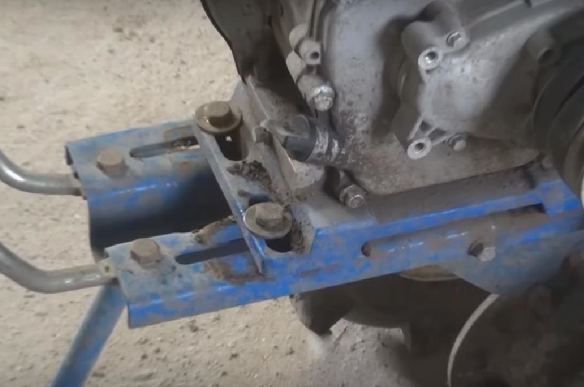

Tensioning with an adjusting bar

Fastening the generator with a bar

This method is used for older vehicles (for example, “classic” VAZs). It is based on the fact that the alternator is attached to the engine with a special arcuate bar and a bolt and nut. By loosening the fastener, you can move the bar with the generator relative to the engine at the required distance, thereby adjusting the tension level.

Actions are performed according to the following algorithm:

- unscrew the fastening nut on the arcuate bar;

- using a mount, we adjust the position (move) the generator relative to the engine;

- tighten the nut, fixing the new position of the generator.

The procedure is simple, it can be repeated if you did not manage to achieve the required level of tension the first time.

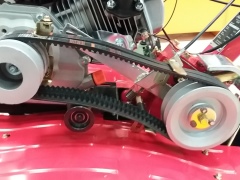

Roller Tension Adjustment

Adjustment roller and key to it

Some modern machines use special adjusting rollers to adjust the belt tension. They allow you to quickly and easily tension the belt. As an example of using this method, consider adjusting the belt on a Lada Priora car with air conditioning and power steering, as one of the most popular cars in our country.

How to tension the alternator belt on the "Prior"

The tensioning of the alternator belt on the Lada Priora car is carried out using a special tensioning roller, which is part of the structure. For work, you will need a 17 key to unscrew and fix the mentioned roller again, as well as a special key for turning the adjusting roller (it is a structure of two rods with a diameter of 4 mm welded to the base, the distance between the rods is 18 mm). Such a key can be bought at any car dealership for a symbolic price. Some car owners use curved pliers or "platypuses" in their work. However, we advise you to buy an adjusting key, given its low price and convenience in further work.

Voltage regulation process

To adjust with a 17 key, you need to slightly unscrew the fixing bolt that holds the adjusting roller, then use a special wrench to turn the roller a little in order to increase (most often) or decrease the belt tension. After that, fix the adjusting roller again with a 17 key. The procedure is simple and even an inexperienced car owner can handle it

It is only important to choose the right effort

After you have completed the tension, you need to check. To do this, start the engine and turn on the maximum consumers of electricity - high beam, heated rear window, air conditioning. If they work properly, and the belt does not whistle, then you have performed the tension correctly.

The automaker recommends tightening the belt every 15 thousand kilometers, and replacing it every 60 thousand. Also, do not forget to check the tension periodically, as the belt tends to stretch.

Tensioning the alternator belt on "Prior"

Another method of tensioning the alternator belt on "Prior"

You will find detailed information on the process of replacing the alternator belt on the Lada Priora car in the corresponding material.

How to tension the alternator belt "Ford Focus"

On different modifications of Ford Focus vehicles, one of two belt tension adjustment systems is used - with the help of an automatic or with the help of a mechanical roller.In the first case, operation is much easier for the owner, since the belt is tensioned using built-in springs. Therefore, the driver only needs to periodically replace the belt (independently or at a service station).

In the case of a mechanical roller, tensioning must be done manually using locksmith tools - pry bar and wrenches. The design of the roller mechanism may also vary. However, the essence of the procedure boils down to the fact that it is necessary to slightly loosen the fastening of the roller, stretch it and fix it again. Also, in some modifications of "Ford Focus" (for example, "Ford Focus 3") there is no tension adjustment. That is, if the belt slips, it must be replaced.

Note! Buy original belts, as often non-original belts have a slightly larger size, because of which, after installation, it will whistle and warm up.

We suggest that you familiarize yourself with the material, which presents the procedure for replacing the alternator belt on a Ford Focus 2 car - article.

How to choose the size of belts for Neva walk-behind tractors?

To ensure a good tension and a long service life of not only the entire drive transmission, but also the transmission, the belt size must be precisely matched to the specific model of the Neva walk-behind tractor. Too long belts, as well as too short belts, will quickly wear out and create an additional load on the gearbox or motor.

It is not difficult to deal with this problem, having at hand a detailed table with dimensions presented below.

For the most popular Neva models you will need:

- drive belt type A-1180 - only for MB-2;

- 2 reverse and forward belts - Z (0) -1400 and A-1213 - for MB-1.

Craftsmen have learned to put belts on such motoblocks and automobile type: AVX 13 × 1175, YaMZ-8401 from BelAZ, YaMZ-238AK, YaMZ-8401 and even from Don brand combines. Experts advise that the size of the selected belt, even if it is not original or not the one recommended by the manufacturer, does not deviate from the permissible value by more than 0.5-1%.

In addition to the above, before buying, it is necessary to externally check the belt: it should not have defects, scratches, protruding fibers, bends that can harm the cultivator during operation. The belt is considered to be of high quality if it retains a clear factory pattern and does not stretch by hands.

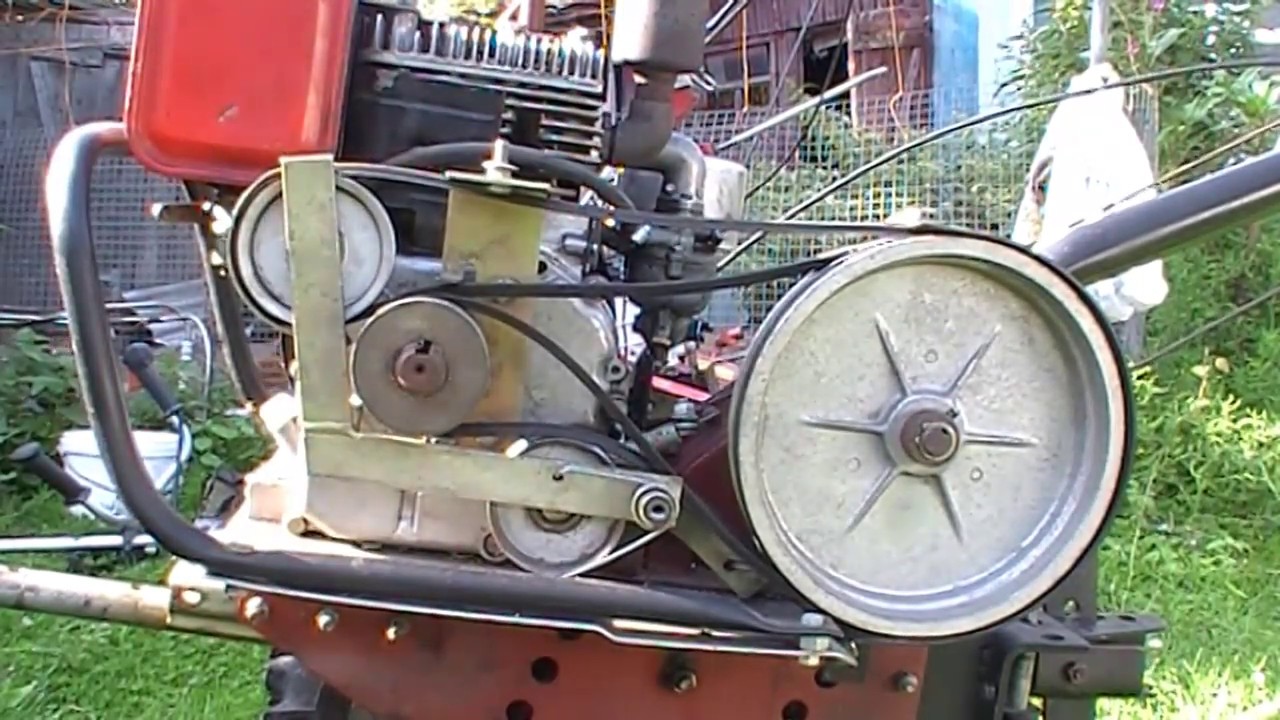

How to change the belt

One of the most common breakdowns of a walk-behind tractor is associated with rupture or wear of spare parts. This situation often arises if the machine is mainly used for cultivating or plowing a land plot. If there is a breakage, the first thing to do is to put the cultivator in neutral and move it to the place where repairs will be carried out in the future. If this is not possible, it can be repaired on the spot.

Next, you need to prepare the necessary tools that will be needed in order to disassemble the part of the apparatus where the tension roller and pulley are located. Now the master proceeds to remove the protective casing and old worn out parts. If the belts have not broken, but are very worn out, they can simply be cut with large scissors or a knife. After these worn out elements are removed, you can start installing new ones.

If this is a Salute walk-behind tractor, which provides for two transmission belts, one of which remained intact, it will still have to be replaced, and there are reasons for this. This situation is explained by the fact that when using a new and old belt, they will differ in different degrees of tension during clutch engagement. This means that the main load will be transferred to the newly replaced structural member.

Thus, it will not last as long as stated by the manufacturer. Therefore, experts advise to immediately purchase two spare elements of this system in order to immediately repair the device if necessary.In order to facilitate the work of the master, you can remove the pulley from the motor drive shaft. Next, one or both belts are put on a pulley located on the gearbox shaft of the unit.

Do not forget to choose a suitable belt for the Salute walk-behind tractor

When the preparation before installing these elements has been done, you can put the transmission belts on the pulley and then install it on the motor shaft. In this case, do not forget about installing the key. If this is not done, the pulley will have to be removed again, since without it, the pulley will not rotate during the rotation of the drive shaft. When installing the belts, they are wound from the top of the tension roller.

Working at high speeds

Expensive models of walk-behind tractors are characterized by the presence of several operating speeds. On the one hand, this option makes it possible to optimize the process of planting, harvesting or processing the field. On the other hand, the functioning of cultivators largely depends on the quality of the belt. The first thing to remember is that the length of the product always meets the requirements specified in the passport. In second place is the requirement related to strength.

Constant switching of speeds does not have the best effect on the operation of the device. That is why it is worth abandoning the use of cheap and not always high-quality belts.

A cultivator is a technical tool that performs the following functions:

- weed control;

- plowing the soil;

- loosening;

- application of various fertilizers to the ground.

During intensive use, some units and parts of the unit may be damaged

... Therefore, it is necessary to purchase the necessary spare parts in advance (it is possible on the day of purchase of the cultivator itself). This will allow it to return to functionality immediately after a breakdown.

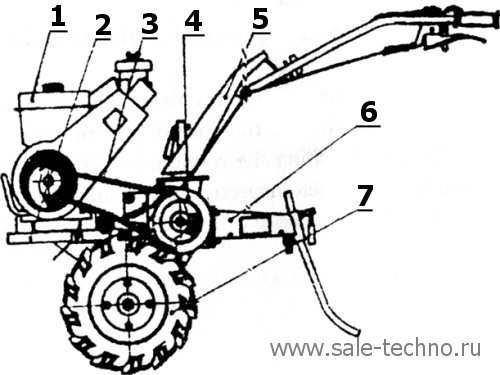

The main elements of the cultivator are a gearbox, levers, a fuel tank, a frame, a motor, a support, a wheel, as well as a working tool knife. The transmission of torque is provided by a gearbox, which is built into the engine.

The machine knives are designed to cut layers of soil, mix and grind them easily. Device management is effortless.

The outstanding representatives of the same reliable and high-quality equipment are cultivators, and.

For more information about the work of the Mole cultivator, see the video:

All this contributes to the intensive growth of plants and obtaining large yields.

The mole is a model of the Soviet and Russian cultivator, which began to be produced back in 1983. Its production was established Moscow Machine-Building Enterprise. Chernysheva.

It is a leading company in the military-industrial complex, employing the best specialists in the country. Now the production of the Krot cultivator has also been established in the city of Omsk.

Today the complex includes several productions:

- foundry;

- galvanic;

- blacksmith;

- mahano-assembly;

- welding.

The main features of the Mole cultivator have always been increased engine life and operational reliability

.

If any parts fail, they must be replaced with new ones. The most popular spare parts for a walk-behind tractor are housings, spare knives, motors, gearboxes. The engine on the Mole is installed with a capacity of 4.5 hp.

If the gearbox is built into a sealed housing, when repairing the device, you will have to change the engine, including. Modern walk-behind tractor models equipped with both gasoline and diesel engines

.

Old-style devices need to be repaired much more often than newer models. This explains the demand for old-style parts.

For example, if the device needs fuel cap

, spark plug cap or starter pawl, it will take time to find the right part.

Belt

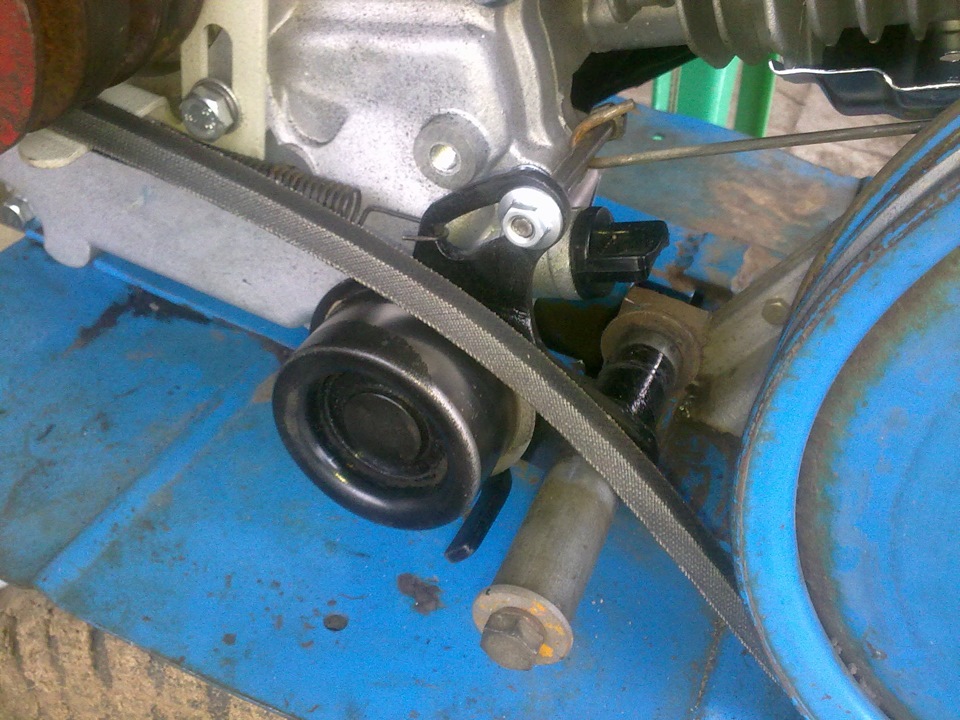

From time to time, when operating the Mole walk-behind tractor, you can notice belt slippage.

This problem can be avoided by installing 2 belts. Correct installation requires an oversized idler pulley with a driven pulley.

The roller is placed on bearings. To improve the cultivator, you just need to remove the old roller and install a new one.

The unit uses drive belt A-750.

It is 750mm long, 8mm high and 13mm wide.

Product composition:

- cord;

- wrapping layer;

- technical vulcanic rubber.

The main task of the belt is to transfer torque from the motor to various components of the device. The belt is marked according to the size (mm). It can be used at temperatures from +30 to +60 degrees.

Used in traditional drives, used in agricultural units. The belt is one of the the most important elements

cultivator. Genuine belts are required for the device to operate at full capacity.

The belt for the Mole 710 cultivator is installed on units with a Russian engine. The product profile is 13 mm.

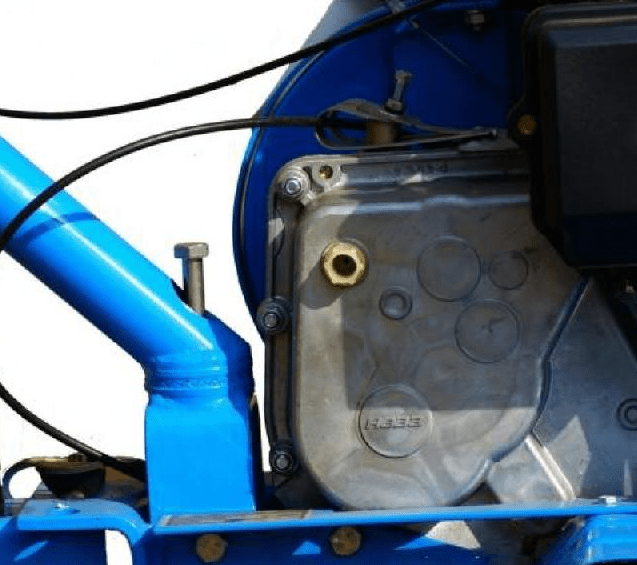

Engine

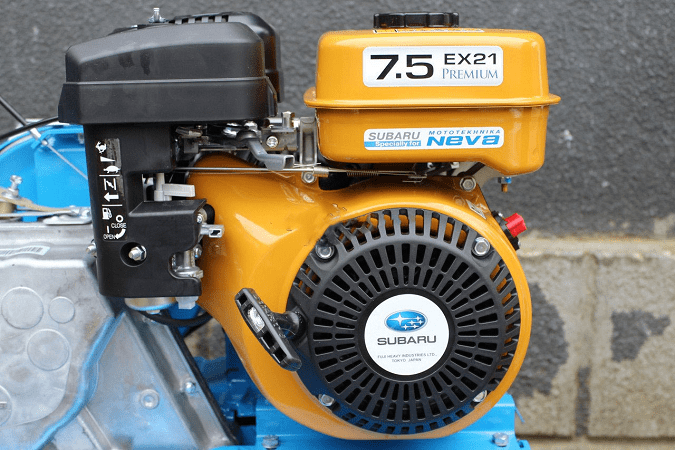

Depending on the modification, the Oka walk-behind tractor is equipped with engines from different manufacturers (DM-1M, DM-1M1, MITSUBISHI GT600 6.0 / 4.4, I / C 6.0 HP 6.0 / 4.4, Honda GX-200 6.5 / 4.8, Lifan 168 F-2A 6.5 / 4.8, Vanguard 6.5 HP 6.5 / 4.8, Lianlong 168F-1A 6.5 / 4.8, Robin subaru ex 17 6.0 / 4.4, Robin Subaru EX21 7.0 / 5.2, KADVI 168F-2A).

Lifan LF177 engine

One of the popular modifications is the "Oka" with a Lifan engine. This engine is economical, and its functionality allows it to be installed in small-sized equipment (cultivators, walk-behind tractors). Lifan is made in China, has established itself as a durable and reliable engine.

The choice of the model is made depending on what area of land the operator is going to cultivate using the walk-behind tractor, as well as on the main tasks (plowing, cultivation, digging out potatoes, etc.) that the device will perform.

Engine malfunctions

Let's see why the engine on the "Oka" walk-behind tractor can junk? So, the main reasons that the engine does not work, and the walk-behind tractor does not start, may be as follows:

- insufficient fuel or oil;

- low-quality gasoline;

- clogged fuel or oil filter;

- a problem with candles or oil seals (oil leaks; candles need replacement);

- the angle of inclination is exceeded when setting the walk-behind tractor (more than 15 degrees, start the walk-behind tractor on a flat surface);

- the integrity of the wiring is broken;

- rupture or delamination of transmission belts;

- poor tire pressure in combination with any of the above reasons;

- an attempt to start the engine without warming up;

- too low storage temperature of the walk-behind tractor, as well as a big minus on the street when starting the equipment (store the walk-behind tractor in a warm room; in freezing temperatures, pour warm oil into the engine and gearbox).

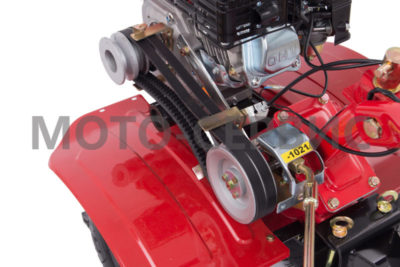

How to change the belt on the Neva walk-behind tractor?

The simplicity of the basic device of modifications MB-1 and MB-2 allows you to replace faulty drive elements without asking for help from a specialized workshop.

This will require:

Carefully remove the old belt, taking care not to damage the tension rollers and other important parts located nearby

To do this, it is necessary to sequentially dismantle the protective shield and the main factory casing, built-in for additional belt protection;

Carefully remove the spring from the structure, which is necessary to tension the drive element;

Unscrew fasteners in the form of screws and standard stoppers, which are used to hold the belt on the standard engine pulley;

Inspect the location of the shaft handle of the power unit and the gearbox - they must be strictly in the same plane

In the Neva MB-1 and MB-2 walk-behind tractors, deviations in the arrangement of the handles are possible by no more than 0.1 mm;

If there is such a need, adjust the position of the pulleys by carefully moving the engine in its longitudinal plane;

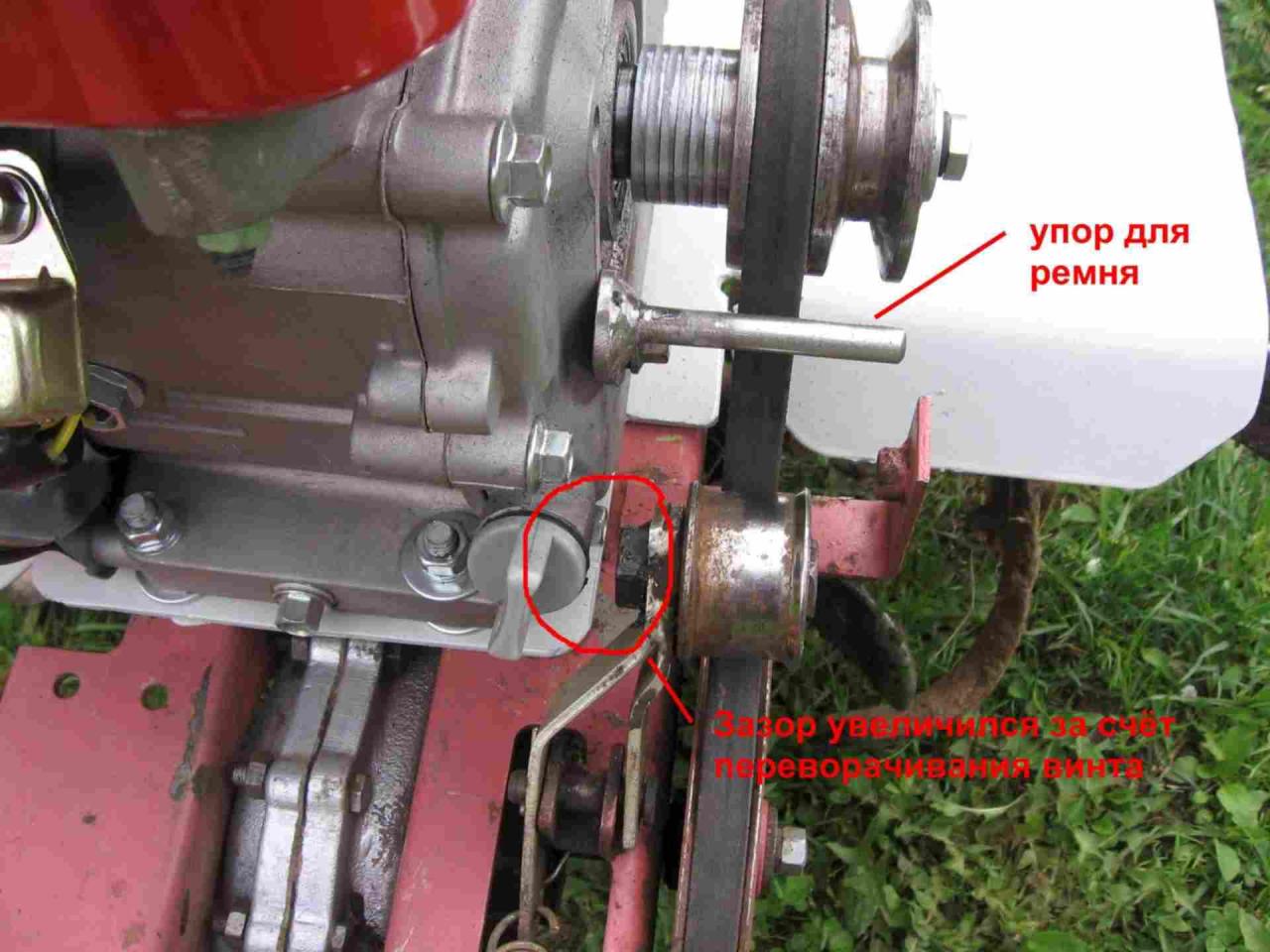

Adjust the installation location of the idler pulley - this is necessary for a suitable tension of the belt being installed;

Install a new drive element - it is important to start putting the belt on the side of the gear part of the walk-behind tractor. The video will tell you in detail about the replacement of the drive element with your own hands.

The procedure for replacing belts is the same for both the Neva MB-2 walk-behind tractor and its counterpart MB-1

In each case, before installing a new element, it is important to inspect the installation site and thoroughly clean it of debris, if necessary.

Belts on the neva walk-behind tractor features dimensions tension

The dimensions of the belt for the Neva walk-behind tractor are information that every owner of this equipment needs. Belt type, length, tension and adjustment, V-belt transmission malfunctions - questions with which we will try to figure it out in this article.

When writing this article, I came across one interesting fact: information on the types and sizes of belts for Neva walk-behind tractors and others on the network is presented mainly by online stores that offer to buy their goods. At the same time, mistakes are very common.

Therefore, when buying a belt, you need to be very careful and focus on the operating instructions for your walk-behind tractor. The data on this page are collected from catalogs from Red October and from the instructions for walk-behind tractors.

There are a large number of modifications to Neva walk-behind tractors. It happens that there are different belt sizes for the MB-2 walk-behind tractor with different engines (see lines 3 and 4 of the table below)

Table of applied belts for motoblocks and cultivators Neva

| Type of motoblock Neva | Belt type |

| MB-1 old modification | Drive belt A-1180 VN-T GOST 1284.1-80 - GOST 1284.3-80 (forward) Drive belt 0-1400T GOST 1284.1-80 - GOST 1284.3-80 (reverse) |

| MB-1 | A53 (1380) |

| MB-2 | А-45 13 × 1143Li A1180Ld or А1180 GOST 1284.2-89 |

| MB-2S-9.0 PRO | A46.5 A (1213) |

| MB-3 | А52 13х1320 Li А1350Ld |

| MB-23 | А49 (data differ in different catalogs) A50 13 × 1270Li A1300Ld |

| MB Compact | A47 (1200 Li A47 (1230 prof A)) |

| MK-75 | FSCOUZ36 |

| MK-80 | А37 13940 Li А 970 Ld |

| MK-80R | Z31 1/2 10x805Li Z825Ld |

| MK-100 | A-100 GOST 1284.1-89 |

| MK-200 | A44 |

Applicability table of pulleys and belts on Neva MB 2 walk-behind tractors

| Modification | Engine | Belt type | |

| Model | Ø to / in | ||

| MB-2K-6.2 | DM-1K (ZAO Krasny Oktyabr-Neva) | Ø25 | А1180 GOST 1284.2-89 or А45 13 × 1143Li А1180Ld |

| MB-2K-7.5 | DM-1K-7.5 (ZAO Krasny Oktyabr-Neva) | Ø25 | |

| MB-2B-6.0 | I / C 6.0 (Briggs & Stratton) | Ø19 | |

| MB-2B-6.0 PRO | Vanguard 6.0 (Briggs & Stratton) mod 117 | Ø19 | |

| Vanguard 6.0 (Briggs & Stratton) mod. 118 | |||

| MB-2B-6,5 PRO | Vanguard 6.5 (Briggs & Stratton | Ø19 | |

| MB-2B-7.5 | Vanguard 7,5 (Briggs & Stratton) mod. 1384320190Е1DD1001 | Ø19 | |

| Vanguard 7,5 (Briggs & Stratton) mod. 1384320162Е1DD1001 | Ø25.4 | ||

| MB-2B-5.5M | I / C 5.5 (Briggs & Stratton) | Ø19 | |

| MB-2N-5.5 | HONDA GX200 | Ø19 | |

| MB-2B-6.5 | I / C 6.5 (Briggs & Stratton) | Ø19 | |

| MB-2S-6.0 PRO | EX17 (Robin SUBARU) | Ø19 | |

| Ø20 | |||

| MB-2S-7.0 PRO | EX21 (Robin SUBARU) | Ø19 | |

| Ø20 | |||

| For more details on the types and sizes of used belts, pulleys and cables for motoblocks and cultivators Neva of other modifications can be found here |

Download the application table of pulleys and belts for Neva motoblocks of various modifications with various engines: tablica-skivov-remnei2013.xls

V-belts designation

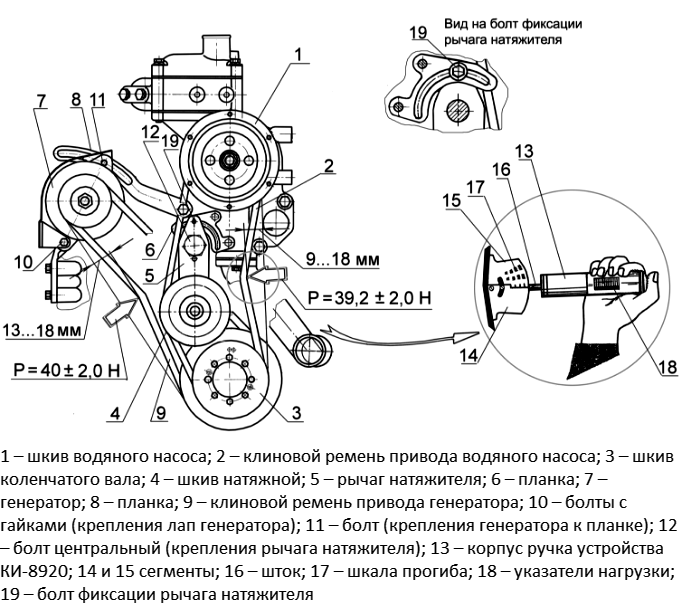

The V-belt transmission of the MB-1 and MB-2 walk-behind tractors performs the function of a transmission and a clutch mechanism and provides:

- transmission of torque from the engine crankshaft to the gearbox input shaft:

- disconnecting the engine from the gearbox during gear shifting and smoothly connecting them again, excluding sudden changes in the load on the engine:

- smooth starting of the walk-behind tractor and stopping it without stopping the engine.

V-belt transmissions of MB - 2 and MB -1 walk-behind tractors are structurally different, which is caused by the use of gearboxes of various types in them

Possible V-belt transmission malfunctions

| The nature of the malfunction | Possible reason | Elimination method |

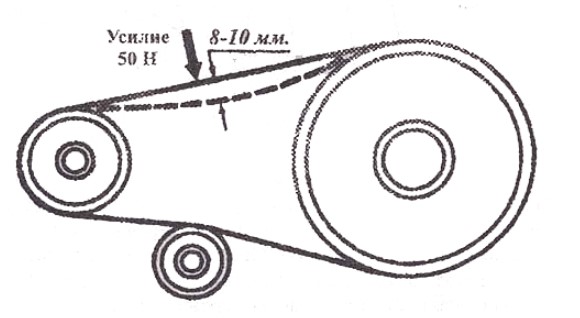

| Incomplete clutch release | Belt tension when the clutch lever is pressed is more than normal | Set the normal tension of the belt with the clutch lever pressed, providing the deflection of the upper belt branch within 8-10 mm when a force of 5 kgf is applied to its middle part between the pulleys. |

| Incomplete clutch engagement | 1.The tension of the belt when the clutch lever is pressed is less than normal 2.The stratification of the belt | 1. The same

2. Change the belt |

Checking the tension and adjusting the belt of the Neva walk-behind tractor

Carburetor adjustment

The carburetor valves of the walk-behind tractor need periodic adjustment. Violation of the norm of the distance between the valves causes a change in the frequency of the stages of gas distribution, as a result, the engine does not reach the declared power. If the gap is large, noise appears, the valves themselves are deformed.

As soon as during the operation of the walk-behind tractor, any extraneous noise appears in the engine, the carburetor should be adjusted. To adjust, a screwdriver, a wrench and a blade are required (after all, the valve clearance rate is from 0.1 mm to 0.15 mm).

On MB-1D walk-behind tractors, a carburetor model DM 1.08.100 of the membrane type is used. The external view of the carburetor DI1.08.100 is shown in the figure below:

The appearance of the carburetor DM1.08.100

1 - full throttle screw; 2 - low throttle screw; 3 - air damper lever; 4 - screw of minimum speed; 5 - flange; 6 - dosing device; 7 - branch pipe; 8 - tide: 9 - hairpin; 10 - nut; 11 - inlet fitting; 12 - button.

The adjustment is done as follows:

- unscrew the valve nut with a screwdriver,

- insert the blade and tighten the nut.

- Once the process is over, the carburetor shroud slides into place.

Replacement and customization

The flexible element of the belt drive on the walk-behind tractor can be independently replaced and adjusted.

The V-belt transmission reliably communicates the force from the motor, but over time the belt wears out, cracks and tears form on it.

The task of changing it appears. This can be done at special service centers. This is the most correct choice, but it will cost a lot. You can make a replacement yourself, and if you have repaired your car at least once, you have experience working with equipment.

1. Remove the used flexible element

First of all, remove the plastic protective cover by unscrewing the fixing nuts. After that, the belt of the units is removed by relaxing the tension between the pulley (friction wheel) of the gearbox and the motor.

On some modifications, there are specialized devices for tensioning and loosening belts. But usually this mechanism is absent in walk-behind tractors. To loosen the drive belt tension, loosen the motor fixing nuts (4 pieces) and move it to the right. Then we remove the belt. Do not forget to move the motor to the right (left) side to tighten (loosen) the product only within 20 millimeters.

2. Putting on new products

The installation of a new unit belt is carried out in the reverse order. Then you need to pull it, taking into account its obligatory sagging by 10-12 millimeters. Be sure to check the alignment of the gearbox and motor friction wheels. We wrap the nuts of the motor fasteners diagonally.

When not in operation, the belt should rotate without difficulty on the input shaft, but not jump off it. To bring the belt of the aggregates to the working status, the clutch handle is squeezed out, the cable lifts the pressure shaft upward, pulling the belt.

3. Self-tensioning

When the new product and the loop former (damper) are mounted, they need to be tensioned and adjusted, since the belt will immediately bend, which is considered unacceptable. This can shorten the duration of its use, the wheels will start to slip, the engine will start to smoke at idle.

To perform tension, it is required to clean the friction wheel with a rag, and also to loosen the bolts fixing the motor to the chassis, with a key of 18 turn the adjusting bolt in the direction of movement of the clock hand, tightening the device. At the same time, it is necessary to try the tension of the drive belt with the second hand so that it springs freely. If you overtighten it, it will also have a detrimental effect on the reliability of the bearing and belt.

Upon completion of mounting and tension, check for distortions. The new product must be level and free from kinks and distortions.

Processes that demonstrate installation and tension errors:

- vibration of the body during movement;

- overheating of the drive belt at idle speed, smoke;

- wheel slip during operation.

The size of belts for the walk-behind tractor Cascade and the procedure for replacing them

Different machines use belts of different sizes.So, for the Cascade walk-behind tractor, belts A-1180 or A-1213 GOST 1284 are used for forward gear, and belts A-1400 are used for reverse gear. The prefix "A" stands for 13 mm.

Before proceeding with the removal or replacement of the belt, it is necessary to dismantle the protective casing, unscrew the pulley, which has three streams, it is attached with a key and a retaining ring to the shaft. When removing the ring, you need to be vigilant so as not to break it. The material from which it is made is very fragile.

Next, you should move the reverse belt pulley forward to pull off the three-ribbed pulley, after which we can remove the belt without interference. If it is just badly worn, you can cut it off with a knife.

Next, we check the belts and, if necessary, replace them with exactly the same ones. If there are two of them on the walk-behind tractor, then it is better to replace both at once. If you replace only one belt, they will have a different degree of tension, and a new one will take a large load on itself, which will lead to its rapid wear.

We begin to collect everything in the reverse order. We tighten the belts on the gear pulley, then install the motor pulley, check the tension rollers and make sure that the belts are installed evenly, without distortions. Do not forget to replace the protective covers and secure them.

A high-quality belt for a walk-behind tractor will ensure reliable operation of the device for processing crops. Depending on the intensity of use and the power of the unit, a suitable alternator belt must be selected. It will be a mistake to buy the first belt for a walk-behind tractor, which will be recommended in the store. The increased physical characteristics of the unit will not improve its operation if the walk-behind tractor itself is not designed for such a thing.

As mentioned above, a careful study of the characteristics of the walk-behind tractor and the field that needs to be processed will help to avoid many problems.

If the belt for the walk-behind tractor-cultivator is selected correctly, then the device will cope with the following tasks:

- plowing of potato crops;

- harrowing;

- landing;

- hilling process;

- fertilization;

- harvest.

In addition to the characteristics of the crop being harvested, the nature of the soil must be taken into account. If we are talking about heavy soil, then a powerful toothed belt of the generator is selected for the walk-behind tractor

For its purpose, it is used to create a drive between the crankshaft and the camshaft. In case of insufficient tension, the shafts literally slip out. The actual power of the device decreases.

The diametrically opposite process is also dangerous. Prolonged increased loads on the drive of the walk-behind tractor lead to accelerated wear of the running elements. All of the above suggests that the efficiency of the cultivator depends on the quality and correct choice of the belt. At the same time, there are no restrictions associated with the choice of original spare parts or analogs.

The key parameter is the size of the part and the required power. The specified parameters are presented on the belt packaging and in the technical description. The direct manufacturer of the walk-behind tractor will help find certain information.

How to replace drive belts on motoblocks "Neva" MB-1 and MB-2: step by step instructions

Based on the differences in the location of the belts on these two walk-behind tractors, we will consider the processes separately.

For "Neva" MB-1:

- we disconnect the shield, for which 2 bolt ties are unscrewed and the protective cover is removed from the gear pulley;

- do not completely unscrew the connection of the guide pulley;

- smoothly remove the reverse belt;

- we loosen the ties, move the stop pins and remove the front gear belt;

- we take new serviceable belts and apply them to the grooves of the required pulleys. After that, we fix them with bolts that were removed in the previous steps.

"Neva" MB-2:

- detach the shield and casing;

- be sure to remove the spring that provides tension;

- we unscrew the screw fasteners and unscrew the stoppers that hold the belt on the motor pulley. Before proceeding to the next step, you must make sure that the grooves of the motor shaft and the gearbox are in the same plane. According to instrumental measurements, the non-flatness between them should not go beyond 0.01 cm;

- adjust the pulleys if necessary. The easiest way to do this is to move the motor in the longitudinal plane;

- adjust the tension pulley by adding or removing the element located between the disc and the bracket;

- we install a serviceable belt to the "Neva" MB-2 walk-behind tractor, starting from the gear part.

The further assembly of the V-belt mechanism is carried out in the reverse order of the parsing process. An important point that is often overlooked by users is the deviation in the range between the guard and the harness. According to the technical documentation, it should be at the level of 2-3 mm.

Causes of wear

Belts fray and tear for many reasons. The main provoking factors are as follows:

- rearrangement or misalignment of the pulleys after replacing the motor (the belt bends, erases against the edges);

- cuts, scuffs, scratches and other mechanical damage arising during operation;

- defective parts, which are indicated by a ring rupture with a correctly tuned mechanism;

- setting the damper too close to the pulley.

It will not be enough for a farmer using agricultural machinery to be able to replace worn out parts of a mini-tractor. He should understand the reasons for the breakdown so that he can prevent them in the future. By fixing the root cause of the gap, the cultivator owner will not spend money on buying new parts as often.

Outcomes

The Mole motor-cultivator is a proven device for mechanical tillage.

It allows you to perform many functions. The appearance of a malfunction is not a reason to worry. Anyone with a minimum of technical knowledge can fix this model on their own.

Each owner of a walk-behind tractor needs to know what characteristics the belt used for the operation of the device has. Units "Neva" differ in some features, so this should be taken into account when choosing a new belt for a walk-behind tractor.

When buying a part, you need to carefully study the instructions provided for the technique.

There are many modifications of this walk-behind tractor (MB-2, MB-23, etc.). Each device has its own type of belt. Basically, the MB-1 walk-behind tractors are used - old-modification motor-cultivators. It should be noted that the functioning of the MB-1 and MB-2 devices is based on the V-belt transmission mechanism. This system ensures the movement of the unit forward and backward, respectively, without its help the device simply will not work. The MB-1 motoblocks have a built-in V-belt transmission of both moves. In MB-2 releases, only one forward gear is used. Based on this, in order to choose a belt for the Neva walk-behind tractor, you should stock up on the following data:

- you need to know the type of belt that matches your particular model of the unit;

- belt length;

- the degree of tension of the part;

- type of V-belt transmission (for certain modifications).