Technical characteristics of popular models of hillers

Two-row hiller OH-2: weight - 4.4 kg. Dimensions - 450x130x45 mm, capture width - 300 mm. It is hung directly on the frame of the Neva walk-behind tractor.

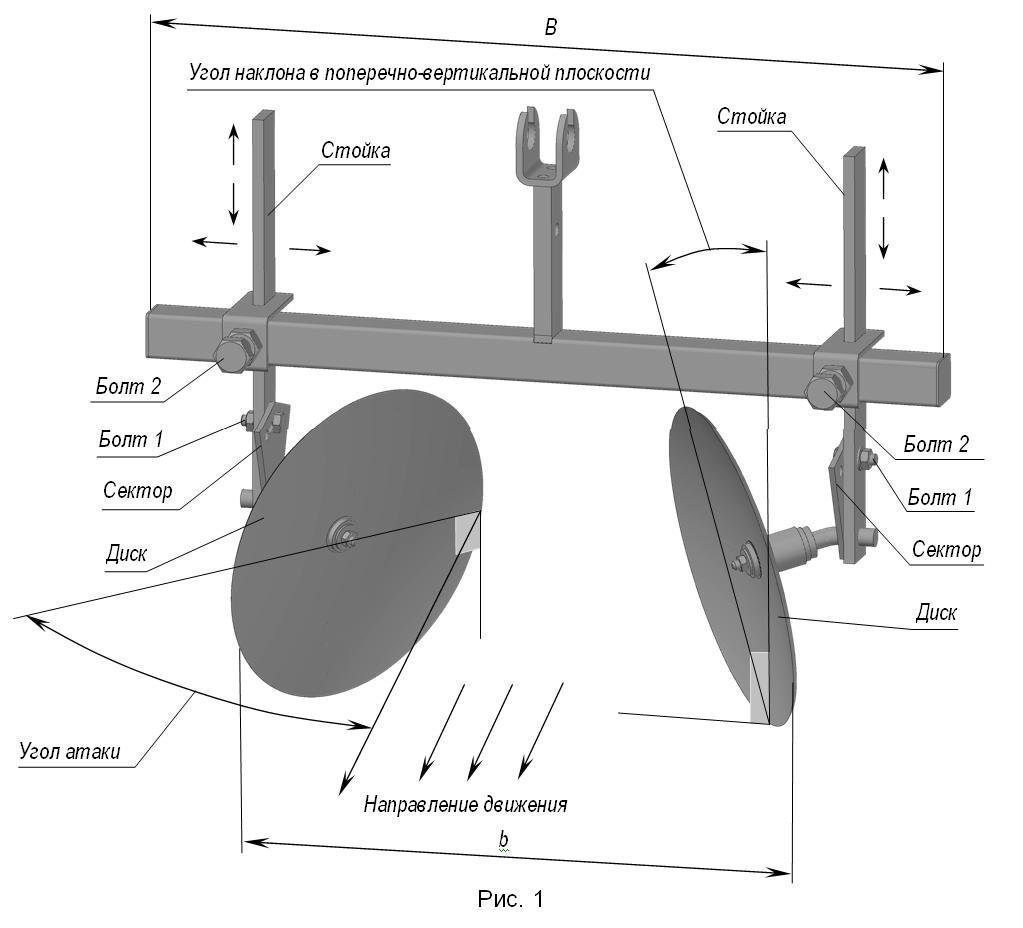

Sliding disc hiller: maximum working width - 700 mm, disc diameter - 370 mm, total equipment height - 625 mm, maximum bed height - 30 cm. This model has the ability to set discs in width, depth and height. For aggregation with the Neva walk-behind tractor, a universal coupling is needed.

Many other models are produced that can also be used to work with the Neva walk-behind tractor - the main thing is that the fastening mechanism matches this particular brand of walk-behind tractor. And the simplicity of the design of the hiller allows, taking the factory version as a sample, it is easy to make it with your own hands. But this is already a topic for a separate conversation.

Hilling

If you decide to huddle potatoes with the Neva motor-cultivator, then you need to take care of the correct planting of the material, since the implementation of the procedure with this device is possible only with a distance between rows of 70 centimeters.

Disk

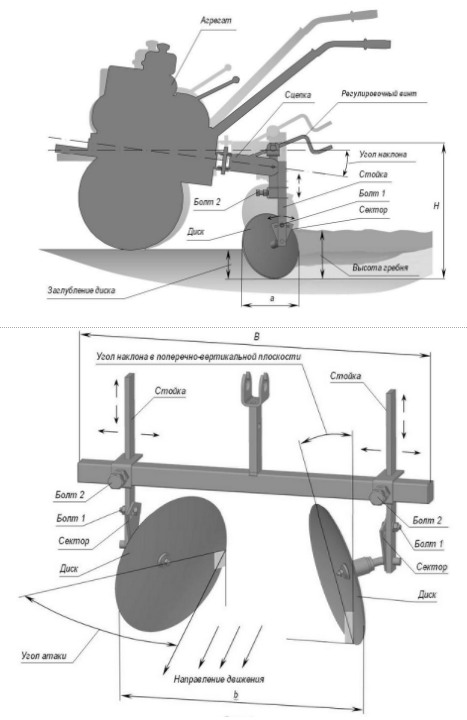

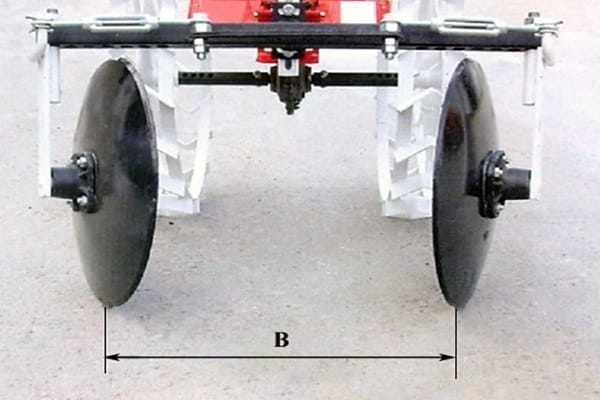

Externally, the device looks like a two-wheeled frame with discs. The following parts are included in the package of the device:

- discs - 2 pieces;

- screw lanyards - 2 pieces;

- racks - two pieces;

- T-shaped leash.

Stands are required to measure the distance between the discs. Due to this, you have the opportunity to set the optimal distance, which depends on the type of crop.

Lanyards adjust the angle of rotation of these discs.

The angle of rotation is adjusted by hand

The angle of rotation is adjusted by hand

The disc hiller has the following advantages:

- even and high ridges;

- good looseness of the soil;

- efficiency in energy consumption;

- ease of use.

With this device, the hilling is carried out quickly and the quality is precisely due to the disks, which evenly cover the potatoes with earth on both sides.

The only drawback of the device is its high price.

Double row plow

Before hilling potatoes using the Neva walk-behind tractor and a two-row plow-shaped hiller, some preparatory steps should be performed. First you need to pick up a trailer. To carry out the procedure, experts recommend using not those intended for plowing the soil, but special structures. Such devices are generally large in diameter. This is necessary to ensure that the bushes are protected from crushing, since small trailers will not be able to sufficiently protect the bushes from the cultivator and the potatoes can be damaged.

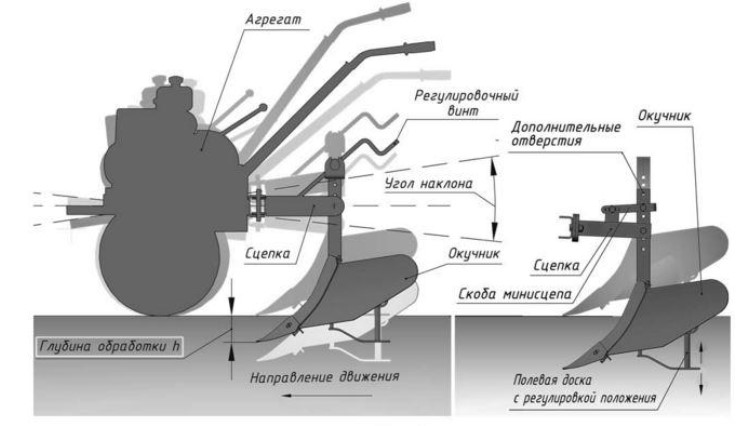

Once the device has been selected, it must be installed on the implement and the width adjusted. The adjustment is carried out in such a way that the hiller falls in the middle of the row. Further, the adjustment of the processing depth is carried out. To do this, the device is immersed in the ground to the desired depth and the axis is set perpendicular to the ground.

When the setting is complete, we proceed to the hilling. In one pass, the device makes trenches on both sides of the row, as well as for the adjacent one. Therefore, the next approach is performed through a row. This feature saves enough processing time.

Single row plow

Hilling potatoes with a Neva walk-behind tractor with a single-row plow-shaped hiller, soil trailers with a smaller diameter are used. Using such a device, trenches are obtained between two rows, and if this distance is too large, then it is necessary to make more row spacings.If you choose the right trailer, then hilling will be carried out immediately between two furrows, on both sides.

After completing the installation, it is necessary, as in the previous case, to adjust the processing depth. Next, simply run the cultivator one row at a time, then move on to the next.

Such a device is less effective than a two-row hiller, however, it greatly simplifies the procedure compared to manual labor.

The main advantage of the device is saving time, effort and energy. It also costs much less than the previous type.

User manual

With the help of a walk-behind tractor and a hiller, planting, loosening and hilling of the grown crop is carried out. The principle of operation of the technique for collecting potatoes is based on uprooting the root crop from the soil and simultaneously sifting the soil. The collection of the vegetable is done by hand. Hilling of potatoes is done in one row. In this case, you can use vibrating equipment of the KKM-1 class, used on soils with low humidity. The soil itself should not contain more than 9 t / ha stones. Let's take a closer look at the full principle of the hiller's operation. In total, there are several methods for preparing the site before planting potatoes. For this, a controlled technique and a mounted potato planter are used.

Method # 1

Planting a crop is performed as follows:

-

lug wheels, disc hiller are hung on the walk-behind tractor, symmetrical furrows are formed;

-

a root crop is manually planted in the finished pits;

-

the wheels are replaced with standard rubber ones, their width is adjusted, it should be equal to the track width;

-

soft rubber does not damage the structure of the root crop and makes it easy to fill and tamp the holes with the vegetable.

Method # 2

Planting a crop using a walk-behind tractor with attachments. This method is used in large cultivated areas. Before starting work, it is necessary to prepare the site in advance: plow the land, create furrows and ridges, moisten the soil. A potato planter is put on the walk-behind tractor, the hiller tinctures are adjusted and the potatoes are planted simultaneously, furrows are created and the crop is covered with soil.

After several weeks, when shoots appear, the land on the site is loosened up with a walk-behind tractor and pedestrian rows are created between the bushes. Hilling delivers oxygen and additional moisture to the plant stems, which have a beneficial effect on the growth and development of potatoes. Weeds are uprooted. For these procedures, a two-, three- or single hiller is used. In the course of work, fertilizers are applied to the soil. The hiller also performs temporary weeding of the land between the rows of the crop. When the potatoes are ripe, the standard work of uprooting the potatoes and harvesting is done using a special hiller with plowshares.

For an overview of the Neva walk-behind tractor with a disc hiller, see the next video.

Let’s block ads! (Why?)

Types of hillers

A hiller is a special equipment that is designed to process the soil furrow. The essence of his work is that the earth is evenly distributed on both sides of the furrow. Thus, the summer resident has the opportunity to carry out the procedure much faster. Another advantage of the design is that you can do it yourself.

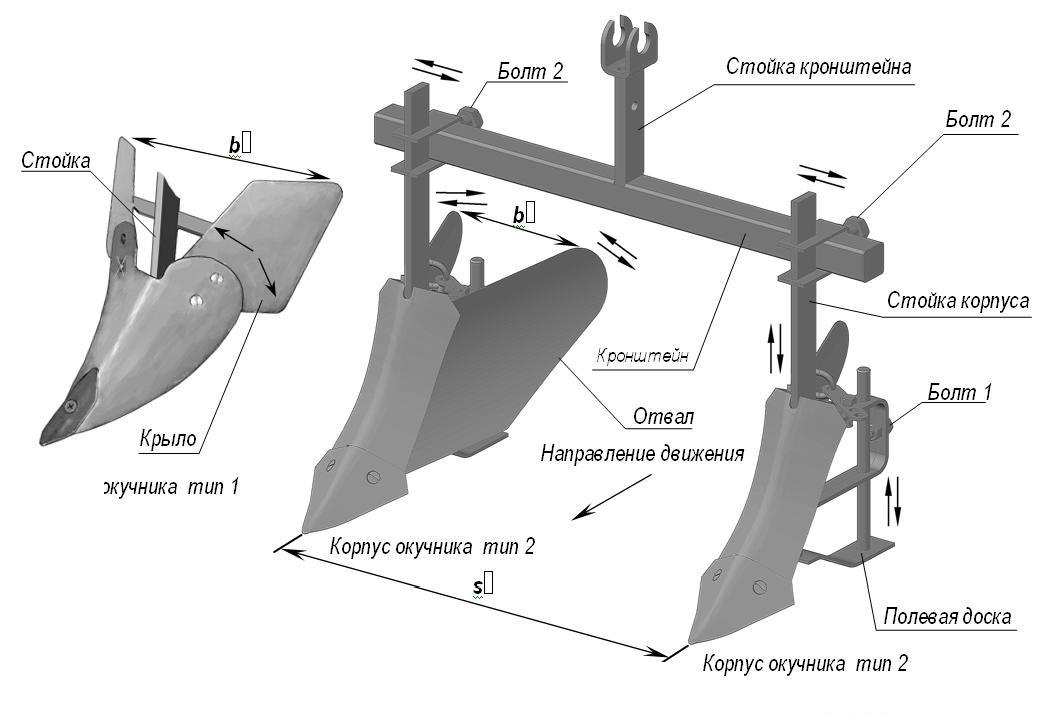

There are several types of hillers for the Neva walk-behind tractor: disc, rotary, double-row. Let's consider each type in more detail.

Disk

The disc hiller for the Neva walk-behind tractor is similar in principle to a two-row one. The main parameters in it are setting the distance between the discs and the angle of attack.

In this video you will learn how this walk-behind tractor spuds:

Regulation of the last parameter is required to ensure high-quality processing of the aisle. This device is intended for hilling one row of potatoes, and not two, like the previous one.As a result, the work will take longer to complete. However, the design has its advantages, it is a higher processing efficiency.

When working with such a device, the following rules should be followed:

- The procedure is carried out on damp ground.

- Weeds must be removed before the operation.

- The distance between the rows of potatoes should be more than 70 centimeters.

- It is necessary to carry out work at first speed.

- The deepening of the disc hiller for the Neva walk-behind tractor must be adjusted as the intended hitch design allows to increase the processing efficiency.

- It is better to do the work measured, otherwise you can damage the bushes.

Rotary

Such devices use two types of forces - rotation and translational motion. A rotary hiller requires a walk-behind tractor to have two gears and a power take-off shaft. The quality of processing is much higher than other types, however, it also costs more.

You can also make such a model yourself. To do this, you only need high-quality metal. The assembly of such a hiller on the Neva walk-behind tractor consists in welding the parts with arc welding and adjusting the corresponding parameters.

The main advantage of the device is its versatility. During the operation, the row spacing is not only loosened, but part of this land is moved to another row.

Double row

Using a two-row hiller, you will need to plant special hilling lugs of the Neva walk-behind tractor on an extension cord. The diameter should be large, which is necessary for the treatment of bushes. Otherwise, during operation, the walk-behind tractor will crush the bushes for itself.

When the lugs are installed, the next step is to adjust the hiller to the Neva walk-behind tractor in the working width, each device should be located in the middle of the row spacing. Then the structure is buried to the required depth and the axis is fixed perpendicular to the ground. This trick allows you to huddle unwanted vegetation in the best quality.

Don't forget to adjust the incline level

Don't forget to adjust the incline level

Now you can go directly to the procedure. Bushes must be processed one by one, going through all the rows. When working, you will get furrows on both sides of the row that you are passing, and one furrow on the side of the adjacent one. The next gap is processed on one side only.

Why do you need a tiller for a walk-behind tractor?

The specified element is used for planting vegetables and caring for them. It works quite simply: after installing the add-on and starting the walk-behind tractor, the part tows the car through the cultivated area with planted seeds, thereby sprinkling the future vegetation with the necessary layer of moist and slightly loose soil

Such an operation is of considerable importance, because it allows you to protect seeds from negative atmospheric influences, increase the level of oxygen saturation, and stimulate growth.

Experts note that hilling with a walk-behind tractor also helps to rid the earth of excess moisture in order to avoid rotting. After treatment, the sun's rays penetrate into the soil much better, and some harmful insects end up on the surface, where they are "removed" by birds. Some weeds are also destroyed, so elementary cultivation can be safely considered a partial replacement for the use of herbicides.

It is important to note that hillers are most often used to process potato plantings.

Types of hillers for a walk-behind tractor

A hiller for a walk-behind tractor is an equipment necessary in agriculture. It is ranked third in importance after structures such as a plow and a winch. If you learn to manage it well, then it will bring a lot of benefits. There are several types of hiller and each has its own purpose, principle of operation, device.

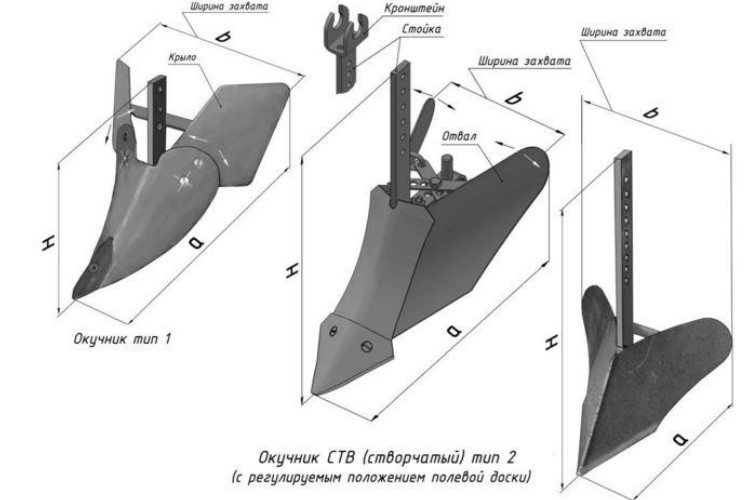

Lister

This is one of the simplest designs installed on a walk-behind tractor. Has a fixed working width.The equipment consists of two fixed wings, which are connected to each other and slightly spread apart. Since the elements are stationary, it is not possible to adjust the furrow width. Therefore, it is impossible to adjust the technique to the size of the row spacing.

There are a number of features:

- Products come on sale with a working width of 25-30 cm. This is not the most convenient option for hilling. The norm for the technology of planting and growing potatoes requires a parameter of 50-60 cm.

- According to the configuration, they note the presence of thin racks that prevent overloading of cultivators if the device is immersed in dense layered soil.

- Many models have an ergonomic, streamlined shape that is recognized as an advantage. So the blades turn out less during work and do not dry out the soil.

When buying equipment, they study compliance with the declared technical characteristics and GOST standards.

Disk

Even if you look at the photo, you can see a number of advantages. The tool is combined with the tool. Suitable for use on cultivators at low speed. With its increase, the output power also increases. This is reflected in the efficiency of plowing, the duration of work on the site.

High usability:

- It doesn't take much effort.

- The structure will gradually move forward without additional nudging from the back.

Versatility and wide range of applications. The tool is suitable for planting tubers, processing growing bushes of potatoes and other crops, during the active growth of the aerial part.

On a note! Models are popular in the manufacture of which high-alloy steel is used, with the presence of additional rolling bearings. They have replaced the bushings and have a large diameter.

Propeller

The hiller type is suitable for equipping a motor cultivator or walk-behind tractor. It has two forward gears. This contributes to an increase in power up to 180 rpm, provided that the vehicle is in second gear. The tool is intended for:

- loosening;

- transferring soil into the garden bed from the area between the rows.

The unit is really useful, but only if you follow the instructions for installation, subsequent operation, maintenance.

Types of hillers

Consider the most popular fixture models.

OND double row

Such a device is intended for processing prepared soils, such as gardens, greenhouses, small vegetable gardens. Its maximum working depth is 12 centimeters and the minimum is 8 centimeters. This parameter can be adjusted. The width of the model's wings varies between 25-45 centimeters.

This hiller has its pros and cons.

This hiller has its pros and cons.

The design has the following dimensions (in centimeters):

- length - 72;

- width - 35;

- height - 54.

Its weight is relatively small - 9.5 kilograms.

STV double row

This model is popular for its versatility. The weight of models of this kind is 10-13 kilograms. The maximum width reaches one meter. The row spacing can be adjusted from 20 to 65 centimeters. The maximum working depth is 15 centimeters.

The main advantage of the design is that each owner can adjust it to suit their needs.

STV NPD single row

These models are used to process fields. The average weight of such a structure is 5 kilograms. The processing width varies from 20 to 36 centimeters, and the maximum depth can reach 15 centimeters.

By using this technique, you reduce the risk of damaging your bushes.

The nuances of one- and two-row devices

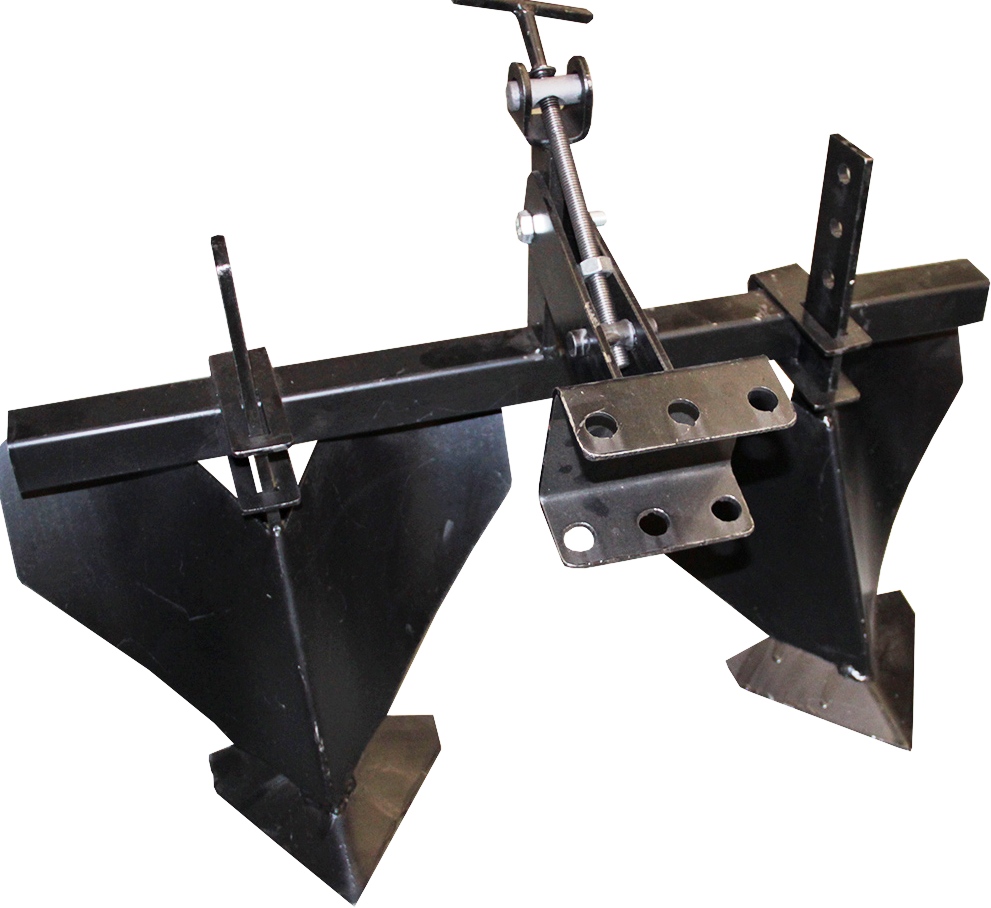

Depending on the type, the models can be one- and two-row. Attachments of the second type are good in that in one pass the operator processes two aisles at once, raking up the soil to the crop and forming furrows.

Basically, a double row tiller is like a bracket post that attaches to the hitch and has 2 posts with hillers that are bolted to the hitch.

The single-row version can process only 1 row per pass. In principle, this is convenient, given that the operator has to spend less time monitoring the progress of the work being performed. So the position and movement of the unit will be more correct, which will reduce the percentage of damage to the crop during the hilling process.

The auger hiller is considered to be low-productivity and is distinguished by a high energy consumption of the technological process of hilling of agricultural crops.

As for the Dutch models, their wings are able to rotate vertically and horizontally. This leads to high-quality cultivation of the land with a reduction in energy consumption. These models are available to most buyers and work well enough.