PREPARING THE MOTOR FOR OPERATION

Fuel mixture preparation

The engine runs on a mixture of motor gasoline with M-8V oil, (M-8A) GOST 30541-78. During the engine running-in period, the oil content in the mixture should be about 8% (by volume), that is, 0.8 liters of oil per 10 liters of gasoline, and during operation - about 4% (by volume), that is, 0.4 liters of oil for 10 liters of gasoline.

Mixing oil with gasoline must be done thoroughly in a separate clean container until the oil is completely dissolved in gasoline. Pour fuel into the tank through a funnel with a fine mesh.

Operating the engine with an insufficient oil content in gasoline is completely unacceptable, as it leads to engine failure. The increased oil content in the mixture makes it difficult to start the engine due to oiling of the spark plug electrodes, impairs the operation of the carburetor, leads to the formation of significant carbon deposits and increases the pollution of the water environment.

When using MC-20 oil during the engine running-in period, the oil content in the mixture should be about 6% (by volume), that is, 0.6 liters of oil per 10 liters of gasoline, and during operation - 3% (by volume), that is 0.3 liters of oil per 10 liters of gasoline.

Installing the motor on the boat

The motor is installed on a boat with a transom up to 384 mm high.

To install the motor on the boat, it is necessary to place it on the boat transom with clamps to the full depth of their grooves and tighten the screws.

The upper part of the gearbox housing must be at least 30 mm deep.

If the transom is high and a cutout cannot be made in it, then it is necessary to attach the motor to an additional frame.

To reduce propeller cavitation, it is recommended to install the upper part of the gearbox housing (anti-cavitation plate) 30–60 mm deeper than the lower part of the transom.

During operation, check the tightness of the screws. To facilitate boat handling, it is recommended to mount the motor as close to the middle of the transom as possible.

When installing the motor, it is necessary to ensure the horizontal position of the propeller axis (taking into account the position of the boat during movement) by repositioning the roller in the holes of the clamp.

Starting the motor

The motor is started in the following order:

1. Loosen the screw on the fuel tank cap 4-5 turns.

2. Open the fuel cock.

3. Fill the carburetor float chamber with fuel by pressing the float damper 19 (Fig. 3).

4. Set the tiller handle to idle (turn clockwise).

5. Make 2-3 jerks with the starting rope. First, with a smooth movement, engage the stop with the flywheel, then jerk it sharply. Do not pull the rope to the very end and throw it after starting.

After the engine has started, check for water leaks and let it run at low throttle for 3 minutes.

If the engine does not start, you need to check the condition of the spark plugs.

6. In case of a difficult start, it is recommended to warm up the motor without immersing it in water, but no more than 15 seconds.

Stopping the motor

To stop the engine, you need to reduce the engine speed to minimum, and then turn off the ignition by pressing the engine stop button. In this case, fuel remains in the carburetor and pipe, which must be drained when the engine is removed from the boat.

In cases where the engine is turned off for a long time, it is recommended to stop it by running out of fuel in the tube and carburetor. To do this, turn off the fuel cock. After running out of fuel in the carburetor, the engine stalls.

Running in the motor

The new motor must not be operated at full load at once. Running-in is necessary for running-in parts.

The duration of the run-in should be 10-12 hours, which corresponds to the time spent on the first 6-8 fuel tanks.

During the running-in of the engine, it is necessary to work at a reduced speed.

After running out of the first two tanks of fuel, you need to check and clean the spark plug electrodes, the tightening of all screws and nuts, including the flywheel nuts, and tighten them if necessary.

After running-in, change the oil in the gearbox.

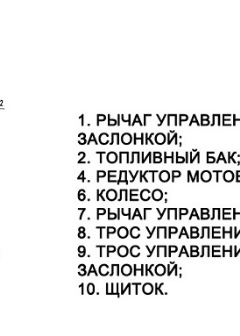

Description

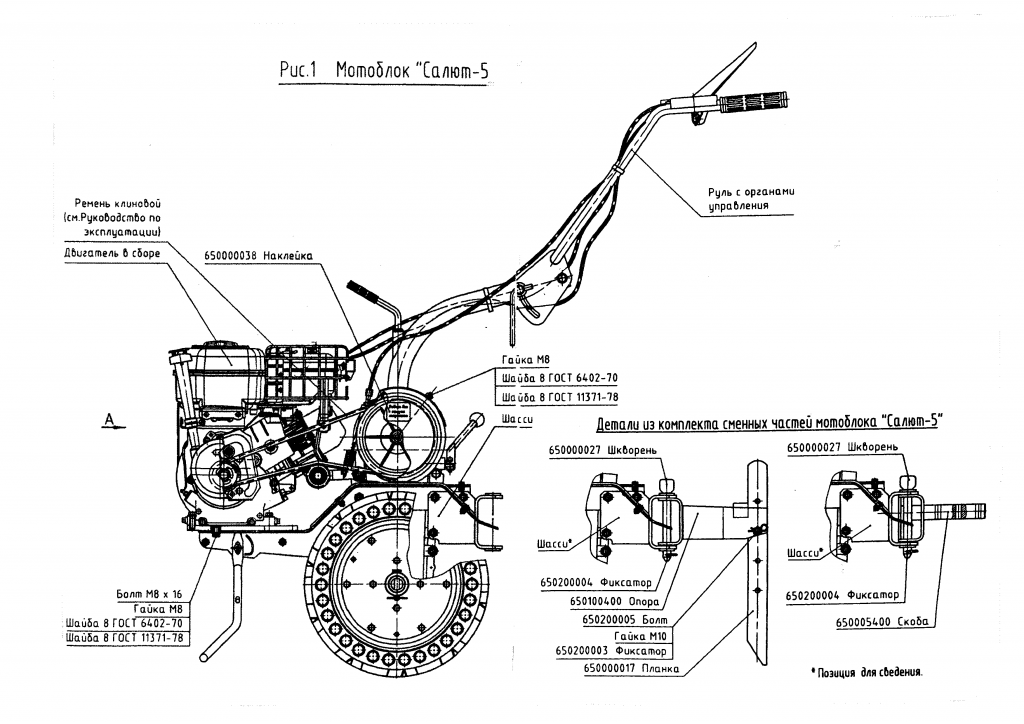

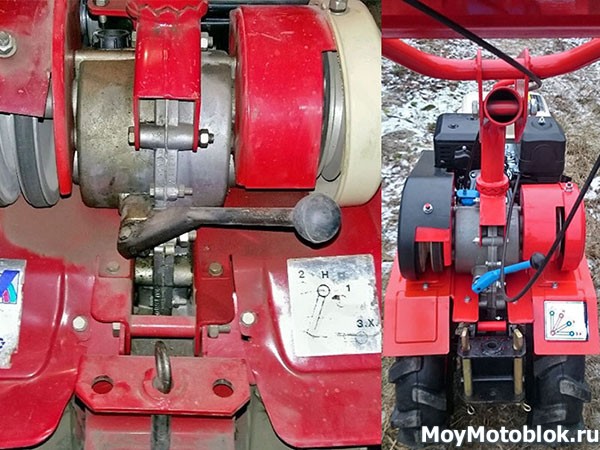

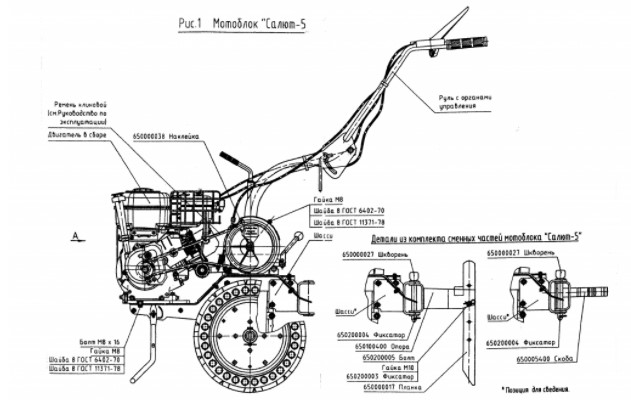

The release of various fifth modifications began in the nineties, and since then the Salyut walk-behind tractors have confidently taken the second place after the Neva in terms of demand.

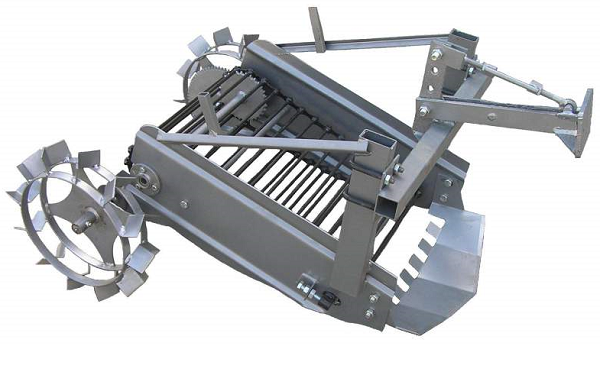

A well-thought-out solution from aircraft designers, high reliability of the transmission in combination with a professional Briggs & Stratton engine make Salyut 5BS-1 durable and unpretentious. A variety of attachments expands the functionality of the walk-behind tractor in many ways, turning it into a universal machine.

Despite its heavy weight, the walk-behind tractor can be transported in the trunk of a car. Removing the wheels and steering wheel is easy. Some similar models of motoblocks cannot boast of this.

Engine

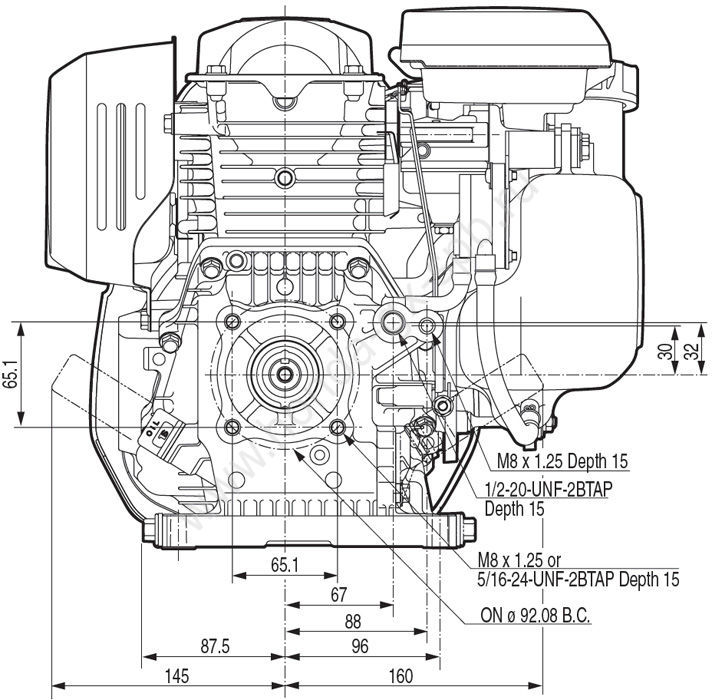

New generation Briggs & Stratton (USA brand) Vanguard engine, model 13H3, 6.5 hp.

Briggs & Stratton 13H3 engine

Engines of the Vanguard series are assembled in Japan (Mitsubishi). The engine is characterized by an extremely high degree of assembly precision.

SAE10W40 oil

The engine operation manual emphasizes the need to change the oil after the first 5-8 hours of engine operation, which is the run-in cycle of the Salyut 5BS-1 walk-behind tractor.

Recommended oil SAE10W40 or SAE30 (at low temperatures).

Vanguard engine advantages

- top placement of valves;

- Provides double protection thanks to Dual-Clean - automotive type air filter;

- the presence of a fuel tank cap helps to reduce the emission of gasoline vapors;

- a reduced noise level thanks to the Lo-Tone muffler;

- the ability to adjust the frequency of rotation;

- thanks to the float carburetor, starting is carried out with one movement of the starter handle;

- not picky about fuel quality - unleaded (leaded) gasoline with an octane rating of more than 85 is recommended;

- The Magnetron electric start and a special Super Lo-Tone muffler can be optionally installed.

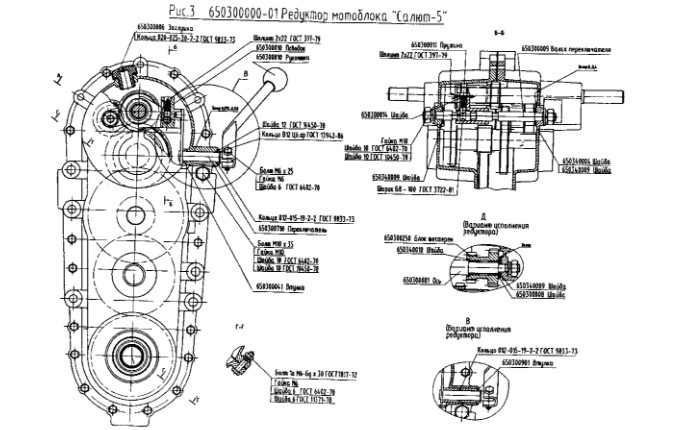

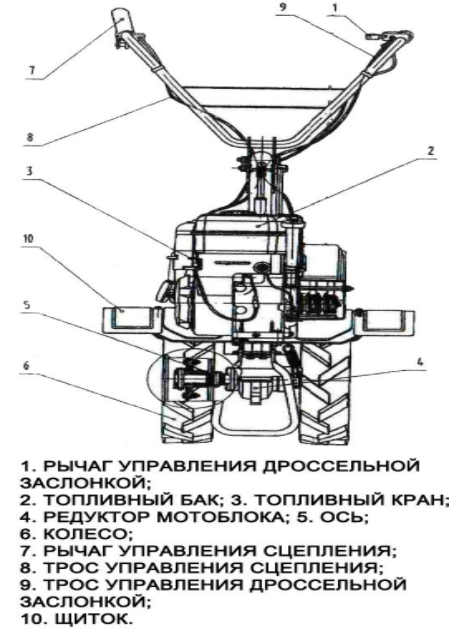

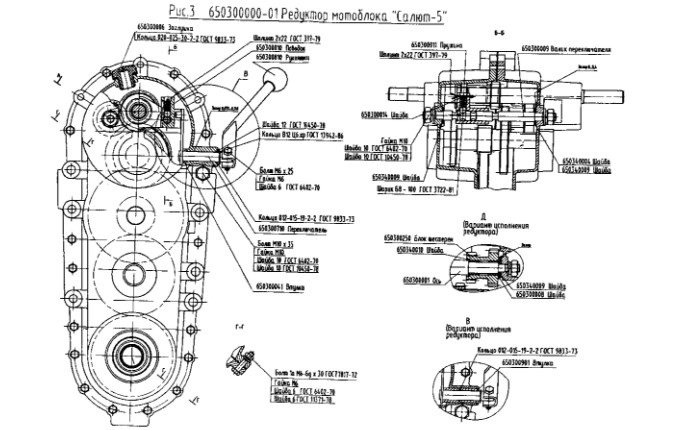

Transmission

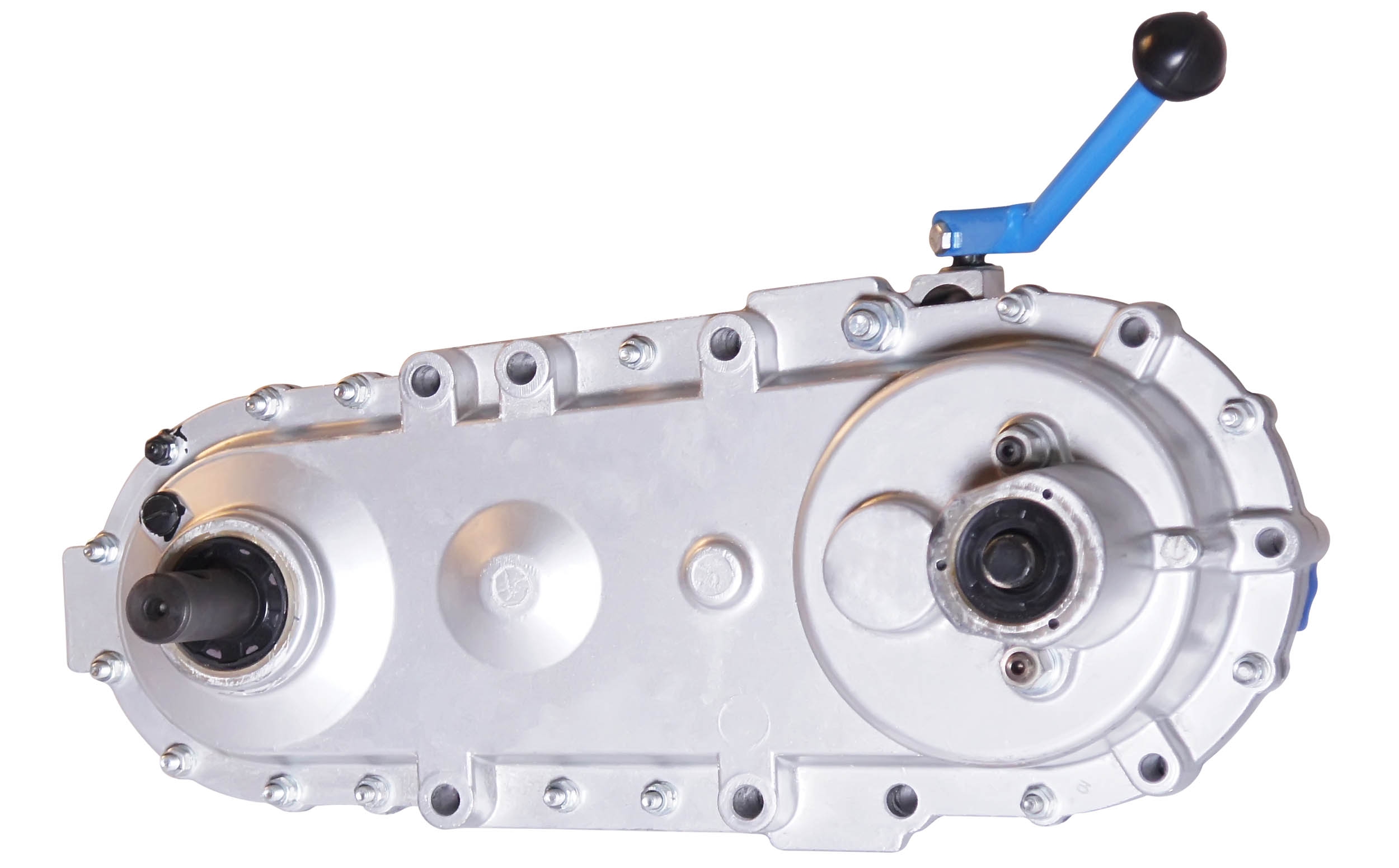

Reducer

Clutch - belt on two belts. The gear reducer is the main feature of the walk-behind tractor. It is able to withstand any load, especially from impacts during plowing (stones, other foreign objects). Typically, such powerful gearboxes are installed on heavy equipment.

Main parameters:

- for ease of use has 2 speeds - forward and backward;

- the steering column can be adjusted in two planes - horizontally and vertically;

- a decrease in speed can be obtained by rearranging the belts;

- reverse speed is included on the gearbox;

SHOM

Pulley

The walk-behind tractor has a power take-off pulley (SHOM) for working with active drive implements. The shaft located on the right side of the gearbox can be used for mounting stationary equipment.

Frame

The frame of the walk-behind tractor is a structure on which, in addition to the engine and the gearbox, protective wings, a support, a steering column are installed. The walk-behind tractor has excellent tipping stability due to the shifted center of gravity towards the front of the structure. The installation of the pin is not provided.

Equipment

When buying a motorbike, the kit includes:

- 4 cutters, as an option it is possible to purchase 6 more. The rotation speed when plowing the soil can vary within the range of 20-130 rpm, the cultivation width is 350-800 mm.

- Pneumatic wheels. They are used when transporting cargo, walk-behind tractor.If it is necessary to mount some types of units, the track width can be increased using expansion sleeves and wheels of larger diameter.

- Coupling bracket. Installed in the rear part of the walk-behind tractor, it is intended for hitching trailed units directly to the bracket or by means of a universal hitch.

- Opener. This is a limiting device for adjusting the depth of soil cultivation depending on the quality of the soil, the maximum depth is 250 mm.

Oka maintenance

Maintenance of the walk-behind tractor includes several stages:

- Daily work before and after use.

- Change of oil.

- Scheduled inspection.

- Long-term storage.

Let's consider the first point.

Before operating the Oka walk-behind tractor, you must:

- check the oil and fuel level, you can only fill in high-quality working fluids;

- check the reliability of bolted connections;

- check tire pressure.

After operation it is necessary:

- thoroughly clean and wash the walk-behind tractor;

- dry in the shade;

- lubricate all components and mechanisms;

- put into storage.

Motoblock Oka with a plow

No less important is the second point - "Oil change". The first replacement is made after running in the walk-behind tractor. Every 25 operating hours worked, the oil level in the gearbox is checked, if necessary, the fluid is topped up. The transmission oil is changed every 50 hours of operation.

Routine inspections should be carried out after the first 100, 200 and 500 operating hours; it is recommended to completely change the oils both in the engine crankcase, gearbox and transmission.

It is recommended to fill the following engine oils into the engine of the "Oka" walk-behind tractor:

- M-53 / 10G1;

- M-63 / 12G1.

We offer you to watch a short video showing the oil change in the gearbox of the Oka walk-behind tractor:

Malfunctions

In the instructions attached to the Oka walk-behind tractor, there is a table that lists all possible malfunctions, but we will focus on the most common ones:

Why the Oka walk-behind tractor does not start:

- the tank is out of fuel;

- the oil level in the crankcase is below normal;

- the ignition system of the Oka walk-behind tractor requires adjustment, or is out of order;

- carburetor adjustment required;

- filters are clogged and require replacement;

- Spark plugs are burnt out, smoked or damp;

- the oil seals are out of order.

Wheels (cutters) stopped rotating:

- the clutch cable is loose;

- it is necessary to change stretched or torn belts, this will help restore the Oka walk-behind tractor to work.

What to do if the speed jumps out on the Oka walk-behind tractor, and the gear change does not work:

- it is necessary to inspect and, if necessary, repair the gearbox - replace broken sprockets, chains, bearings, oil seals;

- adjust the semiaxis decoupling mechanism;

- check gear fixation.

We offer you to watch a video on how to change the bearing and replace the oil seal on the gearbox of the Oka walk-behind tractor:

Installing belts on the Oka walk-behind tractor

In order to perform a replacement, it is necessary to determine what size of the drive belt for the Oka walk-behind tractor is required. The following drive belts are on sale:

For reverse:

- Z (0) 1400 I;

- Z (0) 1400 vn I GOST 1284.1-89.

The belt is dismantled manually by loosening the adjusting bolt. The new belt should not sag, nor should it be under strong tension. Correct tension is when the belt flexes slightly when applied by hand.

Lighting for the Oka walk-behind tractor

Many owners of this technique strive to modernize the device as much as possible, to further increase the comfort and ergonomics during work. One of the modernization methods is to install light (headlights).

It is not so difficult to make light on the Oka walk-behind tractor, it is enough to find and connect a generator of the required power to the unit. The connection algorithm is as follows:

- a button is placed on the steering wheel;

- the generator is attached to the walk-behind tractor;

- headlights are fixed in the front of the motorized device;

- through wires, a connection is made from the button to the generator and to the headlight;

- the wires are insulated.

The more powerful the generator, the brighter the light will be; many people prefer to install automobile electric generators on this agricultural machinery. We offer you to watch a video on how to independently put the light on the Oka walk-behind tractor:

Motoblock Salute Honda GC-190 - the second most popular product of the company

The unit is an excellent choice for those who have small household plots and need a multifunctional assistant capable of withstanding considerable loads. The main "highlight" in the walk-behind tractor is the Honda GC 190 engine.

The design of this part consists of light mechanical elements and reflects the latest developments of Japanese experts. As a result, the novelty pleases with a low level of fuel consumption, maximum environmental friendliness, noiselessness and a single-sided cylinder. Model specifications:

Model specifications:

- Power - 5.5 - 6.0 hp;

- Fuel tank capacity - 1.8 liters;

- Clutch type - belt;

- Engine displacement - 33 cm3;

- Reducer type - gear;

- Weight - 75 kg.

Due to the low center of gravity, the control and maintenance of the walk-behind tractor becomes very convenient. The instruction manual presented on our website will help to solve many problems with functionality.

Advantages and disadvantages

The advantages of these units are as follows.

- The manufacturer uses engines from well-known world manufacturers (Lifan, Subaru, Honda, Briggs & Stratton, Vanguard).

- Motoblocks are equipped with robust gear reducers that combine the reverse function, reliability and ease of use.

- The V-belt transmission has two belts. This ensures comfortable work due to less belt slippage.

- For forward movement there are 2 gears and 1 reverse gear.

- Convenient switching to a lower speed range.

- Due to the presence of a power take-off shaft, it is possible to connect trailed vehicles.

- Due to the shifted center of gravity down and forward, the walk-behind tractors have acquired excellent stability.

- Steering column that can be adjusted in two planes.

- Possibility of combining standardized attachments from different manufacturers.

- The simple design of the walk-behind tractor, which makes it easier to work behind it.

- Processing width up to 90 cm.

- Compact dimensions.

- Quiet engine operation.

The technique also has disadvantages.

- There is little doubt about the Lifan engine. It is inferior in reliability to engines from Honda, Briggs & Stratton, Subaru, Vanguard, so it is worth choosing those units on which engines from these manufacturers.

- The design of the belt drive is quite reliable, but there are many reviews that talk about the mediocre quality of the belts, they have to be changed often.

- Increased fuel consumption.

Motoblocks Salute 5: a series of noteworthy models

The above options for devices are distinguished by their originality and the highest level of popularity. Representatives of the Salyut 5 series are somewhat inferior to them in prevalence, but not at all in functionality. Before considering the specifics of each object, you should familiarize yourself with the general benefits of all members of the group.

- Multifunctionality;

- Significant width of cutters cutting elements;

- Compactness and relative lightness;

- Adjustable steering wheel;

- Solid rubberized wheels;

- The ability to control the transmission and gearbox by means of the steering wheel;

- Reducing vibration levels by means of handles;

- The presence of 2 belts that increase the power of the unit;

- Equipped with a free pulley.

Long-term operation of machines by satisfied owners is a vivid proof that these positive qualities correspond to reality.

Features of SKAT-1200A

- power supply of the load with a constant stabilized voltage according to clause 2 of the table in the presence of voltage in the electrical network;

- optimal charge of the storage battery (hereinafter referred to as the battery) in the presence of supply voltage ("BASIC" mode);

- automatic transfer to backup power from the built-in battery ("STANDBY" mode) when the power supply is disconnected;

- backup power supply of the load with constant voltage according to clause 2 of the table;

- protection against polarity reversal of the battery terminals (self-healing fuse);

- preservation of performance in the event of an open or short circuit of the battery circuit (in the presence of supply voltage);

- automatic protection (disconnecting the output for 1 minute) against a short circuit or an increase in the output current above the maximum value (see table, item 4);

- automatic restoration of operability (nominal parameters) after elimination of the reasons for the increase in the output current above the maximum value or short circuit;

- light indication (indicator "NETWORK") of the presence of mains voltage (mode "BASIC");

- light indication ("battery" indicator) of the presence (within the normal range) of a working and charged battery;

- light indication ("EXIT" indicator) of the presence of output voltage ("EXIT" indicator);

- light signaling (blinking of the battery indicator 1 time per second) about the imminent shutdown of the output voltage due to the battery discharge;

- light signaling (short-term turning on of the battery indicator 1 time in 4 seconds) about disconnection of the output voltage in the "RESERVE" mode by the battery discharge;

- protection of the battery in case of short circuit in the load;

- protection of the battery against deep discharge;

- automatic generation and transmission to external circuits of an information signal in the open collector format ("OK"): about the absence of network voltage "TRANSITION TO RESERVE";

- "cold start" function: restoration of the source operability when a working and charged battery is connected in the absence of mains voltage;

- time of technical readiness for work no more than 20 sec. after connecting to a mains voltage source or battery;

- preservation of performance both under and after exposure to increased and (or) low ambient temperature, increased relative humidity and increased sinusoidal vibration.

Lighting

The most popular modifications, unfortunately, are not yet equipped with a headlight, however, some equipment owners themselves regulate this nuance.

It is very easy to make lighting on a walk-behind tractor; for this, a basic electric generator is usually used. The connection is made as follows:

- a device that generates electricity is connected to a button on the steering wheel;

- from the button, lay the necessary wires to electrical equipment (for example, a headlight);

- the wires are insulated in any way from mechanical damage and water (most often a corrugated pipe is used).

If the generator has enough power, the headlight will be bright. With a lack of power at low engine speeds, the light will go out. Some craftsmen change the generator of the walk-behind tractor for a car or tractor.

How to make a light for a walk-behind tractor or mini tractor with your own hands:

In any case, even without using a generator, you can make light on the walk-behind tractor. This requires only a 12-volt battery and an LED lamp. The battery can be taken from an e-bike or scooter.

It is recommended to put it between the gearbox and the engine. According to the scheme given above with an electric generator, a battery is connected. The battery leads to the switch and then to the headlamp or other electrical equipment.