Tractor mounted sprayer. Varieties, design features

In agricultural activities, the tractor-mounted sprayer is most often used to quickly and efficiently process field crops.

In agricultural activities, the tractor-mounted sprayer is most often used to quickly and efficiently process field crops.

With its help, it is possible in the shortest possible time and with the rational use of chemicals to fertilize plants or protect them from various kinds of pests.

If we talk about the varieties of this attachment, then, depending on the principle of operation, sprayers for a mini tractor are divided into fan (spraying liquid under the influence of the pressure of an air stream created by a special fan) and pumping (spraying chemicals and fertilizers under the influence of pressurized pressure).

Tractor fan sprayers are now widely used for processing both field crops and perennial plants such as grapes and fruit trees. As for the pumping devices, they are used for spraying and fertilizing vegetables, as well as all kinds of grain crops. If we talk about the basic requirements put forward for the work of sprayers, then it is worth highlighting the following:

- A garden tractor sprayer must ensure high-quality treatment with a solution of the entire plant or that part of it that must be protected at the time of processing.

- The spraying grip must be uniform and not subject to change even in gusty winds.

- Plants should not be damaged while the device is being moved.

In addition, a high-quality mounted sprayer for a tractor should have a convenient design, simple and understandable operating instructions, as well as convenient transportation.

Mounted sprayers are designed to work with tractors of a class from 0.6 to 1.4 with a traction force of at least 6 - 14 kN. Before starting work, this equipment is attached to the tractor hitch in accordance with the manufacturer's instructions. To ensure trouble-free operation, the sprayer shaft is connected to the tractor's PTO shaft.

Home-made sprayers for a tractor and devices manufactured by well-known companies, thanks to the large overall dimensions of the boom and a spacious tank, allow the processing of large earthen areas extremely quickly and efficiently without excessive consumption of solutions.

If we talk about the design of sprayers, then it is worth highlighting the following:

- Tank equipped with stiffening ribs to prevent water hammer;

- Steel frame on which the barrel and other equipment are attached;

- Hydraulic boom;

- Arcs-fuses (on the flanks of the boom);

- Shock absorbers;

- Hydraulic corrector;

- Pump or fan;

- Sprayer with built-in nozzles.

Control of the work of mounted sprayers is carried out by means of a special toggle switch installed in the tractor cab, which excludes significant user intervention in the process of processing plants. It is worth noting that, depending on the modification, a garden sprayer for a tractor can be equipped with barrels, the capacity of which ranges from two hundred to several thousand liters. This feature allows you to choose a device for efficient and high-quality processing of both a relatively small land plot and a huge field.

Homemade sprayer

Many home craftsmen prefer to make sprayers for the tractor themselves - this is not surprising, given how many advantages such products have:

- the ability to manufacture a sprayer with an individual shape and dimensions that best meet the specifics of the planting zone;

- when self-manufacturing such an assembly, it can be additionally completed with parts of any other materials;

- individually made equipment allows for width adjustment, so that it can be used for areas with different parameters of the row spacing;

- handicraft installations are suitable for both irrigation and spraying of medicinal and prophylactic preparations for plants;

- if desired, the structure can be made composite - in this case, it will take up very little space during storage and transportation;

- self-made installations can be used for tractors of any type (from GAZ to branded models);

- self-made models are usually distinguished by the simplest design, so they are easy to use and maintain.

Most importantly, homemade sprinklers are much cheaper than store-bought ones. It is no secret that for most farms, the purchase of any field agricultural equipment is often unprofitable, especially if the cultivated areas are small. Therefore, the manufacture of a sprayer from improvised means allows you to get an effective and efficient device at minimal cost.

It is quite simple to make it. You will need:

- tank for fungicides, water or pesticides - you can use a steel or plastic barrel for this;

- spraying system - hoses, water cannons or fans;

- flexible pipes;

- pumps;

- refueling device.

In addition to all of the above, you will need metal corners with different section options.

The procedure for the main steps in the manufacture of a homemade tractor sprayer is approximately as follows:

- first you need to weld a metal frame from a corner - such a desk is complemented by a pipe and liquid distributors;

- a reservoir for pouring the working fluid is fixed on the frame;

- a pump should be placed inside the tank;

If you have minimal technical skills, you can make such a mounted installation quite quickly, easily and simply, and the quality will be no lower than that of the Polish models popular on the domestic market.

For an overview of the mounted sprayer, see the following video.

Let’s block ads! (Why?)

1 Device Description and Specifications

The sprayer for the walk-behind tractor is an attachment. Attached to the motor unit by means of a special adapter. Excess pressure in the working tank of the sprayer is created by a pump (pump), which is not included in the kit and is purchased separately.

The pump is mounted on a separate platform in front of the working tank. The tank serves as a capacity. Its volume may be different, depending on the need. A sprayer pump for a walk-behind tractor is often used as a pressure washer, connecting an engine and a gun.

Motoblock with sprayer

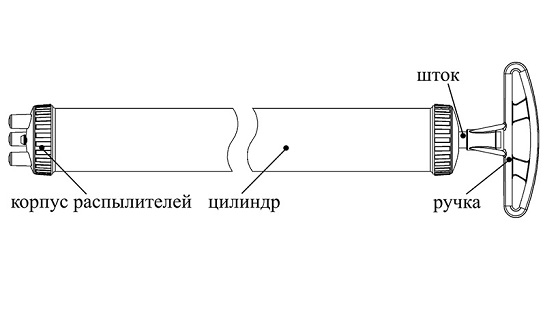

The motor sprayer consists of the following components:

- pair of wheels;

- platform for placing a tank with a pump;

- working capacity (tank);

- water pump;

- rods in the amount of 2 pcs;

- nozzles - nozzles connected to the tank with hoses.

The sprayer boom can be fixed in any position, can be extended and raised as much as possible. Each of the booms has four nozzles, which provides a fine mist when spraying with a uniform consumption of the sprayed liquid.

Garden vertical sprayer

The technical characteristics are as follows:

- maximum coverage 4 m;

- minimum track width 0.8 m;

- length 1.7 m;

- height with the maximum raised rods 2.4 m;

- the angle of inclination of the rods is 0 - 90 degrees;

- number of spray nozzles 8 pcs;

- working pressure from the pump 2.5 - 3 Bar;

- capacity 85, 150, 250 l;

- weight 28 kg.

The walk-behind tractor sprayer is easy to use, easy to assemble and disassemble, convenient and reliable to use.

1.1 Application of sprayers on tractors

Large agricultural enterprises have to cultivate large areas. For spraying, the devices are aggregated with tractors.The device of sprayers for tractors is similar in principle to that discussed above. The differences are in higher performance. It is ensured by the use of large working containers, powerful pumps, rod lengths and, accordingly, a large number of nozzles.

Trailed sprayer to a tractor

There are two types of machines that can be combined with tractors:

- mounted sprayers (NSh - mounted boom);

- trailed.

Attached tractor units can be equipped with a working capacity of up to 1000 liters. They have: a mechanism for adjusting the height of the rods, a stabilizer of the rods, a device that dilutes chemicals, spray equipment with a shut-off valve, a cardan shaft, a high-performance pump. NSh units have a working reach up to 20 m and consist of several sections.

In trailed units, working capacities up to 4000 liters are used. The working grip can reach 30 m. Modern trailed units are equipped with electronics, have a central control unit for the working process.

The choice of this or that type of unit is justified by economic feasibility.

1.2 Homemade sprayer for walk-behind tractor

It is quite affordable to make a sprayer with your own hands. The main thing is to clearly understand its device and know where and how you are going to use it. All of these devices consist of a fluid reservoir, pump and sprayer. For small amounts of work in a summer cottage of 6 acres, you can limit yourself to a manual device. In the mechanized version, the frame serves as the base for the sprayer for the walk-behind tractor.

Homemade sprayer with walk-behind tractor

Here's what you need to build:

- Frame with welded platform for working vessel and pump. It is welded from the existing metal residues (corner, profile, pipe, etc.).

- Working capacity. A metal or plastic barrel will do. It is fixed on the frame platform.

- Pump. The best performance option should be selected so that it does not overflow and gives out sufficient pressure.

- Rods made of metal or plastic pipes of a suitable diameter.

- Sprayer made of spools from old car cameras.

An individually made sprayer for a walk-behind tractor will fully justify itself during service and will not be inferior to industrially manufactured counterparts in terms of its quality characteristics.

1.4 Sprayer for mini tractor

A sprayer for a mini-tractor, according to its design solution, is arranged in the same way as a sprayer for a mounted-type walk-behind tractor with a tank volume of 200 - 500 liters. The version of such a device can also be trailed, if the working containers have a volume of 600-800 liters. The capture width of the devices can be from 4 to 18 m.

Homemade mini tractor sprayers are also common in fields cultivated by resourceful farmers.

Review of the best trailed sprayers

The sprayer "Amazon" is characterized by a boom width of up to 24 meters with a tank volume of up to 3200 liters. They are also equipped with several types of tanks. We can say that the Amazone sprayer is entry-level, but it demonstrates itself perfectly in the work. You can find Amazon with hydraulic and mechanical controls.

Sprayer "Zarya" - boom. This sprayer is an acceptable solution for the treatment of fields. Best for small private farms, gardens.

The MTZ trailed sprayer has a working width of the boom of 12-15 meters. The tank is 300-800 liters. Pump type - diaphragm piston. It is also recommended to buy for gardeners, as it has a good price category.

Trailed sprayer MTZ

Gwarta sprayer is equipped with a set of equipment that provides increased productivity, reliability, ease of use, and also makes its use environmentally friendly.The sprayer was manufactured taking into account every modern requirement used for this type of equipment.

"Remkom" sprayer is mainly intended for processing field crops with special chemicals, as well as for applying liquid and other mineral fertilizers by spraying the surface. It is made as a single-axle semitrailer, which is connected to a tractor of traction class of at least 1.4.

The John Deere Trailed Sprayer is a robust, well-balanced, double-link suspension for robust continuous use, both in the field and on the move. The design helps to transfer enormous weight to the tractor.

Sprayer John Deere

The mounted sprayer "Gaspardo" has a galvanized coating. The main and auxiliary tanks are made of high-strength polyethylene on a Gaspardo sprayer.

All procedures are necessary in order to protect crops, gardens from pests and weeds. The same procedure helps to maximize the effective fertilization required for the normal development of crops.

Interesting! Every gardener or large farmer should understand their special contribution to the development of crops. This is not only quality nutrition for the entire population, but also soil fertility, cultivation of approvals.

Sprayers and other equipment are the most important helpers in the cultivation and irrigation of crops. Of course, you can cope on your own, but it is quite difficult and there is a huge risk of missing out on the entire harvest.

vote

Article Rating

Where is used

A sprayer is considered a spray bottle. This device, by means of a jet stream, supplies compressed air under a certain pressure and distributes small parts of an aqueous solution over a huge area.

Additional Information! This approach helps not only to instantly and efficiently process the field, but also to save on the costs of all associated funds. Trailer-type sprayers are used in agricultural production.

The equipment in question is consumed not only by agricultural workers. Due to them, the football field is irrigated, and in certain situations - wide lawns.

What are garden sprayers used for?

- If the soil cannot fully meet the plant's need for nutrients, it is necessary to make up for this deficiency. Sprayers make it possible to feed the plantings, improving their growth.

- Spraying special formulations on plants allows you to eliminate pathogenic bacteria. Plants are less sick, give a better harvest, are safe for human consumption.

- Sprayers are also used for pest control. Insects and rodents that devour plants can cause significant damage to crops, so they must be dealt with.

- In case of drought, the technique is used to spray water. Unlike other applications that use a variety of chemicals, only clean water is required for irrigation.

Sprayer classification

To choose the right sprayer, you need to understand what types of this equipment are, and on what grounds they are divided among themselves.

By the presence of capacity

There are capacitive and capacityless sprayers. Capacitives are equipped with a tube that goes into an external reservoir. Capacitive devices are more convenient, as they allow you to quickly transfer yourself to any place.

By type of food

There are three types of sprayers, which differ in the mechanism for pumping air into the container. Each of them has its own characteristics and nuances that must be considered when choosing and using.

Pneumatic

These are the smallest sprayers. Air is pumped into them using a built-in hand pump or a lever.When manually pumping air, the entire brush works, and not just fingers - this favorably distinguishes such equipment from ordinary spray guns.

There are also lever sprayers. Their advantage lies in the fact that they can be worn on the shoulders using special shoulder straps. The location of the pump handle allows pumping without removing the sprayer. The lever can be installed on both sides of the sprayer. Knapsack sprayers have a larger tank capacity than those that have to be handled.

Rechargeable

The air in cordless sprayers is pumped by an electric motor powered by a rechargeable battery. This automates the process, so you don't waste your energy on working with a pump or a lever.

To understand which cordless sprayer is better, you need to pay attention to battery capacity, tank capacity and machine weight.

The use of a battery makes electric sprayer models mobile. Although the operator has to hold the battery and engine with the tank, this is a very popular equipment option. A tank with an increased volume makes it possible to process large areas of plantations.

Motor sprayers

Combustion engine models (two-stroke or four-stroke) are the most powerful hand sprayers available. As a rule, they are used where it is necessary to process large areas, however, it is still impractical to use tractors with attachments. Gasoline sprayers are heavy equipment and have the largest tank capacity of the above models. The knapsack system helps take the strain off your hands, making them comfortable to use.

To size

The classification, which is based on the size of the sprayer, is related to the division of equipment by type of supply. Sometimes it happens that the most important factor when choosing is not the environmental friendliness of equipment or comfort in use, but the area of the treated area. In this case, the sprayer can be matched to the size of the tank.

Medium (from 5 to 12 liters)

They have one or two straps that allow you to carry them comfortably. The capacity of the tank of these sprayers is enough to process a plot of several hundred square meters. They are also actively used in greenhouses.

Large (up to 25 l)

Due to their heavy weight, these sprayers can only be found in a knapsack or on wheels. Their volume is sufficient for working with large gardens or plots. They are often a good alternative to tractors with attachments. Large sprayers are powered by an engine (electric or internal combustion).

Sprayer selection

A commercially available sprayer is a good option for a large enterprise, where it is easier to invest money than to divert resources to assemble the unit yourself. Attached machines with a tank volume of 900-2000 liters are suitable for agricultural enterprises with a total area of up to 1 thousand hectares with an average field size of about 20 hectares. The volume of the tank directly affects the performance of the machine: the less frequent refueling, the less the equipment is idle, the faster the work is carried out

It is also important to choose a powerful pump. With a power of less than 200 l / min, the machine will not be able to move fast enough and productivity will inevitably decrease

This is especially important on crops that require copious treatments with garden chemicals.

The sprayer is attached with a special boom

When choosing, you should pay attention to the following points:

Drop size. The smaller the drop, the finer the spray of the solution. This will help to avoid plant burns and at the same time save water and preparation consumption.

Uniform plant coverage. This is the key to successful and high-quality processing.

Constant concentration. Excessive concentration will harm the plants, insufficient concentration will not provide adequate protection.

Consumption

Economical consumption will reduce the cost of pesticides and fertilizers, which is especially important on a large-scale enterprise.

Convenience in storage and operation. In particular, the capacity of the barrel must correspond to the length of the runs.

This eliminates the need for mid-field refueling and ensures optimal performance.

Also, when choosing, you should pay attention to such functions as mechanical adjustment of the height of the boom, their quick flushing, self-priming of water and a tank for washing hands. They make work more efficient and convenient

If possible, it is worth choosing a mounted fan sprayer with a fan design that allows you to change the angle of attack of the blades. This will allow the operation of the sprayer to be adjusted in accordance with the tractor power, as well as to work in the reverse thrust mode, which will avoid repeated suction of the solution into the deflector and, therefore, will reduce the loss of chemicals.

Varieties

Current sprayers differ in many ways:

- By the way of air supply.

- By tank volume.

- By the amount of water spray.

- By the bonding technique.

- By the type of liquid spread.

- By appointment.

Trailed sprayer

By fastening method

The tractor mounted sprayer assumes a special mechanism used by this agricultural machine to solve the problems facing the manufacturer. Sprayers for a mini tractor are installed on a car in the same way.

A sprayer of this type has a non-capacious liquid tank and a boom of 12-18 meters, the tank can hold 1000 liters.

The fan mounted sprayer is suitable for agricultural companies, while the home farmer is able to choose a more economical option.

Among the advantages are:

- excellent maneuver;

- compatibility with Russian agricultural vehicles;

- full automation.

Pump sprayer

Note! The trailed sprayer differs in a large tank volume - 2-3 thousand liters, which is prescribed in the instructions

There is also a herbicide sprayer that is used to control weeds.

By type of liquid distribution

Sprayers are divided into boom nozzles, in which irrigation occurs due to the hydrostatic pressure created in the system. A fan can be attached to a garden sprayer where the liquid is sprayed with internal pressure and air blast.

Fan sprayer can be dusty and tunnel. Its selection should be carried out according to the planting scheme and plant height.

By appointment

Boom sprayers are intended to be used for processing a particular type of crops. Buy this equipment is advised to those agricultural enterprises that focus on growing healthy food.

Boom sprayers

Such sprayers are used for their intended purpose in some specific cases and can be of great use to small farms.

Please note! Other devices are considered universal, they are suitable for processing entire areas for sowing. This will be ensured by the presence of various spraying substances in the kit, which can be replaced based on the need.

Varieties of sprayers

Agricultural sprayers differ in the following parameters:

- the method of fastening and installation on traction vehicles;

- type of switchgear;

- the degree of atomization of the working fluid;

- destination.

By installation method

There are the following types:

- hinged;

- trailed;

- self-propelled.

The mounted sprayer is attached to the tractor hitch. The design of such a sprayer provides for a small tank for the working fluid - no more than 600-800 liters. The working span of the booms does not exceed 12-18 meters.

The advantages of this type of sprayers include their price characteristics (low cost allows them to be purchased even by the smallest farms), good maneuverability, and the ability to operate with domestically produced tractors.

The main disadvantage is the low performance of the equipment.

Mounted sprayers are recommended for small farms where the cultivated agricultural area does not exceed 1000 hectares.

Trailed sprayers are the most popular. Sprayed such a tank Atelier holds from 2 to 4 cubic meters of working fluid, the swing of the hinged rods is 24-36 m.

Atelier holds from 2 to 4 cubic meters of working fluid, the swing of the hinged rods is 24-36 m.

Trailed sprayers are used mainly in medium-sized farms, where the sown area is up to 10,000 hectares.

The advantages of trailed sprayers are their good performance, the ability to process large areas without additional filling with working fluid.

The main disadvantage of trailed sprayers (this also applies to mounted sprayers) is the low ground clearance of the tractor. When processing tall plants (cereals or sunflowers), part of the crop is injured when the equipment passes through the field.

Self-propelled sprayers have recently appeared on the Russian agricultural machinery market. They are a completely autonomous system for spraying plants.

The advantages of this technique are high performance, high ground clearance (up to 1.5 m), high maneuverability, lack of work on installation and dismantling of equipment.

The cost of self-propelled sprayers is quite high and can only be afforded by large agricultural enterprises processing more than 10,000 hectares of cultivated areas.

By the type of liquid distribution in the system

The following types are distinguished:

- rod;

- fan.

In rod attachments, the spray of the working fluid occurs under the action of the pressure created in the system. Such sprayers are used to treat fields.

The crushing of the working composition in fan systems (OPV sprayers) occurs under the influence of an air jet created by a fan and internal pressure. Such systems are used for work in gardens.

By the degree of atomization of the working fluid

There are such sprayers:

- ultra-low-volume (the flow rate of the working fluid is up to 5 l / ha);

- low-volume (consumption ranges from 75 to 100 l / ha);

- ordinary (300 l / ha).

When choosing sprayers, it is necessary to focus on models with an adjustable volume of sprayed liquid or take into account the presence of special nozzles that can adjust the spray dose.

By appointment

Sprayers can be of general and special purpose.

The universal technique is designed for processing various crops, as a rule, it is equipped with several types of attachments.

Special sprayers are designed to treat a specific type of plant. Used by specialized agricultural enterprises specializing in the cultivation of one specific crop.

1 Sprayer for the garden: purpose and device

A sprayer is a garden tool designed to spray preparations for the care of crops. Timely and high-quality processing will help you get a decent harvest. This unit will allow you to do the following:

- add top dressing;

- treat the garden from pests using a minimum of harmful components;

- carry out preventive care in the country.

The sprayer performs its function due to the difference between the air pressure and the liquid, which is in the tightly closed container of the device. The most popular units, for example, "Zhuk", "Stanley", have a similar principle of operation.

The liquid medium under high pressure rushes to the outlet and at the moment of opening the valve moves through a flexible tube into a kind of telescopic structure, which is crowned with a spray nozzle. As a result, the liquid is scattered into a cloud, jet, fan, or a combination of these options.

In this case, the pressure on the agent is formed by different methods. Which method is chosen for the device depends on the manufacturer. There are powerful machines equipped with a motor. They are intended for processing wood up to 5-10 m high. And there are also small sprayers for manual care of flower beds.

Manure spreaders for mini tractors

The manure spreader for a mini tractor is another useful device with which you can easily fertilize crops with organic fertilizers. Due to this, the sowing is environmentally friendly, and the consumer will be able to save money, since chemical fertilizers are much higher.

All models of manure spreaders for a mini tractor have the same type of body design, the only difference is in the capacity of the hopper, the number of discs and types of fasteners. The self-supporting structure has a structure in which the metering holes and spreading discs are located in such a way that the fertilization process takes place quickly and efficiently, and the sowing is accurate and uniform.

This design is designed for surface spreading of organic fertilizers like peat, compost, pus, and others. It is possible to mount an additional attachment in place of the worm adapter, which will allow the use of such natural fertilizers as chicken manure or limestone.