Electric saws Makita (Makita)

The Makita UC 3530 A universal power saw will come in handy on a personal, garden or construction site. This model is distinguished by high performance, reliability and durability, and in addition to everything, it is very comfortable to work with. The saw is equipped with a quick-acting chain tensioner and bar removal device without the use of keys, which not only improves productivity, but also eliminates the need to constantly wear additional keys.

The Makita UC 3530 A electric saw is operated by means of convenient and intuitive buttons and levers. Due to its design features, this model is easy to maintain. The use of sealed ball bearings and a special gear lubrication system ensure continuous operation of the electric saw without specialized maintenance.

In order to increase the safety of the saw, the developers have provided in this model an inertial chain brake that protects the user from accidental injury as a result of "kickback". This system stops the chain in a fraction of a second - even before the thrown tool can “overtake” the user and cause injury. To protect the network from overloads and to prevent premature wear of the mechanism, the Makita UC3530A saw has a built-in electronic system for limiting the starting current.

The Makita UC 3530 A electric saw is equipped with a powerful longitudinal motor providing a high cutting speed of 13.3 m / s. Due to the longitudinal position of the motor, the tool is compact and perfectly balanced. Comfortable rubber grips provide maximum control over the saw during operation. The saw is equipped with an automatic chain lubrication system (the capacity of the built-in oil tank is 0.14 liters), which prolongs the service life of the saw headset and the tool as a whole. Visual control over the lubricant level is carried out through a transparent sight glass.

Subscribe, leave a comment, like.

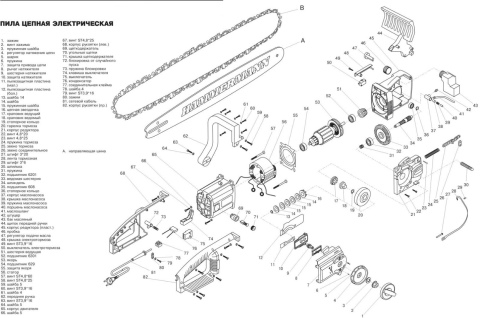

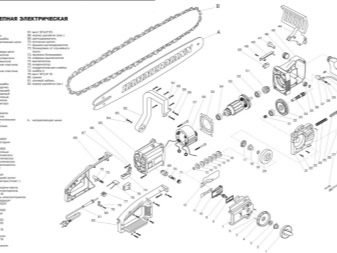

Chainsaw design

All chainsaws have the same design, regardless of which device, domestic (Ural, Kedr, Patriot 3816, Carver - Russian production with Chinese partners) or foreign (Calm, Husqvarna), for example, repairing the Patriot 3816 chainsaw with your own hands will be the same as well as fixing a foreign device. The main components of the tool:

- Engine.

- Fuel tank.

- Starter.

- Handle.

- Tire with chain.

The general principle of the chainsaw is simple - the master sharply pulls the cord, which starts the engine, and he, in turn, - the saw blade. Sometimes, the device malfunctions, in order to eliminate them, you will have to dismantle the saw. Problems that may arise with a chainsaw:

- It just won't start.

- Starts up, but after a while it stops working.

- Does not work in the cut.

- Power drops.

The main problems that arise are related to engine problems (fuel supply, exhaust system, cylinder-piston system and ignition), or smaller problems (chain problems, lubrication, tire, oil seal)

It is important to consider each problem in more detail.

If the chain simply breaks, then it should be replaced with a new one. There shouldn't be any problems with solving this problem. Repairing other parts of the saw can take up to several hours.

No matter how trite it may sound, if the chainsaw does not start, then you need to check the tank for the presence of gasoline.If there is fuel in the system, then the breather may be clogged, equalizing the pressure when fuel is supplied. The breather can be cleaned with a sharp awl or needle. With a candle wrench, the candles are turned out and cleaned with sandpaper. You can also ventilate the combustion chamber. After these procedures, the saw should start.

If the saw shuts off automatically, the trigger is most likely defective. But sometimes it happens that it's not about him. In this case, you need to unscrew the candles and inspect them carefully. If traces of fuel are visible on them, it means that the carburetor is incorrectly adjusted. The spark plug must be cleaned and placed back, after shutting off the fuel supply.

If black carbon is visible on the candles, then the matter may be in poor-quality oil, a poorly adjusted carburetor and an incorrectly calculated ratio of oil and gasoline. In this case, you also need to clean the candle and put it back.

It is also important to check the device for sparks. This is easy to check: you need to connect the spark plug to the ignition cable, use pliers to connect the cylinder and the plug nut, and then observe the presence of a spark.

If not, the candle must be replaced. If, when changing a candle, it turned out that the other does not produce sparks, then the problem may lie in an inoperative contact with the candle or high-voltage wire.

What is required to repair problems with your own hands

For the successful and long-term operation of any technique, it is necessary to understand the structure of the main components and mechanisms. And also know the rules of operation.

It is not recommended to start repairs without familiarizing yourself with the technical side of the matter, since this can only aggravate the problems and lead, in the future, to even greater problems.

If the reader is familiar with the chainsaw device, he can safely skip this section and go directly to the next one, which describes the main types of breakdowns and how to fix them.

Video: disassembling the Stihl 180 chainsaw

For those who hold an idle saw in their hands for the first time, we present a brief, synopsis of the chainsaw device.

The power unit that drives the cutting chain is a single-cylinder, two-stroke, air-cooled gasoline internal combustion engine. The engine is controlled by adjusting the amount of gasoline supplied to the combustion chamber, as well as its quality composition. The control element is a carburetor throttle valve associated with a button on the handle.

Chainsaw controls location

Its operation is ensured by a fuel supply system, consisting of:

-

A gas tank with a capacity of 500 ml. (with a saw power of 2 kW and medium loads, it is enough for 30–35 minutes of work).

- Gasoline pump.

-

A carburetor, in which an airborne mixture with gasoline vapors is formed and injected into the engine's combustion chamber.

The ignition system consists of magnets built into the engine flywheel, an electronic ignition module and a spark plug. A high voltage wire is installed between the electronic unit, in which electrical impulses are induced, and the candle.

2-spark plug, 4-electronics, 5-flywheel

Air enters the carburetor through an air filter.

The air is purified by passing through a dense synthetic fabric

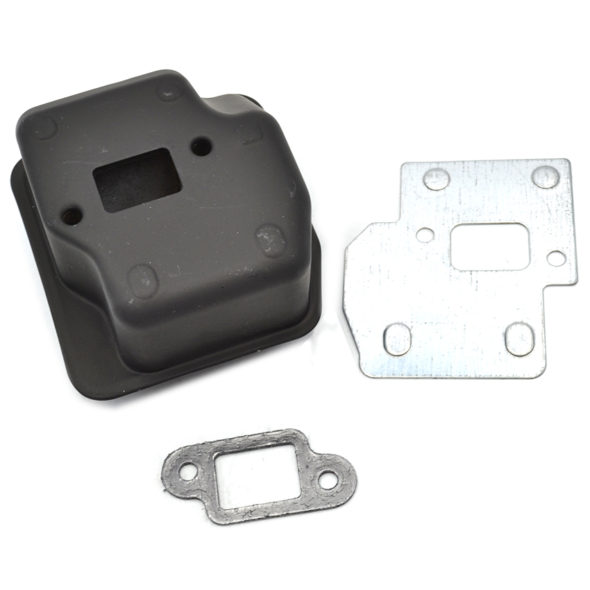

The exhaust gases are removed through a muffler.

A metal gasket is installed under the muffler

There is no engine lubrication system. To prevent the cylinder walls, piston and crank mechanism from wearing out during operation, a special synthetic lubricant is added to the gasoline (in a ratio of 1/50).

Two-stroke engine oil

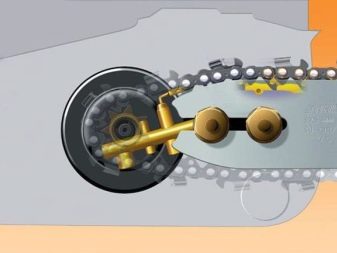

The high speed chain needs lubrication. For this, a system for supplying oil to the chain path is provided. A pump located at the base of the drive sprocket pumps lubricant from the oil tank. There are two types: piston or membrane.Some models are equipped with manual oil flow control.

The clutch of the crankshaft with the chain drive is automatic. The sprocket starts rotating when the number of engine revolutions increases. Thanks to this, the operation of the chainsaw has become much safer - when the chain is jammed in the wood, the clutch immediately opens automatically.

Video: chainsaw device

Modern tools are equipped with additional systems that increase user productivity and safety. These include:

- Anti-vibration system. Reduces vibrations transmitted from the engine to the housing.

- Kickback chain braking system. Increased protection against sudden jerking of the body.

- Lightweight system of starting and fuel supply. Primer, decompression valve, spring starter.

- Fast chain tensioning mechanism without additional tools.

- Additional air purification system when working during snowfall, dusty conditions.

Spare parts for chain saw

Today on the Russian market there is a wide variety of spare parts for electric saws. These are sprockets, saw bars, chains, various oil pumps, drives and flanges. The prices for these elements are very democratic: the main line of the offered goods fits into the price range of 1-10 USD. e. A craftsman using this tool, in some cases, must be able to independently repair or replace a failed part. Let's talk about this below.

Smooth start on the saw

The manufacturer does not always provide for the possibility of a soft start, which is why the engine starts immediately at maximum speed. At the same time, he still needs to spin the working body to the required speed. This mode is very difficult for the instrument, often jolts occur when starting up. To make the operation of the tool normal, it is necessary to purchase a soft start module costing $ 3–5. e. and install it in the tool body. First you need to open the housing cover by unscrewing the mounting bolts. The soft starter has two wires that must be connected to the break in the supply to the power package. Holds this module up to 2 kW. After that, you should assemble the tool body in the reverse order.

Oil pump for electric saw

An oil pump is required to automatically lubricate the chain during operation. Oil exits the pump through the oil channel opening. Oil is fed from the oil tank to the bore of the oil pump seat and the chain is then lubricated. The pump is driven by an eccentric cam on the gearbox shaft. The pump consists of a body, plunger, valve seat, valve itself and a plug. A strap and a lock nut are used to fasten the oil pump to the housing.

Electric saw chain sprocket

Most of the asterisks are not interchangeable. Their main difference is in the inner and outer diameters of the clutch plate, landing on the crankshaft, the total height of the sprocket

It is important what chain pitch they are designed for. According to their design, they are divided into all-metal and collapsible types.

When the all-metal and collapsible sprocket is worn out, you will have to replace the first one entirely. The use of a collapsible sprocket in a chain saw is the most economical solution.

Rotor for electric saw

The armature is represented by a winding of copper wire that passes current, and magnets encircling a rotating shaft. There are two main parts in the armature - the rotor (movable element) and the stator (stationary, static element). The shaft is set in rotation by means of an electromagnetic field, which arises in the process of starting an electric current through copper wires and its interaction with the magnets located there. To choose an anchor for an electric saw, you need to know the dimensions of some elements.It is necessary to measure the following places with a vernier caliper: the diameter of the winding, the total length of the armature, the length of the collector along the lamellas, the diameter of the collector, the bearing seats - rear and front, the distance between the bearings on the inner side

In addition, you need to pay attention to the end of the shaft - whether it is made in the form of teeth or is it a truncated cone. Knowing these parameters, you can pick up an anchor, since you should not be tied to the model or its other characteristics.

Design features and principle of operation

Units such as a chainsaw and an electric saw are made according to the same principle. They differ only in the design of the drive. In an electric saw, the engine is housed in a PVC casing. It also contains: a gearbox, a container for machine oil, a pump, a chain, etc. This design makes it possible to cope with fairly massive timber of various types.

The principle of operation of electric saws is simple, but you should know how the tool works.

The nodes that are in the chain saw:

- working saw chain;

- engine;

- reducer;

- drives;

- oil tank;

- wiring;

- frame.

A chain is nothing more than a sequential number of links that are fastened together. The chain itself moves along a special plate (often called a "tire"). The material for the tire is selected very high quality, with a high strength factor. In many ways, the running time of a chainsaw depends on this unit: the better the tire, the better the electric saw.

Tires are of two different types:

- welded;

- solid, which have a tip.

The latter are always made of high strength alloys. In fact, any tire is a "layer cake" of different blocks (at least three), while a driven "sprocket" is inserted into the structure.

A single device in which the tip is present is very convenient to use in a tool of large sizes (where the length of the bus is longer than the standard format). The one-piece design significantly reduces friction (up to 12%). For work, a unit is best suited where there is a tire made of ultra-strong alloys: they can withstand high mechanical loads and significant heating. Also, strong high-quality alloys do not react to interaction with mechanical microparticles and can serve for a long time.

When working with a power saw, it is important to understand that this tool is a source of increased injury hazard. A "kickback" may occur, that is, the power saw in this case may suddenly bounce to the side and cause injury

Such incidents occur when too much force is applied to the end of the guide bar, which rests on the work material. To ensure that such cases occur as rarely as possible, companies supply the units with a special brake: it blocks the chain automatically.

The automatic chain brake also has a second name - inertial drive. Its work is due to the presence of a protective element (shield). It covers the left hand of the worker. During the labor process, the shield is placed in such a way that it covers the hand. During operation, if a blow occurs, the hand rests against this element, the mechanism stops. Such a device significantly reduces the possibility of injury from the operating mechanism.

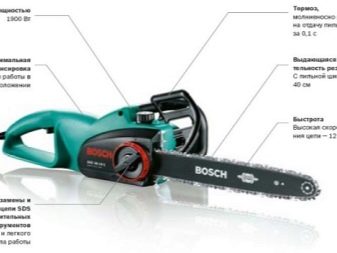

There is a special container on the saw, into which machine oil is added. During operation, oil is supplied in portions to the working unit (sprocket, chain). In expensive units (from the firms "Makita", "Bosch") there is a special dosimeter of oil supply, which contributes to a more rational consumption of a valuable product and an increase in the productivity of the unit.

There are rules of work that should be followed by both a novice master and a specialist.

- During operation, the throttle valve must be constantly open.

- Sawing at 90 degrees away from you is not recommended. The instrument should be held at some angle from the body.

- It is necessary to strictly follow all the recommendations that are mentioned in the instructions for using the electric saw.

- Components can only be used "native".

- Before starting repairs, the tool must be de-energized.

- It is recommended to carry the tool in a cover.

It is not worth lifting the saw above the shoulder during operation: it is life-threatening.

In the case of a tool wedge in the material, the saw is removed with the utmost care.

Fear should be the return impulse, which poses the greatest danger to the worker. When the power saw is switched on, it can cause injury.

You should be especially careful when working with logs with uncut knots.

The probability of jamming in this case is very high.

Do not work with an instrument that is not tidied up and adjusted.

At the beginning of work, a small test run must be carried out.

An important knot to watch out for is the chain. Loose chain tension will damage the tool and increase the risk of injury.

Electric saw repair ElectroLux

The electric chain saw is an indispensable assistant in the household. With its help, it is easy and simple to build, quickly cut the trash for firewood, etc. If only there was an outlet. It is lightweight and comfortable. Of course, you can't prepare firewood for the winter, but otherwise it's a great helper.

However, there is a weak point of the saw - a plastic gearbox, and a complete lack of any protection against emergencies, for example, from an abrupt stop of the chain.

This option happened to me - an imperceptible nail fell under the chain - so unsuccessfully that at full speed the chain got stuck, and the motor was still spinning by inertia.

As you can see from the photo, the gear of the motor is metal, but the driven gear is made of plastic, what is the reason for this decision is not clear.

From an abrupt stop of the chain - there was a shearing of the teeth on the driven gear.

To fix it with improvised means - there is no way, a replacement is necessary. Finding a new part is a dreary task. It is not available in service centers or in other stores. Quite by chance, it was discovered and bought for 500 rubles in the construction market "Elegant". But this is from the category - "lucky".

The gear is in place, the saw is assembled. Now I inspect the cutting place 5 times, instead of three

The electric chain saw is an indispensable tool for owners of private houses and summer cottages. It can cut branches in the garden, cut trees, cut boards and other wood-based materials. But no matter how expensive and reliable this unit is, the moment will come when minor or major malfunctions appear in it. Of course, serious breakdowns should only be repaired at a service center. But minor repairs to a chain saw can most often be done with your own hands.

The device of an electric chain saw differs from the device of a chainsaw only in the type of drive, namely in the presence of an electric motor instead of a gasoline engine. The unit consists of an electric motor housed in a plastic case, a grease tank, an oil pump, as well as a bar and a chain with cutting elements (teeth).

How a chain saw works can be seen in the figure below.

Electric saws can be both with a transverse engine (shown in the picture above) and longitudinal (see photo below).

The sprocket, installed in the same plane with the tire of the unit, rotates and pulls the chain. The latter, mounted on the tire of the unit, slides along it at high speed. Due to the presence of cutting elements on the chain, the wood is cut. Since the saw blade is wider than the bar, the tool does not jam in the material, and the sawing process is fast.

To reduce wear on the saw chain and bar, the saws are fitted with Lubrication system,

supplying oil to the saw head.

The lubrication system includes an oil tank with a volume of about 500 ml and an oil pump. The latter, during the operation of the electric saw, continuously supplies lubricant to the bus. Further, the lubricant is carried by the chain over the entire surface of the bar and falls on both the drive and guide sprockets.

Cylinder-piston group

It happens that the engine does not start or malfunctions due to low cylinder pressure. The malfunction may consist in a worn out piston, cylinder or bearings, sinking of the piston rings. You can consider the problem in general terms, for this you need to remove the muffler and inspect the system.

Compression in the engine can be measured by placing a compression gauge in the spark plug hole. After a while, you can draw conclusions based on the results of the measurement. You can only consider the problem by completely disassembling the system. If scratches or chips are visible on the piston, then it needs to be replaced. The piston ring must be installed in its rightful place, clean and intact.

Dismantling the electric saw to eliminate breakdowns

To start troubleshooting yourself, it is recommended that you first learn how to disassemble the saw. Complete disassembly of the unit using the example of a Makita electric saw is as follows.

- Unfold the flag of the screw that secures the tire, and slightly loosen the fastening. Next, use the chain tension adjuster to loosen the saw chain.

- Loosen the busbar screw completely and remove the cover.

- Remove the chain from the sprocket and disconnect the bar from the machine (including the chain).

- Now you need to unscrew the 2 screws that secure the engine from the sprocket side.

- You should also unscrew a couple of screws on the other side of the unit. For convenience, the oil tank cap can be removed.

- When all the fasteners have been removed, you can disconnect the gearbox from the motor.

- The next step requires remove the leading sprocket

... Since it is secured with a lock washer, it must be removed using a flathead screwdriver. - After removing the retaining ring, remove the washer under it and remove the sprocket from the gear shaft. Then tighten the 6 screws that secure the toothed stops and the handle of the device.

- After twisting the fasteners, disconnect the stops and the handle from the gearbox.

- Next, turn the gearbox over and remove the cover.

- Remove the oil reservoir after removing the tubing from the pump.

- Press the brake lever in the direction of braking until you hear a click and remove it.

- Turn the gearbox over and detach the aluminum housing together with the shaft.

-

Under the plastic cover, as well as on the gears, you can see the accumulation of dust, sawdust and grease.

- All gearbox parts are required clean from contamination.

- Next, remove the oil pump plunger.

- Remove the oil pump from the plastic gear cover.

- While rotating both parts of the pump in opposite directions, try to gently pull them out from one another. After disconnecting the pump, the ball and spring will fall out.

- Next, you need to disassemble the brake mechanism. Put on the lever and turn it until it clicks. The spring tension with this position of the lever will be minimal.

- Pry the spring with a screwdriver and remove it from the aluminum housing.

- Remove the rods together with the spring.

- To remove the brake band, unscrew the screw holding it.

- Before assembly on the pinion grease required

... This can be done as shown in the following photo. When the unit is operating, the lubricant will spread along the teeth of the gears due to centrifugal force. - The next step requires disassemble the motor case

... Remove the gear mounted on the motor shaft. - Take out the electric brushes and unscrew 6 screws on one side of the case and 1 screw on the other.

- Remove the cover.

- Pull out the motor rotor with a little force.

This completes the complete disassembly of the unit. The assembly of the electric saw is carried out in the reverse order.

The main malfunctions of power saws

Electric chain saw breakdowns do not occur from scratch. Most often, they can appear due to power surges in the network, improper operation of the unit, poor assembly quality of the device. The main malfunctions of chain saws include the following.

- When pressing the start button of the unit saw won't start

... The power cable or the power plug of the machine may be out of order. If everything is in order with the cable, then the cause of the unit failure may be a faulty start button, burnout of the motor windings or complete wear of the brushes. - During work the brushes on the electric saw burn

, and an all-round fire is generated on the engine manifold. The malfunction can be caused by worn brushes or a short circuit of the armature winding. -

The chain does not come grease

... This happens if the oil in the tank has run out, the pipe or hole responsible for the lubrication supply is clogged, or the oil pump has failed. -

Unit cannot reach full capacity

... Possible reasons are as follows: brushes worn out; turn-to-turn short circuit or breakage of the armature winding; low voltage in the network; the start button is out of order; jamming occurred in the gearbox; malfunction of the brake system. -

The saw motor stops during operation

... This behavior of the unit can be caused by a jammed gearbox or worn brushes. -

The electric motor of the device overheats quickly

... There may be several reasons for the saw to heat up: high ambient temperature; poor ventilation of the engine when operating at low speeds; ventilation openings are blocked or obstructed; long-term operation of the unit under heavy load; increased rate of work by the apparatus without rest breaks; gearbox malfunction; lack of lubrication; damage to the motor windings. -

The machine makes an uneven cut

... This can be caused by blunt chain cutters or uneven tire wear. -

The chain remains stationary when the motor is running

... Most often, a breakdown occurs due to a failure of the clutch. Also, this malfunction can occur if the gears of the reducer and the drive sprocket are broken.

Causes of electric saw breakdowns

Any malfunction does not arise out of the blue. The most common reason is poor assembly and quality, as well as violation of the operating conditions of the electrical appliance. If you buy a good tool from a trusted manufacturer, it can be difficult to finish it off. Most often, electric saw repairs are needed for the following reasons:

- Voltage jumps in the network. If the electric saw has built-in fuses that protect against voltage surges, then the device will withstand fluctuations from 220 W by 10%, both in the lower and higher directions. If there is no protection, the saw motor will burn out.

- Failure to comply with operating conditions. If the instructions indicate that the device must be used in this mode - 30 minutes work, 15 minutes break - you must adhere to these manufacturer's recommendations. Otherwise, you risk overheating the motor, which will entail negative consequences.

- Untimely lubrication. Many models of electric saws are self-lubricating. You just need to make sure that the oil does not run out. Running the saw dry is death for the engine. If oil stops flowing to the sprocket, you need to lubricate it by hand every 3-5 hours of operation.

- Power overload. If this happens, it is also the user's fault, not the manufacturer's. When it is indicated that the electric saw can cut logs up to 5 cm in diameter, do not use a tool for a 10 cm trunk.

- Design flaws. Such a breakdown happens already through the fault of the manufacturer.Most often, users are faced with such a disadvantage as the rigid coupling of the gearbox with the armature. Under heavy load (hard log or dull tape), it wedges and heats up. As a result, the gears of the electric saw wear out quickly. In this case, you need to sharpen the tool in time and avoid overloading.

Any device is not eternal, and nothing can be done about it. Another working day shortens his life. There are cases when only a professional craftsman can handle a breakdown, for example, when the case is severely damaged. But most often it is possible to repair electric saws with your own hands. This is not so difficult as it seems at first glance.

Alteration of the electric saw

Chainsaw modifications are usually thought of when something is missing. For example, a milling machine. This will require:

- welding machine;

- adapter for cutters;

- steel flat roller;

- reducer.

The procedure is as follows. The wheel is welded at the end of the boom base, cutting off the boom so that the wheel exactly enters the cut contour to prevent tension or loosening of the chain. A removable adapter for cutters is attached to the wheel.

We hope that after reading the information briefly presented in our article, you will be able to independently eliminate minor faults that have arisen and operate this tool as a confident user.

DIY chain saw repair

First of all, when choosing an electric saw, it is necessary to take into account the following: the more its power, the more reliable and durable it will be in operation. Also, the saw will be less sensitive to possible voltage drops, which, unfortunately, are not uncommon in our country.

We will try to consider the most common breakdowns. It is worth noting that they are of varying complexity. For example, if the saw does not turn on, you may just need to check for electricity in the network. Or it could simply be the chain brake applied, blocking the operation of the saw. Try switching it to a different position. If, after that, the tool did not work, it is necessary to check the integrity of the cable and plug for the possibility of defects.

Quite often, when using an electric chain saw, its insufficient power is manifested, or, in simpler terms, the saw "does not pull". This is usually due to the fact that carbon brushes are highly susceptible to wear. In this case, they simply need to be replaced.

Another fairly popular problem that manifests itself after long-term use of the saw is a prolonged stop of the saw chain. For example, if earlier the chain stopped instantly, then over time it takes more and more time to completely stop it. This is often due to the fact that the saw brake band is also subject to demolition and must be replaced in order to avoid the possibility of damage in further work.

Sometimes it happens that when the electric saw starts to make an unpleasant sound, cutting the ear. This occurs if there is no oil on the saw chain. The reason for this trouble is most often the contamination of the oil supply groove. To eliminate the malfunction, it is required to pour oil into the oil tank and clean the oil supply groove from contamination.

It should be remembered that when performing any of the maintenance operations, disconnect the saw from the mains supply. The cooling holes must always be kept clean, watch out for this! It is recommended that you perform independently only those operations described in the instructions. Otherwise, the best solution would be to take the tool to a specialized service center.

When replacing any parts of the electric saw, use only original spare parts.When using in the device inappropriate accessories, non-original spare parts, elements of an unexpected length - conditions of increased danger are created.

Remember that it is best to entrust all types of repairs, as well as maintenance, to qualified personnel who will do all the work with high quality and as soon as possible.