Scope of application

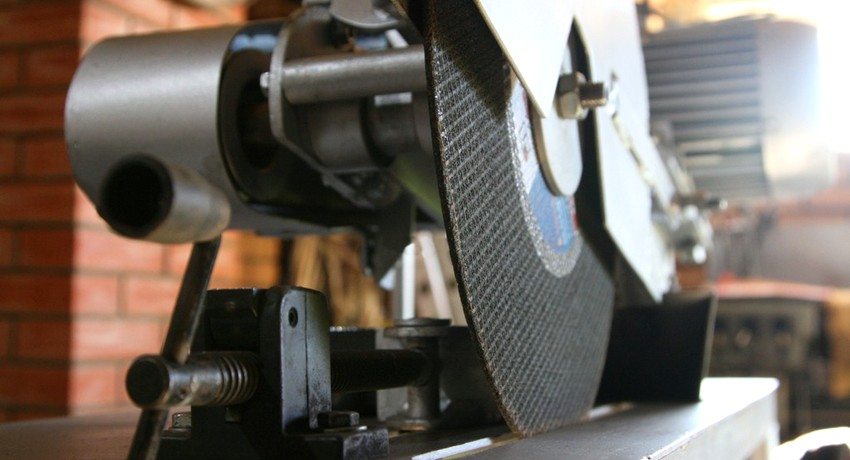

The metal cut-off saw belongs to the category of high-performance power tools.

The metal cut-off saw belongs to the category of high-performance power tools.

The main purpose of this equipment is to perform cross-cutting of rolled metal blanks and products from various alloys and metals.

Disc machines are most widely used when creating blanks from the following types of materials:

- channel;

- shaped tube with round and square section;

- I-beam;

- rod;

- metal strip;

- corner.

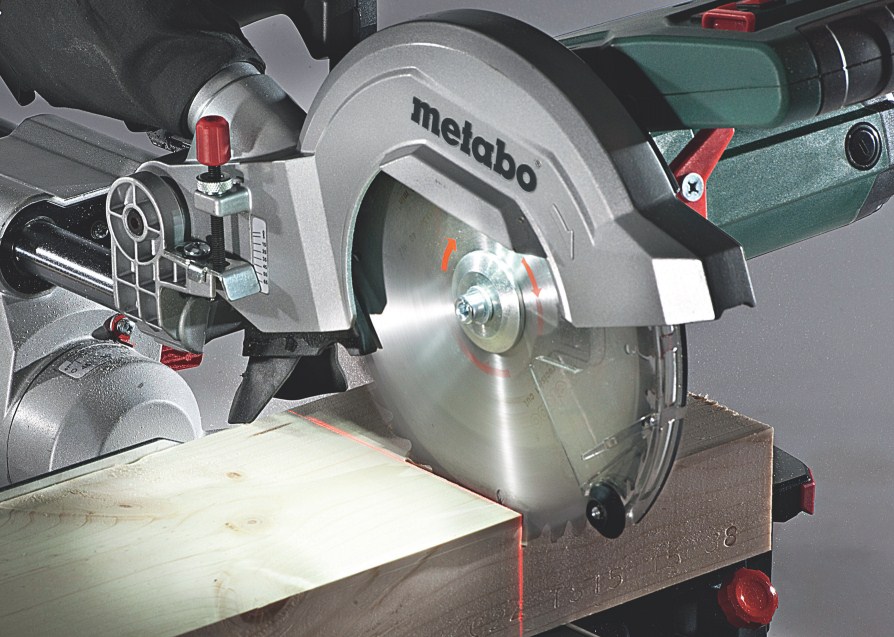

Cutting saws for metal are actively used at enterprises of the metalworking industry. You can also meet them at factories specializing in the production of metal structures. In this equipment, the function of the cutting element is a circular saw.

Machine-type machines have a number of the following advantages:

- Ease of operation.

- Ergonomic handling.

- High cutting quality.

- Simple construction.

A person can learn how to operate the machine even without special training.

In the equipment of band-cutting machines for metal, the function of the cutting element is performed by a long gear saw, which looks like a closed belt. This work unit is made of high speed steel. The kerf created with this machine has a minimum width, which not only minimizes material consumption, but also ensures high cutting accuracy. Such equipment has become widespread in large and mass production.

In the equipment of band-cutting machines for metal, the function of the cutting element is performed by a long gear saw, which looks like a closed belt. This work unit is made of high speed steel. The kerf created with this machine has a minimum width, which not only minimizes material consumption, but also ensures high cutting accuracy. Such equipment has become widespread in large and mass production.

Hacksaw varieties of cutting machines perform a cut using a hacksaw blade, which is fixed on the sawmill. This equipment is of two types: manual and electromechanical. Hacksaw machines are actively used in small enterprises, as well as in blank workshops.

The convenience of use

The use of a cutting disc in the format of a machine greatly facilitates the work, makes the cutting process more convenient, and reduces the time for performing a technological operation. Even when it comes to domestic use, a cutting machine is often much more ergonomic and safer than a portable tool in stationary use.

As an experiment, you can suggest cutting off a piece of an ordinary iron shaped pipe. It is much easier to feed it under a disc mounted on a special pendulum lifting mechanism than to cut off the same with an angle grinder. In fact, the use of the latter is justified only in the case when the structure is stationary and needs to be cut in parts on the spot.

With regard to industrial use, there is no way to do without machine tools. The volume of production requires maximum automation of operations, and the cutting machine makes it possible to fragment the workpieces according to the required dimensions in a fairly simple way and at moderate energy costs.

The best circular saws with a cutting depth of 60-65 mm

In the rating of circular saws, such devices can be found among both household and professional tools. True, in the first case, they must be chosen deliberately - such circulars already have a sufficiently high power, which will not be in demand if the saw is needed only to periodically cut a couple of boards.

| Makita 5477NB | AEG KS 66-2 | DeWALT DWE 560 | |

| Power, W | 1800 | 1600 | 1350 |

| Number of revolutions, rpm | 4500 | 5800 | 5500 |

| Speed control | |||

| Disc diameter, mm | 185 | 190 | 184 |

| Rim diameter, mm | 30 | 30 | 16 |

| Max depth of cut at an angle of 90 °, mm | 60 | 64 | 65 |

| Max depth of cut at an angle of 45 °, mm | 44 | 47 | 42 |

| Smooth start | |||

| Possibility to work with a guide rail | |||

| Maintaining constant speed under load | |||

| Weight, kg | 6,5 | 4,8 | 3,7 |

Circular saw Makita 5477NB

Despite the relatively low disc speed, the engine of the device produces a fairly impressive power of 1.8 kW, which reduces the likelihood of wheel jamming during operation. Used discs 185x15.8 mm, plus a 30 mm adapter.

+ Pros of Makita 5477NB

- The force on the shaft is supplied by a hypoid gear - the motor is located along the cutting line and less effort is spent on moving the saw.

- One of the few tools that allows you to saw with one hand.

- Reliability and good ergonomics - the saw fits comfortably in the hand and moves along the surface.

- Powerful - handles most materials with confidence within cutting depths.

- Good view of the work area - the cutting line is clearly visible during work.

- Cons of Makita 5477NB

- No smooth start - when starting the engine, the saw can "jerk" perceptibly in the hands.

- Large weight is a disadvantage for working on weight, but a plus in terms of the "feel" of the tool.

- The complete set does not include a stop for longitudinal sawing - it can be replaced with a Svenson square.

- When used for roofing work, there is no fastening with which the saw could be suspended from the beam during breaks.

- Sufficiently "gentle" retainer, setting the cutting depth - there are complaints about the breakage of this part.

Circular saw AEG KS 66-2

1.6 kW motor and 5800 blade revolutions per minute define this saw as a tool for solving a wide range of carpentry tasks. She makes cuts 64 and 47 mm when the disc is positioned at angles 90 ° and 45 ° to the surface.

+ Pros of AEG KS 66-2

- Ergonomics at a high level - the anatomical shape of the handles and their rubberized coating allow you to confidently hold the instrument in your hands.

- High build quality - no backlash in the case and adjusting rails.

- The engine is powerful enough to handle materials up to 65 mm thick with confidence.

- Wide range of angle saw adjustment - up to 56 °. The disc position is easily adjusted with thumbscrews with large retainers.

- A long power cord - 4 meters is sufficient for most jobs.

- Cons AEG KS 66-2

- A "flimsy" sole without stiffening ribs is a somewhat unexpected decision of the manufacturer for a sufficiently powerful device. However, there were no complaints from buyers about breakdowns of this part.

- When the engine starts, there is a lack of soft start.

- The tool is nevertheless closer to the household class - the recommended frequency is 15 minutes of work for 10 minutes of rest.

Circular saw DeWALT DWE 560

The combination of 3.7 kg weight, 1.35 kW motor power and 5500 rpm disc output make this tool a good tool for carpentry work with materials up to 65 mm thick.

+ Pros of DeWALT DWE 560

- Light weight, as for a saw of its class - it is convenient to work with the tool, even on weight.

- Build quality and materials used - no backlash and plastic smell.

- Successful sawdust removal design - blows the working area in parallel.

- A 3.5 meter power cord is usually sufficient, even if you need to move around the jobsite.

- A high-quality "native" disc - lives for a long time and, according to numerous reviews, even saws nails. However, most of them are made of mild steel.

- Cons of DeWALT DWE 560

- There are certain difficulties in finding spare parts and accessories. For example, the size of the disc used (184 mm) is not the most popular on the market.

- Changing the cutting depth is performed with a flag - not the best solution compared to wing screws.

- It is advisable to double-check the disc tilt markings with a square.

Trimming saw Dewalt D 28715

Read the same

A good option for professional cutting is offered by Dewalt. This version has a power potential of already two thousand two hundred watts, which makes it possible to easily cut square, rectangular and round metal products. In addition to standard straight cuts, ninety-degree cuts are also allowed.Trimming saw makita lc with carbide blade for metal saws bosch. The device also provides protection for the engine and the user, modern electronic filling for power control and ergonomic design mechanisms for online disk replacement. The features that the assembly saw in modification D 28715 possesses include soft start, protection from abrasive particles and keyless correction of the position of the disc. As the owners of the tool note, the working gears are made of high-strength material, which significantly extends the service life of the model.

Types depending on power

Depending on the power, three types are distinguished:

- The circulating saw motor has a power of 800 to 1200 watts. The thickness of the cut with this tool will be about 45 mm. Discs with a diameter of up to 160 mm are suitable for them. These are the cheapest types of equipment presented. Most often used at home.

- The tool is equipped with an electric motor of an average power of about 1800 W. Its cutting depth reaches 60 mm. This is a semi-professional circular saw. The diameter of its knives reaches 190-200 mm.

- The most productive type of tool, the motor of which has a power of more than 2000 watts. Discs of such circular saws are used from 190 to 350 mm in diameter. Most often, the tool is attached to a workbench. These are the most expensive professional, powerful saws.

Views

The range of cutting devices is extremely wide, therefore, devices that are very dissimilar to each other can appear under the same general name. In order to somehow streamline this variegated variety, various bases of classification can be introduced.

By scope

Depending on where and for what purpose the machines will be used, there are two large groups of devices:

These devices can be completely different in quality. They are used by both amateurs and professionals. The difference is rather in the scope of work and dimensions. Such devices are small in size. Although they have special fasteners for fixing in a certain place, they can be easily transferred from one place to another by one person. Such devices are often called assembly saws or trimmers, hinting at the transverse nature of the cut they make.

These units are not only designed for continuous operation under load. They have engines of a different power, sometimes an order of magnitude superior to domestic varieties. The dimensions of such devices are much larger, as well as the weight. this is due to the fact that industrial cutting machines contain massive bases, feed mechanisms and cutting platforms, where the support with the mounted disc is only a small movable part of a large-sized machine. Devices of this class work for 8, and if necessary, for 12-14 hours without interruption.

By the nature of the movement of the disc

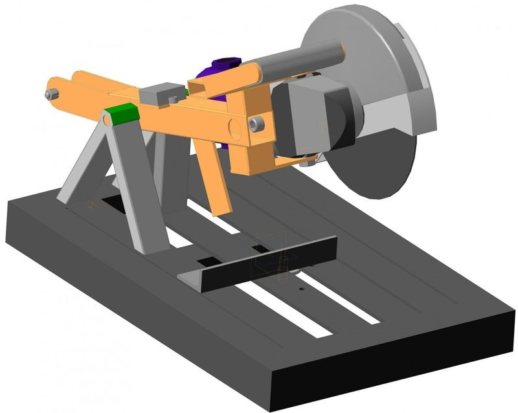

The cutting disc, which is the most important structural element, can move in a special mechanism in various ways.

The cutting disc, which is the most important structural element, can move in a special mechanism in various ways.

Depending on this, the following mechanisms are distinguished:

- Pendulum. all portable trimmers and many industrial machines have such a device. The disc is raised and lowered in a special support. At one end it is connected to the cutting base by a pin or a hinge, a disc with a handle is installed in the free shoulder, holding which, the disc is moved up or down. The mechanism got its name from the swinging system.

- Frontal. If the pendulum mechanisms can be manual and automatic, then the front feed machine operates exclusively according to the program set by the operator. The cutting disc does not move along an arc of rotation, but progressively, as the workpiece of the required length is fed to the cut point.

- Lower. These devices today represent machine tools equipped with numerical control.Feeding the blade from below makes cutting safe, allows you to set the required angle.

By the number of working disks

This class includes all household appliances and most industrial ones without exception. Although the productivity of such machines is lower, they have wide versatility. You can cut almost anything on them - from metal fittings to plastic profiles for PVC windows.

One of the disks is fixed motionless, the other can move relative to it. This gives twice the productivity, but leads to a narrower specialization of the tool.

Rules for the operation of cutting machines for working with metal

After the model of the machine is selected and purchased, it is necessary to carry out the work on the installation of equipment.

Requirements for room conditions:

- sufficient level of lighting;

- the presence of an exhaust type ventilation system;

- lack of flammable and flammable materials in the vicinity of the device.

The basis for mounting the device must be reliable and sturdy. Under the influence of the weight of the equipment and its vibrations during operation, the foundation should not undergo deformation changes.

An important criterion when choosing disk equipment is a high level of device security.

Operating rules:

- workpieces must be securely fixed on the working surface;

- the saw blade is installed only when the equipment is turned off, a similar requirement applies to changing speeds;

- in mobile versions, for safe work outside the premises, protection against moisture ingress (insulation) must be provided;

- it is forbidden to use discs with parameters unsuitable for workpieces.

When installing the tool, it is imperative to adhere to all the manufacturer's requirements regarding the RCD, the ground loop, as well as the maximum loads on the electrical network.

Equipment parameters

One of the main parameters that you should pay attention to when choosing an electric-type hand-held circular saw for wood is the number of revolutions. It would be more correct to choose equipment with the ability to manage this indicator

This function will allow you to produce a better cut with an optimal level of load on the equipment.

Must have protective functions for the electronics. This will help protect both the equipment and the operator in case of emergency situations at work. An accidental start lock must be present.

It will be useful to evaluate the appearance of the equipment upon purchase. It is very convenient to use an additional handle. The material of the product itself must be strong, capable of withstanding loads and mechanical stress.

Depending on the price, circular saws for wood are distinguished by the cleanliness of the assembly. Balance should be comfortable and the handles should not slip. This will allow you to firmly hold the technique in your hands.

Makita 2414NB Metal Cutting Saw Review

In this review, we will discuss removable saws on metal Makita 2414NB. Saw cutting from metal Makita is very comfortable.

It’s like that. I worked for a week, when something continuous (a day for 10-11 hours, in fact, I cut several tons of a corner of 35-50 twelve-meter whips 400 mm in size). Advantages - the engine is absolutely cold, it cuts through without slowing down, and the Bulgarian was left without hands.

(maybe not significant, but it was observed) - the screen from sparks is located close to the frame, and during intensive work, a mass of the hot scale accumulates, and the rubber leg is burned in the front right (then it constantly watered this place), the power button is not fixed, the button, and then her fingers numb her all the time to crush her. Most importantly, that ended, he put the furniture roller on the lowering protective cover so that it folds without jamming (the existing stop starts to jam immediately after less intensive work as thehow the scales behave and act as an abrasive and work in practice is impossible. Installation of films and everything is in order)

A comment

And in general, a thing for corner cutting is irreplaceable.

Smooth, clean cut. Convenient vise to use.

When cutting at an angle - stopping accuracy plus or minus the tram. 45 degrees cannot be set - maximum 40. The protective cover does not fall off as intended, wedges. Solved the problem by attaching a wheel to it. The spark shield accumulates a fine scale on its own. The power button is not fixed (but the safety engineer loves it). Low reliability.

A comment

Purchased at the enterprise and after three months successfully broke down. I smoke. Although it cannot be said that they were intensively exploited 24/7. As a household tool for cutting only at right angles, it is ideal. It turns out to be much faster and cleaner than Bulgarian. But for serious work, this saw does not suit.

A comment

there were 2 such saws, one saw cut 5 tons in one and a half (month), the second - 2 tons (1.5 weeks). In both cases, the gear on the motor shaft dies. With the shaft and gear as one, to change the gear with only the motor, this is 60% of the cost. It turns out to be an expensive tool. Put another saw, 3kW twist on the drive belt, 5 years old I don’t know (Noye tons).

A comment

After a month of active work at the enterprise, the stator winding is fired. The service center refused to guarantee under the pretext of improper operation - he pressed hard on the pendulum saw.

Rules for working with equipment

All metal cutting machines have a common working principle. Therefore, the recommendations for use are suitable for any tool, regardless of its design and other features.

All metal cutting machines have a common working principle. Therefore, the recommendations for use are suitable for any tool, regardless of its design and other features.

First of all, you need to take care of the availability of sufficient lighting in the room where you plan to use the cut-off saw. There should be exhaust ventilation, and the workplace should be located as far as possible from fuels and lubricants. It is necessary to place the cutting machine on a solid base on which the unit should not vibrate or wiggle. It is also necessary to exactly follow all the instructions regarding the load on the network, grounding and others, which are given in the technical passport for the machine.

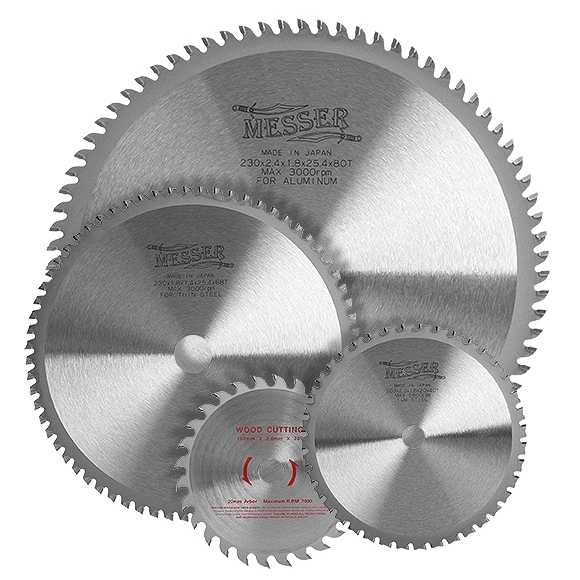

You can ensure the long-term operation of a circular saw for metal if you choose the right working element. The discs with which the cut-off saws work are of two types:

- Abrasive. They are made of fiberglass mesh, used for cutting ferrous metals.

- Diamond. They have a steel base and contain an abrasive mass based on diamond chips, which covers their end part. Suitable for cutting hard steels.

To ensure proper operation of the cutting machine, the following principles must be observed:

- Before turning on the tool, the workpiece must be fixed as tightly as possible in a vice or on the working surface.

- If it is necessary to install or replace a cutting disc, first turn off the engine and wait until the machine has come to a complete stop. The same should be done in those cases when it is necessary to change the speed of a machine with a belt drive.

- The blade purchased for work must match the size of the cut-off saw model.

- During work, it is necessary to smoothly press on the workpiece, without resorting to increasing the force.

- When the workpiece is cut, the cutting element must be moved to the lower position, and after the disc has come to a complete stop, it is raised.

Metal cut-off saws are equipment designed for highly specialized tasks. Its choice should be made taking into account the tasks and properties of the workpieces for which this equipment is selected.

Metal cut-off saws are equipment designed for highly specialized tasks. Its choice should be made taking into account the tasks and properties of the workpieces for which this equipment is selected.

Many models are equipped with a sufficiently powerful electric motor and heavy-duty cutting elements that perfectly cope with their basic functions.This equipment is excellent for cutting workpieces made from a wide variety of materials. They are able to cope not only with metal, but also with stone, ceramics and PVC. But, despite the versatility of these machines, during their use, it is necessary to follow the operating rules. This will not only allow you to quickly perform work operations, but also extend the life of the saw.

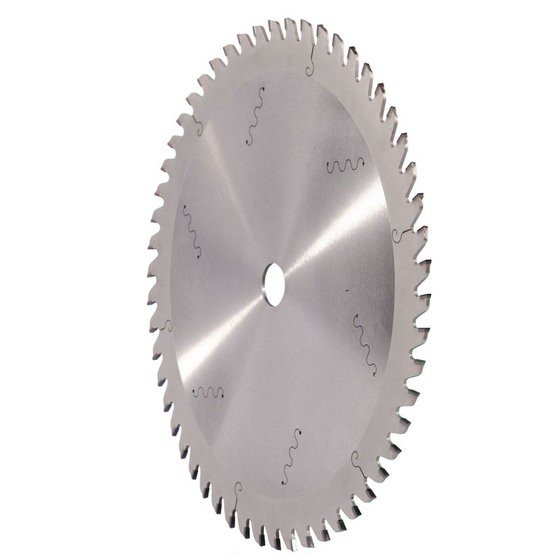

Saw blades

Saw blades differ in different technical parameters. Discs are usually divided into types - for wood and similar materials, for metal.

Wood saw blades have tines inclined in the direction of travel. The more of them in parts, the more accurate and accurate the cutting itself will be. Otherwise, the cut will be rough and ragged.

A hand-held electric circular saw for wood, which will be used to cut fiberboard, boards, will require a type of knife with frequent teeth (about 100 pcs.). For cutting wood with many knots, a reinforced blade with 24 cutting edges should be selected.

Knife markings consist of two numbers. The first characterizes its diameter, and the second characterizes the diameter of the landing rod. Discs with a lower value than provided by the saw should not be installed on the equipment. Otherwise, there will be a space between the part and the casing where a hand can accidentally get into.