Types of gearboxes for brushcutters

The design of the gearbox for the utility trimmer consists of a certain number of built-in gears, which, during the operation of the mechanism, rotate at a speed set by the device. Gear drives are designed to decrease or increase the initial speed of a running input shaft. Thus, when the operator pushes on the accelerator, the mowing reels or cutting blade rotates faster, and when the lever is released, it rotates more slowly.

Gearboxes used by manufacturers of garden equipment are divided into the following types:

- cylindrical;

- wave;

- worm;

- planetary type;

- conical;

- spiroid;

- mechanisms of the combined type.

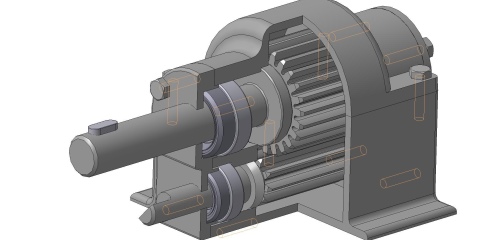

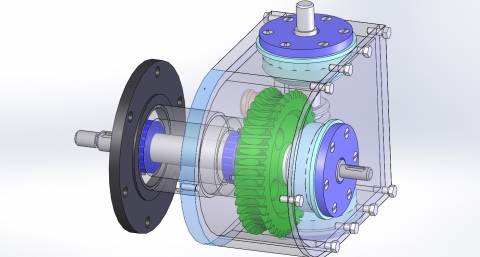

The cylindrical gearbox of the brushcutter consists of several toothed cylinders. They are rarely installed on trimmers, since most petrol cutters are equipped with worm gearboxes.

Special attention should be paid to planetary gearboxes. Their built-in shafts are coaxially located in the mechanism. At the same time, the shafts of the bevel gearboxes are in a cross position.

Another type of gearboxes is a reduction gear. Mechanisms of this type are not included in the standard equipment of brushcutters, but they are almost always used for making homemade products based on garden trimmers.

How to choose the right lubricant

During operation, the units of the mechanism are loaded by contact forces on the teeth, resistance reactions when debris gets in, as well as dynamic and shock loads. Depending on the characteristics of the load, you should choose how to lubricate the trimmer gear.

The selection should take into account the following factors:

- manufacturer's brand;

- the viscosity of the lubricant (the selection of this parameter depends on the torque of the shaft);

- adhesion to the surface of assembly parts;

- the intensity of grease consumption (the ambient temperature, type and amount of work should be taken into account).

In the absence of the necessary lubricant, you can use a universal one. The latter should contain some components:

- antiwear additives (no toxic lead);

- highly refined mineral oils (inorganic);

- solid lubricants with graphite or molybdenum disulfide.

Petrol trimmer service

Most brushcutters and trimmers have a flexible shaft in their design. Its condition must be checked at least once every 50 working hours. To perform this operation, you need to remove the rod end, pull out the shaft and inspect it, then lubricate it.

Inexpensive materials are suitable for maintaining the shaft, it is more difficult to select them for the trimmer gearbox. How to lubricate this mechanism depends on the manufacturer of the tool. It is best to use materials that contain molybdenum disulfide. The latter provides smoothing and filling of cracks on the working surface, therefore it is especially appreciated among users.

Important: the use of a large amount of high-density lubricant leads to overheating of the mechanism, increased friction of working pairs and fuel consumption. Therefore, the process of selection of materials and prevention should be treated responsibly.

What kind of oil to pour into the engine of the walk-behind tractor

Manufacturers of motoblocks and mini-tractors prescribe the use of engine oils for both gasoline products and diesel engines. Motors are tested at the factory. At this time, lubricants are used that are recommended in the instructions. Some manufacturers recommend their own brand oils.Motoblock Patriot is equipped with the engine of the same name and needs oil from Patriot 5W30 SJ / CF, Patriot Supreme HD SAE 30 4T.

For gasoline engines

For motoblocks running on gasoline, it is recommended to pour the following types of liquids into oil containers:

- SA - for work with low loads;

- SB - for work with medium mechanical stress;

- SC - used in engines without PCV valves;

- SD - works in engines with PCV;

- SE is a lubricant for use in engines manufactured since 1980;

- SF - a higher quality analogue of the previous oil;

- SH - Used in many engine systems.

SB category has good anti-corrosion properties. The product provides high quality lubrication of cylinder walls and bearings. SF reduces the amount of oil sludge in 4-stroke and 2-stroke engines.

For diesel engines

With the recommended engine oil, owners increase the unit's life and reduce diesel fuel consumption for a diesel walk-behind tractor. The instructions for a walk-behind tractor with a diesel engine indicate the following categories of lubricants:

- CA - for work with low loads;

- SV - for work with high-sulfur fuel;

- CC - for a naturally aspirated engine operating with increased loads.

The CA category reduces the amount of carbon deposits in the cylinders, but reduces the quality of the lubricant. Any lubricant is poured in the required volume. Decreasing or increasing it leads to the seizure of the motor.

Gearbox oil change intervals

A fairly common question is how often and why to change the oil in the gearbox. Most experts recommend replacing in accordance with the used resource. For automatic transmissions, this figure is 30 thousand kilometers, in the case of mechanics, the figure is 50 thousand kilometers.

The replacement is carried out for the following reasons:

- Over time, due to overheating and other influences, the basic properties of the oil deteriorate. An example is a decrease in lubricity and many other points. That is why the device will not last long.

- Natural wear and tear of metal products becomes the reason why there is a large amount of metal shavings in the composition. It becomes very hot due to the resulting friction.

- The deterioration of the basic properties of the lubrication of the worm gear becomes the cause of overheating and increased wear of the main elements.

- Over time, the amount of lubricant decreases naturally. At the same time, manufacturers do not recommend mixing mining with a new one, as this will only reduce the main operational characteristics.

In addition, attention is paid to what kind of oil you need to fill in to ensure reliable lubrication of the main elements.

Rod and drive of the working body

Rice. The bar of the brushcutter The bar has two very important functions: the first - forms a rigid frame of the entire structure, the second - a shaft passes inside the metal hollow bar, which connects the working body with the engine. By the appearance of the rod, you can determine the class of the tool, if the rod is bent - this is convenient for work, but in this case the drive is a flexible shaft that cannot transmit a large torque. If the rod is straight, a rigid metal rod passes inside, it is much more reliable and it can transmit more torque. Therefore, a professional tool always has straight rods.

Change of oil

- For high-quality operation of the unit, the correct choice of lubricant according to the marking is of great importance. Where temperatures change frequently, an SAE type oil is recommended. API oils are considered a universal solution. Of course, you should also be guided by the instructions in the instructions for a particular cultivator.

- Before filling in a new portion, you must pour out all the used oil.Do not change the lubricant in a heated gearbox; it is better to let it cool down. After adding the liquid, it is worth measuring its amount with a special probe.

- When using the cultivator in normal operation, the gear oil is changed every 100 hours. If the load is very intense, you will have to halve the interval.

How to choose: basic criteria

When choosing a tool, the buyer should focus on the following aspects:

Appointment. In addition to earthworks, a motor drill is often used as an ice screw for winter fishing.

Therefore, when buying, it is important not to confuse these two tools: an earthen motor drill is more powerful and overall, the blades on its auger are more often located and curled at a shallower angle.

Engine. 4-stroke engines are more fuel efficient, quieter and emit less smoke (due to the fact that gasoline and oil do not mix in the same tank)

In addition, they have more power, but they also cost more. Therefore, in order to save money, a 2-stroke engine is suitable for solving simple tasks, in other cases a 4-stroke engine is preferable.

Motor power. The higher the power, the wider the hole the machine can drill. The dependence of the screw diameter on the motor volume is presented in the table:

|

Engine volume, cm3 |

Screw diameter, mm |

| 45 | 150 |

| 55 | 200 |

| 65 | 250 |

| 75 | 300 |

Screw. When choosing a screw, you need to take into account its bore diameter (20 or 32 mm), which may differ depending on the manufacturer. If necessary, you can use a special adapter. Most popular screw diameters: 100, 150 and 200 mm

You should also pay attention to the possibility of replacing the blades. If the turns are welded to the shaft, then if one of them is damaged, the whole auger will have to be replaced.

Extension rod

The length of most drills varies from 600 to 800 cm. For a deep hole, you need to purchase extensions (500-600 mm).

Handles. It is desirable that they are soft and ergonomic.

Fuel tank. It must be roomy enough (up to 2 liters) and with a convenient neck, otherwise the whole tool will be filled with gasoline.

Additional options: Rapid braking system (saves the gearbox from damage when jammed).

Reverse stroke (helps to extract the drill).

Damper spring (dampens vibration, reduces the effects of jamming).

Transmission oil for walk-behind tractor

When choosing a gear oil, the first thing you should pay attention to is the recommendations of the motoblock manufacturer. Each of the brands engaged in the manufacture of agricultural machinery uses mechanisms of different design.

Accordingly, the latter require oils of different composition. In order to avoid mistakes when choosing a transmission oil, we advise you to study the table, which contains the recommendations of the most famous manufacturers of motoblocks.

| Walk-behind tractor manufacturer | Transmission oil |

| Neva MB-1 | Oils of the brand TAP-158, TAD-17I and other compositions corresponding to GOST 23652-79 |

| Neva MB-2 | Oils TM-5, TEP-15, as well as compositions corresponding to the classification SAE90 GI-2 and SAE90 GI-5 |

| Bison | The optimal will be the use of TAP 15 transmission oil |

| Centaur | Transmission oils TAD-17I, TEP-15, Tap-15V, TSl-14 |

| Honda | The 80W90 oil has proven itself best. |

| Cascade | Gear oils complying with GOST 23552-79 or MS-20 aviation oils |

In addition to the correctly selected gear oil, the frequency of its replacement also plays an important role in extending the life of the walk-behind tractor.

Here, as in the case of the choice of the composition, you should pay attention to the advice of the motoblock manufacturer. In the table below you can study the oil change intervals for the most popular brands of motoblocks.

| Walk-behind tractor brand | Manufacturer's recommendations |

| Neva MB-1 and MB-2 | It is required to change the gear oil at least once every 100 hours of operation with the walk-behind tractor |

| Bison | The first oil change is carried out after 50 hours of operation of the walk-behind tractor in a moderate mode.All subsequent replacements are made every 200 hours of operation of the unit. |

| Centaur | Transmission oil must be changed after every 75 hours of operation of the walk-behind tractor. |

| Honda | The oil should be changed after every 100 hours of operation with the walk-behind tractor. |

| Cascade | It is best to change the transmission oil every 150 hours of operation of the walk-behind tractor. |

The difference in the frequency of replacing the transmission oil for motoblocks of various brands is due not only to the design features of the units, but also to their condition. After all, if the walk-behind tractor has a slight breakdown, then the gear oil in it will lose its characteristics much faster than in the case of a completely serviceable unit. Be sure to take this into account, and eliminate all existing breakdowns immediately after their detection.

How to change the oil in a walk-behind tractor

The oil in the cylinders of the walk-behind tractor is changing on a hot engine. This applies to both two-stroke and four-stroke engine operations. The heated waste mixture flows well into the substituted container. The following actions:

- unscrew the breather plug;

- drain the used oil;

- pour fresh;

- screw in the breather plug;

- the operation of the unit is checked.

The lubrication in the cylinders of motoblocks of different designs is replaced in the following order:

- a gasoline walk-behind tractor is installed horizontally;

- using a screwdriver, the plug on the tank is removed;

- drain mining;

- the plug is twisted;

- pour fresh oil into the box;

- the filling hole is closed.

You can drain the oil and pour fresh oil in 15-20 minutes. If you replace the used oil with low-quality products, problems will arise that lead to the repair of equipment. This applies to engine lubrication and gearbox oil. Lubricants age and require timely quality replacement. After how many hours you can fill in car oil, it is written in the manufacturer's instructions. You need to read it so that the purchased expensive unit will provide assistance for a longer period.

The used lubricant is disposed of at special points.

Do you follow the manufacturer's instructions when using motoblock oil?

Operating rules

When using any mechanical device, it is necessary to follow the operating rules. In the kit with each equipment there is an instruction that describes the points for the safe and correct use of the motor-drill.

Here are some aspects of using this device:

- the motor-drill can only be used by adults;

- make sure that there is a sufficient level of oil and grease in the device before use;

- it is necessary to lubricate the elements of the device with a quality product;

- it is necessary to fill in high quality gasoline so that the motor drill works smoothly and properly;

- refuel the tool away from fire, while turning off the engine;

- it is necessary to use oil intended for two-stroke engines;

- it is necessary to move the motor-drill with the engine off;

- work with the tool in a well-ventilated room;

- spare parts must be bought in specialized stores that have special certificates;

- oil and other parts must be changed at service centers;

- keep the motor drill in an upright position in a room where there is no humidity, and with an empty fuel tank;

- when working with a motor drill, you must wear non-slip safety boots, gloves, goggles and a helmet.

An overview of the reduction gear for a manual motor-drill, see below.

Peculiarities

The soil to be cultivated plays an important role in choosing this element. So, a chain reducer, like a worm gear, performs well on light earth - black earth and sandstone

The worm version is suitable only for lightweight and extra light cultivators that will cultivate well-groomed areas up to 6-8 acres.This method of transferring energy occurs due to the adhesion of the screw to the wheel, covered with teeth of a special profile. When the worm rotates (as the screw is called), the thread moves along its axis. The teeth are pushed in the same direction at the same time. The main part of the wheel spins, and the cutters also receive an impulse from it.

The main properties of this design are:

- smooth movement of the cultivator;

- weak noise;

- cost savings;

- low efficiency;

- excessive heating and powerful waste of oil;

- small resource;

- the inability to use the reverse mode and the addition of mounted components.

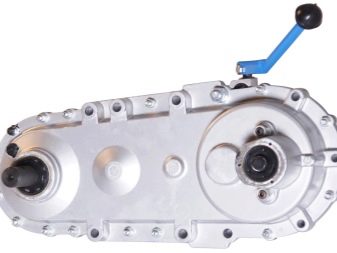

Most of the latest cultivators use chain drives. Simplicity is considered an important advantage of them. There is only a chain and a pair of sprockets: one at the bottom (mounted on the shaft), and the other at the top.

Even experts cannot name the obvious disadvantages of the chain reducer. But its advantages are obvious:

- minimal energy loss between the motor and the cutters;

- affordable price;

- relatively narrow body;

- easy maintenance;

- the ability to reverse.

In most cases, it includes 3 to 5 gears in a closed but disassembled housing. Such devices perform very well in heavy-duty cultivators. They are used even in walk-behind tractors designed to cultivate land with an area of over 25 acres.

But it is important to understand that the cost of gear reducers is very high.

Oil for a diesel walk-behind tractor - features of choice

When choosing engine oil for a diesel walk-behind tractor, you should follow the instructions in the operating instructions. However, if the instructions for use have been lost, then you will have to study the formulations available on the market more carefully.

Diesel engine oils are classified into the following categories. To determine the type and conformity of the composition for a specific walk-behind tractor, special markings indicated on the container with grease will help:

- API CJ-4 - formulations with this marking are designed specifically for motoblocks with a capacity of 10 liters or more. with. and more. The composition of these lubricants has a high viscosity, which guarantees the correct operation of all elements of the motor unit;

- API CI-4 - these oils should be used for engines equipped with different types of injection and pressurization. Such oils have good dispersing properties and high thermal oxidation stability;

- API CH-4 - lubricants with this marking fully comply with all modern requirements and quality standards. Among the advantages of these compositions, one should highlight the ability to fill them in diesel engines running on fuel, the percentage of sulfur in which exceeds 0.5%;

- API CA - formulations of this type are optimal in cases where diesel fuel contains a small amount of sulfur. Oils with such markings protect the walk-behind tractor engine from the formation of harmful deposits on its walls;

- API CB - the use of oils of this oil reduces the risk of corrosion of motoblock bearings;

- API CC - such oils will be the best option for a turbocharged engine that does not have a supercharger. These compounds help walk-behind tractors to withstand prolonged loads and work properly in difficult conditions;

- API CF-2 - oils of this group show themselves well when used in motoblocks that are subject to heavy loads.

After purchasing a suitable engine oil, you can proceed to pouring it into the motor of the walk-behind tractor. The procedure is quite simple:

- Place the unit in a horizontal position first;

- Place a wide container under the drain hole in the engine and remove the plug by gently prying it off with a screwdriver;

- Wait until the old oil is drained from the motor, and screw the plug back into the hole;

- Fill the engine with at least 2 liters of new lubricant.

What kind of oil to pour into the Lifan walk-behind tractor

Choosing the right oil is essential to keeping your engine running smoothly.In the instructions that come with the walk-behind tractor, the manufacturer always notes which oil is needed for a given motor.

Motoblock Lifan needs high-quality oil. For four-stroke engines, it is forbidden to use oil that is suitable for two-stroke. It should also be free of additives.

For Lifan walk-behind tractor with 6.5 hp engine with a gearbox, SAE 5W-30 oil is required. For most models with engines of different power (5.5. HP - 13 HP), SAE oil - 30 year old, or multigrade SAE - 10W-30 is suitable.

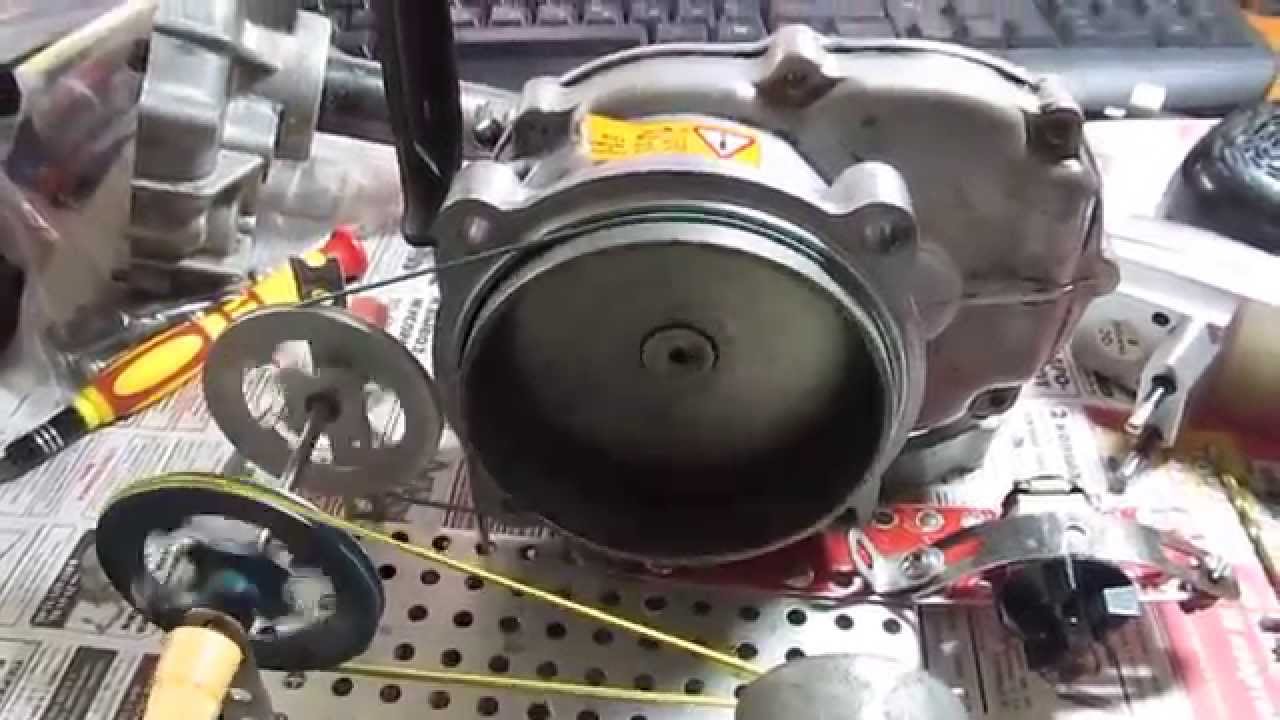

How to disassemble?

Lubricate the gearbox as thoroughly as possible. Even noises can be eliminated if you fill the lack of lubricants... But you should be as careful as possible to the choice of a suitable brand of lubricant, the use of contaminated formulations is unacceptable.

It should be borne in mind that extraneous sounds are often associated with poor tightening of fasteners, wear of bearings and gears. To disassemble the gearbox, you need:

- remove it;

- unscrew the screws;

- remove the protective caps;

- pull out the output shaft sleeve;

- disconnect the lever and then the plug;

- remove the input shaft (in close connection with the gears);

- remove the shaft and chain bushings;

- dismantle the shaft and sprocket block;

- remove the intermediate shaft and gears;

- remove the coupling, axle shafts (assembly is carried out in the reverse order).