How to choose?

The basis of any quality work depends on the right tool. And the discs for the grinder should be given great importance, because this is the main part that will carry out the processing of wood. Many accidents when working with a grinder happen precisely due to the fault of an incorrectly selected disc. A skewed or stuck nozzle in the workpiece makes the grinder uncontrollable - it flies out of your hands and can easily cause damage. Or the disc can break apart into small pieces that fly apart at great speed. The consequences of such cases are the most sad. This usually happens due to tips with defects, chips or cracks. Therefore, there are several factors to consider when choosing the right saw blade.

- Type of work. To begin with, it is worth deciding on the type of operations for which you have to use the disc on the grinder. The varieties of circles, depending on the type of work, have already been presented above.

- The diameter of the disc must also be taken into account. Usually this figure starts from 115 and ends with 230 mm. But large-diameter nozzles are often used for working with metal products. For working with wood, circles with a diameter of 125 mm are considered a universal option. This size is ideal for household work. Circle diameters over 150mm are commonly used by professional carpenters for large surface areas.

For processing chipboard, you can use discs with trapezoidal teeth.

- Disc thickness. The average disc thickness for a grinder for wood processing is 2 mm. Here it is necessary to take into account how wide the cut on the workpiece itself needs to be made. For example, when working with a chain disc, the cut will be very wide - up to 8 mm, because the disc itself is quite wide. Therefore, for thin cuts, it is worth using small-width nozzles. Accordingly, the diameter also plays a role here - the larger it is, the greater the thickness of the nozzle.

- Visual inspection. If everything is decided with the type of work and the model of the nozzle is chosen, then it is necessary to carefully examine it. No one is immune from fakes, so you should choose a disc with no external defects - no chips, with all the teeth present, without cracks.

Among the main manufacturers supplying circles for the grinder to the domestic market, it is worth highlighting the following brands.

"Speedcutter Graff". This accessory model has three large prongs, designed for woodworking and some more durable materials. It is made of tungsten carbide, so it is highly reliable. Even with prolonged operation and strong friction against the workpiece, the disc does not heat up and does not warp.

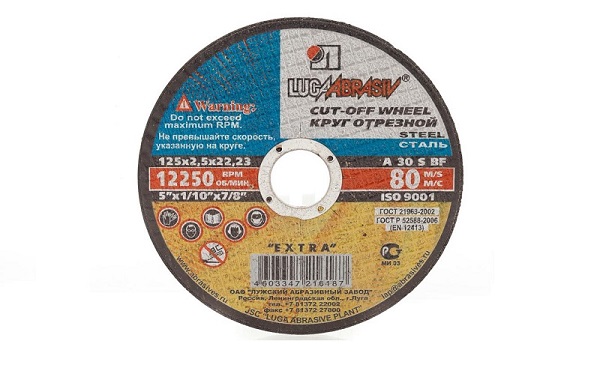

When choosing a disc for a grinder, it is important to pay attention to the EAC quality certification. After all, all discs are manufactured according to the strictly established GOST. It is not recommended to take suspicious models that have not passed certification or from unknown manufacturers

It is not recommended to take suspicious models that have not passed certification or from unknown manufacturers.

Sawing with a grinder

If there is no other way out, that is, there is no special saw for wood (broke) or an urgent little work was required, of course, the grinder can help out. However, it must be remembered that the main purpose of this machine is still not in sawing wood. To use the angle grinder as a hand-held circular saw, you will need to stock up on one or more specialized attachments.

To avoid distortions and jamming, you need to saw in a comfortable position, and fix the tool with both hands. The best results can be obtained if you do not remove the special guide handle, with its help it is much easier to control the grinder. It is not at all easy to saw off the workpiece correctly with the help of a grinder, the mode of operation will constantly change from the heterogeneity of the wood. Therefore, during work, it is better not to be distracted and watch how the cut is going.

Features of the use of grinders for wood

Sawing wood with a hand tool comes with a number of features. Wood is a heterogeneous natural material, its density is unevenly distributed. After a relatively loose area, a denser area may suddenly begin, there may be defects hidden in the thickness, once filled with resin during the growth of the tree. There may be developed or underdeveloped knots, and sometimes ingrown foreign inclusions (nails, wire, shot, or even bullets that hit a tree in the forest, for example, during a hunt).

Thus, it is almost impossible to unambiguously select the operating mode of the cutting hand tool. This can lead to jerks, the energy of which will have to be extinguished with the help of the hands; in special cases, the instrument may even break out. If a cutting tooth hits the metal, it can be broken and ejected by the next tooth fast enough to cause serious injury.

When adjusting this tool for sawing wood, the craftsmen often removed the protective cover, which is categorically unacceptable, given the above-mentioned features of wood, as a natural material with unpredictable variations in properties. If the need to use the grinder as a circular saw nevertheless arises in order to ensure safety and get the greatest effect, you need to purchase a special disc designed specifically for this tool.

Interesting: Electric Concrete Mixer - Selection Guide

Grinding

This is a finishing treatment of wood, designed to remove minor irregularities and roughness. There are several types of attachments:

- Cordbrush. Embossed work surface for deep, coarse wood processing. The cord brush "bites" into the base, smoothing out irregularities and chips.

- End disc. They resemble a bowl in shape. The working surface is just a narrow strip on the outside of the saw blade. This shape allows you to machine end miter cuts, as well as hard-to-reach areas.

- Flap attachments for sanding. The most common type for finishing. Consists of a steel base covered with abrasive material. The depth and quality of sanding depends on the grain size of the sanding paper. The smaller it is, the smoother the surface will be at the exit.

There are two options. The first is a disc pasted over with pieces of sandpaper in the shape of a trapezoid. Each next petal is overlapped. With such a working surface, it is effective to process wood. It grinds down slowly. The second is a petal disc where the abrasive material is located radially. Suitable for processing workpieces in hard-to-reach places.

Velcro sanding disc. It is designed to be reusable. Only the working surface of sandpaper, which is attached to the base with Velcro, is changed. The shops sell sandpaper with different grain sizes. This allows the accessory to be used for both coarse and fine sanding.