the lift should be taken into account. A trolley jack or a screw-type lifting device is ideal for these machines.

We will talk about the types of jack drives below.

The main characteristics of the rhombic jack, which are worth paying attention to when choosing

Carrying capacity

Each mechanism has a calculated weight that it is able to lift without consequences for its technical condition. Exceeding the carrying capacity can lead to damage to the mechanism and to accidents - if at the moment when the tool fails, a person is under the car.

But knowing the mass of the car, it will not be difficult to find the right rhombic jack.

Important!

It is worth not forgetting that you will not have to lift the dry mass indicated in the passport data, but the full loaded one. Consider that the tank can be full, there will be a fire extinguisher in the trunk, some personal belongings, and all this in total can give an increase of 200-300 kilograms .. For example, for a car weighing up to 1500 kg, you can safely take a rhombus jack with a carrying capacity up to 2 tons

So it’s not worth buying a 3t rhombic jack for Lada Kalina at a run - the purchase will be much more expensive, and you will probably never have to use it to its fullest.

For example, for a car weighing up to 1500 kg, you can safely take a rhombus jack with a carrying capacity of up to 2 tons. So it’s not worth buying a 3t rhombic jack for Lada Kalina at a run - the purchase will be much more expensive, and you will most likely never have to use it to its fullest.

Pickup height

Each car has its own value of ground clearance, or ground clearance, - the distance from the ground to the bottom point of the body or attachments protruding beyond it. Most mechanical rhombic jacks are designed for a lifting height of at least 100 mm.

Note!

For understated cars equipped with a sports body kit that reduces clearance, difficulties may arise, because if the wheel is flat, this indicator may decrease even more and the lifting mechanism simply will not fit into its place and you will have to puzzle over the question of how to lift the vehicle.

Lifting height

The choice for owners of SUVs and cars with high ground clearance within the framework of the previous parameter is easier - we can say with confidence that any jack will fit. But here, too, everything is not so simple - one must not forget that there is also an indicator of the working stroke - this is the height to which the jack can lift the load. Off-road vehicles have a long suspension travel and therefore a jack with insufficient travel may simply not hang out the wheel. Standard mechanisms have this figure in the region of 300-350 mm, models with an increased stroke are raised to a height of 400-500 mm.

Vertical mechanical devices

screw and case

The main advantages of vertical fixtures:

- Low handle force, load stability.

- Significant working stroke.

- Substantial elevation.

- Light weight.

- Low cost.

Cons of vertical structures:

- small bearing area and, as a result, low stability;

- large sizes;

- can only be used when lifting vehicles equipped with special lifting eyes.

To insure against the "break" of the vertical jack, experienced motorists recommend additionally fitting logs, bricks or other suitable items under the body of a raised car.

Rack mechanical jacks

Post-screw designs are produced with one or two screws and are capable of lifting loads weighing up to 3 tons. The principle of operation of single-screw products is identical to the vertical one. And for twin-screw, the body serves as a support nut.

The first screw, with a larger diameter, is screwed into another screw with a coarse thread. During the rotation of the handle, a screw of a larger circle is removed, and from it - a screw with a smaller diameter than the height of the lifting of the load increases.

Rack screw structures have excellent stability, have a rigid structure. The disadvantages include serious weight, and for jacks with one screw - also a relatively small lifting height.

Lever-screw devices

On the upper lever there is a pick-up and a nut, and on the lower one there is a screw stop and a support platform. The angle between the lever with a pick-up and the lever with a support platform is changed by rotating the handle.

The advantages of such devices are considered to be relatively low weight, low starting height and significant working stroke. The disadvantages include low stability and low rigidity of the structure.

Screw mechanical rhombic devices are used to lift machines weighing up to 2 tons. The set of the bearing component includes four levers, which are connected by hinges located in a rhombus.

Lowering and raising the device is carried out by changing the angles of the rhombus. Screw jacks have a rigid structure and a large support surface, they are versatile in use. There is only one drawback - it is a small working stroke.

Rhombic jacks

Their design is distinguished by reliability, small size and significant lifting height. The only drawback is the relatively high cost.

Combined lever-screw products are a kind of combination of lever and rhombic jacks. Such jacks are not oversized and have a low initial height.There are two disadvantages - low stability and insufficient structural rigidity.

The described types of screw mechanical products can be attributed to devices mainly for domestic use, however, for each type, you can also choose models that differ in their power. So, the screw mechanism used in construction has large dimensions and is capable of lifting tens of times more weight.

It is necessary to choose a suitable device, starting not only from the planned scope of work, but also carrying out the necessary calculations.

Screw type mechanical jacks

Often, when selling a car, the buyer is given a gift in the form of a spare wheel, a cylinder wrench and a jack - this is a screw mechanical lifting device. Most passenger cars are equipped with such jacks, the clearance of which allows the installation of a similar lifting mechanism. Its design is quite simple: four movable steel arms with a clamp are based on a stand (movable diamond-shaped horizontal structure). In the upper part of such a device there is a support platform for holding the car.

Screw jacks can be of vertical design: a movable screw is located inside the body. It should be noted that the lifting capacity of such lifting devices directly depends on the pitch of the screw thread, and the larger it is, the higher the lifting capacity of the jack. In both cases, raising and lowering the vehicle is carried out by rotating the drive handle. Such a car jack can be used to lift not too heavy machines. Vertical hoists are superior to diamond hoists because they are more powerful and much more durable.

Positive aspects of mechanical screw jacks

They are as follows:

- high reliability throughout the entire operational period in comparison with hydraulic devices;

- the mechanical drive does not require the use of filling mixtures and excludes unexpected breakdowns;

- large lifting capacity with small jack sizes;

- simple design, easy repair;

- use under a variety of circumstances from hanging wheels during routine repairs to regular maintenance;

- the possibility of using a low-slung car for repairs in road conditions;

- compactness in assembled form, which allows you to conveniently place the device in the trunk;

- stability of the device in a loaded state;

- strictly vertical lifting of the car without repulsion;

- affordable price.

How to choose?

Important: it is better to choose such a mechanism, the carrying capacity of which with a margin covers the needs of the owner. Exceeding the permissible load capacity can even result in serious injury if someone works under the lifted machine.

Another relevant point is the vehicle's ground clearance, which differs from model to model.

The vast majority of rhombic jacks with a mechanical base are designed to pick up a load at a height of at least 10 cm.Problems can arise when working with low profile sports cars. Especially when one wheel is also deflated. In such a situation, many lifting mechanisms simply will not fall into the designated place. And we will have to somehow solve this problem.

Judging from this point of view, it turns out that SUVs, jeeps and other vehicles with a large ground clearance are much more convenient when servicing. You can safely put any jack under them. However, not everything is as easy and simple as it seems.

It is also important what this jack will do next.

Therefore, you need to pay attention to the lifting height, since it is an indicator of the working stroke. The greater the suspension travel, the more this indicator should be, otherwise it will not work to "hang" the problem wheel

And a few more recommendations regarding the choice of a lift:

- carefully study reviews;

- contact only reputable stores;

- do not strive to buy a cheaper model;

- refuse to purchase noname products.

Rolling jack

The only type of jack that is located on a mobile carriage. This allows the mechanism to be used in situations where it is not possible to get close to the center of gravity of the load - then the jack is simply rolled up under it and the lever is applied (it is also a handle for controlling the trolley).

There is a hydraulic drive inside the steel body - that is, lifting is carried out due to the increase in the pressure of the working fluid in the vessel, which occurs when the lever is pressed.

Along with this, we highlight such disadvantages of the jack as low lifting capacity at a rather high price, as well as the need for careful maintenance of the hydraulic mechanism.

Pros - versatility, compactness and ease of use. Conclusion: suitable for work in the enterprise, but not recommended for use on the road.

We recommend to buy