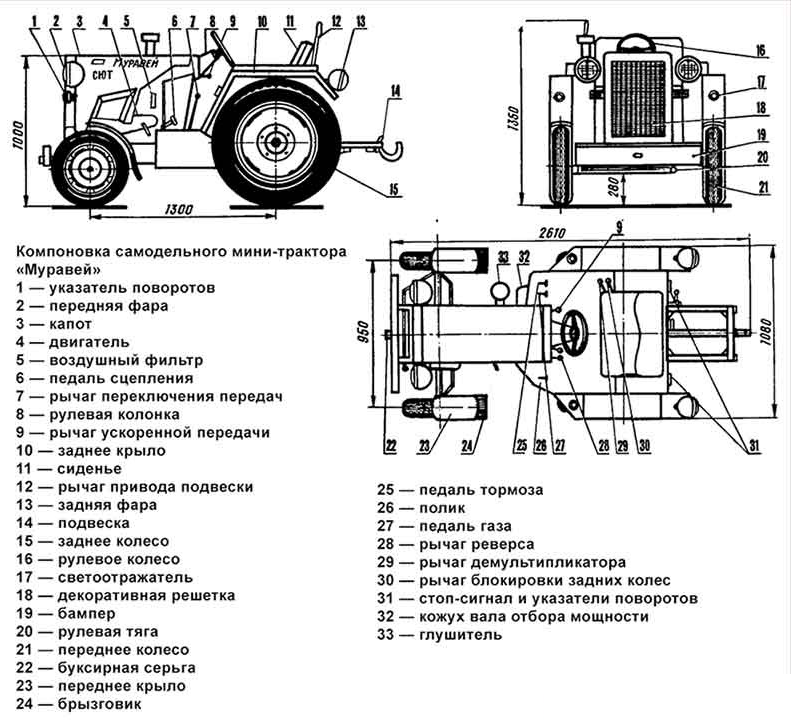

The procedure for assembling a homemade tractor

The production of a mini tractor itself is as follows: according to the drawing, you weld steel profiles and sheets, forming the frame of the future tractor. This, in fact, is the body of the car. Further, it is installed on the equipment of its "internal organs" - the engine, transmission, chassis.

When installing and securing these parts, it is extremely important to carry out all work correctly and in full accordance with the drawings. After you have installed these essential parts of the mini tractor, you should add the cherry on the cake: install the seat, steering wheel, as well as feet and turn signals if you are going to drive on the roads

Usually the last point is unnecessary, but you may want to make your technique really perfect.

Drawing 1

Agro

However, it is worth considering some of the features of motoblocks, which will manifest themselves when using a mini tractor made from it. So, Agro walk-behind tractors are distinguished by such a disadvantage as weak axial arcs.

For more details about the Agro walk-behind tractor, see the video:

Of course, for the walk-behind tractor itself, this is completely imperceptible, but for the design of a minitractor, this can be critical, especially if you want to transport weights on your equipment.

How to make mini tractors from motoblocks of various models?

From the Bison walk-behind tractor

If you need a mini tractor with high power, then the Zubr walk-behind tractor is best used as a base. The drawings that will help you create a small tractor yourself assume the use of the same parts as the previous version.

The manufacturing procedure for this type of equipment is identical with the Agro-based minitractor.

Drawing 2

How to do it yourself from the Neva walk-behind tractor

If you do not want to spend a lot of money on creating home-made equipment, then you can use the Neva MB 1 walk-behind tractor as a basis for it (see how to make a snow blower from this walk-behind tractor here, as well as how to make an adapter for a Neva walk-behind tractor with your own hands, drawings and dimensions) You can buy this type of walk-behind tractor for a penny, and after your processing it will turn into an irreplaceable assistant in the household.

The only thing is that it will be difficult to find suitable new parts for it, since the MB 1 walk-behind tractors have some design features.

Drawing 3

Fracture from the walk-behind tractor Cascade

If you want to use a new walk-behind tractor, but buy it for little money, then one of the best options is the Cascade.

Also, the purchase of MTZ 05 will be very profitable.

Cultivator from the Centaur walk-behind tractor

For those who appreciate maneuverability, power and the ability to perform a wide range of work, you can also recommend the Centaur walk-behind tractor. However, it should be borne in mind that it is quite expensive. But this basis for a mini tractor can be safely called one of the best, because it will work like a clock.

Oka walk-behind tractors are often used as the initial raw material for the manufacture of mini tractors.

For the manufacture of a minitractor, the Salyut S. walk-behind tractor is also suitable.

Here, motoblocks of domestic production have been specially selected, since they are cheaper than foreign counterparts. You hardly want to spend extra money on a product that will be altered and improved anyway. Therefore, the models listed above are ideal as a base.

Specifications

| Walk-behind tractor type (GOST 28523-90): | Average |

| Dimensions: | Length: 135 or 151 cm Width: 60 or 62 cm Height: 110 or 133.5 cm |

| Dry weight: | average 72 kg (62 to 81 kg) |

| Power: | 3.5-6.5 HP (2.6-4.5 kW) |

| Tractive effort: | 60-70 kgf (up to 100 kgf on grousers) |

| Fuel consumption: | 290-435 g / kWh |

| Number of gears: | 2 (4) forward gears, 1 (2) reverse |

| Maximum speed on pneumatic wheels (second value when working on a large pulley diameter): | First gear - 2.8 (3.5) km / h Second gear - 6.3 (7.8) km / h Reverse - 2.0 (2.5) km / h |

| Reducer: | Mechanical, gear |

| Gearbox oil: | TM-5-18 (TAD-17I), MS-20 |

| BОM shaft: | Power take-off pulley (SHOM) for V-belt transmission |

| Coverage of cutters: | 35, 60, 80 cm |

| Cultivator cutter diameter: | 310 mm |

| Plowing depth: | 10-25 cm |

| Wheel diameter: | 39-41 cm |

| Ground clearance: | 11-12 cm |

| Steering gear: | Rod |

| Limiting angle of inclination during operation: | 15° |

Engines

One of the main decisions of Salut engineers is to use not only domestic, but also imported engines from foreign manufacturers (Briggs & Stratton, Honda, Subaru, Lifan, etc.) on a domestic-made frame. Thanks to the use of imported motors, the durability and reliability of the Salyut-5 walk-behind tractor significantly increases, as well as the comfort in the process of work.

According to the reviews of the owners of the walk-behind tractor, the most reliable engines are American Briggs Stratton and Japanese Robin Subaru and Honda motors.

The first Salyut 5 models were equipped with Russian-made engines of the Kaluga Dvigatel plant (KaDvi) of the DM series. They were significantly inferior to foreign engines in terms of technical and operational parameters, therefore, in the first half of the 2000s, they were completely abandoned.

Reducer

The pride of Salyut-5 motoblocks is the legendary gearbox, the mechanism of which is completely made of gears. This is the plant's own development, which was originally manufactured at the main enterprise in Moscow, and then at the facilities of the Omsk Motor-Building Association named after V.I. P.I.Baranov.

The gearbox is housed in a single housing, all connections are bolted.

According to Salyut and many users, only a fully gear reducer is the most reliable, durable and maintenance-free for many years.

Manufacturers pay attention to the fact that during the production of the gear regulator, all technological processes of processing parts are observed, field supervision and design support of production are carried out. Some factories tried to make copies of this gearbox, which were significantly inferior to the original - both in terms of service life and technical and operational qualities.

Transmission

On Salyut-5 walk-behind tractors, the transmission consists of a gearbox (reducer) and a clutch mechanism. Through the V-belt transmission belts and the tension roller, the drive is made from the drive pulley to the power take-off pulley (SHOM).

The speed selector knob on the Salyut-5 is located on the body of the walk-behind tractor, but the company has developed a special set of gearshift mechanism for transferring it to the steering wheel.

The plant produced a special installation kit for gear shifting, which allows you to transfer the speed lever to the steering wheel as on the MB Salyut-100.

The speed of the walk-behind tractor and the rotation of the cutters can be adjusted with a 4-strand drive pulley: you need to turn it around with respect to the SHOM, unscrewing the fastening nut, install the belts in the grooves of a larger diameter and screw the nut back.

The gear pulley consists of 3 grooves, the middle one is free for attachments, the other two are for transmission belts.

Description

Human thought does not stand still and is constantly evolving. To facilitate their work, many farmers decide on the need to buy a walk-behind tractor, which not only allows you to work the land faster, but also to cope with the work more efficiently. But just walking behind a walk-behind tractor is hard, because you need to make an effort to maneuver with it.And this affects the overall performance, so some craftsmen came up with the idea of converting the MTZ walk-behind tractor into a mini-tractor.

There were more positive moments at once. Now you do not need to go after the unit, but you can comfortably sit on the seat and only control the steering wheel. Maneuverability has become more, since it does not depend on the force applied by the farmer. You cannot drive on public roads, but you can get to the field or home by roundabout ways. And the ability to connect a trailer and transport goods is simply invaluable.

Mini tractor from the Neva walk-behind tractor

Such a home-made tractor is one of the best, as it has compact dimensions and high productivity. For alteration, a walk-behind tractor is used as a basis, two additional wheels and an axle.

To correctly carry out the alteration, you should adhere to the following rules:

- Additional wheels should be 14 to 18 inches in diameter. Too small ones can throw the tractor, and large ones will not allow it to move normally.

- The engine of the walk-behind tractor can be located at the back. In this case, it is necessary to widen the track width for better balancing.

- The tires of the equipment are equipped with lugs for higher grip on the ground.

This model is very simple and suitable for conversion. It will be a good option for working in any area.

All-terrain attachment

Track attachments allow you to build a real all-terrain vehicle from an ordinary walk-behind tractor! For this, there is no need to rebuild anything in the walk-behind tractor itself, or in its individual nodes. It is enough just to remove the ordinary wheels, and install all-terrain tracks in their place.

Tracked attachment for MTZ walk-behind tractor

In the conditions of our winters, this is simply not an interchangeable assistant, the all-terrain vehicle can be used for driving on snow, for this you can connect an adapter, but not the usual one in the form of a seat and wheels, but in the form of skis.

Also, the track attachment can be used after rain. Ordinary wheels are not designed for driving on wet soil, because even the lugs slip. The tracked all-terrain module allows you to significantly increase the grip ability and ride on any surface.

Video review of the MTZ-09N walk-behind tractor on skis

The Russian plant "Krutets" offers its all-terrain tracked attachments for MTZ walk-behind tractors. They are designed to work together, because despite the heavy weight, the Krutets prefix can withstand it.

Feature of the tracked attachment "Krutets":

- compatible not only with MTZ, but also with other walk-behind tractors. Due to their design, they are ideally suited to the "drilling" of each of them.

- The length of the all-terrain attachment is 140 cm, height - 29 cm, width - 54 cm.

- The weight of the structure is 71 kg.

- The power of the walk-behind tractor allows you to set this equipment in motion without problems.

Motoblock "MTZ" 06

A motoblock of medium power level, designed to perform a variety of field and utility work. It has a uniaxial design, typical for MTZ motoblocks, which is powered by a 4-stroke SK-6 petrol engine with a cylinder of 245 cm³ capacity. With a similar 5th version, gasoline consumption generates 5.5 hp.

Compact, which is important for storage and transportation. Due to the relief protector of pneumatic tires, the walk-behind tractor overcomes off-road and swampy places without slipping and does not require the installation of lugs

Advantages:

- reliability of the material and technical equipment, which makes the unit practically "unkillable";

- 6 working modes, among which 2 are for reverse;

- manual clutch friction clutch;

- a special hitch that facilitates the attachment of auxiliary devices;

- reasonable price.

Operational parameters:

- Passage width - 0.45 / 0.6 / 0.7 m;

- Carrying capacity - 650 kg;

- Wheels - 15 x 33 cm;

- Dimensions - 1.8 / 0.85 / 1.07 m;

- Weight - 135 kg.

General assembly instructions

The process of converting a mini-tractor from a walk-behind tractor is the same for all of the above models. In order not to repeat the same information every time, we decided to separate it into a separate block. The exception is homemade mini-tractor based on MTZ walk-behind tractor, but we'll talk about it a little later.

Before starting work, you need to prepare the necessary parts and tools. For convenience, you can purchase a ready-made kit for converting a walk-behind tractor into a mini-tractor. The purchase will cost you about 30,000 rubles. From the tool you may need:

- welding machine;

- electric drill with a set of drills;

- wrenches and screwdriver;

- grinder and discs for cutting metal;

- fastener (bolts and nuts).

Before starting work, it is recommended to calculate in advance the kinematic diagram of the future mini-tractor and make the corresponding drawing. Having prepared everything you need, you can start assembling.

Adapter for motoblock Neva

Frame

To begin with, you need to supplement the supporting structure, because you will need to install an additional pair of wheels. To do this, you need metal corners or a pipe.

The section of the pipe does not play a big role, the main thing is that it can withstand the expected loads. The thickness of the walls can also be approached creatively, because the extra weight will only increase the traction of the tractor with the road and will serve as a good help when performing arable work.

The blanks for the manufacture of the frame are cut with a grinder and fastened together with bolts or electric welding. You can combine the connection. For example, connect the elements together with bolts and additionally weld the seams.

It is recommended to immediately mount the attachment to the frame to work with additional equipment. The hitch can be attached to either the front or rear of the frame. If a homemade mini tractor will work with trailed equipment, a towbar is welded to the rear of the frame.

Chassis

For the front wheels, you can buy two ready-made hubs with brakes. The front wheelset is attached as follows: a piece of metal pipe is taken that fits in width to the front axle. The wheel hubs are attached to this tube.

A through hole is drilled in the center through which fasteners to the front frame are carried out. After that, the steering rods are mounted, which are matched to the frame through a worm gear. After securing the gearbox, the steering column is installed.

The rear axle is mounted on bearings pressed into the bushings. A pulley is installed on the axle to transmit torque from the engine. Wheels can be used from an old passenger car or leave the "family" ones, supplementing them with one more wheel pair from another walk-behind tractor.

Mini-tractor from the Agro walk-behind tractor

Engine

Typically, the power unit is mounted on the front of the frame. Thus, the mini-tractor maintains the necessary balance when working with trailed equipment. A mounting system is made at the engine installation site.

Remember that the PTO shaft must be aligned with the pulley on the rear axle of the machine. The transmission of force passes through a belt drive. To facilitate the adjustment and tension of the belts, it is recommended to make the engine mount floating.

Optional equipment

Having assembled the main structure, a brake system and a hydraulic valve are installed to work with attachments. If a homemade mini-tractor will move on the roads, it makes sense to install headlights and parking lights. This will avoid problems with traffic police officers and facilitate work in the dark.

To give the mini tractor a more attractive look, you can equip the equipment with trim elements and a sun canopy. Additional tuning is done based on personal preference.

After assembly, the mini-tractor must be run-in and you can start working.

Mini-tractor from the MTZ-05 walk-behind tractor

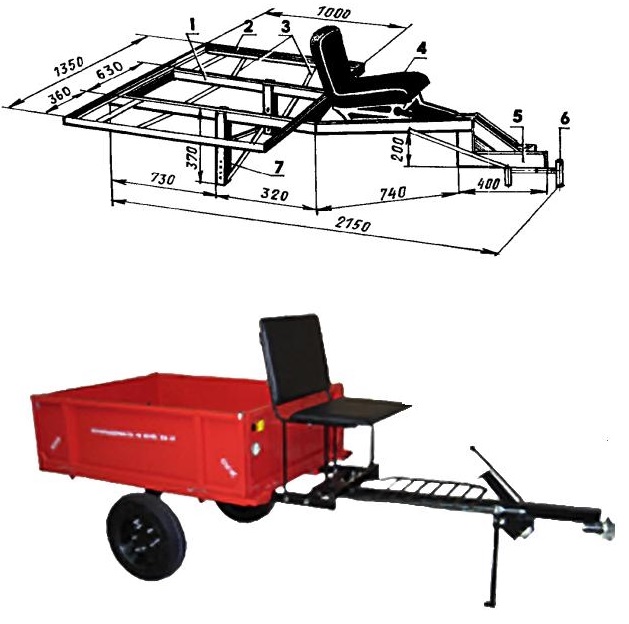

Trailers

Trailers are an integral part of any Belarus and allow you to transport goods over distances.

From the manufacturer

Smorgon plant offers to buy such a vehicle from them.

The PM-00.000 trailer is a standard type of trailer that is attached to the walk-behind tractor using a hitch. On the front side there is a seat for comfortable movement with a load and control of the steering wheel of Belarus.

Trailer PM-00.000

Peculiarity of the PM-00.000 trailer

- Its maximum lifting capacity is 300 kg. And the weight of the trailer itself is 200 kg.

- The trailer is equipped with pneumatic wheels. The ground clearance is 27 cm and the track size is 120 cm.

- The body is made of high quality steel. Its total area is 2.36 m2, or 0.705 m3 in volume.

- Overall dimensions of the trailer: 308 cm long, 151 cm wide and 92 cm high.

This cart has a slight drawback. Its platform is welded to the frame. And you have to unload the cargo yourself.

Analogs

Other manufacturers have a more advanced model - the MP-480 trailer.

Its carrying capacity is 500 kg. The frame is additionally reinforced to give the trailer more stable performance and prevent rollover during operation.

Trailer MP-480

Feature of the MP-480 trailer

- It has a tailgate, thanks to which you can easily empty the load from the trailer.

- If the body height is not enough, then you can additionally build it up with the help of special shields that come with the cart.

- There is a convenient box under the seat for transporting various tools, which allows you to always keep them close at hand and, if necessary, carry out repair work with the cart.

There are a large number of trailers for different tastes and colors, for example: TM-360 and 350 manufactured by Belarusmash, TM 500-700 from Akimovskiy metallurgical plant, etc. But their designs are similar.

The only difference is whether it is a dump truck or not. When choosing a trailer, be sure to consider this point.

Homemade option

In fact, there is nothing better than something that is made by hand. And there are no problems with the trailer. And you don't need to have special skills. If you have a chassis, metal, a grinder and a welding machine at hand, then you can make a trailer yourself.

Trailer manufacturing scheme

Trailer device

- First you need to make a frame. It is best to use a square tube for the frame.

- Then we move on to the body. During the assembly of the body, it is necessary to provide for the possibility of folding the sides, this greatly facilitates loading and unloading operations. And if you wish, you can even make a dumping version so that you do not need to unload.

- Then just put it all together and install a comfortable seat in front, since without it, driving on an MTZ walk-behind tractor with a trailer will be impossible. The range of the seat must be calculated depending on the position of the steering wheel for comfortable control.

If you are interested in the issue of making a homemade trolley for Belarus, then you can look at the forums, there is a large amount of information that relates to drawings, diagrams, trailer sizes, explains the nuances of assembling dump and conventional carts, and much more.

Video review

Review of the transportation of long cargo (firewood) on the MTZ walk-behind tractor

Sedox:

“I didn’t even consider making on my own, I can handle the tool and metal. But there is no time. I work every day and even happen on weekends. It is possible to buy a new trailer and not the best option, but in my situation I did not see any other way out. I chose TS-350. It suits me completely. He is able to go up and down a small hill (you just have to ride on a hill). Plus, its small size makes it easy to manage. Small payload does not matter, I don’t need any more ”

Valerich:

“I transported 10 sacks of potatoes uphill.And I want to say that the road in this case must be solid, if the soil is softened - do not pass. The walk-behind tractor simply rises up and does not withstand the load. Take it and drive backwards. I tried it this way, but in this case there is not enough grip on the ground and Belarus slipped. I had to reduce the load and carry five bags each. Longer, but still easier than wearing with your hands. "

The lineup

The first MTZ-05 walk-behind tractor weighing 135 kg was produced from the 78th to the 92nd years and became the basis for further development of small agricultural machinery. The model was intended for the processing of small land plots: vegetable gardens, garden and backyard agricultural plots and other individual and municipal lands. The device was equipped with a domestic single-cylinder gasoline engine UD-15.

MTZ-06 is one of the most common motoblocks used in personal subsidiary plots and small farmsteads. Thanks to the adopted improvements, the unit has found wide application in all climatic zones of agriculture. The new closed disc transmission and the presence of differentials on autonomous wheels allow convenient pre-sowing soil cultivation and other seasonal field work.

In 1992, MTZ models "08N" and "09N" entered production, similar in production parameters and differing only in engine power. They represent a difficult area of small special equipment with advanced functionality:

- agricultural purpose - plowing, harrowing, hilling, haymaking;

- communal use - snow removal, lawn cultivation, path sweeping;

- transport functions - moving goods, trawling logs.

Thanks to a wide range of additional equipment and the ability to move the power take-off shaft to the front position, the MTZ Belarus 09N model has become one of the most popular heavy motoblocks in the post-Soviet small agricultural machinery market.

The most powerful modification MTZ-12 is designed to work on heavy and virgin soils. The large mass of a single-axle machine does not allow this model to adequately compete with modern two-axle mini tractors, which are more convenient in operation.

Preparation of the MTZ walk-behind tractor for plowing

Plowing is the culmination moment for which any walk-behind tractor is purchased. But for its implementation, it is necessary to properly prepare, adjust the walk-behind tractor, and only then check it in operation.

The preparatory complex of works is presented in the video below and includes:

- Assembling the walk-behind tractor according to the user's manual;

- Tighten all threaded connections;

- Filling of reservoirs for engine, transmission lubricant and gas tank;

- Preliminary start of the motor:

- open the fuel tank tap and pump fuel into the carburetor;

- cover the air flap. We do the opposite with the throttle flap, which should be open by one third;

- we place the starting cord in the groove of the pulley;

- after cranking the crankshaft until compression begins, pull the cable sharply and start the engine;

- if it is turned on successfully, let it warm up at low speed for several minutes and go to work;

- Running-in is a mandatory step for all new MTZ walk-behind tractors:

- duration - 50 hours;

- requirements - performing light transport work under half load;

- Aggregation by weights:

Motoblocks "MTZ" are compatible with a variety of attachments, which can be conditionally divided into 3 groups:

- only 1 or 2 gear:

- Mounted plow PU;

- Soil cutter FR;

- Cultivator KTD-1.3;

- Hiller OU;

- Mower KRM-1;

- only 2 or 3 speed:

Harrow BT-1.6;

- high speeds (3-4) with increased tire pressure up to 0.12 MPa:

PM trailer.

- Attaching the plow for plowing:

- adjust the track to 60 cm;

- we transfer the plow hitch to the working mode and tighten it with a bolt;

- put a 16 cm block under the left wheel;

- we loosen the plow bolts so that its rack takes a vertical position;

- take the handle to set the plowing depth and turn it counterclockwise so that the plow nose is 1.5 cm higher;

- turn on the differential lock and start cultivation in 1st gear;

- we bring it up to 18 cm with the plowing depth regulator;

- gradually move to 2nd gear;

- in case of wheel slip, reduce the plow width.