Views

The spread of motoblocks began in 1980 after the manifestation of the agrarian reform. The mechanized block for cultivating the land existed before, but from this period it became widespread in the country. Its design provides for the convenience of controlling the process without any additional human effort. The walk-behind tractor is powered by a gasoline or diesel engine. The gear shaft is equipped with left-hand or right-hand equipment, which provides the mechanism with extended device functions. The unit moves on powerful wheels with sturdy tires, which are equipped with self-cleaning mechanisms from dirt during movement.

The mechanism performs a variety of tasks on the personal plot:

- processes, plows the land, preparing it for planting and sowing;

- helps to care for them, to harvest;

- helps to loosen and weed flower beds and beds, while clearing them of dirt and weeds;

- mows and collects grass;

- saws firewood;

- shovels snow and carries loads.

Naturally, all these tasks are performed using special equipment, in accordance with the manufacturer's brand. All such elements have the same structure, differing only in minor details, as well as accessories. They consist of a base - chassis, engine, transmission and control mechanisms. Modern cars mainly contain an internal combustion engine. Units of lower power are equipped with such gasoline engines.

The single-cylinder 4-stroke engine is available in machines designed for the processing of a small area of land and consists of the main mechanism, control systems, gas distribution and ignition and starting of the mechanism. The transmission determines the travel speed and the target direction. With the help of a gearbox, gear changes are made. The undercarriage consists of a frame, wheels and main assemblies. Control elements consist of a steering axle, gearshift levers, clutch and other structures. Lift height and steering axle angle are adjusted with a lever. And the role of the battery is performed by a one-piece self-charging battery.

To perform various tasks in the garden and vegetable garden, various types of motoblocks have been developed that successfully cope with the tasks set. Their assortment today is so great that it is simply impossible to bring everything. Therefore, in this article we will consider the most basic ones. All mechanisms for soil cultivation are divided into light, medium and heavy.

Lungs

Mini-devices of this type are used by owners of small land plots of several tens of acres. They are often small in size, with only four horsepower, which equates to 20 centimeters of soil cultivation in depth. They weigh no more than 30 kilograms, are compact and maneuverable. All kinds of attachments are used to strengthen them. Light tillers are unsuitable for heavy virgin soils. In large areas, untouched islets of unplowed land will remain. Light peat soil with low resistance is optimal for them.

Average

Average motoblocks weigh about 100 kilograms, their power is about six horsepower. They are good at moving loads weighing up to half a ton. Equipped with additional attachments, which also include a pump for pumping and pumping liquid. Medium walk-behind tractors are semi-professional, equipped with several cutters and can harvest root crops.They are ideal for small garden plots. In winter, they can be used as a snow removal device.

Heavy

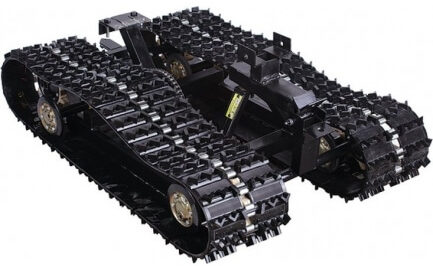

Heavy four-wheeled walk-behind tractors have relatively large dimensions, which directly correlate with the power of the devices. They are also equipped with special attachments for a variety of functions. They are versatile, but due to their impressive dimensions, they cannot be transported.

"Claas" Tucano 450

Universal combine "Claas" of premium class. It first entered the market in 2008. It combines innovative technologies from older model lines such as Lexion, Medion and Mega. In particular, the design of the striker beater, the two-drum threshing system, and the specialized shape of the headers are all that make this machine one of the most demanded on the modern market.

"Pros":

- "Auto Contour" - the function is included in the basic package;

- functional "intelligent" control of the harvesting mechanism, which has a memory of operational properties;

- "APS HYBRID" - improved threshing;

- improved design of the grain receiver, which is able to work longer without unloading and unload the crop almost 40 liters faster than the previous modification;

- balanced headers "VARIO";

- easy control of the harvester;

- the ability to activate the options CEBIS, TELEMATICS, GPS PILOT, fully automating the work;

- separation "ROTO PLUS";

- efficient chopping of straw with Special Cut knives, the thickness of which has increased by 4 cm;

- optional connection of a belt-driven straw spreader and a straw distributor deflector.

Specifications:

- Engine volume - 7.2 liters;

- Traction indicator - 320 hp;

- Gas tank - 650 l;

- Seed receiver - 9 tons;

- Unloading auger speed - 105 l / s;

- Straw walker - 7.2 m2;

- Weight - 12,750 kg.

Features of the Torum740 model

Combine Torum 740 is a versatile unit and shows the highest efficiency when working with rice and corn. In temperate climates, when standard crops are harvested, there may be an increase in energy consumption. The model is effective on large cultivated areas. Among the advantages are:

- The cleaning system is adapted to extreme loads. The two-piece fan creates a powerful air flow. The sieves have a large area, an additional sieve is also provided. These features ensure that the most refined grain is delivered to the hopper.

- The volume of the bunker is 10,500 liters, and it takes two minutes to unload it. Thanks to the spacious reservoir, equipment downtime during unloading is minimized.

- The elongated unloading auger allows you to drive up to the combine even when a nine-meter header is installed.

- The engine of the technique is powerful and at the same time economical. The optimized rotor system reduces fuel consumption.

Attachment overview

The popularity of motoblocks in our country is due to the ability to connect a large number of attachments. Each owner should be familiar with the possibility of his car, for this, let's consider the most common hitch.

Milling cutter

This attachment is delivered disassembled from the factory with the walk-behind tractor. With its help, it is possible to mix the upper layer of soil and increase fertility.

To assemble the cutters in the correct sequence, you must use the diagram in the operating instructions, because due to improper assembly, they can immediately break off or fly off and cause harm to health.

Plow

This attachment is also used to mix the topsoil before planting and after harvest. There are two options for the plow: conventional and swivel. They differ in the shape of the share. The second option is made in the form of a feather and breaks up large blocks of soil when plowing.

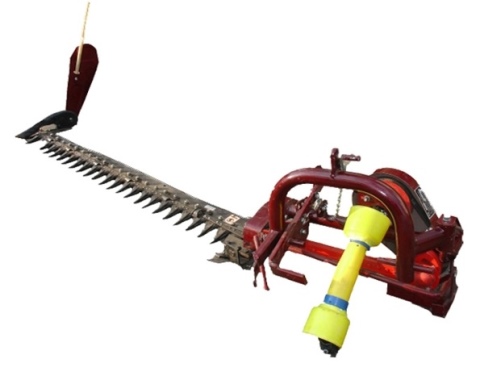

Mowers

For mowing grass and further harvesting of hay for the winter, mowers are used.Thanks to the PTO, the Brait walk-behind tractors can work with rotary mowers. They work by rotating knives, which, under the action of centrifugal force, unwind and cut off vegetation.

And here is a photo of the mower for the Bright walk-behind tractor

Motoblock Brait BR-135G with a mower

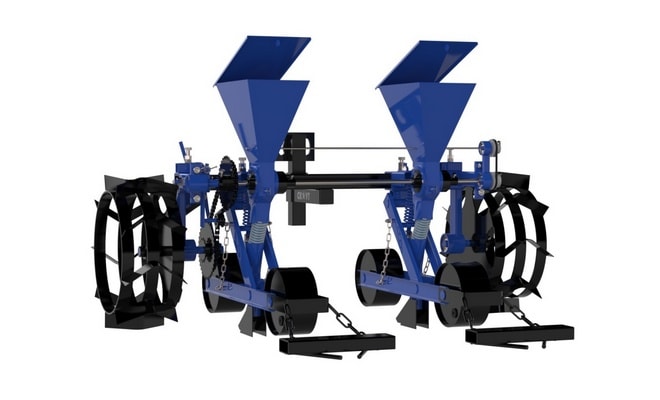

Potato digger and potato planter

Potatoes are considered a widespread agricultural crop, which are cultivated throughout the territory of our country. However, the work of planting, leaving and collecting it requires a lot of physical and time costs. To facilitate these works, Bright walk-behind tractors are used in conjunction with a potato digger and a potato planter.

To care for potatoes, hillers are used, which are two metal discs, which, when driving, throw the earth from the row spacing onto the bushes, thereby cutting off the weeds.

Trailers and trolleys

Trailed equipment is used for the transportation of goods.

On the trailers, an operator's seat is installed in front, which allows you to control the walk-behind tractor while sitting.

Depending on the object to be transported, it is necessary to select the appropriate trailer:

- The option with folding sides is convenient when transporting bulk cargo;

- With high sides, it is used for bulky items;

- The elongated type is used when transporting pipes or log cabins.

Adapter

The main problem when working with a walk-behind tractor is that you need to walk behind it while standing on your feet, which makes it impossible to operate for a long period of time. Therefore, the manufacturer offers special adapters with a seat. They are connected to the Bright walk-behind tractor and allow you to conveniently control the machine.

Snow blower and blade shovel

After the end of the harvest, many owners put the Brait walk-behind tractor for conservation until next spring. However, they can also come in handy in winter for removing snow cover.

Snow blowers are special attachments that pick up snow with a pulley and then, using a rotor, throw it aside at a distance of 5 meters.

A shovel blade looks like a curved sheet of metal set at an angle. While driving, he simply throws the snow layer aside. A shovel blade is commonly used by utility companies to clean roads.

Wheels and lugs

The motoblock manufacturer Bright offers a variety of tire widths that have high grip due to the aggressive tread.

If the walk-behind tractor still slips or jumps over sections of the ground, then to improve its cross-country ability, you can install lugs. While driving, they enter the ground, and give the walk-behind tractor additional stability.

Weights and couplings

The official manufacturer offers a wide range of motoblocks from light to heavy. If its weight is not sufficient, then special weights can be hung to increase it. They are produced in the form of pancakes that are hung on the wheel axle.

A universal hitch is installed on the Bright walk-behind tractor, which allows you to use attachments from third-party manufacturers: Cascade and Neva.

The best models of motoblocks Farmer

All Fermer models come with a low gear and different engine power:

| 15 l. with. | 13 p. with. | 9 p. with. | 6-7 liters. with. |

| FM 1507 PRO-S | FM 1311 MX | FM 901 PRO | FM-811 MX (7.5 HP) |

| FM 1511 MX | FM 1307 PRO-S | FM 902 PRO-S | MB-6.5 T (6.5 HP) |

| 1309md | FM 903 PRO-S | FM 653 M | |

| FD 905 PRO | FM 702 PRO-SL | ||

| FDE 905 PRO | FM 701 PRO | ||

| FM 907 PRO-S |

The amount of horsepower in a vehicle affects the size of the area that it can handle.

FM-653 M

This cultivator runs on gasoline and has the following specifications:

| Motor | Four-stroke |

| Power | 7 p. with. |

| Width and depth of soil processing, m | 1 and 0.3 |

| Number of reverse gears | 1 |

| Number of forward gears | 2 |

| Fuel tank volume, l | 3,5 |

| Work speed, m / min | 6-10 |

| Maximum workable area | 50 ares |

| Wheel dimensions | 4-8 |

| Weight, kg | 80 |

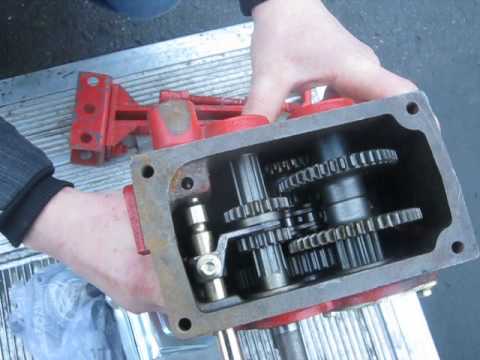

This model is equipped with a gear-type gearbox with a housing made of aluminum. Gear shifting takes place by means of V-belts, which ensures safety and ease of operation for the user. The engine also has a two-stage filter.

This unit is designed for ground operation only and can be modified with optional equipment. There is no power take-off shaft installed here, so all attachments are attached using a bracket. It is possible to adjust the steering rod in height.

FM-653 M is used during planting and harvesting, tillage.

FM-1011 MX

The unit was released in 2006. It can be operated both in summer and winter seasons.

This is a gasoline walk-behind tractor with 10 horsepower. It has the following technical indicators:

| Soil processing width, m | Up to 1.15 |

| Plowing depth, m | 0,3 |

| Engine | Four-stroke |

| Number of cylinders | 1 |

| Forward gears | 2 |

| Reverse gears | 1 |

| Reverse | Yes |

| Fuel tank volume, l | 6 |

| Weight, kg | 135 |

| Wheel dimensions | 12-6,5 |

| Wheel type | Pneumatic |

A gear reducer and a mechanical gearbox are installed here. The direction of rotation of the cutters is straight.

The control is carried out thanks to 2 handles that are adjustable for the height of the person, the design itself is balanced.

Among the advantages of this model are:

- differential for turning without slipping;

- the presence of a high tire tread;

- folding support, which makes it convenient to store the unit;

- the presence of reinforced sickle cutters.

FM-1303 PRO-S

This is a versatile technique with which you can process a plot of 5 hectares or more.

The walk-behind tractor is equipped with wheels that are enlarged in size, which makes it possible to work in off-road conditions. Ergonomic handles made of rubber are adjustable to the user's height. The design includes a power take-off shaft.

Specifications:

| Installed motor power | 13 p. with. |

| Fuel tank volume, l | 6 |

| Width and depth of the cultivated area, m | 0.9 and 0.25 |

| Manual starter | Yes |

| Number of forward gears | 2 |

| Number of reverse gears | 1 |

| Weight, kg | 121 |

| Work speed, m / min | 12 |

| Wheel dimensions | 6-12 |

The advantages are:

- low noise level during operation;

- easy start;

- the ability to work in the winter;

- the weight of the unit allows you to work on heavy soils;

- thanks to the universal mount, you can attach additional equipment to the walk-behind tractor;

- the unit is unpretentious in maintenance (A-92 gasoline and any engine oil are used);

- increased grip with cutters.

FM-1511 MX

This is a powerful motor-cultivator that will cope with the processing of any type of soil, as well as virgin soil. Due to its heavy weight, high power and large wheels, the unit is comfortable to operate and stable during operation. Due to the pivoting axle shafts, the equipment can be turned 180 ° on the spot. The handle adjusts to the height of the user.

The size of the area that the FM-1511 MX can handle is up to 5 hectares.

Technical indicators of this model:

| Motor power | 15 l. with. |

| Forward gears | 2 |

| Reverse gear | 1 |

| Hitch | Universal type |

| Tank volume, l | 6 |

| Tillage width, m | 1,35 |

| Plowing depth, m | 0,3 |

| Weight, kg | 145 |

Advantages of a walk-behind tractor:

- increased power reserve due to the cylinder (volume 0.5 l);

- the level of compression is reduced, which allows you to run the equipment under any temperature conditions;

- gear-type drive;

- easy turn back;

- anti-slip handles;

- due to the wheelbase, slipping and additional load on the motor cultivator are excluded.

Model range of motoblocks from the manufacturer "Don - Inter"

K-700

It uses a 170F seven-horsepower Chinese gasoline engine, equipped with a modified air filter and an engine oil level sensor that will shut off the engine when there is a lack of lubrication.

The motoblock gearbox has two forward speeds and one reverse.

The gear housing is made of aluminum; for an additional charge, a heavier cast iron can be installed for processing heavy soils.

Complete set of the walk-behind tractor:

- transport six- or eight-inch pneumatic wheels,

- cutter cultivator.

Additional equipment and spare parts for the don k-700 walk-behind tractor can be purchased directly from the manufacturer or ordered by phone 8 (863) 272-31-96.

For more details about the operation of the Don K-700 walk-behind tractor, see the video:

DON 1000

Motoblock Don 1000 is distinguished by an extended cultivation width (1000 mm), as well as a modernized gearbox. It has the same 170F engine with an oil air filter. For an additional fee, the walk-behind tractor is completed with:

- lugs;

- potato digger;

- hiller;

- plow.

DON 1100

The heavy Don 1100 walk-behind tractor (its weight is 110 kg) has a classic layout for such devices with a disc clutch and a direct motor drive instead of the belt used for light walk-behind tractors. The center of gravity of the walk-behind tractor is located above the wheel axle, which makes it easy to operate despite its heavy weight.

Don 1100

However, since it uses the same seven-horsepower engine, the power of the walk-behind tractor may not be enough for heavy-duty soil processing.

In addition, the Don 1100 walk-behind tractor has the following modifications:

- Don 1100A is more expensive by 11 thousand rubles due to the use of a diesel engine instead of a gasoline engine, another 6 thousand will be added to the price by an electric starter (model 1100AE).

- Don 1100AD and 1100AED - the most expensive versions (50 and 55 thousand rubles), differ not only in the use of a diesel engine 178F with a capacity of 6 horsepower, but also in the presence of a differential with the possibility of its forced locking.

- Don 1100AED is additionally equipped with an electric starter, which makes starting a diesel engine more comfortable. Motoblock Don 1100AED is the heaviest, its weight is 143 kilograms.

DON 900 (Senda 900)

A light motoblock with a belt drive for a two-stage gearbox, which also has a reverse speed. It is powered by a 160 cc Senda 168FB six-horsepower gasoline engine.

The walk-behind tractor gearbox is heavy (the total weight of the walk-behind tractor, despite its small dimensions, is 74 kilograms), and the processing width is increased to 1200 millimeters.

Don 900

Like other Don walk-behind tractors, this one is equipped with pneumatic wheels and a milling cutter-cultivator, and the rest of the attachments is purchased for a fee.

DON 980

This walk-behind tractor is currently produced only in a version with a differential (980D), which, in combination with a large weight (125 kg), a powerful nine-horsepower gasoline engine and a gear reducer, makes it suitable for long-term work on heavy soils.

DON XS980

Unlike the previous walk-behind tractor, it does not have a differential, due to which it is lighter by 10 kilograms. It also has a variant XS980C - a walk-behind tractor equipped with a less powerful seven-horsepower engine. Both Don 980 and Don XS980 provide a plowing width of 1100 millimeters.

Combine "Case" 5130

Equipped with a high-power motor and a capacious grain hopper. In addition to the basic header, it is equipped with an alternative one that increases the width of the workpiece up to 7.3 m. It is adapted for installing adapters for harvesting rapeseed and maize.

Advantages:

- axial-rotor threshing system;

- sectional concave design;

- smooth running thanks to disc brake pads;

- rotor "Axial-Flow";

- 3 working speeds;

- uniform grain separation by the "Cross Flow" fan;

- possibility of continuous work without unloading.

Specifications "Case" 5130:

- Engine - 6.7 L;

- Fuel capacity - 950 liters;

- Power - 299 hp;

- Bunker - 8.8 m3;

- Weight - 17.3 tons.

Operating instructions for the "Stavmash" walk-behind tractor

Before starting the operation of "Stavmash" walk-behind tractors, it is necessary to study in detail the user's manual, which is included in the delivery set. This document contains complete information about the unit purchased, including the following:

- The device (in diagrams and with descriptions) of the "Stavmash" walk-behind tractor.

- Safety requirements.

- Technical characteristics of the motorized device.

- First start-up guide, running-in.

- Maintenance.

- Typical problems.

Let's take a closer look at some of the sections.

First start-up and running-in of the "Stavmash" walk-behind tractor

Before carrying out the first start-up of the walk-behind tractor, you must:

- fill the unit's fuel tank with fuel;

- pour engine oil into the engine crankcase and transmission oil into the gearbox and gearbox;

- check tire pressure;

- check the reliability of the fastening bolts;

- study the startup instructions.

Immediately after start-up, the "Stavmash" walk-behind tractor is run-in. Correct running-in is a guarantee of the serviceability of all units and mechanisms of the motorized device. What does “correct” run-in mean?

- The duration of the break-in period is at least 8 hours.

- Gentle mode, operation should be carried out at low and medium engine speeds (50% power is ideal), but not more than ¾ of its power.

- During the running-in, the operator checks the operability of all mechanisms, gears, etc.

- At the end of the break-in period, drain the completely used oil from the system and replace it with a new one.

Maintenance

Proper care of the equipment, compliance with all the rules for the maintenance and operation of the walk-behind tractor, will extend its performance and minimize the occurrence of breakdowns. There are several maintenance steps:

- Daily maintenance:

- before work: check the amount of working fluids in the appropriate containers, check the bolted connections, check the pressure in the tires:

- after use: clean, wash and lubricate the walk-behind tractor.

- Oil change:

- engine oil (grade 10W-40) is changed every 25 hours worked;

- transmission oil (brands Tap-15v, Tad-17i) is replaced every 100 hours of operation.

- Scheduled inspections.

- Conservation for a period of long downtime:

- drain fuel and oils;

- clean and wash the walk-behind tractor;

- lubricate;

- put away in a dry place.

Malfunctions characteristic of "Stavmash" walk-behind tractors

We suggest that you familiarize yourself with some of the typical malfunctions of Stavmash units, a more complete list of breakdowns can be found in the instructions:

Strong vibration during operation:

- check the fastening bolts, they may be loose and require tightening;

- the attachment is incorrectly fixed;

- the drive belt is loose or worn out;

- too high density of the processed surface.

The power plant does not start:

- poor quality of fuel or lubricating fluids;

- lack of fuel in the system or the oil level is below normal;

- filters are clogged and need to be replaced;

- lack of compression in the cylinder head;

- for gasoline models:

- the carburetor is clogged or requires adjustment;

- breakage of the high-voltage wire;

- the ignition is not adjusted;

- candles are out of order or smoked;

- the magneto is out of order.

- for diesel units:

- the fuel system is clogged or out of order;

- problems with the high pressure fuel pump (high pressure fuel pump).

Combine "Claas" "Mega" 208

This self-propelled Klaas keyboard harvester with a volumetric chopping drum was produced for a decade from 1993 to 2003 in two generations. It has a unique "APS" technology, which, thanks to the accelerating mechanism, threshes the grains more carefully and efficiently while maintaining their natural quality indicators. Due to the multifunctional connector, it is easily reconfigured for harvesting different types of plants. Combines with alternative threshers covering up to 9m fields in one strip.

Peculiarities:

- functional "Auto Countur" - you can work without any problems on stony soils and fields with complex geometry;

- power plant from the Daimler Chrysler brand;

- the ability to install a larger alternative header than for the above-considered 204 model;

- 2-drum threshing, which better separates the grain from the straw;

- adjustable frequency of rotation of the drum-grinder;

- 3-speed gearbox, which includes speeds from a few hundred meters to 26 km / h;

- a comfortable place of the combine operator, from which all units of the combine are controlled and monitored;

- full light equipment for long work shifts;

- accelerated separation due to toothed turners on straw walkers;

- cleaning the crop from a heap in 3-D projection;

- excellent cross-country ability due to wide pneumatic wheels;

- productive screw conveyor.

Working properties:

- Traction - 135 hp;

- Max. width of one passage - 6 m;

- Seed accumulator - 8 t;

- Main drum diameter - 45 cm;

- Gas tank capacity - 500 liters;

- Weight - 10.5 tons.

User manual

This document must be studied by all new owners of Centaur mini tractors without fail in order to understand its technical characteristics and principle of operation.

Instructions for the first start-up and running-in

The key to long-term use of Centaur mini tractors is the correct first start. The assembly of the machine must be carried out strictly in accordance with the requirements of the instruction manual.

- For the first 8 hours, the Centaur mini-tractor should work in a gentle engine running-in mode. This is done so that the motor parts are lubricated from all sides and fit into the corresponding grooves.

- It is recommended to carry out the break-in by driving with an empty trailer or using cutters to a depth of 5 cm.

- Some salons offer automatic break-in on special machines.

- After that, the oil should be replaced, since a large amount of mechanical impurities will collect in it, and with further use they can damage the Centaur mini tractor.

Conservation

If you do not plan to use the Centaur mini tractor for 2 months or more, then it is recommended to preserve the unit. This requires:

- drain the oil and fuel (they will still collect moisture during this period and become unusable),

- disconnect the wires from the spark plugs,

- lubricate the gearbox (to prevent them from jamming),

-

cover and place the machine in a dry, sun-protected place (to prevent corrosion).

Service

Centaur tractors are unpretentious in daily use.

- Before leaving, you should visually inspect the condition of the Centaur minitractor, check the operation of the steering and brake systems, check the presence of fuel and oil.

- It is recommended to change the engine oil once every 100 hours of operation. As a replacement, the manufacturer recommends using the M-10G2.

- Transmission oil must be changed once before starting spring work or after 1000 operating hours. It is recommended to use Tap-15V.

- Minitractors Centaur diesel. And an important factor in maintaining their technical characteristics is the use of a high-quality and fresh diesel engine.

- It is also necessary to periodically check the condition of the spark plugs, fuel and air filters, tires, etc.

Major faults and repairs

Repair of Centaur mini tractors may cause difficulties for some owners, although the main malfunctions can be easily solved on their own:

If the hydraulic system of the mini tractor does not raise the attachment:

- The oil level may have dropped (it needs to be topped up);

- The hydraulic pump is off (turn it on);

- Hydraulic safety valve hangs up (disassemble and clean valve).

If the engine does not run stably, then here are the possible reasons:

- The fuel level has dropped below the minimum mark (it is necessary to top up it);

- Stretching the belts (must be correctly aligned);

- Clogged fuel or air filters (clean them);

- The carburetor is clogged due to dirt (it must be disassembled, washed and cleaned);

- Problems with the ignition system (most often the plug comes off, or it has become unusable).

If the brakes fail:

- The pedal free travel has increased (adjust its position);

- The brake disc or pad is worn out (replace the corresponding parts).

If the transmission overheats:

- Small gear or bearing clearance (adjust);

- Lack of oil or its poor quality (add oil to the required level that is suitable for this model);

If the starter does not work:

- Broken or poor contact of the wire (solder or link it);

- Weak battery power (charge it);

- Short circuit (clean the surface of the collector or replace the brushes);

- Poor magnetic switch contact (turn switch travel 2-3 turns).

Disassembly and assembly of the engine

Consider the procedure for disassembling / assembling the Don walk-behind tractor engine using the 168F motor as an example, since it is a typical representative of its class - the procedure for repairing the motors of the following walk-behind tractors is absolutely similar: Texas, Foreman, Forza, Sadko, Hooter, Profi, Plowman, Champion.

Assembling the engine

- Drain the engine oil by removing the drain plugs and filler plug.

- Remove the air filter cover and the filter itself, disconnect the gas tank and muffler from the brackets.

- Disconnect the recoil starter housing and cooling fan shroud from the engine.

- Disconnect the governor rod from the carburetor, then remove the carburetor itself.

- Remove the ignition coil.

- Using a three-legged universal puller, press the fan (aka flywheel) from the crankshaft by unscrewing the nut that secures it.

- Disconnect the field winding and its fasteners.

- Remove the cylinder head cover with the gasket.

- After unscrewing the cylinder head mounting bolts, remove the head itself and remove the pushrods.

- Remove the rear crankcase cover by unscrewing the bolts around the perimeter. The camshaft and tappets can then be removed.

- Remove the connecting rod bolts, then you can remove the lower connecting rod cover and remove the crankshaft.

- Push the piston and connecting rod into the freed crankcase. On engines with a sufficiently noticeable cylinder depletion, this is much easier than pushing the piston outward, since a step forms in the upper part of the cylinder in the area that the upper compression ring does not reach.

Oil lubrication

The assembly of the engine is carried out strictly in the reverse order, taking into account the following:

- All parts rubbing against each other should be lubricated with engine oil before assembly;

- When installing the camshaft, it is necessary to combine the marks on the crankshaft and camshaft gears, otherwise the engine will not be able to start;

- After installing the cylinder head, set the piston to top dead center on the compression stroke (both valves must be closed) and adjust the valve clearances according to the manufacturer's instructions. Typically, they are 0.15 mm at the intake valve and 0.2 mm at the exhaust.

- A common mistake is to adjust the valves not at the compression TDC, but with a difference of one revolution - at the exhaust TDC. In this case, the actual valve clearances will be much larger than the specified ones, which will lead to a loss of power and an increase in engine noise.

- Do not allow dirt to get inside the crankcase when assembling the engine and during its operation, otherwise the connecting rod and crankshaft journal may be damaged.

In conclusion, it should be said that, despite the relative cheapness, Don walk-behind tractors are a good choice for cultivating land on a personal plot or small farm. Their design is simple, but at the same time quite functional, and their maintenance and repair are not difficult.

Description of construction

A distinctive feature of motoblocks of a domestic manufacturer is high cross-country ability. The manufacturer's assortment is distinguished by a wide range of attachments. The design of the walk-behind tractor has a Chinese-made engine. This allows you not to think about the selection of the necessary spare parts and components.

The walk-behind tractor is a universal unit, working with which you can use special trailed and mounted implements. Depending on the type, the walk-behind tractor can have an aluminum or cast-iron gearbox, seven- or eight-inch wheels and an engine power of 6.5, 7 liters. with. or even 9 liters.with. In addition, the design can provide for a wide chassis, not a gasoline engine, but a diesel engine and an electric starter. Their presence significantly increases the cost of the walk-behind tractor.

The drive of the device of some models in the line is belt. Other options are equipped with a gear reducer, which allows them to be used when working with heavy soil. The backlash of the hexagon in the gearbox of the walk-behind tractor is small, this is the norm. The key nodes of the walk-behind tractor are the transmission, engine, chassis, and controls.

The transmission is needed to transfer the rotation of the electric motor to the wheels, as well as change the speeds and direction of movement of the unit. Its components are a gearbox, clutch, gearbox. The gearbox device can provide for gear shifting and at the same time gearbox functions.

The clutch provides the transfer of torque from the crankshaft to the gearbox shaft, as well as the disconnection of the gearbox from the engine at the time of gear shifting. It is responsible for a smooth start, as well as stopping the walk-behind tractor, preventing the engine from shutting down. The device has a breather, which is responsible for equalizing the pressure during heating and cooling, which helps to extend the durability of the product. The clutch lever consists of an axle, fork, bolt, clutch cable, nut, washer and bushing.

It is interesting: Review of the best diesel motoblocks from around the world - introducing the question