How to fix it yourself?

Diagnostics

The serviceability of a mechanical nature is easy to determine by eye or by ear. An uncharacteristic hum or clicking sound is heard when the hammer is in operation. Sometimes there is a distinct grinding or knocking sound, which is accompanied by a disgusting smell from the case.

The serviceability of a mechanical nature is easy to determine by eye or by ear. An uncharacteristic hum or clicking sound is heard when the hammer is in operation. Sometimes there is a distinct grinding or knocking sound, which is accompanied by a disgusting smell from the case.

The most typical mechanical failure due to high loads on the equipment is the excessive exposure of dust and dirt to the tool body. It undergoes constant switching and switching of operating modes, which suffers from the entire hammer system.

If the chuck fails, this is detected immediately when the hammer is connected to the electrical network. This is due to the fact that the parts are overloaded, and with constant vibration, a large stream of dust enters. Mechanical failure of the bearing, damage to the teeth of the gears, the clutch and cracks in the spindle clamp are easily repaired by hand.

Diagnostics of the electrical part occurs by identifying the following signs:

- there is no reaction of the motor when the device is connected to the electrical network;

- when scrolling, there are sparks from the collector brush;

- you can smell burnt insulation;

- a stream of thin smoke with a pungent odor is visible from the body.

Disassembly and cleaning

- The first task when disassembling the hammer is to unscrew the retainer spring and remove the lance.

- Then unscrew and put aside the retaining ring on the muffler. This procedure requires special tools with a twisting property.

- Remove the ring on the top of the bump stop, remove the intermediate link retainer, and if it works out, the connecting link itself.

- If, during the diagnosis, freezing of the barrel channels was detected due to moisture ingress, then the compressed air pressure is checked first. The base is blown out with a compressed air stream and, in the event of a malfunction, the sleeve is replaced.

- If it was not possible to eliminate the breakage by squeezing out with air, then rinsing and cleaning from dirt, hardened water are used.

- When the hammer is working slowly, the sleeve is disconnected from the network and the hammer, and the air pressure is checked. The length of the rubber hose from the air duct to the hammer should be 10–12 m. If the indicator is exceeded, the excess part of the hose is cut out or replaced with a suitable size.

If the sleeve is pinched due to too abundant or, conversely, thick grease, you need to disconnect the sleeve. Blow out the released sleeve, and rinse the hammer and run in.

If the sleeve is pinched due to too abundant or, conversely, thick grease, you need to disconnect the sleeve. Blow out the released sleeve, and rinse the hammer and run in.

Weak blows of the tool when the valve distribution is not firmly pressed to the end of the barrel is corrected by disconnecting the hammer and removing the muffler. In this case, move the retaining ring and remove the retainer from the equipment.

In order to correctly position these parts and obtain the required impact rate per unit of time, you need to turn the link all the way and install the retainer so that it falls exactly into the holes of the barrel and the link. If foreign objects come across between adjacent parts, they are removed by disassembling the tool into its constituent elements. They are removed from the body by flushing:

- dirt;

- sand;

- accumulated shavings;

- other extra particles.

After washing, all parts are well doused with air, collected, and then run in.

If it is not possible to repair the jackhammer with homemade elements, then parts are used that will restore the first-order functions of the tool:

- air and fuel filters;

- egnition lock;

- motor collector brushes;

- butter;

- spark plug;

- rotor;

- stator;

- cartridge;

- bearing;

- cord and plug;

- armature and stator winding;

- ring;

- anther.

Views

By weight

The wide range of applications of jackhammers is achieved due to the specific differences between the individual models. So, the lightest devices (weighing less than 6 kg) are used mainly for domestic purposes. They can confidently cope with crushing tiles, plaster, relatively thin cement floors. Devices of the middle weight category are widely demanded by builders, they are used to break asphalt. The most powerful devices weigh up to 30 kg and are needed mainly in large-scale construction work.

By drive type

Demolition hammers with pneumatic engine are used more often than other options. Compressed air is produced using a compressor. The chisel moves under the action of the air flow. Air-driven household appliances must strike with a force of at least 5 J. For industrial units, the bar is twice as high. Such characteristics make it possible to:

- destroy sidewalks;

- demolish buildings made of natural or artificial stone;

- breaking through concrete and so on.

Electric hammers are equipped with special internal strikers. The strikers are driven by rotating parts. Motorized units can easily break a wall or covering

But it is important to understand that the high power of the force generated by an electric motor is not always good. This property makes it difficult to fully drill and cut materials. Problems can also be associated with the appearance of sparks.

They are found even in the most reliable models. Due to this feature, electrical devices cannot be used in places with high fire risks. Conventional models are not capable of operating disconnected from the mains. Battery versions can be considered an exception, however, they are heavier than analogs plugged into an outlet.

Problems can also be associated with the appearance of sparks. They are found even in the most reliable models. Due to this feature, electrical devices cannot be used in places with high fire risks. Conventional models are not capable of operating disconnected from the mains. Battery versions can be considered an exception, but they are heavier than analogue plugged into an outlet.

Hourly current consumption (in terms of continuous operation) reaches 1.7 kW. Each blow has a force of 45 J, and such blows are delivered 2000 times per minute.

Important: all modern models of fenders with an electric motor are equipped with double insulation, so you can connect the device to a home outlet without any fear. The gasoline (aka gasoline breaker) hammer is easy to use. Such mechanisms can work even where there is no electricity and it is not very convenient to use compressors.

Versions with internal combustion engines, in addition, are safer than electric or pneumatic deflector systems. But it must be borne in mind that the heat engine creates a lot of noise. And you will also have to constantly pour fuel into the tank, that is, the continuity of work is a big question.

Such mechanisms can work even where there is no electricity and it is not very convenient to use compressors. Versions with internal combustion engines, in addition, are safer than electric or pneumatic deflector systems. But it must be borne in mind that the heat engine creates a lot of noise. And you also have to constantly pour fuel into the tank, that is, the continuity of work is a big question.

Gasoline powered jackhammers perform well:

- when rocky and icy soil is destroyed;

- when dismantling asphalt and concrete;

- in the process of extracting resources.

Chippers with internal combustion engines help in a short time to break materials of different hardness. The size of the processed blocks does not play a special role either. Hydraulic devices deservedly stand out in a separate group. There are various devices for them.Basically, the hydraulic chipper, due to its versatility and high performance, is used by rescue teams.

This is interesting: Soldering iron for polypropylene pipes, nozzles for soldering polypropylene - we will consider in detail

What is a jackhammer used for?

Extraction of rocks, processing of stone, demolition of old capital buildings, road works - all these activities have long been associated, in the literal sense of the word, with hard labor. Indeed, try every day, from morning till night, to anoint with a pickaxe, sledgehammer or crowbar! And it was not for nothing that forced labor of slaves or convicted criminals was widely used for such occupations.

A pick, a sledgehammer, a wedge, a shovel - and so the entire thousand-year history of mankind, up to the beginning of the XX century, when the first jackhammers began to come to the aid of miners.

But slavery, we hope, is almost completely a thing of the past, the attitude towards prisoners has also undergone great humanistic changes. And the scale of modern construction projects or the extraction of minerals cannot satisfy unproductive manual labor in any way. Without mechanization - no way!

The appearance of jackhammers greatly facilitated the solution of the above problems - they began to be widely mastered in the first decade of the last century. In fact, a special tool was born, in which the energy coming from outside underwent transformations and was "converted" into an accented blow at the end of the working tip - lances, chisels, blades, etc.

Undoubtedly, for more than a century of history, jackhammers have undergone serious "evolutionary transformations" - they have become lighter and more compact, more convenient and productive in work. But the sphere of their activity did not receive any fundamental changes. As before, these tools take on the most difficult operations that require great physical effort:

This is a partial or complete demolition of old structures - where it is impossible or impractical to use heavier construction equipment.

Demolition of the old building along with its reinforced concrete strip foundation

This is the dismantling of walls or ceilings, making openings in them for windows, doors, staircases - during construction, with changes in the design documentation, or during redevelopment. Including a jackhammer, you can cut the rods of a metal reinforcing frame - using a special lance-chisel.

Making a window in the interfloor overlap for the subsequent installation of the stairs

Dismantling of old pavement, including asphalt or concrete.

Removing old pavement is a challenge for heavy duty jackhammers.

Loosening of packed or frozen soil for further excavation work.

Sometimes there is no way to go to earthwork without "ripping open" with a jackhammer the top layer of soil, which does not lend itself to shovels - it is too stony, caked or frozen.

Compaction of soil in places where the use of other devices is impossible.

The task with the "opposite sign" - sometimes the soil in a separate area needs to be compacted as much as possible. It is also solved with a jackhammer, but with a special attachment.

- Despite the introduction of special mining equipment, this industry still cannot do without “manual clean-ups” using jackhammers. And in some places they remain the main tool of miners to this day.

- Come up with jackhammers and other uses. For example, cunning craftsmen make special equipment for driving small piles or pipes into the ground.

Device

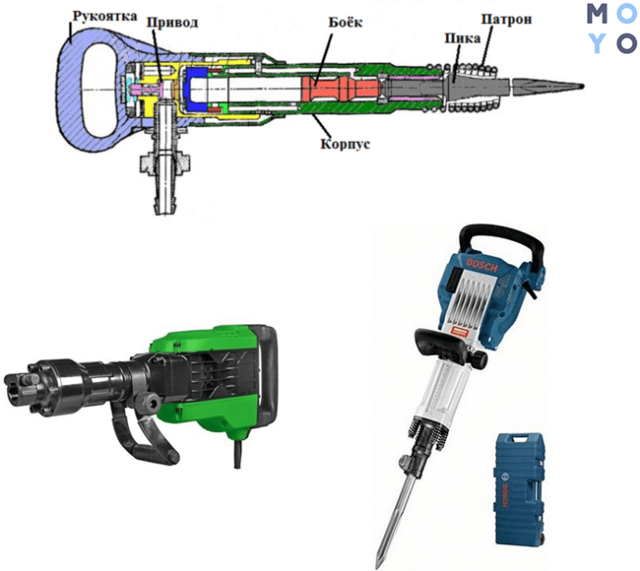

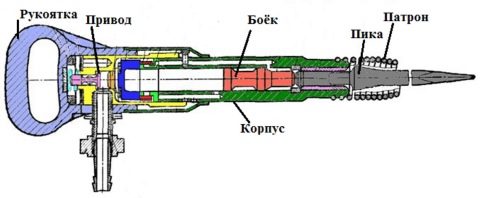

The main structural elements for any type of jackhammers are represented by a striker, a nozzle, a chuck, etc.

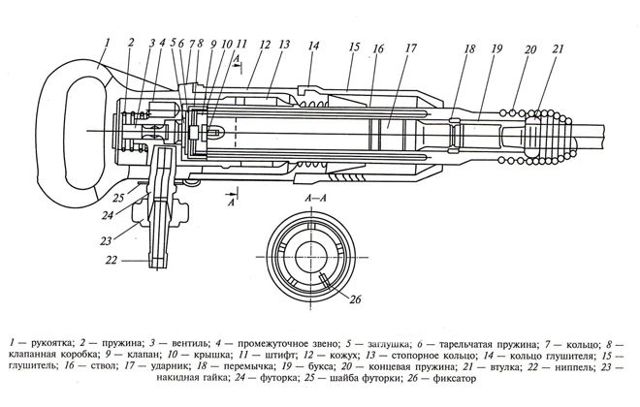

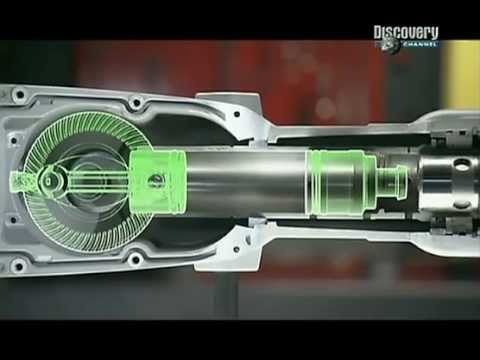

Pneumatic piston models are arranged according to the scheme of piston systems based on the shock principle.The main structural elements are represented by a start valve, a striker, represented by a piston, a fitting for a compressor hose, a cup with a ring valve and a valve box, a muffler. In addition, the jackhammers include two springs, a shock absorber, a retaining ring, a handle, and a body.

The named parts are combined into several nodes.

- The impact device, also called the launcher and air distribution mechanism, includes the firing pin and the barrel.

- Vibration protection of the handle is represented by a glass and sealing sleeves.

- The anti-vibration chisel protection includes a manipulator and a spring-loaded bushing.

- The handle housing includes a housing, an aerodynamic noise suppressor and a trigger.

The shock system has two main functions: supply, distribution and removal of air, converting its energy into work.

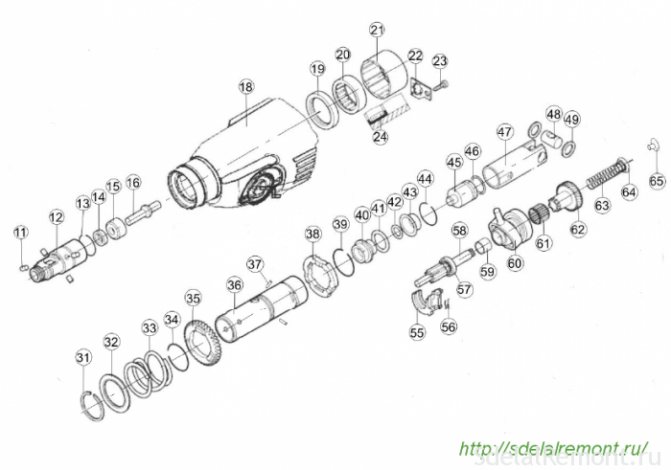

Electric models are equipped with such specific units as an electric motor, a gearbox that converts the rotation of the shaft of the latter into a reciprocating movement, a crank mechanism with a piston that provides pressure in the cylinder acting on the firing pin.

Components specific for jackhammers with internal combustion engines include the carburetor, fuel tank, starter, ignition system, and fuel pump. In addition, taking into account the increased vibration of these devices, the handle and control elements are separated from the body by a spring suspension.

In addition, there are additional accessories for the hammer. It includes the following four attachments. An automatic speed governor, called soft start and idle speed limiter, serves to extend engine life by avoiding overloads and gradual acceleration. The principle of its operation is based on adjusting the speed in accordance with the load. The side handle increases ease of use by promoting proper hold and distribution of forces. The impact frequency adjuster increases tool control by allowing the breaker to be adjusted to suit different hardness materials. The latching button ensures that there is no need to hold it down continuously during operation.

The principle of operation of jackhammers is to create reciprocating movements of the striker located in the barrel, which is not kinematically connected with other parts. This is done by different mechanisms depending on the type of hammer.

So, in piston pneumatic models, the air supplied by the hose from the compressor overcomes the resistance of the valve spring when acting on the handle. As a result, the valve moves, opening the opening of the percussion mechanism. Alternately, in the lower and upper parts of the cylinder, a vacuum and excess pressure are created due to the bypass of compressed air between them by the valve system, generating reciprocating movements of the striker.

The operation of the pneumatic turbine hammer is based on the drive of the energy generated by the rotating air of the turbine wheel.

Gas powered hammers are also commonly equipped with pneumatic hammers. The piston, by changing the pressure in the cylinder, leads to the movement of the hammer piston with the tip attached.

Peculiarities

It is customary to distinguish two stages of repairing such equipment. During fault detection (it is also a fault finding), they find out what exactly went out of order, as well as how large the resource of the device is. At the second stage, the problematic parts are changed. Experts believe that there is no point in repairing a very worn-out device. It still will not work as long as it takes to compensate for the efforts and costs of spare parts.

In order to repair the jackhammer as rarely as possible, it is necessary to systematically check its condition. Maintenance of products is carried out without special equipment, and it saves a lot of time.As for spare parts, only a limited range of them can be found on the market. It is simply pointless to change many parts, since it is more profitable to purchase a new tool. You can purchase:

- air distribution mechanism;

- firing pin;

- valve;

- spring;

- some other details (but much less often).

A number of faults can be eliminated only by contacting a specialized service. It must be said that most of the repair kits can be used for different models and even for products of different companies. Power does not really matter either

Important: The cheapest jackhammers made in Asian countries are rarely repairable. Usually they are refused even in the service.