How to choose a hand hacksaw

By combining all the basic parameters of the saw, everyone can easily decide for himself which one suits him best. When choosing a tool, you need to decide for yourself which saw is more suitable - carpentry or joinery. If the cutting speed is most important, then, undoubtedly, you need to purchase a carpentry. The carpenter's hacksaw has fewer teeth per inch for quick productivity and sawdust removal. If cutting accuracy is a priority, then you should use the carpentry.

The quality of a hacksaw can be determined in simple ways. First, you need to visually verify the flatness of the canvas. Then you need to bend the canvas with a little effort and release it as soon as resistance appears. After the blade plays back and calms down, you should again look at the evenness of the blade. If it deviates slightly from its original position, then the tool is of poor quality and it is not recommended to buy it.

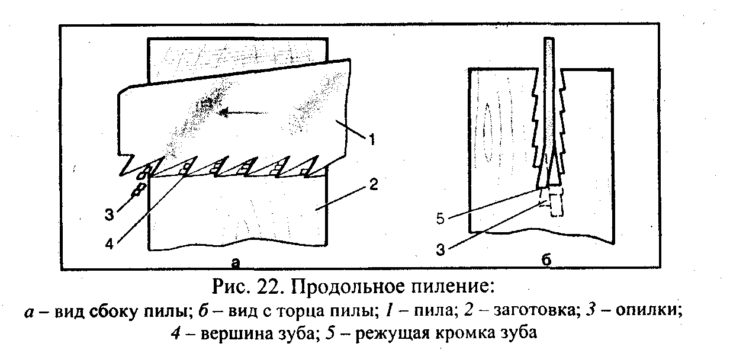

If you are looking for a rip saw, you need to choose a hacksaw with a sharp tooth angle. The teeth of such saws are sharpened only on one side, so the sawing will be done only in one direction - away from you.

Rip saw blade teeth are sharpened in an acute triangle

Rip saw blade teeth are sharpened in an acute triangle

When ripping, the sawing occurs parallel to the grain of the material. For rip sawing, circular hacksaws and bow saws work well.

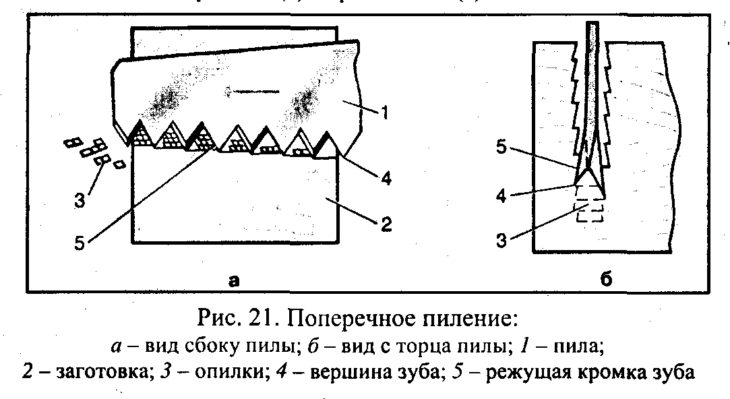

Cross-cut saws are the most common. Their teeth are made in the shape of an isosceles triangle and are sharpened on both sides. This allows cutting in both directions.

For transverse sawing, the blade teeth are made in the form of an isosceles triangle and sharpened on both sides

For transverse sawing, the blade teeth are made in the form of an isosceles triangle and sharpened on both sides

When cross-cutting, the material is cut across the grain. For such sawing, classic hacksaws, hacksaws with a backrest, and with a large material thickness - two-handed saws are suitable.

The price of the saw is also an equally significant factor when choosing. A more expensive hacksaw provides a guarantee of reliability and wear resistance. Those saws, the price of which is much lower than the average, are made from cheaper raw materials and do not guarantee you a long-term service.

A car

Evan wakes up in a car in a scrap yard. He is stripped to the waist and glued to the seat with the skin of his back. Saw's voice from the tape recorder tells him that he, his girlfriend Tara and two of his friends are racists and they have to pay for that. The car is on jacks, the girl lies under it (face directly under the wheel), and there are chained guys in front and behind the car. The voice says that if Evan does not lift himself from the seat (thereby realizing that, despite the color of his skin, all the people inside are the same) and does not pull the lever, after 30 seconds the car will fall from the jack. The tape ends, the car engine starts, Evan tries to free himself with all his might, but does not have time - the car falls, crushing his girlfriend, drives through the garage, ripping out Dan's jaw and hands and knocking Jake chained to the door, drives out into the yard, crashes, after which Evan by inertia, it tears it off the seat and throws it out, from which it instantly dies.

How to choose your tool: selection options

The main indicators of the instruments are:

- Blade length. To perform precise work, small tools with a working base of about 30 cm are used. More productive and efficient results can be obtained using a hacksaw with a blade of 45-55 cm. In this case, the path of the working edge along the workpiece increases, increasing the cutting speed;

- Web width. This indicator demonstrates the stability of the saw when performing precision work.Wide base allows for more precise control of the vertical, which provides a clean and straight cut;

- size and type of sharpening of teeth. The size of the teeth is determined by the degree of cleanliness of the cut - the more accurate it is, the smaller the size and distance between the elements of the notch. The sharpening method makes it possible to obtain a blade intended for longitudinal sawing (triangular teeth with vertices directed forward), transverse cut (notch in the form of an isosceles triangle), and a universal type (triangular tops are slightly sharpened for softer contact with the part);

- Wiring. To reduce friction and heat the blade, the tops of the teeth are alternately deflected from the plane by a certain amount. Modern tools immediately go on sale in a form fully prepared for work, but on old hacksaws, the wiring has to be updated as the notch is grinded. If there are hard-alloy solders, wiring is not required, since their thickness is greater than that of the blade;

- The grade of the metal from which the tool is made. The stronger and tougher the canvas, the freer the master works with it. Increases productivity and quality of sawing;

- The type and angle of inclination of the handle in relation to the cutting edge. This indicator refers to the organoleptic properties of the instrument. The comfortable handle, set at the right angle to the working edge, allows the worker to more confidently control the direction and quality of cutting of the material, spend less effort and get a more efficient result;

- Saw blade material. The harder the metal, the less problems with the cleanliness and accuracy of the cut. Steel from 45 HRC is considered the norm, but more rigid grades 55-60 HRC will be able to provide increased reliability in operation. Some hacksaws have an additional Teflon layer, which eliminates friction and heating of the blade during operation.

Some indicators can be perceived subjectively - it may be more convenient for users to work with a non-standard tool, this is normal, for each master the canvas can be slightly modified (sharpening changed, handle turned, etc.).

Varieties and their characteristics

There are many tools for pruning branches. A novice gardener will have to thoroughly understand all the varieties in order to make the right choice for himself. Garden saws are of the following types.

- Classic - have different blade lengths and a different number of teeth. In most cases, they are equipped with a replaceable blade.

- Narrow - due to their parameters, they allow you to cut any lines or holes. Often the teeth are located on one or two planes, which makes the tool very convenient to use. The canvas itself should not bend, so you should choose steel ones.

- With backing - stiffening rib is provided, which does not allow the hacksaw to bend during operation. In this regard, it is impossible to make low cuts, since this design does not contribute to this, but thanks to the comfortable handle, this option is very comfortable to use.

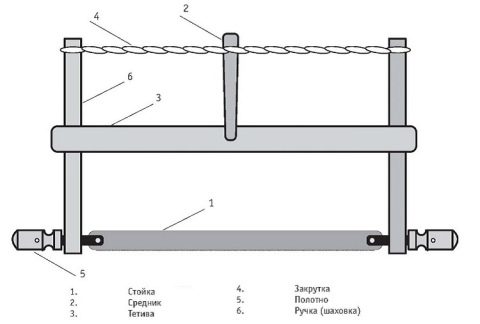

- Onion - used for sawing off knots and rough parts of plants, in addition, you can saw both lengthwise and across. This modification is quite varied and, in its practicality, resembles a small woodworking plant. But this tool is not easy to handle, since it is bulky and has a narrow blade, which is rather fragile and often breaks.

- The reward is outwardly similar to a plane, has several handles. This kind of tool is easy to use, it is easy for them to work on different types of trees.

- Foldable - well suited for both gardening and hiking due to its compact size and light weight.

The electric chain saw is very easy to handle and the lightest of all mechanical sawing equipment. The power supply of such a tool comes from the mains and is limited by the length of the cable.The big plus of this option is that they do not emit exhaust gases. The electric reciprocating saw handles branches of any diameter perfectly. Chainsaws, which have an internal combustion engine, provide for filling the tank with a mixture of gasoline and oil. Approximately it is enough for an hour and a half. For this reason, such a saw is more practical than its electric counterpart.

When buying this type of garden tool, you should take into account some of the nuances:

- power;

- the number of revolutions of the chain;

- the weight;

- availability of a protection mechanism.

Some experts advise using a Ferm electric vibrating hacksaw instead of a hand saw. Such a tool is well suited for tree care in the spring and autumn. The Bosch Keo cordless saw allows you to perfectly cope with various types of work in the garden or in the country. She saws off easily branches up to 80 mm and a significant plus is the presence of a special A-Grip hook, thanks to which such saws are called one-handed, since it is very convenient to work with them with one hand.

The set includes a soft storage case and a battery indicator. The tool is quite maneuverable, and the switch has several cutting modes depending on the type of material. The charge is enough for three hours of work. It is also lightweight and easy to use. Many people know that using a stepladder or ladder in the garden is not very convenient, which creates problems when pruning large plants. In this regard, a special bar saw has been developed for tall trees. It has a telescopic handle that extends to different lengths and allows you to work from the ground without the need for additional tools. The long, maneuverable handle makes it possible to cut branches at different angles.

Types of steel

They make hacksaws of any type from various types of steel, including alloyed or carbon steel. The quality of the product is indicated by the hardness of the canvas - it is checked using the Rockwell method.

Hardened hacksaw blades are made of hardened high quality tool steel. They are very hard, but in some situations they are not very susceptible to bending stress. Flexible blades contain hardened steel on the teeth only. The backing is a flexible sheet of metal. They are sometimes referred to as bimetallic blades.

The high-alloy metal blades cut accurately but were extremely fragile. This limited their practical application. A softer form of this material was also available - it was highly stress-resistant, more resistant to breakage, but less stiff so it was bent and the result was a less accurate cut.

Since the 1980s, bimetallic blades have been actively used in the manufacture of hacksaws for wood. The advantages were obvious - there was no risk of breakage. Over time, the price of the product has dropped, so such cutting elements are used as a universal option everywhere.

Carbon steel is usually the softest and cheapest of the other types. It began to be used in the manufacture of household-level tools. The material is appreciated by craftsmen because it can be easily sharpened. Most woodworking tools are made from carbon steel, as it is sometimes quite expensive to use a different material.

Stainless steel is heat-treated, its hardness coefficient is 45. It is used for the manufacture of tools with a high-quality cutting edge. It can be operated in difficult conditions, but it is more expensive than carbon.

High alloy is widely used in tool making. It is available in different versions: M1, M2, M7 and M50. Among them, M1 is the most expensive variety. Although few hacksaws are made of this material, this type of steel will last longer. It is not used for making large tools due to its intrinsic fragility.Hacksaws made from high alloy steel are often marked HS or HSS.

Carbide steel is used in hand tools because it allows you to perform tasks efficiently. Being very hard, the alloy is carefully processed so that it can be used in the future, since the products can easily break.

Popular manufacturers and models

There are a large number of manufacturers that produce tools for different types of machining.

Among them are:

Sturm 1060-53-400

- German brand, but made in China.

- The blade is 40 cm long and has teeth with durable soldering.

- Purpose - longitudinal sawing of wood.

TOPEX Shark 7 TPI 10A450

- A Polish instrument with a blade length of 50 cm and a width of 6.5 cm in the middle.

- Able to carry out both transverse and longitudinal cuts.

- It has a comfortable two-component handle.

FIT IT Profi 40474

- 40 cm saw blade with plastic handle is designed for cross-cutting wood.

- Small size hardened teeth (11 per inch length) are highly resistant to working loads.

STAYER MASTER 1506-45_z01

- Reliable and stable tool.

- The blade length is 45 cm, there is a possibility of longitudinal and cross-cutting.

- The large hardened teeth are designed for high performance and speed.

Runex Сlassic 577401

- The blade is 40 cm long and has universal teeth that can handle almost any task.

- Russian brand, but production is in China.

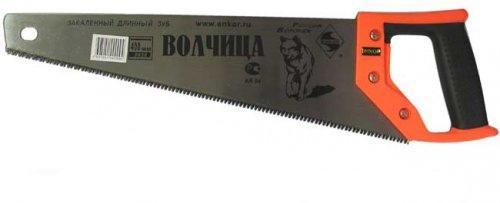

ENKOR 9858

- The tool of a domestic manufacturer belongs to the "Wolf" series.

- 40 cm blade with hardened trapezoidal teeth made of high quality steel.

- The notch size is 4.5 mm.

IZHSTAL 030108-050

Production of the plant in Izhevsk. Blade length - 50 cm, tooth pitch 6.5 mm. A distinctive feature is the lack of wiring, which is perceived by some as a disadvantage. However, experts prefer to create their own cutting edge geometry. The price of a hacksaw is low, which was an additional reason for high demand.

Expert opinion

Dmitry Levin

It is impossible to list all manufacturers and models, since the number of quality tools on the market is huge. An experienced specialist and a novice master can find for themselves a hacksaw of any type and size that fully satisfies his requirements and wishes.