Overview of Lynx walk-behind tractors

Motoblocks TM Lynx are universal, mobile units designed for agricultural work on household plots and land plots with any type of soil, small and large area.

The equipment is completed with attachments and trailed equipment, which increases its functionality. Motoblocks can perform the following technological operations:

- plowing a land plot;

- weed control;

- loosening, leveling the soil;

- mixing mineral and organic fertilizers with soil;

- mowing vegetation, small shrubs;

- hilling of industrial crops;

- carrying out landscape works;

- snow removal;

- digging up root crops;

- planting and embedding of grain and vegetable crops;

- transportation of goods.

All parts of the units are made of high quality materials, therefore, cultivators and walk-behind tractors have a long service life. Reviews of agronomists who purchased the equipment of this manufacturer show that in practice it works without failures and does not need additional maintenance and repair work.

Each model is equipped with a powerful, 4-stroke, air-cooled Lifan gasoline engine. The maximum motor power has the following indicators:

- for MBR-7-10 model - 7 hp. with engine volume - 170 cm³;

- for MBR-8 model - 8 hp. with engine volume - 170 cm³;

- for the Lynx MBR-16 walk-behind tractor - 16 HP with an engine volume of 440 cm³.

The reliable internal combustion engine of the largest Chinese manufacturer ensures trouble-free operation even in difficult terrain.

- the average cost of the MBR-7-10 is 25 thousand rubles;

- MBR-8 can be purchased for 30-33 thousand rubles;

- the MBR-16 model costs 45 thousand rubles on average.

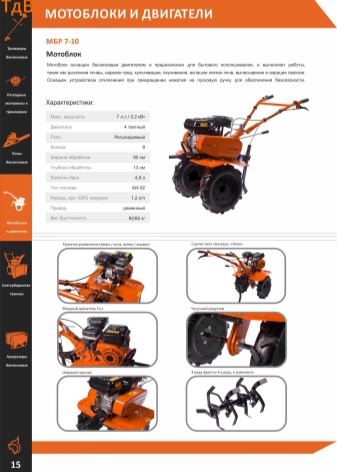

Gasoline motoblock Lynx MBR 7-10 7 hp

The MBR-7-10 machine has the following technical characteristics:

- Reducer type - chain.

- Engine start is mechanical.

- Engine - Lifan 170F.

- The clutch is belt.

- The diameter of the wheels is 5-10 ″.

- Gearbox - 2 forward / 1 reverse.

- The volume of the fuel tank is 3.6 liters.

- The diameter of the cutters is 350 cm.

- The maximum tillage width is 80 cm.

- Machine weight - 82 kg.

The mechanism is equipped with pneumatic wheels with a release for easy movement.

Gasoline-powered motoblocks Lynx MBR-8 8 h.p. and MBR-16 16 hp.

The Lynx MBR-8 motor-block and the powerful MBR-16 are equipped with a fuel tank with a capacity of up to 7 liters, a gear reducer capable of taking heavy loads and a mechanical, multi-plate type of clutch.

The maximum tillage width for machines in 1 pass is 65-95 cm, and the depth is 12-38 cm. Each of the 4 cutters has a diameter of 320 mm and rotates at a speed of 93 rpm.

Fuel consumption for efficient operation in 1 hour is 1.5-2 liters, while moving with increased load - 2.5 liters.

Both agricultural devices are equipped with pneumatic wheels with diameters 10 "and 12" with unlocking devices.

This technique has the following advantages over walk-behind tractors from other manufacturers:

- Quiet operation.

- Economical fuel consumption.

- Robust and reliable construction.

- High power.

- Wide functionality, especially when aggregated with attachments.

- Improved maneuverability.

- Simple controls.

- Convenient transportation.

- The availability of spare parts in the sales markets.

All about the Lynx walk-behind tractors: scope, features and varieties

Motoblocks "Lynx" are fully mechanized devices belonging to the category of heavy agricultural machinery. Demonstrate extreme endurance when used in large land holdings - an area of 10 acres. They are indispensable in the household farm, where several agricultural units functionally replace at once - a hiller, a potato digger, a harrow, a truck, a snow blower, a communal machine, etc.

All this is achieved by installing auxiliary attachments thanks to which the Lynx monoblocks are capable of:

- loosen and plow the surface layer of the soil;

- remove unwanted vegetation mechanically;

- level the territory;

- apply and embed mineral and organic fertilizers;

- to mow down herbaceous-shrub cenoses in cultural landscapes;

- hilling agricultural crops;

- remove snow and ice;

- harvest root crops;

- sowing and embedding in the ground grain, legumes, small-seeded, vegetable crops;

- transport cargo over distances (mainly weighing up to half a ton).

"Pluses" of "Lynx" walk-behind tractors:

- high-quality and wear-resistant spare parts of the unified type;

- durable belt drive;

- two-dimensional steering column adjustment;

- competitive indicators of the width and depth of plowing - up to 100 cm and 36 cm, respectively;

- the most complete set, allowing immediately after the purchase to start cultivating the land plot;

- ideal adaptability for large areas and soils of any granulometric composition;

- compatibility with additional hinges for multipurpose use of equipment.

The "Lynx" walk-behind tractors are not devoid of disadvantages. The main one is the presence of a belt pulley. With its low cost and undemanding lubrication, it more often than other types of gears needs replacement and additional maintenance.

Other "cons", according to customer reviews, include:

- no differential lock - unequal load on the wheel part complicates the turning of the cultivator;

- the inability of the headlight to work in the dark.

All Lynx walk-behind tractors can be classified into:

- Light - with a capacity of up to 7 hp;

- Heavy - develop from 7 to 10 hp;

- Super heavy - generate 13-16 hp.

Operating Instructions

The rules for operating the unit are similar to the rules for using any gasoline motoblocks with a four-stroke engine. An important period of operation is running-in, which is preceded by the assembly of the machine and its first start-up. The assembly is carried out according to the instructions included in the kit.

Running in

The run-in lasts about 20-25 hours. During this period, all the nodal connections of the unit, as well as the engine and gearbox, undergo so-called running-in. During this period, the machine must not be overloaded.

Check the fuel and oil levels in the gearbox and engine before each start. Run-in is considered complete after 8 hours. At the end of the break-in period, drain off the remaining oil and fuel and refuel the unit with a fresh one.

Maintenance of the walk-behind tractor

High-class semi-synthetic oils are recommended for gasoline engines, for example, 10W30 (if the air temperature is above 5 degrees Celsius), at low temperatures, high-class synthetic oil is chosen, for example, 5W40 from any well-known manufacturer.

Machine oil SAE 10W30

Suitable gear oil: 85W90 or equivalent viscosity. Fuel: local high-octane gasoline.

Major malfunctions and their elimination:

- The engine does not start (check the fuel and oil levels, the positions of the fuel cock and the engine switch).

- The spark plug does not fire (adjust the clearances or replace the spark plug).

- When the walk-behind tractor is in operation, extraneous sounds, noise are heard (adjust the carburetor).

- Thick smoke and a burning smell appear (check the quality of the fuel, whether there are oil leaks, whether there are oil spots on the gearbox - if so, contact the service).

Basic rules for caring for a walk-behind tractor:

- Observe the operating rules and before each work inspect the walk-behind tractor for minor damage.

- Clean the outer surface of the engine and cylinder ribs from dirt and plant debris.

- Clean the cutters regularly after cultivation.

- At each scheduled technical inspection (after 50 operating hours and the next 50), add oil to the engine and gearbox, change the air and fuel filters.

It is necessary to store such equipment in a room with a positive temperature. Use only high quality oils and fuels, so the engine will last longer without breakdowns.

On the advantages of "Lynx" walk-behind tractors

Motoblocks of this brand are distinguished by an attractive price, and according to this parameter, they can successfully compete in the market with similar products of other Chinese manufacturing companies. They are also quite simple and unpretentious in direct operation, do not require special care and attention to themselves.

The "Lynx" walk-behind tractor has good efficiency indicators: during operation, its engine consumes about one and a half liters of fuel per hour of operation.

The handles are conveniently located, and the rotary nature of the handle allows you to use the walk-behind tractor in any, even the most inaccessible places. Two-chamber steering column adjustment. The belt transmission of Lynx walk-behind tractors, despite all the seeming frivolity, shows itself to be of high quality, unpretentious and durable in work. The basic configuration of the "Lynx" walk-behind tractor allows you to start cultivating your site immediately after purchasing it, by loosening the soil with milling cutters. The unit is well suited for easy equipping with the widest range of additional attachments and trailed equipment that is possible for use with a walk-behind tractor.

They praise both the compactness and portability of the Lynx walk-behind tractors: the ability to easily and easily disconnect the steering column and fold the unit into the body of an average passenger car.

Motoblocks "Lynx" effectively work with soils of the most varied composition and structure. Best of all - of course, in those areas where the land is cultivated annually. On solid soils and lands close in their characteristics to virgin or meadow, additional weighting agents and (or) lugs on wheels are certainly required for normal operation.

The lineup

To date, the manufacturer offers only 4 modifications of its equipment: MBR-7, MBR-8, MBR-9 and MBR-16. The hyphenated number is responsible for the amount of horsepower.

All Lynx walk-behind tractors run on AI-92 or AI-95 gasoline. Despite the fact that it is possible to fill in the AI-80, it is not recommended to do this, since there is a high probability of clogging of the fuel filters and further failure of the fuel system.

Of the features in the technical characteristics, buyers distinguish the following:

- Low noise level during operation;

- Economical consumption of fuels and lubricants;

- Sturdy frame;

- Great power;

- A wide range of applications when aggregating attachments;

- Excellent handling and maneuverability;

- Possibility to compactly fold the device during transportation by detaching the steering bar;

- 360 ° swivel steering wheel.

As we can see, this technique has a lot of advantages, so it is not surprising that many consumers choose Lynx.

| Name |

MBR-7 |

MBR-8 |

MBR-9 |

MBR-16 |

| Engine power (hp) | 7 | 8 | 9 | 16 |

| Wheel width | 8 | 10 | 12 | 12 |

| Width/

working depth (cm) |

80/

13 |

65-95/

12-35 |

65-95/

12-38 |

65-95/

12-38 |

| Fuel tank capacity (l) | 4,8 | 7 | 7 | 7 |

| Fuel consumption at maximum load (l / h) | 1,2 | 1,8 | 1,9 | 1,8 |

| Net weight (kg) | 82 | 120 | 120 | 140 |

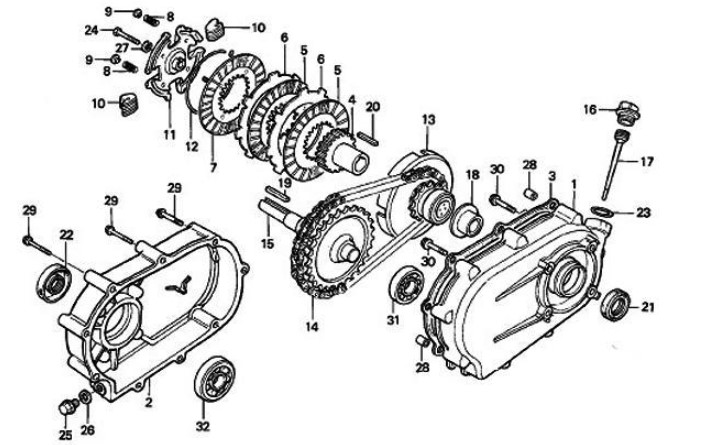

Motoblock Lynx MBR 8

It is the Lynx MBR 8 walk-behind tractor that is considered one of the most popular "assistants" in caring for the land, because the device is compact, low fuel consumption, excellent power and financial affordability. The four-stroke engine (8 HP) can be safely called one of the most high-torque in the class.

Everyone who has ever dealt with the design or disassembly of walk-behind tractors, for sure, if necessary, will be able to carry out the procedure for repairing or replacing parts, because the presented schemes contribute to this.

The availability of components is also a plus, because if problems with functioning begin several years after the purchase, the owners want to be sure that in the event of a breakdown, they will be able to find the necessary parts without problems and extra time. The machine allows you to transport cargo weighing up to 500 kg.

Specifications:

- Fuel tank capacity - 7 liters;

- Drive type - geared;

- Maximum processing depth - 35 cm;

- Fuel type - AI-92;

- Weight - 120 kg.

Particular attention should be paid to the ergonomic handle with a very comfortable grip. Moreover, it is on it that the basic controls are taken out.

The operator can also easily adapt the handle height to suit his height.

About attachments and trailed equipment for motor-blocks "Lynx"

Milling cutter

It is the basic attachment for the "Lynx" walk-behind tractor, which is already included in the standard factory delivery set. The milling cutter is used for high-quality loosening of the upper fertile soil layer, giving it uniformity and increasing productivity. The curved blades of the milling cutter literally turn the earth into "fluff", and also rid the top layer of the soil from the roots and rhizomes of weeds, pulling them out of the ground and grinding. Motoblocks "Lynx" can work with cutters with a working width of 120 cm or 150 cm (more powerful models).

Plow

If it is impossible to start cultivation immediately with milling cutters, then you can work on dense soil with a plow. In the process of plowing, a track is made, after which one wheel is placed in it, the required level of immersion of the plow is set and systematic plowing is carried out.

Mowers

Tillers "Lynx" can effectively work with rotary mowers. They are installed in front of the walk-behind tractor and allow you to cut tall and medium-sized grass.

Hillers

They are used for hilling potatoes and other crops planted in rows, as well as for inter-row cultivation and weeding of a vegetable garden. Potatoes are a very demanding crop, the care of which is greatly facilitated with the help of hillers.

Potato digger and potato planter

Planting and, in particular, collecting potatoes has always been a laborious task. This additional equipment is used to automate this process. The potato planter is made according to the following design: in front there is a plow that makes a trench, and in the back there is a special device with a tank, from which potatoes are taken with a conveyor belt and planted into the soil. At the back of the machine, this makeshift trench is buried with two hillers.

The potato digger with the "Lynx" walk-behind tractor is used of the screen type. She has a knife in front, which cuts the layer of earth and directs it to the roar, where it breaks, leaving potato roots on the surface.

Snow blowers and shovels

If you wish, you can force the Lynx walk-behind tractor to work hard in winter. He will be able to help in cleaning areas from snow. For this, two versions of snow removal equipment can be connected to it. In particular, a snow blower is a special bucket that picks up a layer of snow and directs it to the rotor, with which it spins and is thrown to the side. A more budget option is a shovel blade, which simply pushes the snow to the side.

Lugs and weights

In the standard configuration, any Lynx walk-behind tractor has sufficiently high-quality tires with off-road tread, which provide reliable grip during the processing of light soils.

However, when cultivating heavy - meadow and virgin lands, the walk-behind tractor can begin to slip, slip and "jump" out of the furrow. To improve its adhesion to the soil and optimize the course of the walk-behind tractor, an additional installation of weighting materials and (or) lugs is used.

Weights are used those that are made in the form of pancakes, and they are hung on the wheel axle.

Trailers

With the help of "Lynx" motoblocks, it is possible to carry out transportation of goods weighing up to 500 kilograms over short distances, if you use a special trailer.

Adapter

The main disadvantage of any walk-behind tractor is that you have to stand behind it. Because of this, rapid fatigue sets in, and this puts an increased load on the back (especially in the lumbar region). In order to eliminate this detrimental effect on health, you can use a special adapter that connects to the back of the walk-behind tractor and makes it possible to control it while sitting. An adapter is also needed to work with a trailer.

On the disadvantages of motoblocks "Lynx"

Among the disadvantages of motoblocks of this brand, a rather significant vibration load is often mentioned, which comes from the transmission elements to the manual controls of the equipment.

There were no major breakdowns by any of the owners of motoblocks of this brand for the first 2-3 seasons of their operation. Anyway, they do not report such cases. But on the little things the "Lynx" walk-behind tractor breaks down quite often and a lot.

Often the point here is that the quality of the metal from which it itself and its individual parts is made leaves much to be desired (which, as you know, is not uncommon for Chinese technology). It is good that spare parts for this technique are quite cheap, but in the event of a really major breakdown (for example, the engine "flies"), it will be cheaper to purchase a new walk-behind tractor.

By the way, during operation it is necessary to ensure that the engine does not overheat. If you work in hot weather, at temperatures above 25 degrees, then the motor begins to heat up excessively quickly enough and at the same time loses its power.

Also, the quality of welds is not always what it should be. One of the owners of the Lynx walk-behind tractor broke off the coulter mount at the first attempt to plow the dense virgin soil.

According to the owners of the "Lynx" motoblocks, the belt pulley, for all its cheapness and undemanding lubrication, still needs replacement and additional maintenance more often than other types of gears.

Another drawback, according to the reviews of buyers of motoblocks of this brand, is the lack of a differential lock function - an unequal and uneven load on the chassis and wheel part complicates the maneuverability and turning of the cultivator.

Often, when working from the engine and (or) transmission of the walk-behind tractor, engine oil begins to ooze and gradually leak.

When working with a mower, you have to independently make a homemade protective shield in front of the engine, otherwise, while mowing the grass, dust flies off from it and quickly enough sticks to the engine, including clogging the ventilation holes.

In order to extend the service life of the "Lynx" motoblocks, it is advised not to forget that the durability of each technical device is determined by the care it takes for it, as well as the regularity of inspection and maintenance.

The walk-behind tractor must be run in at minimum loads, during the first eight hours of its operation, in order for the parts to run in to each other properly. Since the build quality of Lynx walk-behind tractors is far from always of decent quality (most often, on the contrary, it is quite careless), before starting to operate a new walk-behind tractor, you need to check the tightness of all bolt and screw ties, and do the same again after the running-in is completed.

It is necessary to strictly monitor the oil level, change the engine oil and air filters in time.

Construction site

A walk-behind tractor is a multifunctional unit and a good purchase for any summer resident or owner of a private house who annually works on his own plot or in the garden. But due to the widest possibilities of use, this type of equipment is suitable for representatives of public utilities, as well as for some companies.

With us, you can independently analyze the presented walk-behind tractors at any time: the prices on the site are always up-to-date, and the list of characteristics and detailed descriptions are detailed enough so that you can compare the models and make the right choice.

In fact, the only point worth dwelling on in more detail is general information about the installed engine. It can be petrol or diesel.

Attachments

With the help of additional attachments, it is possible to increase the functionality of your unit.

Plow

The plow is used to cultivate the land after harvest or before sowing.

There are standard plows and reversible plows. While working with the walk-behind tractor, level the first bed, then place one wheel in this track, and continue plowing. This will make the job much easier.

Cutters

If the plow does not cope and it is necessary to work with hard virgin lands, where there are a large number of weeds and solid objects, then it is better to use cutters to mix the soil. They are saber-shaped and in the form of "crow's feet".

Snow blower

With a small modernization of the unit, it can be converted into a snow blower. For a cheaper option, you can simply attach a shovel - a curved steel sheet - that will effectively shovel snow and, if necessary, other bulk materials.

Lugs

Lugs

When working in heavy soils, the attachment often jumps over and makes up uncultivated land. You can replace conventional wheels with lug wheels.

Weights

Weights

The second solution to this problem may be to increase the weight of the structure. For this, special weighting agents are used. In the factory version, these are steel pancakes that are attached to the wheels, but you can also use improvised means.

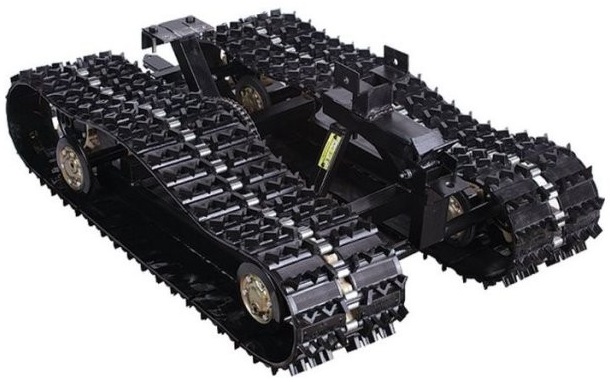

Caterpillars

Track attachment

When carrying out winter work, the main problem is traction. Therefore, to improve the effect, pneumatic tires can be replaced with caterpillars.

When choosing tracks, you need to pay attention to their width. The larger it is, the better the grip will be.

Adapter

Universal adapter

The main inconvenience for the operator during work is the fact that the equipment has to be operated while standing. By using an adapter, a driver's seat can be made. Adapters are an intermediate link between the hitch of the walk-behind tractor and the hitch to it.

Wheels

Additionally, you can install more powerful, wider wheels on the Lynx. The factory assembly provides for the installation of wheels with dimensions 4.00-10 on the unit.

Wheels 4.00-10

Complete set of the Lynx walk-behind tractor:

- walk-behind tractor in the package;

- a set of cutters and fasteners;

- pneumatic wheels (2 pcs);

- assembly and operating instructions.

Detailed overview of varieties

MBR 7-10

This version of the walk-behind tractor belongs to heavy types of equipment that can easily handle large areas of land. The continuity of the unit's operation on the site to prevent its failure should not exceed 2 hours, as stated in the operating instructions. Aggregates are used for the processing of personal territories, plots of land in the country, and so on. The successful placement of the main controls makes such a walk-behind tractor easy to control, maneuverable and ergonomic.

The equipment is equipped with a 7 horsepower gasoline engine and is air-cooled. The engine is started with a starter. With the help of a walk-behind tractor, you can perform the following types of work:

- weed areas;

- mill;

- plowing;

- loosen;

- spud.

When using attachments, you can use this technique to harvest or plant potatoes. The weight of the machine is 82 kg.

Features of operation

Before buying, it is important to assemble the unit according to the instructions and run it in.Break-in must be performed immediately after purchasing the device and must be at least 20 hours in length.

If after that the machine works without failures in the main units, then the running-in can be considered complete and in the future the equipment can be used to perform various functions. It is also important to drain the used oil and change the fuel in the tank immediately after running in.

After carrying out various types of work, it is recommended to perform the following actions:

- clean working parts from dirt;

- check the reliability of the fastening of the connections;

- check fuel and oil levels.

MBR-9

This technique belongs to heavy units and has a balanced design, as well as large wheels, which allows the unit not to slip or overload in a swamp. Thanks to these characteristics, the equipment perfectly copes with the tasks, and, if necessary, it can be equipped with attachments from various manufacturers.

Advantages:

- the engine is started with a manual starter;

- large diameter of the piston element, which ensures high power of the unit;

- multi-plate clutch;

- large wheels;

- large capture of the width of the processed surface;

- all metal parts are coated with an anti-corrosion compound.

Features of operation

To increase the service life of these devices, they must be properly looked after and periodically maintained. Before leaving the site, you need to check the presence of oil in the engine and fuel in the tank. It is also worth visually assessing the condition of the machine and checking the fixation of the equipment before each exit. After 25 hours of operation on the device, it is necessary to completely change the oil in the engine and use the 10W-30 composition recommended by the manufacturer. The transmission oil is changed only 2 times a year.

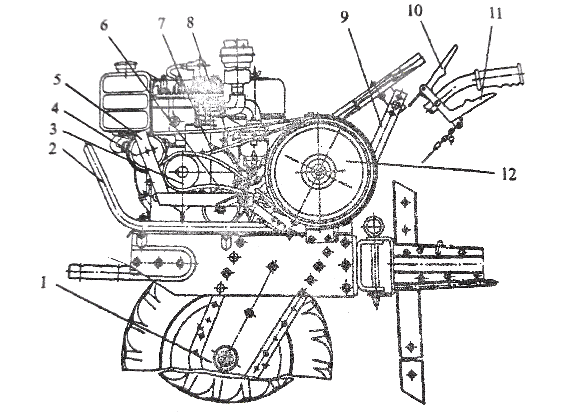

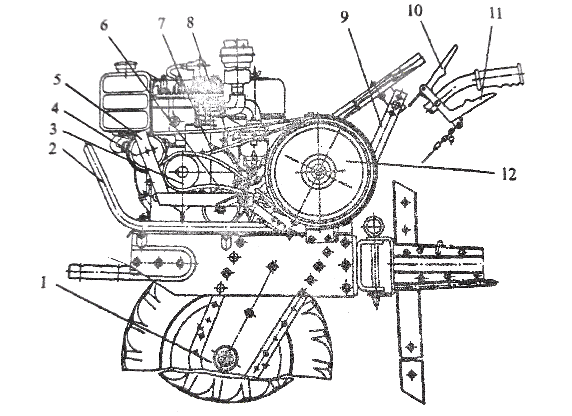

The device of motoblocks "Lynx"

Motoblocks of the "Lynx" trademark are distinguished by a typical arrangement of working units and parts.

The main working bodies depicted in this diagram are:

- reducer;

- arc element;

- main pulley;

- reverse pulley;

- lever arm;

- front wheel drive pulley;

- belt transmission;

- reversible belt;

- steering column adjustment block;

- lever for forward gear;

- toggle switch for reversing;

- gear pulley.

In addition, the important components in the construction of Lynx walk-behind tractors are:

- two handles with an integrated control unit;

- fuel tank;

- retractable support for vertical storage;

- two protective shields that reduce the likelihood of injury in the process of work.

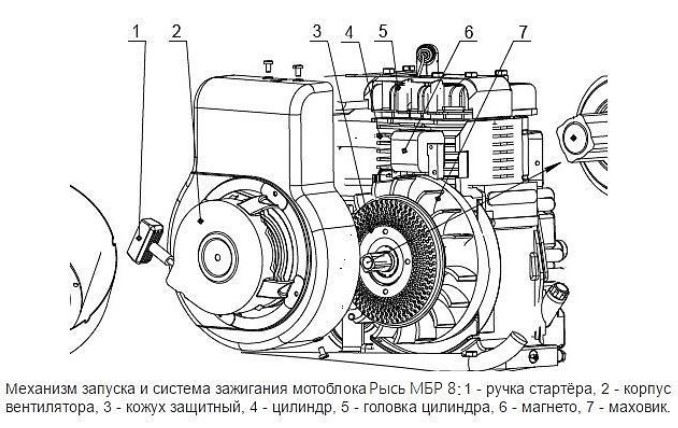

Engine

Motoblock 7-10:

- holds 7 horsepower;

- air-cooled;

- starting comes from a recoil starter.

Engine 170F, fuel tank capacity - 4.8 liters. Crankcase capacity - 0.6 liters. 2 forward gears and 1 reverse gear.

The engine of the Lynx 16 walk-behind tractor is four-stroke. The working volume is 0.5 liters, the volume of the tank is 6.5 liters. The oil sump holds 1.1 liters. The gearbox consists of of 2 front and one reverse speed. Gasoline consumption per hour of operation - 2.5 liters.

Engines, in different models, are different

Engines, in different models, are different

The device and characteristics of the Lynx 8 motor cultivator:

- Fuel tank capacity - 7 liters.

- Drive type - geared.

- Fuel type - AI-92.

- The machine has a 7 liter fuel tank.

Considering the fact that the device consumes gasoline quite economically, the owner does not have to think about refueling or worry about overheating of the Lynx walk-behind tractor.

Technical characteristics of the walk-behind tractor 9:

- Engine - 170F.

- Oil tank capacity - 0.9 l.

- Electric starter - missing.

Description

The Lynx MBR-16 motor-block is equipped with an air-cooled 192F gasoline engine. The volume of the fuel tank is 6.5 liters. Engine power - 16 hp, its volume - 438 cm3.

192F engine

The gearbox of the walk-behind tractor is gear. The device operates at two forward and one reverse speeds.Due to its impressive weight, the unit easily overcomes soils of any composition and moisture level without requiring special weighting agents. The unit is started using a manual starter.

The depth of tillage with the installed cutters is 33 cm. The width of the tillage strip is 115 cm. Powerful stable wheels with dimensions of 6.00x12 give the equipment stability when working in any mode, both on loose soil and on virgin soil.

Features of the petrol motoblock Lynx MBR-16:

- The presence of a power take-off shaft (you can use a walk-behind tractor in combination with various types of mowers, a snow blower, a snow shovel, a sprinkler and other types of attachments powered by a PTO shaft).

- Convenient adjustable control handle; Due to the considerable weight, the passability of the walk-behind tractor on any type of soil is increased.

- When connecting a cart or trailer, the walk-behind tractor can perform the functions of a mini tractor.

- Powerful motor and reliable gearbox - withstands high loads.

- High work productivity.

- Mechanical clutch.

- Recoil starter for quick and easy starting of the engine.

The Lynx MBR-16 motor-block can be adapted to any type of attachment (plow, lugs, hiller, harrow, snow blower, mowers of any type, cart, trailer, potato digger, potato planter, pump for pumping water, shovel-blade).

The standard configuration of the Lynx MBR-16 includes:

- walk-behind tractor packed in a box;

- user manual for assembly and operation;

- opener with fastening;

- protective wings (2 pcs);

- universal hitch;

- cutters (1 set).