Technical Recommendations

Before choosing a walk-behind tractor, or rather its model or belts, in order to repair the unit, it is worth first studying not only the characteristics of the equipment, but also the land plot itself, which will need to be processed in the future. If any spare part is selected correctly, the unit from the Salut company can easily cope with the following tasks assigned to it:

- hilling;

- harvesting;

- plowing sowing potatoes;

- fertilization;

- harrowing;

- landing.

In addition to the characteristics of the harvest harvested in the future, it is worth paying attention to the characteristics of the soil. If the ground is heavy, the machine must be equipped with a powerful alternator toothed belt.

Given its purpose, it is used to create a drive between the camshaft and crankshaft. If the tension is insufficient, the shaft may pop out. This will also reduce the actual power of the device.

Considering all of the above, we can conclude that the efficiency of the walk-behind tractor depends on the correctness and quality of the choice of any element of the system. At the same time, the manufacturer does not establish restrictions related to the selection of a spare part or its analogues.

This is interesting: the dimensions of the belt for the Oka walk-behind tractor.

Dimensions of belts for the Neva walk-behind tractor

When selecting the appropriate consumable, it is important to determine the number of the belt installed on the Neva walk-behind tractor model. To do this, the following recommended activities should be carried out:

- the old consumable element is dismantled from the walk-behind tractor using special tools and technology;

- then the device is checked for the presence of digits (usually there are values on the outer surface);

- as a rule, the belt number used for the Neva walk-behind tractor is white, blue or orange;

- if these figures are absent due to the long-term operation of special equipment, then the distance between the rotating elements is measured;

- then, using a special table (a table with values is posted on the manufacturer's website), determine the size;

- also, if necessary, the desired parameter can be clarified with the seller, since these data are also present in stores;

- after that, the same model is purchased, which will be freely mounted on rotating mechanisms.

Don't forget to choose the correct belt size

Don't forget to choose the correct belt size

It is recommended to rewrite the number from its surface after purchasing a new consumable item so that you do not search for values again later. The cost of this element is quite high, which is why it is necessary to accurately own the information.

Recommendations for use

In order for the components for the Cascade walk-behind tractor to wear out less, they use it carefully. Experienced summer residents advise:

- check the mini-tractor upon purchase for defects;

- carefully read the attached instructions in order to properly use and store the equipment;

- do not bend or stretch parts;

- do not keep the device in high humidity conditions;

- before use, sometimes check the pulley, remove it from scratches, chips, cracks;

- buy components only in reliable stores, choosing parts designed for a specific model and produced by the manufacturer of the agricultural machine;

- when one of the belts is worn out, immediately change the front and rear so that their condition is the same.

If the work on the site is not difficult, it is recommended to loosen the details. This will extend the life of the walk-behind tractor.

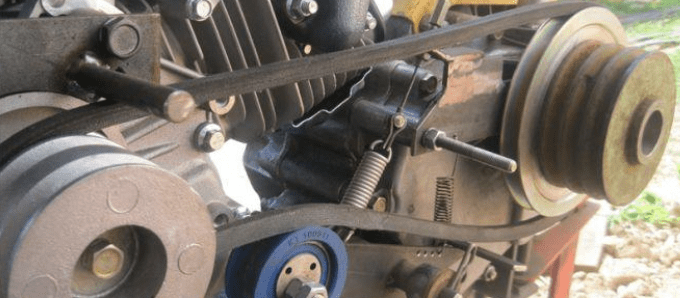

Service of drive belts

The V-belt is the main part of the clutch of the walk-behind tractor. Its service life depends on what kind of work the agricultural machinery is used for. As a rule, if the MB is used as a mover for a carriage, a mower or a drive for a mill or planer attachment, the rubber parts of the clutch mechanism can serve for several years. If the device is used for plowing and cultivating heavy wet clay arable land, the load on it is very large and several belts may wear out during the spring season.

For a long, trouble-free operation of the clutch mechanism, you must do the following:

- when filling oil and gasoline into the engine of an agricultural machine, it is not allowed to get technical liquids on the rubber parts of the mechanism. Petrochemical products destroy the rubber surface, belts wear out quickly;

- Do not press the forward and reverse movement levers at the same time. When pressed simultaneously, both belts are tensioned and jammed, the walk-behind tractor fails;

- do not operate agricultural machinery with cracks on the surface of the parts. During operation, pieces of rubber can fly out and injure the worker working on the walk-behind tractor;

- it is not allowed to install spare parts of a different size or profile. A short belt will quickly burn out from strong tension and pressing against the motor shaft, a long one will slip and the device will not be able to work. Installing a part with a smaller profile shortens the life of the clutch mechanism. A larger profile for installation and operation will require the removal of protective covers, which can lead to injury;

- the clutch must be correctly adjusted. Strong belt tension quickly destroys it; if it is weak, the engine will develop excessive power, which simply will not reach the transmission parts.

V-belts are an important part of the walk-behind tractor mechanism. The operation of the mechanism depends on their state. Self-replacement of the drive belt will require a common set of tools and is quite within the power of a gardener. Regular inspection, maintenance and timely replacement will protect your equipment from damage.

Belt selection rules

Motoblocks Neva have been produced by the St. Petersburg CJSC Krasny Oktyabr-Neva for over 35 years. On sale there are modifications MB-1, MB-2, MB-23 (with a Subaru engine), MB-2K and others. The devices are equipped with engines of different manufacturers and modifications. For each set, use their own type and size of V-belts on the Neva walk-behind tractor.

On a note! As a rule, the marking and the number of the necessary spare parts can be found in the service book attached to the walk-behind tractor.

To move the MB-1, you need two V-belts (forward and reverse). In the Neva MB-2 walk-behind tractor and its modifications, only forward gear is used, so only one belt is needed for it.

Rubber products for automotive and agricultural machinery are produced by many companies. The rubber products of the companies Gates, ContiTech and Optibelt have become world famous. In the Russian Federation, the products of the Balakovorezinotekhnika (BRT) and Rosteco factories are famous. All rubber products are unified in length and profile, therefore, parts from different manufacturers must be suitable for the walk-behind tractor. The price for parts depends on their profile, belt size and manufacturer and can be from 300 to 700 rubles.

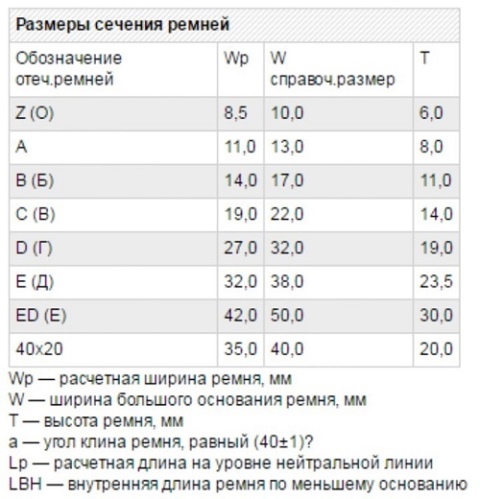

To choose a belt for the Neva walk-behind tractor, use the following table

| Modification of the device | Applicable parts |

|

Old MB-1 |

For the movement of vered, A-1180 VN-T GOST 1284.1-80 or GOST 1284.3-80 is used Reversing requires 0-1400T GOST 1284.1-80 or GOST 1284.3-80 |

|

MB-1 |

А53 length 1380 mm |

|

MB-2 |

А-45 13 * 1143 Li А1180Ld or А1180 GOST 1284.2-89 |

|

MB-2S-9.0 PRO |

A-46.5 A (1213) |

|

MB-3 |

А52 13 * 1320 Li А1350 Ld |

|

MB-23 |

А49 or А50 13 * 1270Li А1300Ld |

|

MB Compact |

А47 1200 Li А47 (1230 Prof А) |

|

MK-75 |

FSCOUZ36 |

|

MK-80 |

А37 13940 Li А979 Ld |

|

MK-80R |

Z 31 ½ 10 * 805 Li Z825 Ld |

|

MK-100 |

A 100 GOST 1284.1-89 |

|

MK-200 |

A 44 |

Knowing the name of the spare part, it can be ordered from a specialized workshop for the repair of agricultural machinery or purchased at a regular store selling parts for cars and agricultural machinery.

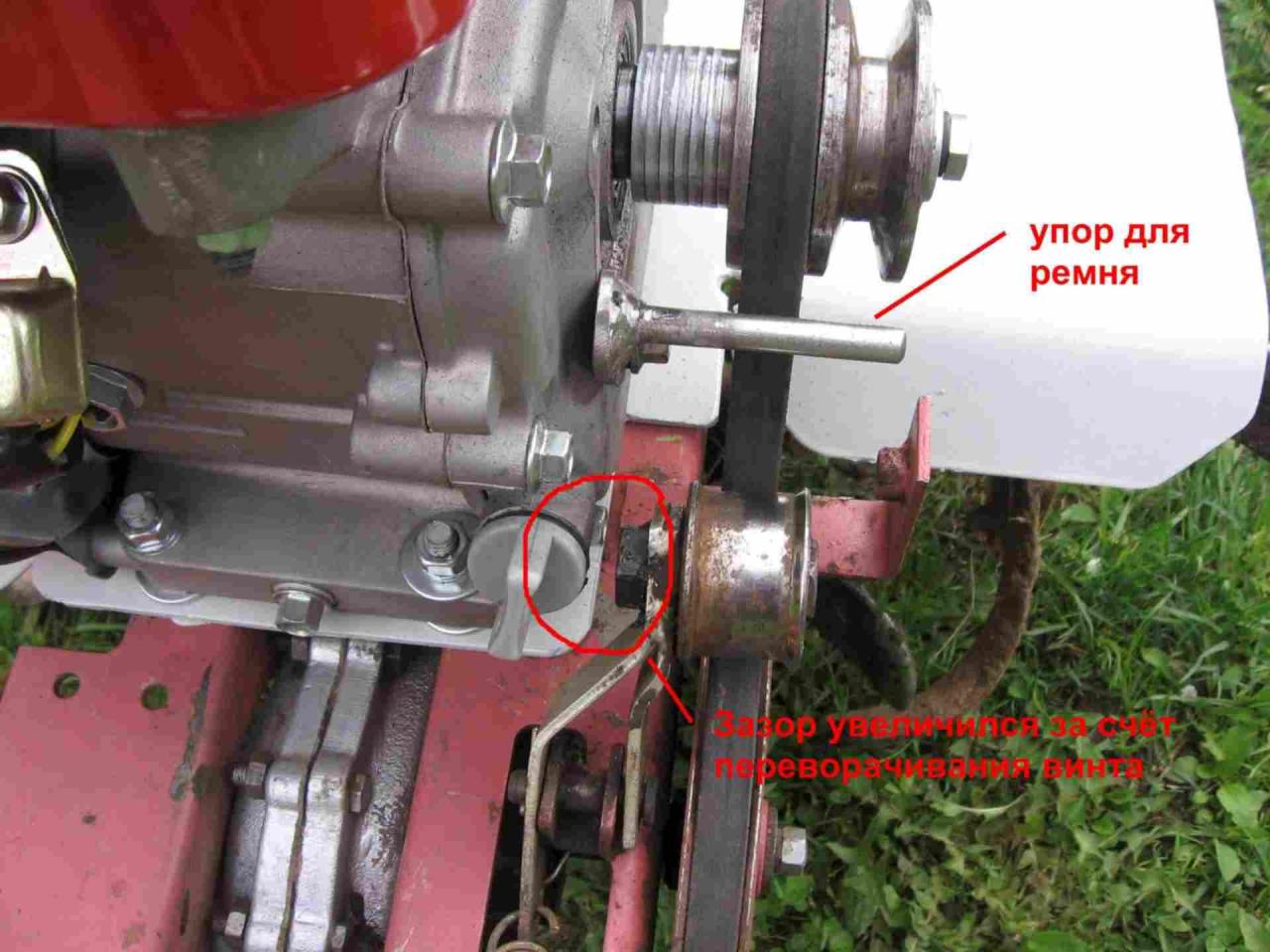

In order to tighten the belt on the "Neva" MB-2 walk-behind tractor, we need:

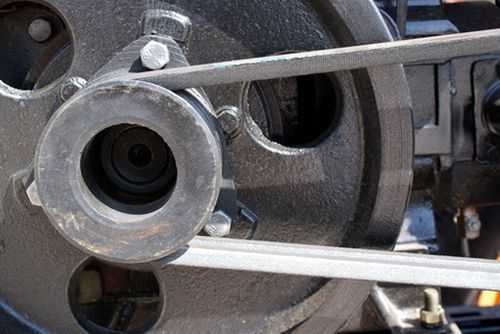

- inspect the pulley for contamination with soil particles and, if necessary, remove all excess from the installation grooves;

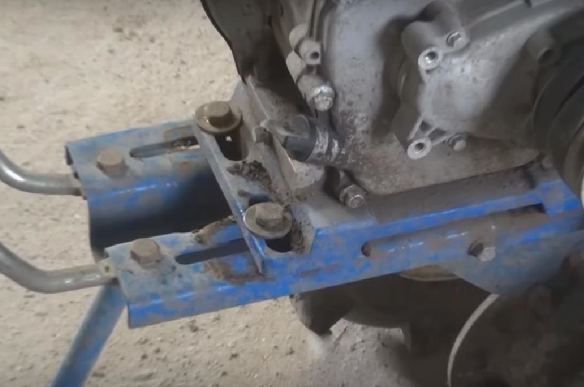

- using a universal wrench, unscrew the nuts, thereby freeing the frame on which the motor part is located;

we take an 18 mm wrench and put it on the thread of the adjusting bolt and turn it clockwise, thereby bringing the engine closer and pulling towards ourselves. It is advisable to periodically check the belts by hand: correctly tensioned, they spring easily and quickly return to their previous position under load. An overtightened belt is also a problem that will cost the bearing that holds the motor pulley;

- we check if there is a skew of the motor, which is often observed in these motoblocks. If this nuance occurs, loosen the adjusting screw one turn and fix the nut located on the opposite side of the case from the belt drive. This makes it possible, on the one hand, to accurately fix and immobilize it on the frame, and on the other hand, to leave it movable for alignment;

- tighten the bolts (4 in total).

The tension of the drive belt on the MB-1 walk-behind tractor looks somewhat different. It is produced using a clutch lever, which is most often installed on the left stick.

For the new MB-1 walk-behind tractor, which is just getting ready for operation, the course of action will be as follows:

- unscrew the clamp screw;

- we put the lever on the left side of the steering wheel, combining its fastening with the clamp fasteners;

- tighten the fasteners with a screw tie;

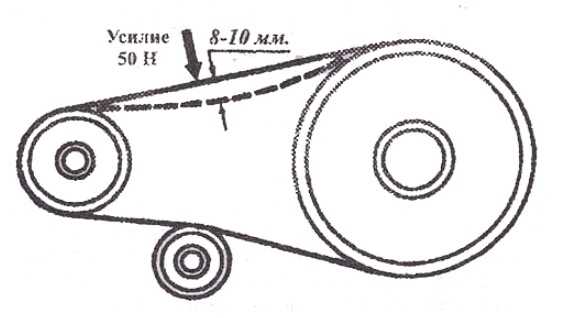

- while turning the clutch adjusting screw, we monitor its tension: with a load created by the fingers of the hand, the deviations should not exceed 10 mm.

Adjusting the belt on the Neva MB-1 walk-behind tractor after repair or replacement of the belt drive is reduced only to adjusting the clutch lever screw. Correct adjustment will be indicated by the immobility of the gear pulley when the engine is running and a slight slack in the belts when the clutch handle is lowered.

For motoblocks "Neva" MB-2 and MB-1, it is important to check the serviceability and tension the belt drives every 25 hours of operation. To increase the "lifespan" of these details will help:

To increase the "lifespan" of these details will help:

- elimination of pulley misalignment;

- installation of a damper;

- shortening the rocker arm or installing a longer reverse gear belt (for MB-1).

Replacing the V-belt

After purchasing a spare part, you can replace it yourself. This requires a set of keys. To preserve the edges of nuts and bolts, it is better to use socket heads. Each modification of the walk-behind tractor has its own characteristics, so the procedure for replacing spare parts is different.

Replacing worn-out parts on the MB-1 walk-behind tractor

On the old model of the walk-behind tractor, two belts are installed for forward and reverse movement. To replace them, do the following:

- agricultural machinery is cleaned of dirt;

- by unscrewing the mounting bolts, remove the protective cover;

- loosen the screws securing the guide plate, move it up;

- by pressing down the tension roller by hand, remove the worn parts. If it is required to replace the reverse belt with the MB-1 walk-behind tractor, first remove the forward gear;

- new parts are installed instead of worn-out ones;

- the guide plate is installed in place, the screws are tightened;

- install the protective covers in place;

- check how the belt moves along the pulleys, finally tighten the bolts and nuts of the protective casing.

On a note! Never use excessive force to tighten the guide plate fixing screws, as this can break the threads and destroy the motor housing of the unit.

Replacing the belt on the Neva MB-2 walk-behind tractor

On new motoblocks, the transmission of torque is carried out using one belt. To replace it, do the following:

- clean the mechanism from dirt and soil;

- unscrew the fastening bolts, remove the protective covers;

- weaken the fastening of the tension roller;

- remove the bracket;

- remove the worn out part;

- install a new belt.First, it is put on the motor shaft, then on the gearbox pulley;

- install the bracket in place;

- adjusting the belt tension by moving the bracket up and down;

- install protective covers in place;

- by rotating the pulley, check the ease of the belt, the absence of distortions;

- finally tighten the mounting bolts of the bracket and casings.

Features and functions of belts

If it will be easy to find a replacement for a worn-out link for a Chinese walk-behind tractor, then maintenance of the Perm mini-tractors Cascade is associated with certain difficulties. There are not many motoblocks of this brand on the market, but each of the models requires its own components. If you ignore the specifics of the model, the purchased belts will quickly break, and the device itself will break. Therefore, when choosing a new part, be sure to look into the instructions and look at the marking number on the worn out element.

Interesting! The drive V-belt for the Cascade is made of polyurethane or rubber.

This constituent element affects the quality of land cultivation. Its main function is to transmit motion. If stretching increases the length of the rubber ring, the tension becomes insufficient and the shafts begin to slip. As a result, the technique breaks down. In this case, the correct choice of new components will determine the service life of the entire cultivator.

Self-tensioning belts

After the new product and the looper are installed, it is necessary to tighten them, since the belt will immediately sag, which is unacceptable. This can shorten its life, the wheels will slip, and the engine can smoke when idling.

To tension, it is necessary to clean the pulley with a rag, and also loosen the bolts securing the engine to the frame, turn the adjusting bolt clockwise with a key of 18, tightening the device. In this case, you need to check the tension of the belt with the other hand so that it springs easily. If you overtighten it, it will also have a bad effect on the durability of the belt and bearing.

During installation, all work must be done in stages and carefully to avoid the risk of damage to the consumable element. This can lead to its breakage or premature failure of the drive.

Processes demonstrating the erroneousness of actions:

- vibration of the body during movement;

- overheating of the belt at idle and smoke;

- wheel slip under load.

After installation, it is necessary to run in the walk-behind tractor without loading it so as not to damage the structural elements. When operating the walk-behind tractor, tighten the gear attachments every 25 hours of operation. This will help prevent rapid wear on the pulleys and ensure smooth movement of the unit itself.

How to install the second belt on the Neva walk-behind tractor, see the video below.