Selection criteria

Of course, safety footwear should be as convenient and comfortable as possible for those working at a particular facility. A seemingly momentary distraction and constant mental fatigue can become the very accident that will lead to injuries, accidents, or "just" will not allow you to do the job clearly and on time

It is equally important to take into account the aesthetic side.

Regardless of the purpose of use, safety shoes must:

-

to carry vibrations with a strength of 2 dB (for a frequency of 16 Hz);

-

to carry vibrations with a force of 4 dB (at frequencies of 31 and 63 Hz);

-

protect from blows to the toe with a force of at least 5 J;

-

have shields that absorb blows to the ankle with a force of at least 2 J;

-

be equipped with a sole with a hardness of at least 70 units on the Shore scale.

But the general requirements are far from all. It is necessary to take into account the nuances of a particular specialty. Builders are usually advised to use boots. Models with a three-layer construction can be used well during the winter months. Then boots made of thick felt are also suitable.

In the warm season, it is advisable to use leather boots with protection against punctures and impacts. The problem is that they are not suitable for welding and other operations where molten metal can appear. Welders need to wear leather boots with a tightly closed tongue. It will not allow hot metal to get inside. But if there is much more metal around (in the foundry, for example), then you should wear boots with an elastic boot.

Leather boots with high ankle boots are almost a universal option. They are equipped with a built-in tongue. Most often, leather or even chrome leather is used for sewing. These boots can be used for heavy work indoors and outdoors. The grip of the outsole minimizes the risk of falling even on ice.

Asphalt paving is usually carried out in leather boots without a tread, but with a thickened sole. Such shoes will not fall even into a thick loose layer of asphalt concrete

What is important, there will be no traces on the road surface either. Designers today achieve reliable foot protection even at asphalt temperatures up to 270 degrees

But when facing work, they usually try to buy the most lightweight shoes.

For a warehouse, they usually choose special footwear designed for maximum loads. The list of requirements is determined by what specific items and material values are stored in the warehouse. Depending on this, you may need:

-

resistance to petroleum products;

-

protection against toxic substances;

-

immunity to cuts and impacts;

-

shielding from caustic reagents, acids and alkalis;

-

the minimum level of slipping and some other parameters.

The house starts with the foundation, and the shoes start with the sole.

How comfortable a person will feel during the whole working day depends on the degree of stiffness of the sole and on the comfort of the last.

The method of fastening the sole affects both the price and the strength of the entire structure: the method of fastening with nails is cheaper, but the glue-stitched method will significantly increase the reliability of the safety shoes, and therefore the time of its operation.

The polyurethane sole is a good choice for working in wet environments: unlike rubber, it is much lighter. Also, this material is stable when used in an aggressive environment, but sudden temperature changes lead to its deformation.

A nitrile outsole will best protect your foot when there is an increased risk of puncture. It is more durable, unpretentious and wear-resistant, but at the same time quite heavy and expensive.

For work in conditions of strong temperature fluctuations, a thermoplastic elastomer sole is perfect. It also tolerates aggressive environments well and provides excellent grip. But in such shoes it is better to avoid interaction with petroleum products and oils.

With the risk of slipping, the best choice would be PVC - a sole (made of polyvinyl chloride), but it must be borne in mind that it is susceptible to acids and alkalis.

Now about the bootleg.

The material chosen for its manufacture largely determines the quality and durability of work shoes. Both leather and leatherette are used here.

By itself, the phrase "leather shoes" is a strong association with the quality and reliability of this type of product. This is primarily determined by its durability and environmental friendliness. That is why responsible manufacturers of modern safety footwear preferred the material yuft - combined tanning leather. An excellent choice is work shoes made of chrome-plated leather, aesthetics are also added to all the listed advantages.

When working with low risk factors and low wear and tear of shoes, a leatherette bootleg is also appropriate, but the service life will be shorter. Therefore, in most cases, the use of leatherette has become partial: as a rule, in the form of small inserts or lining, giving way to the main surface of the bootleg to natural leather.

Rubber shoes are a classic protection against moisture and current, but with well-known drawbacks: rubber does not "breathe" at all, at low temperatures the feet will freeze, and at high temperatures they will be "in the bath".

Top brands

There are many worthy manufacturers in the domestic and foreign markets.

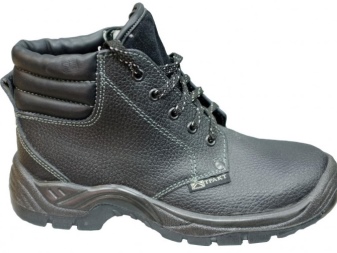

"Tract"

One of the leaders producing high-quality and varied products is the Tract brand. Its products are not only popular in the domestic market, but also sent to other countries. The brand widely uses the latest technologies and modern materials, for example, nitrile rubber, which has increased wear resistance, remains elastic even at temperatures of -40 °, and does not slip. EVA material is characterized by light weight, shape retention under load.

Non-metallic anti-puncture insoles, composite toe caps with low thermal conductivity and low weight are used in boots and boots. Additional protection is provided by special pads on the bow. Special footwear can be used by builders, miners, electric and gas welders, road workers, warehouse workers and workers with electrical equipment. The assortment includes winter insulated and summer lightweight products.

Technoavia

The manufacturer Technoavia has proven itself well. The company produces footwear not only for aviation, as the name suggests, but also for various industrial sectors, taking into account their specific requirements. Boots are not afraid of oil and oil products, they can be worn in hostile environment. The sole will withstand contact with a surface heated to 300 ° for a minute.

Products are sewn from water-repellent, heat-resistant, leather materials. Performance is enhanced by the use of breathable and breathable liners, puncture-proof metallic and non-metallic pads.

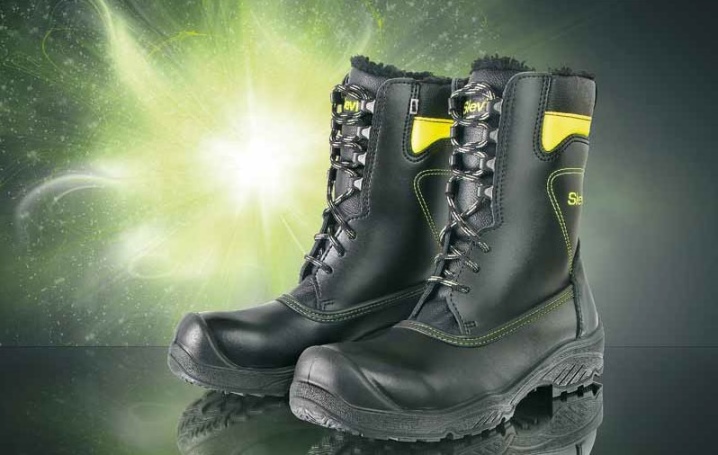

Sievi

Products of the Finnish brand Sievi are in demand among foreign companies. Founded as a shoe workshop in 1951, the brand is today one of the largest manufacturers in Northern Europe. The use of advanced technologies allowed the company to launch the production of lightweight Sievi-Light Boot boots. Their purpose is to use in conditions of high humidity, they will not suffer from the effects of oily substances, chemicals. Manufacturing material - microporous polyurethane.

The company produces safety footwear for various types of activities.Among the products are boots with protection against static electricity, with anti-puncture insoles, non-slip elastic sole. The company also cares about the stylish appearance of its products.

Selection recommendations

Advice on the choice of footwear for work can only be conditional, since, as has already become clear from the characteristics of footwear and its types, each man selects those shoes, the parameters of which must correspond to the conditions offered in the production where he works. If he has to spend a lot of time in the forest, on the river, he will choose waterproof shoes. Under working conditions in winter there can be only one option - a warm model with a non-slip sole. Chemical industries will require models with a protective layer against harmful chemical influences. The welder will desperately need boots with special spark protection

Before going to the store, a man will already know for what work he buys boots or boots, which means that he should pay attention to all these characteristics, which are paramount.

But with strictly individual characteristics, there are some general recommendations that apply absolutely to all work shoes.

First of all, it should be comfortable shoes. You have to stay at the workplace for a long time. Therefore, it is best to go to a specialized store where you can try on several pairs of different shoes, and then decide for yourself which one is more comfortable on your feet.

Any shoes or boots should be suitable for the size of your feet. They should not rub or dangle on the leg. This will create not only discomfort during the working day, but also fraught with injury. The only exceptions are winter boots designed for extremely harsh conditions in wind and frost. Here you need to keep in mind that you may also have to wear warm socks.

Preference should be given to high-quality footwear made from natural materials, it should be well-stitched, have a solid sole, on top of everything else, and it should look beautiful.

Another important factor is the ability to quickly and easily clean the surface and put work boots in order. The lifespan of any couple depends on how you care for it. It must be cleaned of dirt and dust, dried in a timely manner, stored in a special cabinet or box, excluded from moisture and direct sunlight.

An overview of Dutch-made working men's boots in the video below.

Lifetime

Only high-quality work shoes made in accordance with all norms and requirements will meet the established service life. All terms regarding clothing and footwear for special purposes are regulated by article 221 of the Labor Code of the Russian Federation. Several factors affect the service life:

- pollution conditions;

- temperature indicators;

- climatic zone;

- Kind of activity;

- production materials.

Do you use work shoes?

Not really

If these are shoes with wooden soles, their service life is on average six months. If we consider several climatic zones, the service life of workwear and shoes will be as follows:

The lifespan of a shoe is calculated from the date of issue. Even if a man received winter shoes in the summer, the countdown of his use immediately begins.

A few words about the lining.

Its use in the manufacture of footwear has two objectives: creating internal comfort and protection from the cold. The range of materials used here is very diverse. Insulation, as a rule, are fur or synthetic winterizer - depending on the target for the final price. For the production of budgetary special footwear, based on the purpose, various fabrics or leather splits are used as the lining material.

Employees of the purchasing department are well aware that a successful purchase is an investment in the common cause of the entire team: the growth and development of the enterprise.The catalog of workwear and work footwear of the "Meridian" company will help you to make this "investment" as effective as possible!

Models

Everyone chooses shoes for themselves that match their specialty. Considering all the characteristics, a person acquires the best option for himself. But there are specialized businesses and trading companies that offer specialized shoes that meet certain requirements. Let's consider some models.

The Flagship boots have a composite toe cap, a three-component sole, equipped with anti-slip pads. The shoes are equipped with reflective elements, soft inserts for foot comfort. It has a surface resistant to gasoline, oils, acids and alkalis. This option will be the best for those who deal with various chemicals, in addition, work in difficult conditions. These shoes can be purchased at retail for 2200 rubles.

Varieties

Different classifications can be applied to work shoes depending on the criteria used. The main one is the protective function.

The most common problem is mechanical influences. Therefore, it is necessary to organize the protection of the legs from punctures, cuts, squeezing by heavy objects, falling of heavy loads, vibration. In this case, it will be advisable to use boots, low shoes, boots, for the manufacture of which natural leather or its artificial analogue is used. They have a durable rubber or polymer sole, anti-puncture insoles. Boots or boots cannot be without protective toe caps - special elements made of metal or composite materials. They can handle up to 200 joules. Composite toe caps are often perforated to wick moisture away from the inside, making the boot breathable. However, these elements are very voluminous, and men's safety shoes are becoming larger. For works where the main damaging factor is mechanical stress, shoes with metal toes are more often used, since this material is cheaper and does not give a large volume.

It should be noted that many models have several protective functions and provide comprehensive protection. To indicate the properties of the models, there is a special marking, the application of which to the packaging from July 2018 is mandatory for all manufacturers and suppliers to Russia.

Features of operation

Choosing the right shoe for the job is only half the battle! It is equally important to understand when it is time to replace your old safety shoes and take proper care of them in order to extend their lifespan as long as possible. Wear criteria are subjective, but the basic rule is to replace with noticeable damage to the toe, heel and metatarsal protection

For moisture and chemical resistant rubber and PVC footwear, any delamination of materials will be critical.

The same applies to the situation if the tread pattern has worn off, which can become slippery or pass harmful substances inside. You can check the tightness with regular newspaper or a towel. To do this, just shove a dry cloth inside and leave the boots overnight in a container of water, if they remain dry, then everything is in order. Or, conversely, pour water inside the shoe, wash and wrap the outside of a dry boot with newspaper, looking for a leak.

Take care and take care of your shoes. Ideally, you should have two pairs of shoes, because a man's leg can produce up to 200 milliliters of sweat per day, and this is fraught with rapid acidification of the inner lining and insole. Change the insoles occasionally, safety shoes must also be kept clean, which will increase not only their service life, but also your own labor productivity.

How to choose work boots for winter, see below.

Basic requirements for work shoes

In order for work shoes to fulfill their functional purposes, and also to assume a long service life, a number of generally accepted requirements and norms established by law are put forward for its production.At the moment, shoes of this purpose must comply with the following parameters:

- be resistant to mechanical stress, protecting the limbs of a man from cuts, blows, moisture, cold, etc.;

- it must have a sole that will provide a stable position without slipping;

- shoe materials must be resistant to temperature fluctuations and low temperatures;

- the surface of the shoe must protect from current, radiation, toxic substances and poisons;

- shoe materials must be waterproof.

Important! Today, all requirements for work footwear are included in GOST and TU of Russia.

If it is leather shoes, natural leather should be either its top or the entire area, in addition, the bottom is necessarily made of rubber or polymer with molded or stud fastening of the sole. The tops of the shoes are treated with water-repellent or fire-resistant products, and sometimes they are supplemented with metal toe caps. Winter shoes are additionally insulated with fur.

How to care?

Any footwear needs careful care, and the one that is intended for builders is no exception, it must be carefully stored from the negative effects of the environment. To extend the life of such safety shoes, it is worth following the following recommendations:

- at the end of the work, clean it from dirt (for this, shoes are wiped and left to dry in a well-ventilated room at a distance of at least 50 cm from heating devices);

- do not clean safety shoes with organic solvents;

- once a week, surface treatment with a special cream should be performed;

- continuous use of shoes should not exceed 12 hours;

- you need to store safety shoes in the off-season in plastic bags.

See an overview of the Spark work boots.