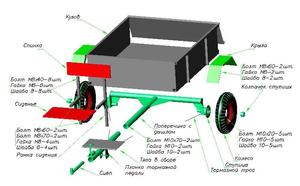

Factory versions of trailers

Currently, more and more manufacturers are producing trailers for various purposes on an industrial scale:

Figure 3. Diagram of construction and fastening of wheels.

- "Bulat PMB-1", made in Ukraine, has a side dimensions of 1100x1300 mm. Its carrying capacity is 350 kg. Equipped with cast wheels.

- Ukrainian manufacturers also produce a trailer of the Motor SICH AD-2V brand. This is a cargo device with dimensions 1200x1300 mm with a lifting capacity of 350 kg on cast wheels.

- "Bulat PMB-1U" is also produced by Ukrainian specialists. This is a dump truck with a body measuring 1100x1400 mm. Its carrying capacity is 450 kg. Wheels are not included.

- Ukrainian trailer without wheels "Bulat PMB-2U" is a dump truck with body dimensions 1300x1700 mm. Carrying capacity of the body - 550 kg.

- "Motor SICH TS-1" from Ukraine has a dump truck with dimensions of 1200x1300 mm, carrying capacity 350 kg, wheels included.

- The Russian unit "Mobile K TPM-350-1" is equipped with a dump truck with dimensions of 1000x1300 mm. Its carrying capacity is 350 kg. Made of galvanized iron, equipped with wheels.

- Chinese dump truck "PRORAB TT-502" with a carrying capacity of 380 kg has a body of 1100x1500 mm and cast wheels.

- The Russian "KADVI PM-04" is a flatbed trailer. The body of 1150x1200 mm has a carrying capacity of 500 kg and is mounted on pneumatic wheels.

- "KADVI AMPK-500" with all-wheel drive is a trailer with a flatbed body with dimensions of 1100x1100 mm. Its carrying capacity is 500 kg. Wheels are included. Manufactured in Russia.

- Grillo G55-107 is a device of joint production of Russia and Italy. Onboard version with a body of 1250-1400 mm. Carrying capacity - 350 kg. Equipped with wheels.

- "Belarus MTZ-750" made in Belarus is an onboard version with a body of 1200x1650 mm. Its carrying capacity is 750 kg. Equipped with wheels.

Some manufacturers of well-known motoblocks offer to purchase ready-made conversion kits. For the manufacture of a mini-tractor, they produce kits, which include:

- bearing frame;

- protective cover for belts;

- wings;

- brake cylinder with reservoir;

- levers that block the axle shafts;

- brake drum;

- support disk;

- steering column;

- earring.

Similar kits are produced by Ukrainian and Chinese manufacturers. From them, you can assemble a mini-tractor at half the price of buying it ready-made.

What are the types of hillers

A tool for hilling beds can be purchased at an agricultural equipment store or made with your own hands.

There are such types of this technique:

- single row;

- double row;

- propeller;

- rotary;

- disk;

- listeric.

Single row

This type of hiller is often used for light soil types. Furrows can be made by completing preliminary loosening of the soil with a cultivator.

Double row

Before planting the crops, he cuts a pair of furrows. In addition, it is used for loosening and hilling soil. The device includes a frame on which two hillers are fixed at once. Due to this feature, the process of processing with such a tool significantly saves time. It can be attached to the walk-behind tractor with a hitch. However, this type of hiller needs a lot of resistance to work. Therefore, it is often used in conjunction with lugs.

Propeller

Such hillers work with special propellers. Under their influence, they dig up the soil and remove the weeds, and only then can one begin to loosen the beds. This option is used for motoblocks with front-wheel drive and a pair of speeds. This is due to the fact that at the last speed the power rises to almost 200 rpm.

At maximum speeds, the cultivator can also be used to transfer the soil from the space between the beds to the furrows.

Rotary

In this tool, the wheels are replaced by rotors with helical teeth.In practice, this hiller delivers impressive levels of performance in furrowing, loosening the soil and hilling potatoes. Can be used on a three-speed walk-behind tractor (two speeds and reverse). At the lowest speed, the tool spuds the planting, and at the next, it throws the soil out of the row spacing.

Disk

It is versatile for soil cultivation. Working part - steel concave discs. Plunging into the ground for a given distance, they loosen it, thus forming a ridge. To make use more efficient, the discs should be angled vertically and in relation to the direction of travel of the equipment.

Making a disc hiller for a walk-behind tractor with your own hands is described below. Drawings and dimensions, along with a photo, are attached to the description of how to make the tool.

Lister

Endowed with a fixed tillage width. It is often used on rather weak walk-behind tractors, whose power does not exceed four horsepower. It can handle beds about 30 cm wide. It has a thin stand and a pair of side wings. The stand protects the tool itself from overload and mechanical damage. This type of hiller can only be used on dry soil - soil adhesion will greatly interfere with the work of moving parts of the structure.

You can also find lister nozzles on which you can control the width of the tillage. They are intended for more powerful motoblocks - from four horsepower. Such a tool can also be used for working with moist soil.

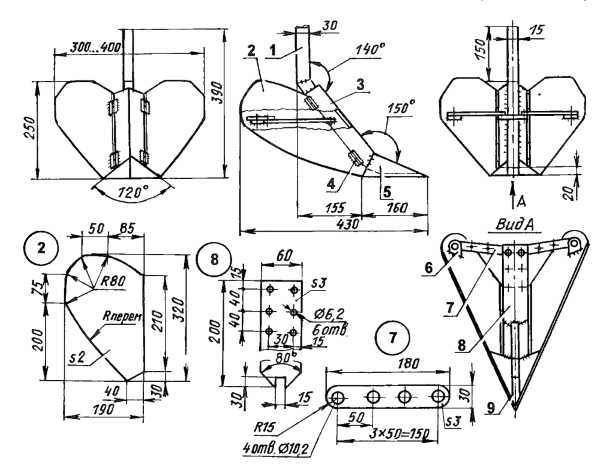

Assembling a trailer for a Neva walk-behind tractor with your own hands

A special home-made adapter can make a small tractor out of a Neva walk-behind tractor and automate household management the most.

A special home-made adapter can make a small tractor out of a Neva walk-behind tractor and automate household management the most.

Its elements are:

- metal frame;

- transverse bar;

- coupling;

- axle, wheels and wheel stands;

- braces;

- control units;

- cart;

- comfortable seat.

A typical trailer frame is made of any steel tube up to 2 meters long. At one end, a hitch is attached to it by welding. This is the knot with which the entire structure is attached to the towbar of the walk-behind tractor. On the other side, a transverse rod is welded, the size of which should be selected based on the width of the vehicle's wheelbase. Further, braces and wheel stands are attached to the bar, which are necessary to ensure frame rigidity and shock absorption when moving around the garden. The wheels should be removed from the vehicle trailer or garden cart.

Usually, the adapter and the hinged units of the walk-behind tractor are connected using a single hitch. All functional units are controlled by a special lever with several knees. When switching them, it is possible to regulate the change in the position of the supplied attachment. And you can also use an additional lever to adjust the applied force. At the end, a metal base must be attached to the transverse bar, on which the driver's seat will be located.

With a long adapter drawbar length, the most powerful walk-behind tractor is required. The power of the motor will also affect the size of the wheels and the size of the pipe from which the base frame will be later assembled.

Universal attachments for motoblocks

The compatibility of various attachments and attachments to agricultural equipment is universal, since when it is replaced, the design of the walk-behind tractor remains unchanged. Operation of a motor-cultivator with attachments allows you to carry out various types of agricultural work, from digging up the land and ending with the collection of the grown crop. The overwhelming majority of types of devices for motoblocks are developed and produced for work on soil cultivation, as well as for growing various crops in small areas.

Versatile attachments help to carry out various types of work

Attachments for walk-behind tractors are divided into 3 categories:

- Basic equipment.

- Additional devices.

- Supporting tools.

With the help of attachments, you can plow the land, cultivate the soil, milling, cutting furrows, dragging and harrowing the land. A large number of attachments can be used to carry out soil preparation work. It is offered by firms that sell agricultural tools.

The use of additional mechanization is necessary for the implementation of delicate types of work. They involve planting seeds, harvesting. The equipment includes a hay press for a walk-behind tractor, mowers and other types of work attachments.

The use of auxiliary attachments and special attachments reduces the time for performing certain types of work. To carry out transport operations, harvesting or others, it will take about 1/2 operating hours of the unit. The range of attachments is divided by manufacturers into 2 main groups:

- Complicated fixtures.

- Simple attachments with additional devices.

The high rate of unification of a motor-cultivator allows the owners of such a device to adapt it to do-it-yourself attachments. The active demand for complex fixtures does not depend on the high cost of the tool. This is due to the urgent need for planting seeds and subsequent harvesting.

You can purchase an extension cord, lug or tow hitch at an inexpensive price. The use of conventional attachments and additional devices increases the efficiency of agricultural work. You can buy them together with the unit itself.

Homemade devices for a walk-behind tractor

The list of accessories is not limited to a mower, plow or harrow. This list is large enough, and no other walk-behind tractor has such a strong package. After calculating the amount that will cost to purchase all the necessary equipment, many refuse this venture. It should also be remembered that not every model can be considered universal.

The list of accessories is not limited to a mower, plow or harrow. This list is large enough, and no other walk-behind tractor has such a strong package. After calculating the amount that will cost to purchase all the necessary equipment, many refuse this venture. It should also be remembered that not every model can be considered universal.

Their drawings are often found on the Internet, but it is important to make sure that they are compatible. When developing attachments from scratch, you need to focus on the available walk-behind tractor model

DIY trailer adapter

With the help of this unit, the walk-behind tractor can be easily converted into a mini-tractor, which makes it possible to automate a large number of work on the processing of the personal plot. The trailer adapter structure consists of the following elements:

- Metal supporting frame.

- Coupling.

- Cross bar.

- Braces.

- Chassis.

- Governing bodies.

- Seat.

To make a supporting frame, you should use a pipe of any section, the length of which ranges from 1.5 to 1.7 meters. On the one hand, a device for attaching to the walk-behind tractor is welded, and on the other, a transverse beam. The width of the second element is selected in accordance with the dimensions of the wheelbase of the walk-behind tractor. Then braces are attached to the bar to increase the rigidity of the structure and wheel stands.

To make a supporting frame, you should use a pipe of any section, the length of which ranges from 1.5 to 1.7 meters. On the one hand, a device for attaching to the walk-behind tractor is welded, and on the other, a transverse beam. The width of the second element is selected in accordance with the dimensions of the wheelbase of the walk-behind tractor. Then braces are attached to the bar to increase the rigidity of the structure and wheel stands.

The final step in creating the trailer adapter is to install the seat, and to do this, you attach a pillar in the middle of the crossbeam.

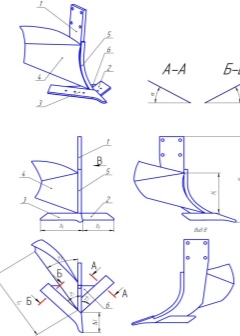

Homemade disc hiller

The optimal type of hiller for a personal plot is disc. When working with it, it is not required to apply great efforts, and with a decrease in the speed of movement, the power increases. Do not forget that the disc hiller is a versatile tool, because it can be used not only after planting crops, but also during their growth.

The design of this type of attachment is not very complex and includes:

- Ramu.

- Disks.

- Screw type talers.

- Racks.

Discs can be taken from worn-out agricultural equipment, for example, an old seeder, or made of high-quality steel, the thickness of which is 1.5-2 mm. The outer edges are bent, and a hole is drilled in the center for attachment to the frame.

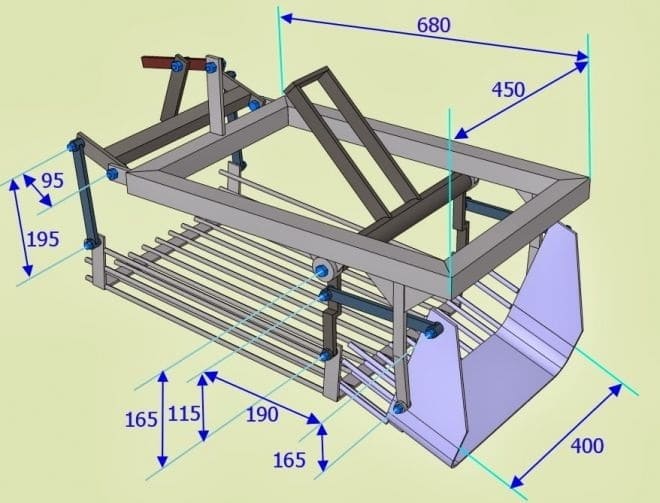

Making a potato digger

This unit is able to significantly facilitate the work of harvesting all tuberous crops, not only potatoes. Among the main structural elements of the unit, it is necessary to highlight:

- Welded frame.

- Ploughshare.

- Drum cleaner.

- Editorial site.

A ploughshare is a movable element of a potato digger and can be made of sheet iron. The cut plates should be sharpened, but at the same time all edges should be blunt so as not to damage the tubers. Frame fabrication should also be straightforward. To solve this problem, you will need a corner, channel No. 8 and a profile pipe. The dimensions of the frame are selected on an individual basis, and the required amount of materials is determined on site.

A ploughshare is a movable element of a potato digger and can be made of sheet iron. The cut plates should be sharpened, but at the same time all edges should be blunt so as not to damage the tubers. Frame fabrication should also be straightforward. To solve this problem, you will need a corner, channel No. 8 and a profile pipe. The dimensions of the frame are selected on an individual basis, and the required amount of materials is determined on site.

The main element of the entire structure of the unit is the editorial unit. To make it, you need two metal cylinders, into which the connecting sleeves are then installed. After that, it is necessary to make the hubs from a metal pipe, the diameter of which is 25 mm. They are used to mount sprockets, which are pre-fastened to the bushings by means of dowels.

The torque from the engine of the walk-behind tractor is transmitted to the ploughshare connected to the casing. During movement, the angle of inclination changes, and digging movements are performed. To adjust the angle of inclination of the working element of the structure, and, consequently, the depth of the dig, you can make a slider. Fluoroplastic will be an excellent material for the manufacture of this part.

Attachments for MTZ walk-behind tractors. 1 Attachments for MTZ walk-behind tractors

Attachments for MTZ walk-behind tractors are designed to expand the capabilities of walk-behind tractors. Today there are a considerable number of models that allow you to harvest hay, mow lawns, plant and harvest potatoes, chop wood, transport goods, etc.

Attachments for motoblocks

Before purchasing such equipment, you should determine the range and scope of work, the purpose of the selected model. The following devices are very popular among the population: mowers, hillers, potato diggers, cultivators and trailers.

Potato diggers help to dig potatoes out of the ground by throwing them to the surface. Mowers are used for mowing grass on lawns, gardens, parks. Hillers are used for weeding and hilling the earth. Cultivators loosen the surface, level the soil after processing. With the help of a hiller, you can also fertilize the soil with high quality. A variety of goods are transported by trailer in farms and municipal services.

The plow for the MTZ walk-behind tractor is a mechanical means for tillage, which is intended for plowing the land. Plowing is the main tillage operation, which crushes the soil and places its top layer in the furrow. The plow structure consists of working bodies, which are mounted on a metal frame, and auxiliary parts.

1.1 Adapter for MTZ walk-behind tractor

The adapter for the MTZ walk-behind tractor is a device that is equipped with mechanisms for installing and securing a variety of attachments. Outwardly, the device resembles a single-axle trailer. With the help of the adapter, the productivity of the unit increases, and the possibilities for performing work are expanded. The adapter turns the walk-behind tractor into a mini-tractor, which makes it possible to cultivate the soil, hilling and cultivating crops.

1.2 Design and types

In terms of functionality, adapters are divided into bodywork used for the transportation of goods and mechanisms used only for cultivation of the land, not equipped with a body.Among all the models of such mechanisms, there are devices that are equipped with telescopic drawbars and have the ability to change the wheel track width.

Attachments on the MTZ walk-behind tractor for planting potatoes

Adapters are divided according to the power of the walk-behind tractor, on which they are installed:

- heavy ones that are equipped with a long drawbar and are used to work with powerful single-axle tractor units with power plants that work with a water cooling system;

- lightweight that work with low-power, air-cooled equipment and a short drawbar.

1.3 DIY adapter

A trailer of a simple design can be assembled by hand. As the experience of users shows, self-assembled adapters are not much inferior in quality to models manufactured at the factory. The cost of a homemade trailer is much lower than a factory one. In addition, do-it-yourself devices more meet specific requirements (working conditions) than store-bought ones, which often have to be refined.

In order to make an adapter yourself, you must follow the following stages of work:

Attachments for motoblocks. What an attachment tool kit can do

The universal nature of the walk-behind tractor design implies that additional working tools and equipment are used exclusively as a hinged one for the walk-behind tractor. During operation, it can be easily removed and replaced without interfering with the design of the walk-behind tractor.

In the overwhelming majority, attachments for a walk-behind tractor are developed and produced, first of all, for tillage and growing vegetables and grain crops in small areas of personal plots. Therefore, all attachments can be classified into three categories:

- Equipment for plowing, cultivation, milling, cutting of furrows, dragging and harrowing of the earth. To work with soil preparation, the largest number of attachments and attachments are produced, both by manufacturers of motoblocks and by firms selling agricultural tools;

- Additional mechanization used for fine work with planting seed and harvesting, these also include motor cultivators, mowers and other equipment for working on the beds;

- Auxiliary attachments and attachments. Oddly enough, but the performance of auxiliary work, transport operations and use as a snow blower account for almost half of the operating hours of the walk-behind tractor with attachments.

Important! Due to the high degree of unification of the design of the main unit with the motor, owners of different models of walk-behind tractors can partially adapt attachments and attachments for "foreign" models to their units. Especially when it comes to "Soviet" models

Potato digger for walk-behind tractor

Potato diggers of various types are very popular among farmers. These devices save people from hard manual labor, speeding up the harvesting process several times. has a very simple design. It can be made from the metal that remains after the construction and repair of the house.

For work you will need:

- Bulgarian;

- welding machine;

- electric drill;

- heavy hammer;

- anvil;

- profile steel pipe 20x40 mm;

- reinforcement 12 mm;

- tin (preferably stainless);

- bayonet shovel without a handle.

The attachment to the walk-behind tractor is made in suspended or trailed (modular) design. The hanging tool only digs out the tubers, leaving them lying on the surface for subsequent manual harvesting. The modular type potato digger not only extracts the crop from the ground, but also collects it in a mobile container on the chassis.

The digger is made in the following sequence:

- Drawing up a drawing. The width of the digger should be within 25-30 cm. The angle of attack of the point is taken perpendicular to the opener so that the tool does not burrow into the ground.

- The reinforcement is cut into pieces of a given length. With the help of a hammer and anvil, they are given the required bend.

- A container for tubers is assembled from a profile pipe and sheet metal. The chassis or runners are welded to the container frame. The runners are made from pipes, and the chassis is taken from an old stroller, cart or lawn mower.

- The holder and reinforcement rods are welded to the shovel. The drawbar is welded to the holder, which is fixed to the assembly container. Connections are made movable by bolts or hinges.

- Rust and weld build-up are removed. The finished product is treated with an anti-corrosion agent and painted over.

Adjustment and adjustment of the digger is carried out using stands and steel ties.

In the kit for the digger, you can immediately make a disc hiller. You will need this tool when planting tubers after they have been buried in a plow trench. Hillers are made from old pot lids, profile pipes and bolts. A trolley is assembled from pipes and small wheels, onto which holders for lids are welded at a certain angle. After sharpening on the stone, the discs are mounted on the holders.

What attachments for a walk-behind tractor can be made by hand?

It all depends on the qualifications of the home craftsman and the set of tools that he has. We advise beginners to start their experiments with the simplest designs - a fan potato digger or a hiller.

The design of the device for digging potatoes is shown in the sketch. It consists of a wide bent plate (paw) welded to the vertical bipod and the field bar. The teeth from the reinforcement are attached to the rear edges of the paw by welding.

It is easier to make a disk model from hillers. Its main elements are discs that can be cut from the ends of old gas cylinders. They have the right shape, diameter and metal thickness.

Quite a lot of design solutions have been invented for the device itself, you can be convinced of this by watching videos of self-made people, as well as various assembly diagrams.

One example of an adjustable disc hiller device

In addition to discs, you will need:

- two posts made of steel strip;

- two rolling bearings;

- bolts for attaching the struts to the frame and adjusting the pivot sectors;

- crossbeam from a profile pipe;

- T-shaped leash.

The main condition for the high-quality operation of such a mechanism is the accuracy of the manufacture of all parts and the symmetry of the installation of the disks. Otherwise, it will be taken away from the furrow while driving.