How to choose an electric jigsaw for your home

For the optimal choice of jigsaw, you need to take into account the characteristics and availability of additional functions.

Criteria for choosing a jigsaw:

- power. Shows energy consumption and work efficiency. The ability to cut thick parts, the cutting speed and the time of continuous work depend on the power;

- sole. Each jigsaw has a support sole for improved precision. For inclined sawing, the sole swivels to both sides. In some models, you can choose any angle up to 45 degrees, in others - the rotation occurs only at certain angles, which is not very convenient. There are jigsaws with the ability to adjust the rotation without additional tools;

- speed control. The presence of this option expands the capabilities of the tool, because different materials cannot be sawed at the same speed. If the number of revolutions of your jigsaw is less than 1000, then it will not take plastic. But do not forget that at very high speeds, such as for woodworking, the plastic will melt;

- pumping the canvas. It is also called the pendulum stroke. This is the forward and backward movement of the file. Increases cutting speed, but quality deteriorates. If speed is important for a large volume of work and without high requirements for cut quality, a very useful function;

- laser pointer. It makes it possible to make a very accurate cut along the markings. Even the ingress of sawdust into the cut zone does not spoil its trajectory;

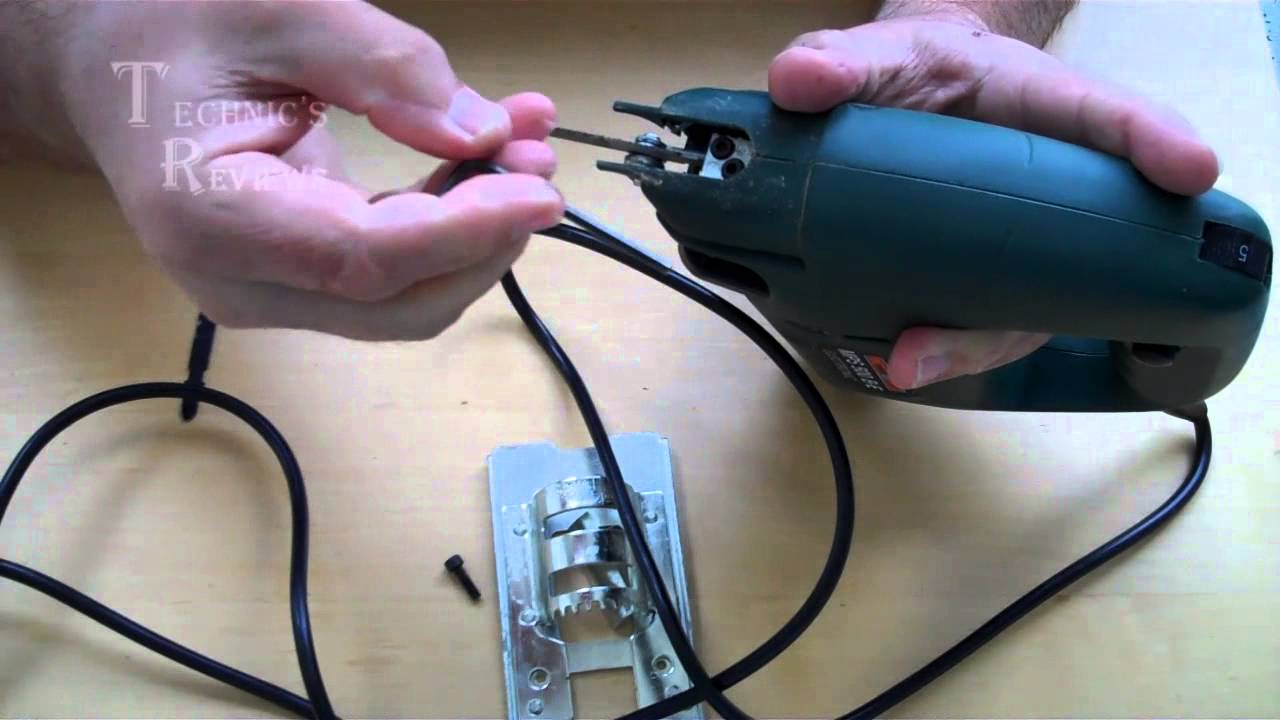

- file attachment. The attachment type can support different types of shanks or one used in a given tool. Also in specific models there is the ability to quickly change the equipment with one hand;

- illumination of the working area. The entire working surface with its irregularities is visible. Convenient when working in low light areas;

- ergonomics. Equipped with balancing and rubber inserts. If the tool is comfortable to hold in the hand, then the ergonomics are good;

- equipment. Jigsaws are completed with a box, canvas bag or case. The bag does not get wet, but there are no additional compartments for accessories. The case is shock-resistant and does not get wet. It has special sections for consumables and accessories;

- connection to a vacuum cleaner. If there is a branch pipe for blowing out sawdust, you can connect a vacuum cleaner to it;

- availability of additional functions:

- increasing the stroke rate improves productivity, but the tooling wears out quickly;

- automatic blowing off of sawdust from the cutting line;

- 360 degree blade rotation is useful when sawing circles.

Choosing a jigsaw

Jigsaw accessories:

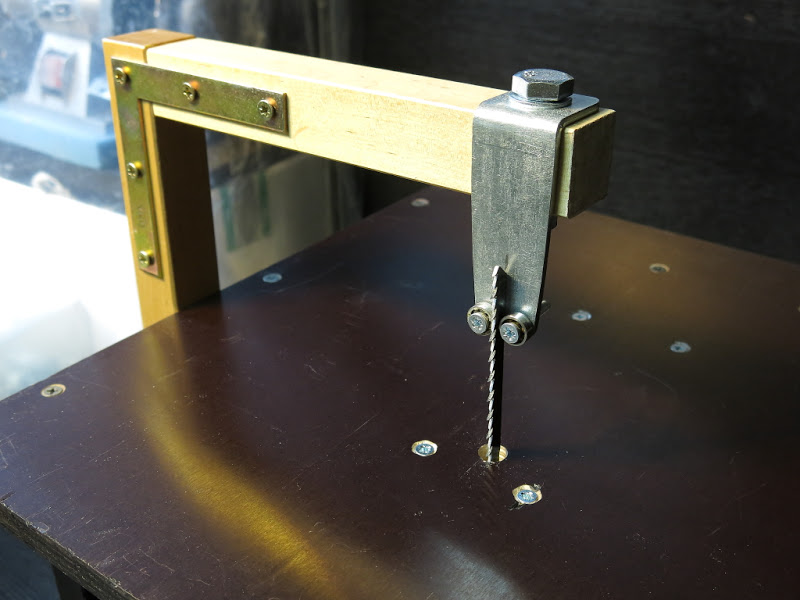

- a table for fastening the tool at the workplace;

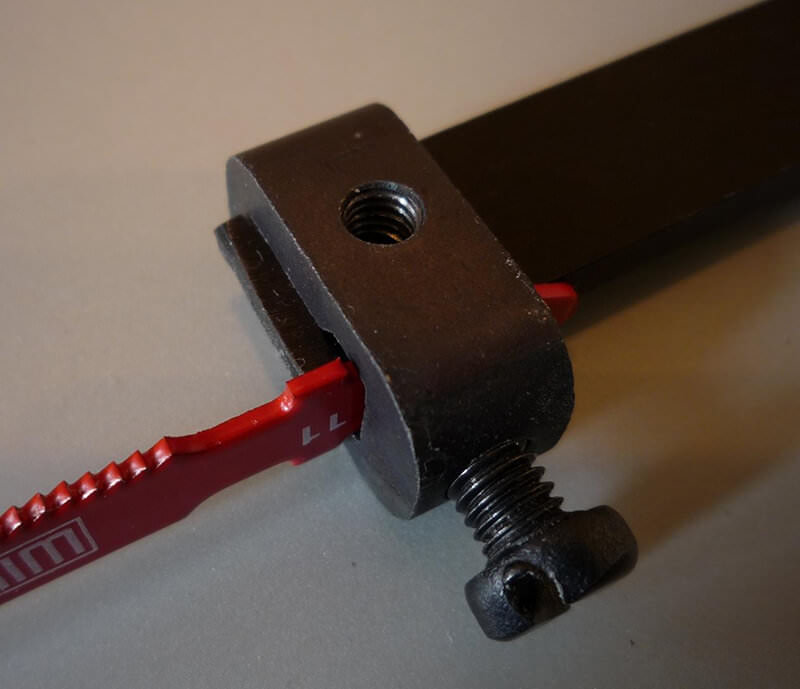

- connector for guides;

Rail connector

- guide with millimeter scale kwb line master 7844 00;

Guide with millimeter scale

- square for the guide;

Guide elbow

- splinterproof liner.

Splinterproof liner

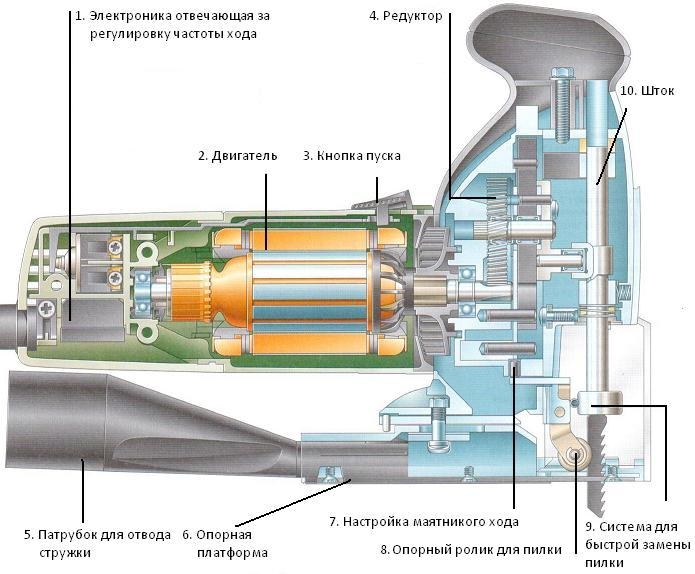

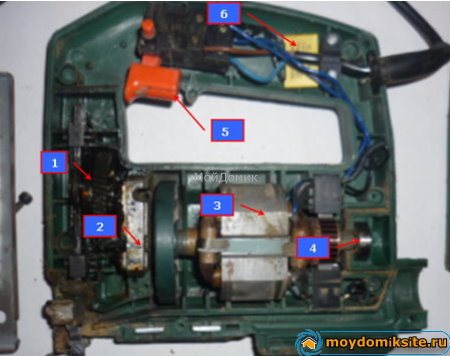

Device and principle of operation

Let's consider in detail the jigsaw device

What a jigsaw consists of

Jigsaw device

Jigsaw device

Power cord.

Cord terminals.

Trigger stopper.

The trigger.

Speed selection knob.

Eccentric hinge.

Cooling fan.

Reducer.

Pendulum action regulator.

Pendulum mechanism.

File.

Protective limiter.

Saw support roller.

Air duct.

Base plate.

Electric motor.

Sawdust removal.

Baseplate adjuster.

In simple jigsaws, the rig only moves up and down.And when using the pendulum mechanism, even forward and backward. This tool cuts faster. How is vertical movement formed? The motor transfers its rotation to the gear of the reducer. An eccentric hinge is attached to it, which creates an up and down movement. The base plate presses and holds the tool on the work surface, eliminating hand shake. The sawdust is blown out by a cooling fan and discharged through a special branch pipe.

Frequent malfunctions

Like any mechanism, a jigsaw may experience various malfunctions:

- the tool cuts crookedly, the blade “leads” to the side at an angle that is unacceptable;

- the mounting of the cutting tool has broken, the file flies out;

- the unit does not turn on;

- the gear wheel or its teeth breaks down;

- the worm gear, which is anchored, wears out;

- the blade jumps or falls out when sawing;

- the clamp does not work, the file does not hold;

Mechanisms often fail when mechanical microparticles hit the dynamic elements. It is imperative to carry out timely preventive inspection and cleaning of the internal components of the device. It is necessary to flush the unit with a special WD-40 compound. It is also useful to use a vacuum cleaner to clean the power tool: the reason for the breakdown of the gearbox can be if dust gets on it.

Stem breakage most often occurs during mechanical damage.

Breaking a tooth on the collet also happens most often due to the fault of the master. This happens if the working blade is fastened too tightly.

The worm gear cannot withstand the loads if you "drive" the tool on afterburner.

If you do not follow the recommendations, then such malfunctions occur:

- the bearing wears out quickly;

- the cam block is erased;

- the gear becomes unusable.

Also, a fairly frequent breakdown is the abrasion of brushes, which are easy to replace. Preventive cleaning of running units is a must. Lubrication should also be done regularly.

Another common malfunction is the breakage of the holder, which causes the blade to fall out.

Often, the attachment of the jigsaw loses its rigidity, as a result of which backlash appears, which affects the quality of work. Clamps are almost impossible to repair - they have to be changed.

Some unscrupulous manufacturers make bolts from fragile materials. Such cheap alloys break at the slightest load and are extremely short-lived - you have to change the "native" bolts for fasteners made of strong steel.

For example, the standard web feeding function (available on almost all models) greatly helps the job by reducing stress on the worker's hands. However, the presence of such a mechanism leads to a great deal of wear and tear of individual units of the unit, such as:

- guide roller;

- bushings (especially in the stock).

Another example can be cited when too much load appears, which can be caused by the physical impact of an inexperienced worker: if the model is not too expensive, then, as a rule, the file in it can break the fragile holder.

The platter roller may suddenly “freeze”. The reasons may be as follows:

- lack of lubrication;

- bearing breakage.

To change the roller, you need to dismantle the microsaw, separate the body by unscrewing the bolts. Pull the roller out of the niche and put the "fresh" one. You can do this operation yourself - it is simple.

If the protection is triggered, which protects the unit from overheating, then there may be several reasons, for example, the air duct is clogged with dust, which does not allow the engine to fully cool. You should take a brush or an old toothbrush and clean the sections of the grill. You can also use the following "tools" for cleaning:

- a needle;

- cotton rag;

- alcohol.

Thermal protection is available to protect the motor from overheating. It can be triggered due to contamination of the air intake grilles with dust and sawdust.Clean the grates, let the jigsaw cool down a little. After a while, the thermal switch will turn on automatically.

The cord may be damaged and the engine will not run. You can check the cord with a tester. If there is a defect, the readings on the device will be equal to infinity. The cord is inexpensive, it will need to be changed.

There are models that operate on portable chargers. When working with such jigsaws, the battery must not be discharged by more than 15–20%.

The most frequent breakdowns, how to avoid them and safety precautions

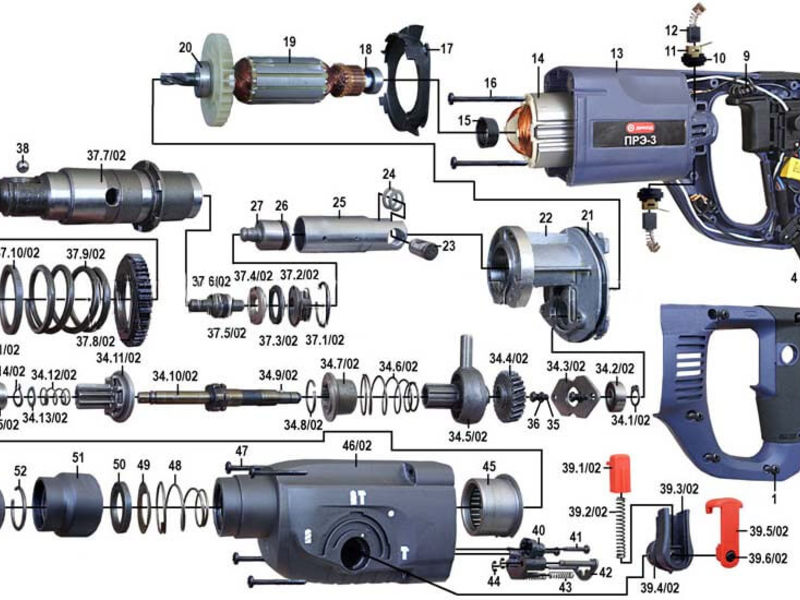

It is important not only to know how to saw with a jigsaw, but also to try to avoid causes that can lead to tool breakage. Electric motor

Most often, the engine fails in jigsaws. There may be several reasons for the breakdown: burnout of the rotor, stator, wear of the notch on the shaft. To avoid rotor burnout, you need to purchase a tool that will be powerful enough to perform the required tasks. For example, if you need to cut thick workpieces, a 400 W jigsaw will not be enough - the engine simply will not withstand the load and will burn out. An insufficiently high voltage in the network can also lead to this. It is not recommended to set low speed too often: lack of cooling and high currents can lead to burnout of the winding

Electric motor. Most often, the engine fails in jigsaws. There may be several reasons for the breakdown: burnout of the rotor, stator, wear of the notch on the shaft. To avoid rotor burnout, you need to purchase a tool that will be powerful enough to perform the required tasks. For example, if you need to cut thick workpieces, a 400 W jigsaw will not be enough - the engine simply will not withstand the load and will burn out. An insufficiently high voltage in the network can also lead to this. It is not recommended to set low speed too often: lack of cooling and high currents can lead to burnout of the winding.

The notch on the shaft can wear out due to constant shock loads on the tool stem. Shock loads on the rod appear due to improper selection of equipment. Therefore, always follow the guidelines when selecting a saw blade.

Power button. Sometimes the owners of a jigsaw are faced with a malfunction of the power button. Pulling the trigger will close the circuit and start the engine. If metal dust enters the case, the power button may not function properly. To remove dust during operation, you can use a special vacuum cleaner (a household one will not work). The failure of the "trigger" can lead to natural wear and tear of the conductive tracks. I must say that this process is quite lengthy.

Mechanics. Among the mechanical components, the stem may be problematic: this part is subjected to serious mechanical stresses that occur during the sawing process. The blade locking mechanism is the weakest in this system, since it is directly connected to the stem. Do not be afraid of damage to the gearbox if the housing reliably protects the internal mechanisms of the tool from dust.

Jigsaw safety and maintenance

The basic safety rules are necessarily indicated in the operating manual. It is strictly forbidden to perform any work while intoxicated. Before starting work, make sure that the tool is in good working order, the presence of protective glasses and gloves, the stability of the voltage in the network. It is necessary to take care of good lighting of the workplace in advance. Jigsaw work should be carried out in a dry room. There should be no flammable substances nearby.

At the end of the work, the tool is thoroughly cleaned of dust, if possible - blown with air (when the engine is running, the blowing efficiency will be higher). Lubricant is applied to moving parts as needed. Store the instrument in a dry place. Compliance with these simple recommendations will significantly increase the life of the jigsaw.

Major tool malfunctions

How to determine if the jigsaw needs repair or preventive measures? There are a number of signs to look out for:

- the body began to heat up too much during operation;

- when switching on and further operation, uncharacteristic sounds are heard;

- collector brushes sparkle;

- the engine cannot be adjusted, there are other problems.

Replacing the jigsaw rod guide bushings.

When the listed symptoms are found, you must immediately turn off the jigsaw, then inspect it, determine the malfunction. All types of such breakdowns can be conditionally divided into 2 large groups.

Electrical breakdowns:

- A factory defect in the form of a rotor breakdown (cannot be repaired, you must contact the service center).

- The stator or rotor gets very hot during operation, there is a melting on the insulation. The reason is dust ingress, pollution, incorrect loading.

- The brushes are worn out (replaced).

- If the speed regulator does not work, then it needs to be replaced. It is best to contact a master.

Breakdown of the mechanical part of the jigsaw:

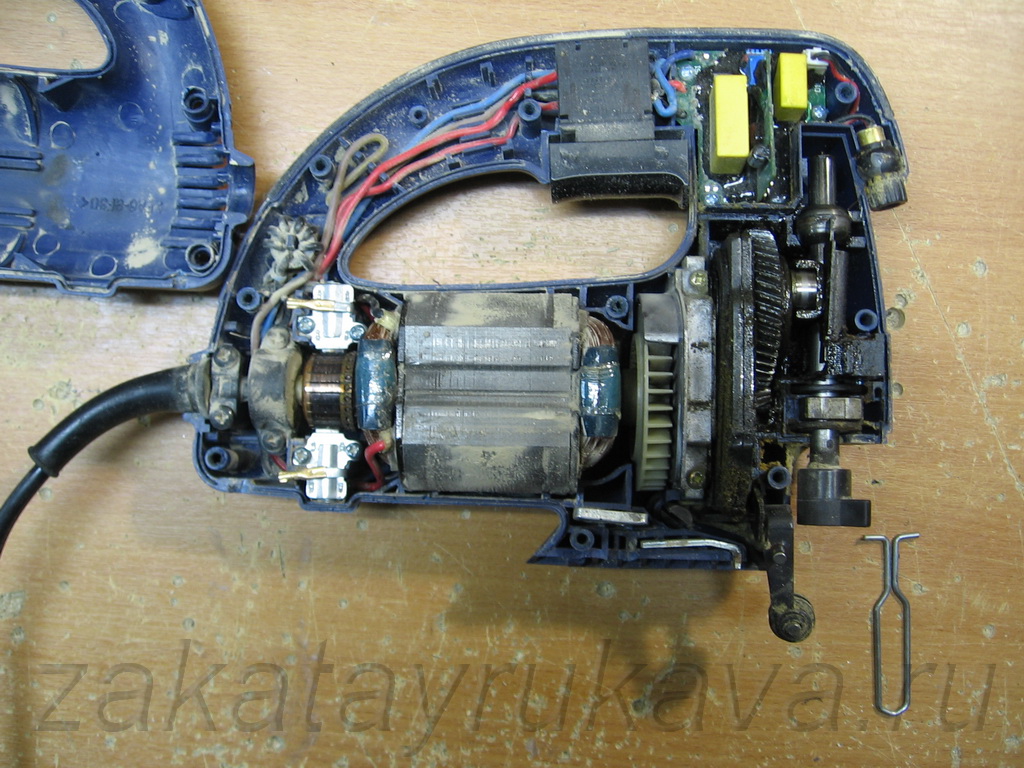

The internal structure of the jigsaw.

- The gear has teeth that are worn or deformed. It is possible to repair the jigsaw, a complete replacement of the gear is required, in the future it is necessary to carefully monitor the loads, the correct choice of the blade.

- The stem breaks, there are kinks on it. It is required to repair the jigsaw by replacing the stem, in the future, choose the right saws in accordance with the type of material. For example, for wood or metal, take only specially designed devices.

- The balancers that guide the rollers are worn out. Need to replace the balancers, in the future you need to monitor the loads.

- If the bearings are worn out, they are replaced. It is best to contact a master.

Other types of breakdowns can also be observed. For example, a strong impact may cause the body to crack. Do not drop the jigsaw, in which case other parts of it may be damaged. It is best not to fix engine breakdowns with your own hands, but immediately contact a service center. You can handle the replacement of worn parts yourself. To do this, the manufacturer provides instructions, following it, you can easily cope with the work yourself.

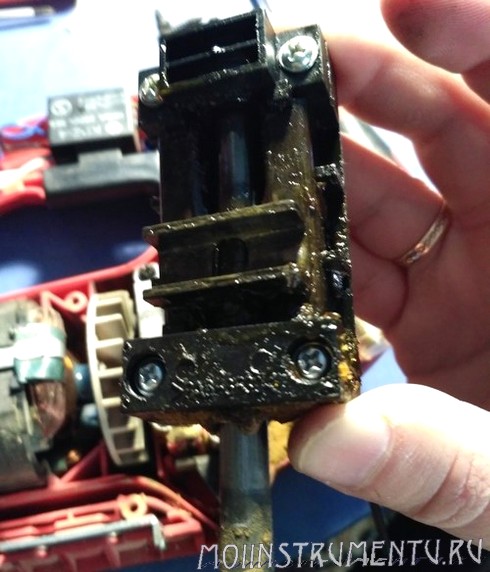

Breakage of the support roller and fixation unit: prevention, repair

The main characteristics of household jigsaws.

How do I repair when I find a problem? The support roller can break if the load is applied too much, i.e. cutting technology is broken. The file is attached to this particular roller if it is broken, but the file cannot be used. To prevent a breakdown from occurring:

- Use only high quality hacksaw blades.

- Blunt files must not be used.

- Hacksaw blades should be selected only in full accordance with the purpose. For example, for metal, only the fabric is used that is intended specifically for this material.

If the roller is not replaced when it is broken, the equipment may jam during operation. The repair will begin not with replacing the roller, but with cutting it with another tool and then replacing it. The renovation itself is not too complicated. The support roller with traces of damage must be removed, and then replaced with a new one corresponding to the used jigsaw model.

The blade fixation unit usually breaks when a large amount of dust gets on it.During operation, dust is not uncommon, therefore, for prevention, it is regularly required to clean the surface of the fasteners. Over time, the situation will get worse, the equipment may completely fail. Repair usually consists of completely replacing the retainer.

It consists in performing a number of actions:

- The assembly must be constantly cleaned and then lubricated.

- During work, you must use a dust collector, which will prevent a large amount of dust from entering the tool.

Breakdown prevention

Preventive measures always extend the life of any tool, including jigsaws. At the beginning of work, unscrew the screws, open the case. With the help of alcohol and a cotton cloth, it is necessary to clean all units of old grease. Then a new lubricant is applied to the desired points (in accordance with the recommendations prescribed in the instructions-memo)

It is very important to process precisely the dynamic parts of the unit (current, gearbox)

There are also a number of preventive measures:

- using only "native" parts;

- produce canvases by 70 percent and then change them;

- use canvases only those that correspond to the nature of these works;

- during operation, do not "strain" with excessive mechanical loads;

- clean the tool from accumulated dust at least once a week;

- use WD-40 lubricant;

- use a vacuum cleaner for cleaning;

- do not hit or drop the tool - this often leads to damage to the bearing rod;

- do not tighten the file too tightly in the mount;

- for too dense materials there are special devices, they must be used;

- each material has its own optimal operating mode (speed, angle of inclination, etc.);

- the base of the support roller should be treated with special technical grease at least once a week;

- you should actively use technical brushes to process the tool after finishing work;

- always monitor the ventilation grill of the instrument and clean it from mechanical microparticles.

How to repair a jigsaw with your own hands, you will learn from the video below.

Rules for a straight saw with a jigsaw

- For a perfectly straight saw, use a device with an increased blade speed. Better to choose a large file. A board is suitable as a guide. Pre-prepare 2 clamps with a workpiece and a guide. In order for the jigsaw to be freely positioned, it is placed on an elevation. Measure the width of the material with a tape measure, draw marks, make one line of them using a ruler.

- The guide is placed a few centimeters from the cut. It is attached with clamps. The jigsaw is attached with the cutting part to the cutting line. Connect it to the guide, attach it with a clamp. You need to make sure that she does not move.

- The same manipulations are done from the other side. So that there are no defects on the tree, you need to clamp it slightly.

- The next stage is the transition to the first clamp, checking its stability and clamping. After that, turn on the jigsaw, setting the highest speed. The number 2 is set on the pendulum. The file is set along the cutting line. The guide is pressed against the side of the platform and sawing begin.

- Controlling the position of the platform, the tool is moved forward. When just a little bit remains until the end, the sawn-off needs to be supported so that it does not break off. The cut pieces will be perfectly straight.

- For the saw to glide smoothly and easily, some use an indexable insert. It comes from different materials. It is fixed on the support sole of the saw. The bar and adapter ensure an even cut.

- Some materials require additional cooling. When working with them, you need to keep a bowl of cool water near you. It can be installed on a support sole.

The jigsaw is a versatile tool, indispensable in the household.Knowledgeable people say: skill in handling it comes with experience. The more you train, the better the result will be.

How to use: operating rules and safety precautions

If the cutting speed needs to be increased, there is no need to press down on the handle of the jigsaw and "adjust" it. Better to adjust the rotation mode of the motor and pendulum

The correct selection of the file is also important.

The workpiece must be securely attached to the workbench. Never saw with the workpiece suspended in your hands

Good fasteners will give good results - cutting accuracy, speed and quality of the cut edges.

Straight cuts are made using the ruler supplied with the jigsaw (linear lock).

Round holes and curved lines on thin plywood or plastic are better cut when the jigsaw is secured with the blade up and the part is fed to the cutting tool. Smooth circles can be made using a circular cutter.

It is much more convenient to make a cut on a thin metal surface if you put plywood under the sheet. This will prevent deformation of the edges of the metal.

If there is a noticeable decrease in the sawing speed, it is recommended to replace the saw immediately. Prolonged use of a dull blade will cause engine overheating with all the ensuing consequences.

If the cut needs to be made at an angle, the support sole is offset by the required number of degrees.

When working in cold weather, it is advisable to run the engine at idle speed for 1–2 minutes. After that, you can work in load mode.

Take breaks from work whenever possible. Stop for 5-10 minutes every half an hour.

We also list the basic safety rules.

- During work, it is recommended to use work clothes, in which there are no fluttering floors or hanging sleeves. Hair should be tucked under the headgear. The position of the body is stable.

- Do not slow down the movement of the file with your hands or a clamp.

- It is unacceptable to leave the switched on and working tool unattended.

- Use the tool only for its intended purpose. Do not hammer in nails with a file.

- If you find damage to the case or other functional breakdowns, you need to stop working and fix the problem.

- Switching the power cord on and off is done only when the engine is off.

- Do not allow minors to play with the instrument. This is dangerous.

How to properly saw various materials with a jigsaw

With practice and experience, knowledge comes. But at first, a novice user will need information on how and with what to cut different parts.

- Wood, plywood and laminate are the main materials the jigsaw is designed to cut. If the cut is rough, you can use high revolutions and oscillations of the pendulum. This will increase speed but decrease quality and accuracy. Exact cuts, depending on the density of the material, are cut at medium speed, with the pendulum turned off. This is especially true for laminate flooring if it is precisely fitted. On a six-point scale - 5.6.

- Metal parts, including pipes, are cut at low speeds without turning on the pendulum (or use a pendulum at low speed). 1.2 speed. Profiled sheeting and sheet metal are sawn at 1 speed, making sure that the edges are not wrapped. For aluminum and other non-ferrous metals, the speed can rise to 3-4 levels.

- Plastic and plexiglass can be cut at high speeds, but care must be taken to ensure that the material does not melt. 4-6 on a six-point scale.

- Ceramic tiles, like other hard types of stone cladding, are processed at 4-5 speeds. The pendulum is installed in its initial positions.

- Drywall can be cut at high speed and with maximum swing of the pendulum. The natural limitation is the level of dust. If the sawing takes place indoors, the dustiness from the cutting can be very high.And therefore the turnover is reduced.

Laminate is cut at high speed with the pendulum off

Laminate is cut at high speed with the pendulum off

Electric jigsaw Metabo: perfect in quality, but difficult to repair

One of the best jigsaws on the world market are the models of the German company Metabo. Everything is good in him. High power, aluminum body, pendulum device. In addition, the tool is stuffed with electronics, which allows you to customize the jigsaw to individual programs for each type of cut. And the cut is just perfect both in quality and straightness. The Metabo power tool is the best jigsaw to date.

But not eternal. Breakdowns happen here too. The reasons can be very different. But as practice has shown, the weak point is mechanics. After significant loads, and in particular, cutting metal, it may fail.

Typically does not support the axle on the bearing bracket, arm and stem. To restore the tool, it is better to purchase original spare parts, and assemble them at a service center by specialists.

When self-assembling the Metabo jigsaw, it is imperative to apply Castrol LMX grease to all rubbing surfaces with the addition of RiMET grease in a ratio of 3: 1.

Electric jigsaw Fiolent: the main reasons for failure

Replacing the stem

In the first case, in order to avoid this damage, it is enough to carefully and carefully handle the tool. But if this did happen, you will have to replace the damaged stem. For this you need:

- Remove the housing cover by unscrewing 4 screws.

- Remove the rectangular washers and retaining rails from the stem.

- Unscrew 4 bolts and remove mechanism cover. Below it is the flywheel and the stem itself.

- Unscrew 2 screws each, remove the upper and lower stem holders. The latter is with a spring, so you need to clean it carefully.

- Dismantle the destroyed stem with guide washers.

- Lubricate the flywheel and eccentric with a special gear lubricant.

- Put the guide washers on the new stem and refit it.

- Attach the saw blade holder to the bottom of the stem.

- Install the upper and lower holder, screw on the mechanism cover and install the washers and retaining rails.

- Insert the cutting tool and test the jigsaw at idle speed and under load. If the check shows no abnormalities, install the housing cover.

Tool lubrication

In the second case, everything is much more serious. It would seem, what is difficult about lubrication? But due to the fact that the tool constantly works in extreme conditions, the ingress of wood dust into the device cannot be avoided, it is necessary to carry out service work according to the intensity of operation, but at least once a year.

All mating parts and assemblies need to be lubricated. To do this, you need to disassemble the jigsaw. But if in the first case, for example, you limited yourself only to dismantling the stem, now we disassemble the tool completely and re-lubricate all the rubbing surfaces of the parts.

For lubrication, the manufacturer offers Litol 24, but it will not work in the jigsaw gearbox, due to its thick consistency, therefore, as a rule, it is lubricated with oils. You can combine Litol 24 with Feol 2U graphite grease in a ratio of 3: 1.

Modification of the design

However, it should be borne in mind that now the fluidity of the lubricant mixture is higher, and after some operating time it will begin to enter the engine rotor. The reason for this is left-hand drive. When the rotor rotates, the lubricant mixture is captured by the teeth and is fed to the rotor like a screw. The oil separator installed inside the motor housing does not fulfill its function. In theory, it should discard the incoming mixture, but in practice this does not happen. This is evidence of the imperfection of the design proposed by the manufacturer.

To avoid this problem, some work needs to be done.Or rather, put the oil separator not inside, but outside the motor housing. At the same time, in order for the oil separator snail to work and discard oil, it is turned over.

One more nuance. The bore diameter is Ø 9 mm, and the diameter of the outer part of the oil separator is Ø 9.2 mm - it ideally blocks the passage for the lubricant mixture. But when installing it, you need to apply a certain effort and a nozzle in the form of a pipe of a suitable size.

In addition, it is advisable to install a dust washer on the rear bearing of the armature. It will protect it from wood dust and extend its service life.

After that, you need to assemble the oiled jigsaw and test it for performance. After 10 hours of operation, check the tool for grease penetration into the motor housing. If everything is done correctly, then such an option is excluded.