Screwdriver "Makita"

Description, general information

The Makita company produces various power tools, among which there are screwdrivers. The company began its history from the beginning of the 20th century, and to this day it continues to delight consumers with its high quality goods. Let's take a look at the general features and characteristics of the models of this company.

Makita screwdrivers are very powerful. The average stroke rate for various models is about 2300 rpm, which is a good indicator compared to other brands. The weight of most models of tools is within 1.5 kg. Its small mass means that it will be comfortable to work with such a tool. The manufacturer also took care of the convenience of working in poorly lit rooms, making LED backlighting for most models. Separately, it is worth highlighting the type of handle for holding these tools on the weight. As a rule, they are made rubberized, and therefore it is convenient to hold them in a brush, respectively, the workflow is much easier.

The disadvantage of these screwdrivers is the strong vibration of the handle during operation, as well as their short-lived batteries.

In addition, the price for the products of this company is quite high, which is important for the domestic consumer.

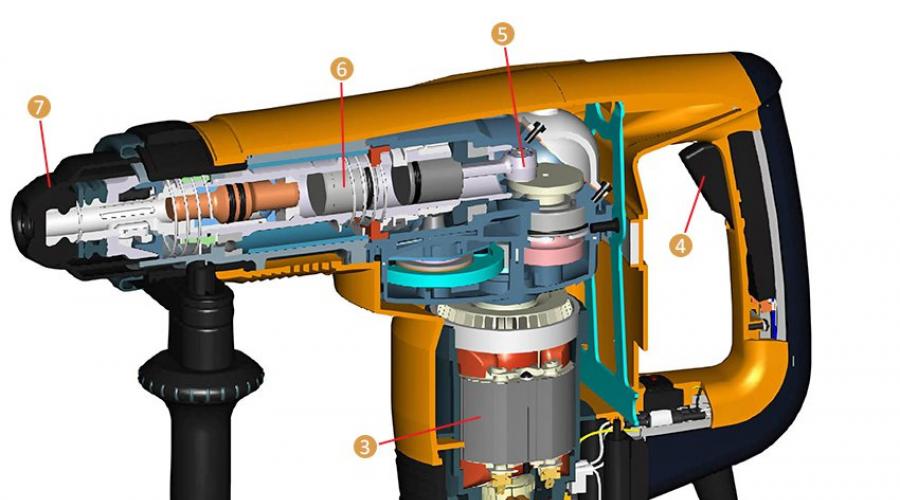

Consider screwdriver device on specific model 6271D. The diagram of this model is shown in the figure below.

Scheme 1

The diagram shows:

- Shift lever

- Body assembly

- Nameplate

- Screw

- Spring

- Reverse shift lever

- Start button

- Contact terminal

- Screw

- Keyless chuck

- Gearbox assembly

- Electric motor

- Screw

- Body assembly

- Charging unit

- Battery

A modern screwdriver is a high-tech device. Important structural elements:

- Removable battery

- Rubberized handle handle

- Powerful electric motor

- Metal planetary gearbox

- Soft start button

- Reverse switch button

- Torque regulator

These are the main components of the screwdriver design, which are included in the basic package of any screwdriver model.

Dismantling the Makita screwdriver

To disassemble the screwdriver, you need a Phillips screwdriver and some personal time. To disassemble the screwdriver completely, you need:

- unscrew the screws securing the case;

- remove the integral mechanism of the start button;

- remove the electric motor together with the gearbox;

- disconnect the gearbox from the engine by unscrewing the bolts holding them together.

To disassemble the battery of a screwdriver, you need to loosen the bolts connecting the body, or separate the body joints on an adhesive basis using a soldering iron. Inside the battery there are several nickel-cadmium batteries with a certain capacity and carrying a charge. In case of battery repair, they need to be replaced with new ones.

The chuck is changed with a screwdriver and a hex wrench. First, use a screwdriver to loosen the fixing screw in the chuck by turning it clockwise. Then the hexagon is inserted, the reverse button is turned on, clamped, and then the chuck easily yields.

Malfunction of the drill stop during hammer drilling

The reasons when the Makita hammer drill drills with a blow, and the drill turns, is the wear of the teeth of the safety gear and the teeth of the barrel. Often such a malfunction appears when using a perforator as a mixer for mixing mixtures. During operation, the safety clutch slips, and if we take into account the spring load, then the load is large.

With a visual examination, the diagnosis will not work.You can remove the barrel and fix it in a vice and turn the gear with a wrench, but this can be understood with heavy wear, in most cases only disassembling the barrel for diagnostics will help.

Even slight wear of the clutch edges leads to turning the drill and triggering when drilling with an impact.

Even slight wear of the clutch edges leads to turning the drill and triggering when drilling with an impact.

Advice on what to do in this case. If it is not possible to remove a suitable part or replace it, then assess the barrel wear. This is done like this, insert a new drill and move around, if the backlash is large, then it is better to replace the barrel completely.

It is worth noting that the reason for the scrolling of the drill during hammer drilling can be:

- wear of blast-hole bearings;

- the gear near the drunken bearing can be licked off.

Video:

On sale, if you look, you can buy a gearbox assembly for a perforator and its cost is about 2,000 rubles.

The reliability of some sellers raises doubts, and if you consider that often these are spare parts taken from analogs of the instrument that are traded, for example, on Avito. How to distinguish a fake hammer drill from the original.

For example, there are many Chinese Makita analog punchers. An example of a network puncher FAVORITE RH 950 and its cost in the aisle is 3000 rubles. which is profitable to sell for spare parts.

Perforator Favorit is an analogue of Makita 2450

Perforator Favorit is an analogue of Makita 2450

We change the parts for serviceable ones and get ready to assemble. Learn more about the lubrication and assembly of the rock drill.

Read if there are problems with the electrical part of the hammer drill.

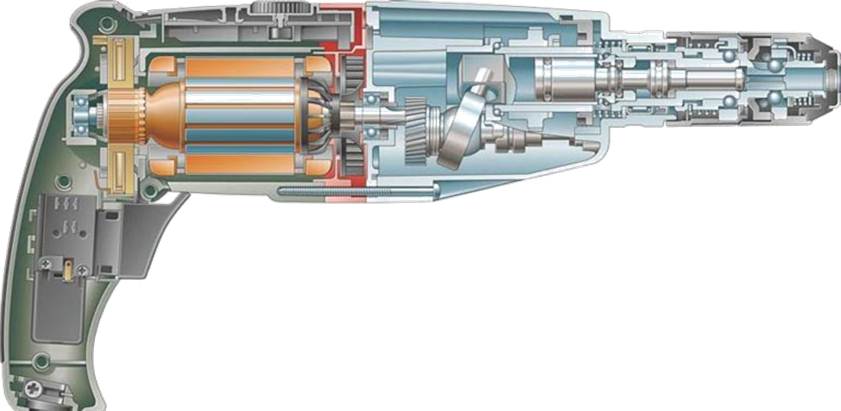

Dismantling and repair of the electrical part of the rotary hammer

If you suspect that the unit has a malfunction in the operation of the electric motor, then you need to dismantle the electrical part of the device. During disassembly, it is necessary to check the serviceability of parts of the mechanism that could break during operation.

Disassembly diagram:

- Remove the back cover by first unscrewing the screws holding it.

- Disconnect all fasteners that hold the network cable.

- We remove the start button of the unit.

- Carefully detach the wires attached to the motor stator.

- We remove a pair of engine brushes by unscrewing the mounting bolts.

- Using a flat screwdriver, we separate the mechanical and electrical parts of the unit.

- We remove the rotor of the electric motor from the gearbox. When replacing bearings, a special bearing removal tool must be used.

- We remove the air intake for engine cooling, located directly in the unit body.

- Disconnect the stator. This operation is best done with a light tap on it with a wooden mallet.

If it is necessary to disassemble the barrel puncher, first remove the handle of the device, and then unscrew the bolts holding the engine.

Replacing brushes

The main symptom of a malfunctioning brush is the presence of sparking in the collector area, overheating of the engine and the presence of a burning smell.

The brushes are located in special holders and are pressed against the armature by springs. This element will have to be replaced after the plates are worn by one third of the nominal value. To ensure good contact during operation, new brushes must be rubbed onto the rotating part of the motor. To do this, place a piece of fine-grained emery paper on the motor manifold and rotate to round the working surface of the brushes.

In rotary hammers, brushes of three types can be used:

- Coal - easy to rub in, but wear out very quickly.

- Graphite brushes have a harder surface and are therefore more durable.

- Carbon-graphite contacts are considered ideal brushes.

It is imperative to clean the rotor and stator of the device from coal or graphite dust using a technical alcohol solution.

Repairing damage to the stator and rotor of an electric motor for an inexperienced craftsman is a big problem. Preventive measures for cleaning and lubricating the rotating parts of the unit will be appropriate here.Breakdown and short circuit of the winding are determined using a multimeter, while such breakdowns are difficult to repair due to the compact and dense arrangement of parts.

Selection options

In order for the perforator to serve for a long time, and not break down after six months due to excessive loads, it is recommended to choose equipment taking into account its operational parameters

There are main points to pay attention to

Drill impact force

This is the main parameter for the performance of the equipment. This parameter is measured in joules. This does not mean pressure on the handle, but the features of the device, with what force it will hit concrete or other material. One of the parameters that is responsible for the drilling depth.

- For workers constantly involved in repairs, it is preferable to choose models with an impact force of 4 to 12 J.

- For periodic use, a perforator with an indicator of 1-2 J.

- And for frequent work with concrete surfaces, equipment with an impact force of 27 J.

Impact frequency

Impact frequency is the second important operating parameter of a rock drill. If the impact force is high and the impact frequency is low, then the work will go slowly.

- For professional use of the equipment, parameters of 5-6 thousand beats per minute are suitable.

- If the hammer drill is planned to be used at the household level, you can buy a tool with rates of 3-4 thousand beats per minute.

Rotation frequency and power

The drilling depth is influenced by the force and frequency of the impact. And the power and speed of rotation of the chuck with the drill is an important parameter that determines the speed of processing thick surfaces. A powerful motor is needed for speed.

- If it is necessary to work with thick walls, partitions, the power indicators of the perforator should range from 700 to 1200 W (rotation speed within 2500 revolutions).

- If you plan to work with thin partitions (up to 4 cm), a motor power of 500 W and a rotation speed of up to 1200 rpm is sufficient.

When choosing power parameters, you should pay attention to the drill diameter. High rotation speed is justified if a thin drill is used in the work.

And a thick drill at high speeds will wear out quickly.

Modes of operation

Each hammer drill model has several operating modes. This is a feature of the instrument. If the model works in two modes - rotation and rotation with impact. Three-mode modifications can only work on impact.

The cost of the punch directly depends on the number of modes. If the master has a variety of activities (drilling through holes, mounting fasteners), it is worth purchasing a three-mode tool. For the same type of work, you can purchase a dual-mode rotary hammer.

Body shape and weight

Equipment of this type is used in work in different conditions, therefore, the productivity and speed of fatigue of the worker depend on the shape and weight of the body. Lighter models have a horizontal engine. They are the best option for installing a false ceiling.

Vertical drills are heavier, but have a smaller body. They are more productive for wall drilling. The heaviest T-drills have been developed for road work.

Battery capacity

When choosing a cordless hammer drill, you need to pay attention to the battery capacity. The duration of the equipment depends on this indicator.

For frequent use, you should pay attention to models with a 3-4 A battery.

Instrument disassembly and assembly procedure

Before proceeding with the disassembly of the punch, you need to stock up on tools that you cannot do without: hexagons, screwdrivers with various cuts (minus, cross, curly), special bearing pullers, vice.

Always useful:

- grease, solvent;

- spare brushes (if replacement is needed);

- copper wire of a suitable cross-section.

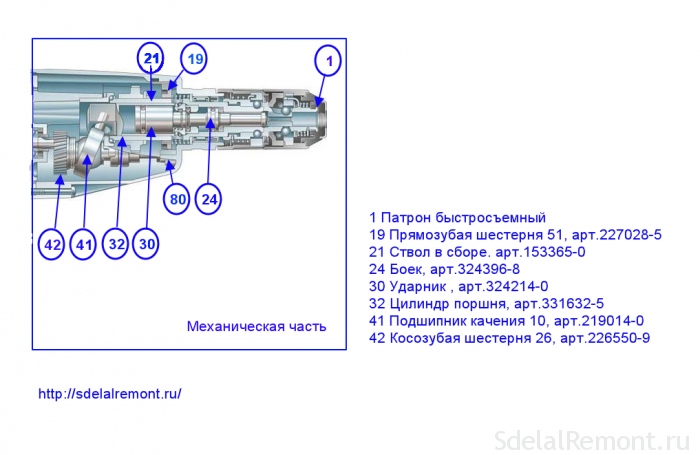

Disassembly

First you need to remove the quick-release master. After dismantling, remove the four screws that secure the "body" of the mechanical gearbox. Next, press the gable of the shaft, remove the black cover. Then pull out the mechanized block from the green side, for this you need to perform the following manipulations:

- in the handle, remove the three screws that hold the cover;

- dismantle the cover;

- remove the carbon brushes, release the brush holder springs.

After all the steps taken, pull out the mechanical stator block. Free the rotor.

Then you should disassemble the shock unit mechanics block, unscrew the two bolts located in the housing foundation.

Now it's time to remove the intermediate shaft, you will need to remove it from it in order:

- ring, bearing;

- spur gear;

- friction bearing;

- the washer is flat;

- 606 bearing;

- S-7 retaining ring;

- compression spiral;

- clutch.

Next, remove the barrel shaft of the chiseling mechanism. It is necessary to remove it from the inside of the housing, and remove the cylinder from the shaft itself.

Continuing to carry out the parsing sequence, dismantle it by following the following points of the instructions:

- knock out the piston connector;

- remove flat washers;

- remove the drummer.

To expand the shaft itself, you will need to remove the washer, compression and annular springs, a steel ball, and a spur gear. And from the inner cavity, remove the metal and rubber (2 pcs.) Rings, an annular spring, a ring, a flat washer made of metal.

Observing all the rules for the sequence of disassembly, we proceed to dismantle the electrical part, which includes the following parts:

- stator;

- switch;

- rotor;

- carbon brushes;

- brush holder.

Then you need to remove the two self-tapping screws.

Assembly

Before returning all the parts that make up the hammer drill, apply a new layer of grease. Clean the housing with petrol. If necessary, change all parts that need to be replaced, varnish the coils. Degrease the collector with a cotton pad moistened with alcohol solution to avoid dust adhesion to the lubricated bearing. Collect everything in reverse order.

It may need to be repaired, serviced, prevented or even replaced.

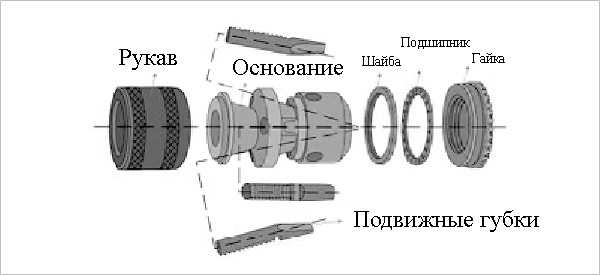

How to remove a cartridge from a hammer drill?

First of all, you need to understand type of cartridge used inside your power tool. There are three of them: quick-clamping, cam and collet SDS.

Quick-clamping is additionally divided into subspecies: single-sleeve and double-sleeve. The easiest way to change a part is on the SDS collet version. In this case, you just need to turn the drill. In the cam and quick-clamping type, the part is fastened with a key, so you have to work here.

Once the type of cartridge used is determined, you can proceed to the next stage: it is necessary to study the mount due to which it is held.

The drill is mounted either on a screw rod or on a spindle. As a rule, the parsing process takes place quite quickly and without problems, but there are cases of too tight fixation, which will take time and some additional tools to disassemble. In the first case, to remove the part, you will need to stock up on a hammer, wrench and screwdriver.

In order to remove the cartridge, you will need to perform the following steps:

- Reduce the fixation of the drill by lightly tapping the tip with a hammer;

- unscrew using a screwdriver;

- clamp the part in a vise or wrench, and then rotate the spindle.