Caravan material

Often in the garages of car owners there is an unnecessary load of various rubbish, which it is a pity to throw out, but he did not find a use. You need to delve into these things and see, maybe something will work for making homemade products. What can come in handy:

- wheels and springs from an old car, disassembled for parts;

- pieces of sheet iron;

- channel or corner;

- various fasteners (nuts, bolts);

- pieces of car wiring.

For yourself, you need to decide what should be the carrying capacity of the car trailer (AP) - the passport data of the car indicates for what maximum mass of the trailer it is designed. If some material is not enough, you will have to buy it, you will also need a plug to connect the car's wiring to the AP.

DIY car trailer: drawing up a drawing

When all the necessary material has been collected, you can start drawing up a drawing. It is not too easy to draw a sketch of a future product on paper yourself, therefore, to facilitate the task, you can take a ready-made drawing from the Internet as a basis, and make your own adjustments to it during the creation of the structure.

The car owner should also remember that the homemade product will have to be registered with the traffic police, and it is important to note that the coupling device can only be used here factory-made

For example, a drawing of the Zhiguli enterprise can serve as an example of a future trailer, if the car itself is similar in size and carrying capacity to this car model. Any car trailer consists of the following main parts:

- body;

- frames;

- drawbar;

- coupling device.

In any case, the frame must be rigid, so it is made of solid steel. As a rule, the body is also made of ferrous metal, but it can also be made of aluminum or wood.

Correct connection of the trailer to the mini tractor

It is important to note that a trailer for transporting a minitractor must also have a reliable attachment to the vehicle, and it is best done on the basis of an articulated drawbar, which is inserted into a special tubular body. In the upper part, it must be fixed with a special fuse, which will provide additional protection against accidental disconnection.

The design of this unit should be approached very carefully, since there is a high load in this place, combined with vibrations and strong friction.

Assembling individual catch into a single whole

When all structural systems are ready, they must be carefully assembled into a single whole, which is best done with an assistant. At the same time, it is necessary to carefully monitor the entire assembly process, rechecking the reliability of the connected nodes, the strength of the hinge joints, bolt ties. When the mechanism is ready, the resulting trailer must be run in without load so that all the necessary parts fit well together.

conclusions

Summing up the above, we can say that with due perseverance and care, homemade dump trailers for mini tractors are quite within the power of many domestic craftsmen. The only thing is that during installation, it is advisable to make all structural elements from durable, non-rusting materials that can withstand heavy loads. It is also recommended to cover all metal elements with oil paint for their reliable protection against corrosion, which will significantly extend the useful life of the trailer.

Video review of a homemade trailer:

The cost of an industrial car trailer for a passenger car

Industrial trailers have different prices, the price depends on:

- from the complexity of manufacturing;

- dimensions;

- the quality of the materials used;

- type (destination);

- complete set.

The simplest general-purpose AP will be the cheapest in terms of cost, for example, you can buy a LAV-81011 trailer from the Vector company for an average of 40 thousand rubles. The characteristics of this design are as follows:

- own weight - 175 kg;

- weight of the transported cargo - 525 kg;

- the maximum weight of the loaded AP is 700 kg.

The trailer has dimensions of 2.9 / 1.6 / 1.28 m (length / width / height), has a very good ground clearance of 167 mm. LAV-81011 is equipped with an awning, its height is 0.45 m. The sides of the body of this model can be reclined or completely removed, there are two modifications.

There are trailers and much more expensive, for example, a trailer for transporting boats costs an average of 200 to 350 thousand rubles.

Wheels

The trolley wheels can be used from the stroller. The hub is assembled. The axle ends must be sharpened to match the bearing diameter.

Sintering with a walk-behind tractor

With the help of a cantilever beam, the trolley is connected to the walk-behind tractor. The upper part of the console is similar to the contour of the grip. It is mounted in the bracket of the hinged devices of the walk-behind tractor.

When the cart is operated in difficult conditions, it is necessary that its connection with the walk-behind tractor be articulated.

The drawbar must be inserted into the tubular body of the hinge. The drawbar is fixed with a thrust ring. With the help of this design, it is possible to achieve independence of the wheels of the trolley from the wheels of the walk-behind tractor. When driving with a loaded cart, this allows better control of the walk-behind tractor.

Swivel unit - diagram

3.6 Bearings (36206);

5. Spacer sleeve;

7. The sleeve is remote;

The driver will sit on a cushion, which has medium rigidity, because it is made of wood. The driver's seat is in front of the body. Management is carried out from the cart. The operator's hands hold the handle of the walk-behind tractor.

Overview of manufacturers and models

Plant of light trailers "Vector".

- LAV-81011V:

Trailers manufactured by LAKER.

- Heavy Duty 400:

- OOO Europritsep model 711914-ATHOS, tilting back with a lifting capacity of 2 tons. Equipped with an electric jack and an awning of 1.5 m. It involves the installation of a mesh superstructure.

- LLC "Trailer" model 829450 with a carrying capacity of 0.48 t, body dimensions - 3x1.5 m. Equipped with a low or high awning, hydraulic jack.

- Plant of light trailers "Vector" model LAV 81012A - a platform with a folding ladder and leaf spring suspension. Carrying capacity - 0.6 tons.

- LLC Trading house "SaranskSpetsTehnika" model SST-7132-6K - single-axle trailer with extended functionality, carrying capacity -0.54 tons.

Examples of developments by DIY craftsmen

Let's turn to the well-known home-made mini tractors that have received decent reviews in the world of self-made agricultural machinery.

Minitractor "Volchok" with a breaking frame

Recommended drawings and dimensions

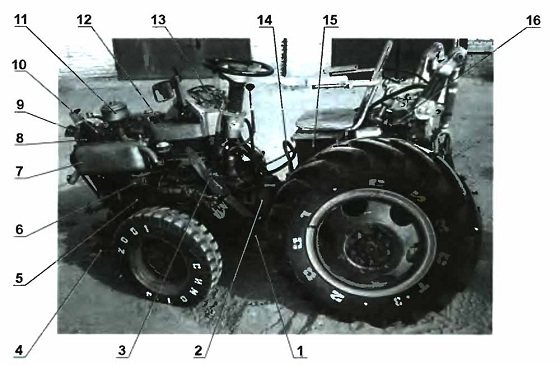

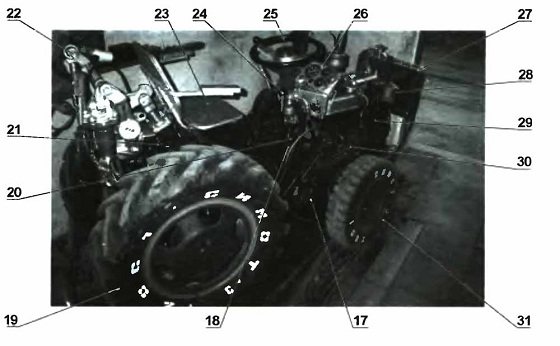

Layout of nodes (Figure 1)

Layout of nodes (Figure 2)

- 1 - articulated frame hinge mechanism (cardan crosspiece of MAZ car);

- 2 - drum-type braking mechanism (GAZ-51);

- 3 - pedal drive of the clutch mechanism;

- 4 - front axle wheel suspension assembly (ZAZ-968);

- 5 - two-cylinder diesel engine of 20 liters. with.;

- 6 - starter starter (GAZ-51);

- 7- exhaust suppression unit (ZAZ-968);

- 8 - electric generator (GAZ-53);

- 9 - cooling fan;

- 10 - pump of the cooling system;

- 11 - air filter housing;

- 12 - fuel tank;

- 13 - hand brake drive;

- 14 - crosspiece of the hydraulic system;

- 15 - battery box;

- 16 - hydraulic system tank and pump NSh-10;

- 17 - power take-off;

- 18 - checkpoint (GAZ-51);

- 19 - wheel (Belorus);

- 20 - hoses of the hydraulic system;

- 21 - hydraulic valve;

- 22 - hinge unit (Belorus);

- 23 - operator's place;

- 24 - gearshift lever;

- 25 - power steering (electric car);

- 26 - instrument panel (Belorus);

- 27 - radiator of the cooling system (Zhiguli);

- 28 - oil filter;

- 29 - fuel supply pump;

- 30 - gas pedal;

- 31 - wheel (electric car).

Control scheme

a - turn left; b - turn right.

1 - a steering wheel with a control unit for a hydraulic turning cylinder; 2 - half-frame stand; 3 - hydraulic cylinder rod attachment unit; 4 - steering cylinder; 5 - back half-frame; 6 - power hinge of the breaking frame; 7 - flexible hoses of the hydraulic system

DIY tractor trailer - step by step assembly

In order for the dump cart to be balanced and strong enough, you need to adhere to the correct procedure during its manufacture.

The assembly algorithm should look like this:

First of all, the manufacturer must make a reliable base frame. Its device should include a front traverse, a stable central axle with reinforcement in the form of a plate-like leaf, as well as a powerful rear beam. For the manufacture of each of the frame elements, thick pipes are suitable, the cross-section of which should be at least 25 cm. Welding is used to fasten the pipes. So that in the future the structure does not stagger during movement, it must be reinforced with spars made of channel and installed on the sides. In the place where the side members and the rear beam are attached, gussets will need to be installed - they will make the tractor trailer more resistant to vibration when driving off-road;

Then you need to start assembling the wheelbase. Its standard axle is best made in the form of a metal rod with a diameter of about 30-35 cm. After that, the axle will need to be attached to the supporting frame using longitudinal hinges, side metal spars or supports made from a steel corner... A homemade cart made in this way will be able to successfully transport not only crops, but also various building materials;

Next, you need to move on to assembling the body. It can be made from thick planks or sheet steel. The second option will allow you to transport heavier loads. You need to fix the metal on an ordinary corner, which plays the role of a base. In the same way, you will need to attach the side parts of the cart. Thanks to this, the homemade design will not skew during sharp turns;

The next step is to move on to the manufacture of a trailing mechanism. It is best to assemble the drawbar, which, during the operation of the trailer, will go into a special canvas.

It is important, however, that the supporting frame of the cart is in an ideal horizontal position. If it is violated, then the fastening of the cart for the tractor will need to be adjusted.

Otherwise, the structure will not be able to withstand the friction and intense vibration that the agricultural machine creates during movement;

Then you need to assemble the trailer lifting mechanism. It must be based on a hydraulic cylinder capable of tilting the cart 50⁰. To connect the lift to the frame, the manufacturer will need to assemble a brace that follows the shape of a truncated triangle. For its manufacture, a channel is suitable, on top of which an emphasis should be attached - it can be made from a cut out metal sheet. In order to operate the lifting mechanism, it will be necessary to be connected by pipes to the hydraulic drive of the tractor. The video will tell you more about making a homemade trailer.

The finished tractor cart will need to be covered with a layer of primer and several coats of paint. This will protect the metal parts of the structure from rust and rot.

Selection Tips

When choosing a trailer for a mini tractor, you need to carefully study the market. It is highly likely that without first considering the characteristics, you will significantly overpay, since prices for this type of product can fluctuate.From the mass of options, you should choose without undue haste, since you will still be working with this technique for a very long time. The photo shows a tipper model made on the principle of a single-axle bogie.

Trailer diagram for walk-behind tractor

Often, when buying such a trailer, farmers are guided by not entirely justified principles.

Basically, they prefer to pay all their attention to the trusted brand of manufacturers. This is not always the right decision, since modern firms are pursuing many strategies to attract customers, the design of trailers is subject to many modifications and changes.

Therefore, it will be more logical when choosing to rely on other criteria that are independent of marketing, for example:

- strength;

- price;

- number of axles.

These bogies are designed for mini tractors with a certain power (up to about 24 hp). There are enough model varieties, so they are suitable for absolutely any transportation. These devices are in demand for owners of a small farm. Any version of trailers for mini tractors has an average carrying capacity, which is associated with small dimensions.

Even an experienced farmer will not be superfluous to consult with experts and find out about the reviews of many buyers. Expert opinion will help you avoid problems in the future.

How to make a homemade mini tractor trailer with your own hands?

First you need to choose the type of cart, its capacity and size. Drawings are expedient, which greatly facilitates the implementation of construction work.

Single axle trailer manufacturing

- The frame and crossbar are constructed. The pipe joints are welded together.

- Wheelbase installation. A single axle cart requires two wheels, which are attached to the frame with side spars and a steel bar.

- Body installation. Boards or metal plates must be fixed to the frame structure.

- Installation of the articulated mount for coupling with the tractor.

Creating a biaxial system

A more complex design provides for more installation work. The biaxial cart has two axles, which are made of durable metal pipes. You also need to use four wheels, which are installed in pairs.

A four-wheeled trailer makes it possible to transport bulky goods.

Building a dump trailer

Its design is similar to conventional carts, but it has a special lifting mechanism. It can be manual self-tipping or mechanical. Manual can be done by welding the handle to the front of the trailer and installing an L-shaped pin. The tractor driver will be able to lift the structure on his own.

For a mechanical one, you will have to use a special lifting mechanism from other equipment, the dimensions of which will fit the trailer. For example, you can use an electric motor, jack, hydraulic system, winch.

The final touch to creating a homemade design is painting and installing it on a mini tractor. You need to check how the homemade product works and start work.

Homemade construction is designed to perform a variety of jobs in agriculture, utilities, industries.

Many farmers are interested in how to make a homemade mini tractor trailer. Most of the villagers appreciated agricultural equipment, but only more economical and compact, such as a mini-tractor. On such a vehicle, you can not only plow, loosen the garden, mow the grass and remove snow, but also transport various goods. And for this type of work it is necessary to have a convenient and reliable trailer. Many do not dare to buy such a simple but expensive product on the Russian market, but try to do it with their own hands. But where to start and how to make a tractor trailer with your own hands?

Trolley making

In order to understand how to make a cart to a walk-behind tractor with your own hands, you need to perform the following algorithm of operations:

- For the manufacture of a bearing welded rigid frame, take 5 pipe blanks, cut off the ends with a grinder.

- Press with clamps to the chipboard sheet and weld the joints of 3 longitudinal blanks with 2 perpendicular ones so that they create a lattice frame.

- Check the geometry of the structure using a regular construction square. The angles of the connected ribs should be 90 °.

- Install spacers between the tacked workpieces in the corners of the bottom and in the center, tack with welding.

- To the longitudinal pipes of the bottom, make tacks with a welding electrode 4 vertical posts in the corners.

- Check the perpendicularity of the corners, check the dimensions of the sides of the structure with the dimensions in the drawing of the cart for the walk-behind tractor.

- Finally weld all the workpieces to each other, grind the welded seams, clean them of sagging and formations.

- The body can be made of plywood or wooden planks, while the corner joints are secured with steel corners.

- The boards are mounted on the frame and bolted on.

- More durable sides of the master are made of steel sheets. The sides can be hinged and fixed. Hinged sides of the body are considered more rational, because unloading cargo of large volumes is easier. The sides are also made of square or rectangular metal pipes. They are performed, like the frame, they are grabbed, the geometry is checked for strength and to avoid braces and deviations, they are finally welded, rigidly attached to the frame. The tailgate is attached with ordinary door hinges and equipped with latches.

- Take a metal rod with a diameter of 30 mm and a length of about 1050 mm to make an axle for wheels, connect it with a longitudinal hinge and corner supports. The length should be chosen so that the axle does not go beyond the limits of the wheels. Sharpen it to the required diameters of the bearings in the hubs.

- As a running gear, you can take a wheelbase from a scooter, stroller, wheelbarrow or other agricultural machinery. Heavy wheels from a car trailer with hubs are not recommended to be installed.

- For the manufacture of the drawbar, 2 profile pipes with a diameter of 25x50 mm and a length of about 1.85 m are taken, they are welded to the frame beam so that a triangular structure is obtained. For reinforcement in the corners, metal kerchiefs with a thickness of 4 mm are attached by welding, and a plate with a thickness of 8 mm is attached to the front of the trolley.

- Tipper technology provides for the installation of door hinges that are attached to the bottom of the beam and to the bottom struts.

- Sheathed the frame of the structure made with wooden boards, plastic or metal.

- The driver's seat on a walk-behind tractor with a trolley is installed ready-made or in the form of homemade boxes from a piece of chipboard and foam rubber sheathed with dermantin. Such boxes are necessary to hide inventory and materials.

- The machine's parking brake can be used as a brake. Fix the brake pedal made of 6 mm thick plate on the footrest under the seat, weld 2 corners. In the front part, install the pedal, in the rear - a plate with 2 holes for fastening the brake cables, the ends of which are connected to a T-shaped plate with a rod.

In this way, you can make a trolley for a walk-behind tractor with your own hands.