Bosch jigsaw: high price and expensive repairs

And of course Bosch. The power tool of this manufacturer is distinguished by the high quality of components, assembly and a long service life, provided that it is treated with care. He also has a drawback - the price. Moreover, both the product as a whole and the spare parts are expensive.

It should be noted that the Bosch tool practically does not break, but there are some nuances that appear during long-term use. For example, wear on the brushes of the electric motor, failure of the speed controller or the device for holding the saw blade. There are accidents and more complicated ones, failure of a rod or an anchor, but this is, rather, from incorrect handling.

As in the case of Metabo, Bosch jigsaws are best repaired at service centers. There they will install original spare parts and give a guarantee for the repair performed. But this is an expensive pleasure.

After reading the article, the user received theoretical knowledge about jigsaw failures. Now, in the event of a breakdown, he will be able to determine the cause and make the right decision, and maybe even perform minor repairs.

Drill button connection diagram with speed controller and reverse

An actually visual connection diagram is shown in the image below.

I will give a few clarifications.

- In the figure, the most common type of spare part in question. Fastening of electrical wires from the mains plug is carried out to the terminals, which are bolted. The rest are stuck in self-clamping contacts. If your button is not like that, then it is better to make notes on the old copy of what is attached where. Also, a diagram can be drawn on the body itself, according to which you can also navigate.

- If you connected the capacitor as described above, then after connecting the wires from the plug, you will have only two contacts on the bottom of the case, where you need to plug two cables from the stator. They usually have the same position on the stator as shown. They need to be longer than the other two so they can reach their clamps. In this case, there is no difference which wire to stick into which of the two contacts.

- The remaining two electric wires from the stator, as well as cables from the brushes, are connected to the reverse clamps. In this case, the connection is carried out diagonally: the wires from the stator are stuck on opposite sides into the diagonally located contacts; and from brushes as well. In this case, from where exactly the wires will be stuck, only depends on which direction the cartridge will rotate at a certain position of the reverse trigger. The main thing is to connect diagonally.

This is the connection diagram. I hope you can get everything connected correctly and the drill will work as it should.

Electric jigsaw Bosch PST 650

There is no need to talk about what an electric jigsaw is intended for. The topic will cover the main issues:

- how the electric jigsaw motor works;

- electric jigsaw diagram;

- connecting an electric motor through a capacitor;

- repair of the electric motor;

- sharpening the jigsaw blade.

Device

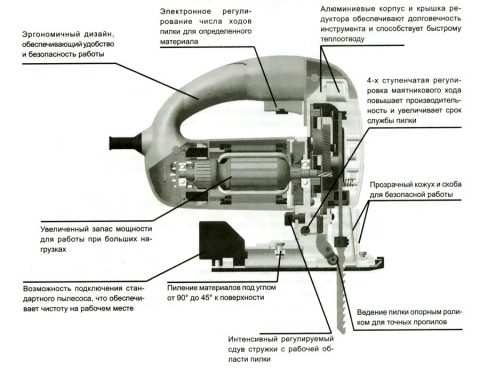

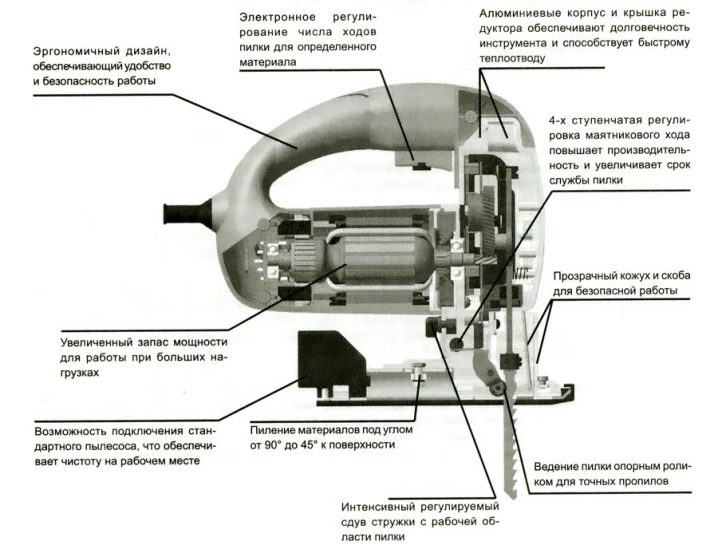

The general design of the Fiolent jigsaws differs little from the generally accepted one. All models are equipped with a plastic bracket-shaped handle, which facilitates visual control of the cut line, but makes it difficult to work on inclined surfaces.All models are equipped with a pendulum blade motion (the so-called "pumping"), which has three modes that differ in the amplitude of the longitudinal motion of the saw.

Unlike most competitors, the saw holder in jigsaws of the Crimean plant is a reliable steel lock, which is fixed with one flat-head screw. Such a simple design provides a strong clamping of the file, reliably fixing it without backlash and distortions. The gear housing in all versions of the tool is made of durable aluminum alloy, which significantly increases its reliability compared to products where this part is made of plastic.

All models use a stamped steel sole, which is attached to the steel ski. This increases the reliability of the structure, although it makes it noticeably heavier. At the same time, all models have the ability to install the sole at an angle of 45 ° to the plane of the blade (in two directions). All jigsaw options have sawdust blowing function and are equipped with a mount for additional connection of a vacuum cleaner.

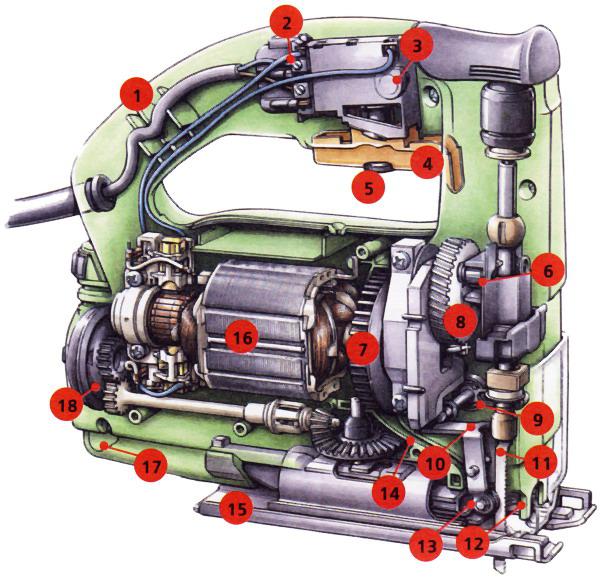

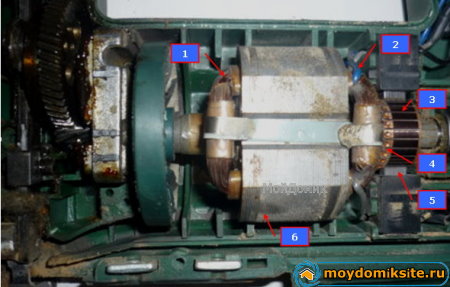

The device of the electric part of the jigsaw

The electrical part of the jigsaw looks like this:

- Motor stator winding

- Copper winding terminals

- Rotary collector plates

- Rotor

- Brush holder with graphite brush

- Stator (electrical steel core).

As you can see, the tool uses a collector electric motor, the main elements of which are: stator, rotor, carbon brushes. The stator is made of electrical steel and has a rectangular shape with slots in which the stator windings are located. There are two stator windings - they are located opposite each other.

The rotor of the motor is a shaft (located inside the stator) with special grooves in which the so-called armature windings are located. From these windings, leads come out that are connected to the collector plates. The manifold itself is pressed onto the end of the rotor shaft.

During the operation of the electric motor, graphite spring-loaded brushes move along the collector plates. Thanks to the latter, an electric voltage is applied to the armature windings.

By the way, when repairing any power tool, priority is given to the condition of the brushes.

The last thing to consider in the jigsaw device and its electrical part is a button and a capacitor. The jigsaw button is a rather complex element in terms of functionality. With its help, voltage is supplied to the engine and the frequency of rotation of the armature shaft is regulated. The shaft rotation speed is controlled by a rheostat built into the button. In other words, due to the rheostat button, the user can manually speed up or slow down the movement of the saw blade.

As for the capacitor. The main purpose of this element is to remove the residual voltage from the windings after turning off the jigsaw. In addition, the capacitor smooths out the ripple that occurs in the power grid due to the operation of the tool.

With the electrical part sorted out, we turn to the consideration of the mechanical component.

Models

The current model range of the company's products includes models of medium and high power.

- PM3-600E - the cheapest option with a power of 600 W, allowing to achieve a cutting speed of 2600 strokes / min. These characteristics allow him to cut through steel to a depth of 10 mm. The maximum cutting depth for wood is 85 mm.

- PM3-650E - a tool with increased power up to 650 W. Starting with this model, all jigsaws are equipped with a guide roller, which increases the machining accuracy.

- PM4-700E - a variant with a power of 700 W, which allows you to cut wood to a depth of 110 mm.

- PM5-720E - increased power up to 720 W and travel speed up to 2800 strokes / min allow cutting wood up to 115 mm.

- PM5-750E is the most powerful version (750 W).

How does it work?

The pump mode improves chip removal from the cut and is only intended for soft materials such as wood and plastic. When processing hardwood and soft metal, it is desirable to reduce the pumping rate. In the case of making cuts in ceramics and steel, the pendulum stroke must be completely turned off - otherwise, jamming or rupture of the blade is possible.

When disassembling the tool, pay particular attention to the circuit breaker wiring diagram. Controlling the travel speed due to the force of pressure leads to the need to use a rather complex connection, therefore, before dismantling this unit, be sure to familiarize yourself with the circuit diagram of the device and mark the required wires with a marker or electrical tape

Before reassembling, be sure to clean all parts of the tool from contamination and add new grease to the parts that require it.

The lineup

Over the past decades, more than a dozen Fiolent electric jigsaws have been sold on the woodworking machinery market. Today we will consider the most popular models among domestic users. Some of them have already been discontinued, others have just appeared on sale.

Advantages of the Fiolent jigsaw:

- Price;

- Reliable double insulated motor;

- The presence of a pendulum stroke;

- The ability to adjust the tabs to improve the accuracy of the cut;

- High maintainability;

- An extensive network of service centers.

Disadvantages of the Fiolent jigsaw:

- Most models have no backlight;

- Poor basic equipment;

- There is no case for storage and transportation.

Fiolent PM5-720E (IU)

One of the latest models from the manufacturer. It features a powerful 720 W motor, which is enclosed in a die-cast metal case. The model has 4 stages of pendulum movement, which makes it possible to increase the accuracy of sawing and the productivity of the tool.

Jigsaw Fiolent PM5-720E (IU)

Jigsaw Fiolent PM5-720E (IU)

Fiolent PM3-600E-K1

The jigsaw is designed for sawing wood, steel, aluminum, plastic and other materials. The model can be used for a variety of repair work, the construction of residential and utility rooms, the production and repair of furniture.

Jigsaw Fiolent PMZ-600E-K1

Jigsaw Fiolent PMZ-600E-K1

Fiolent PM3-600E

An improved version of the previous model. It houses an upgraded 600 W motor with an aluminum alloy casing that improves cooling and extends motor life. Productivity is ensured by a three-stage pendulum system.

Jigsaw Fiolent PMZ 600E

Jigsaw Fiolent PMZ 600E

Fiolent PM5-750E M

The tool has a modern ergonomic design, a powerful 750 W motor. and an improved engine cooling system. Side tabs reduce saw blade runout, thereby increasing sawing accuracy. The jigsaw is designed to work with a variety of materials.

Jigsaw Fiolent PM5-750E M

Jigsaw Fiolent PM5-750E M

Jigsaw cutting depth:

- Wood - 135 mm;

- Steel - 10 mm;

- Aluminum 20 mm.

The operator's work is facilitated by the "On" position lock. To increase labor productivity, a five-stage pendulum system is installed on the jigsaw. The Fiolent PM5-750E M model can be used both in households and for industrial purposes, in particular in the furniture industry. This model is currently discontinued and can only be purchased on the used market.

Fiolent PM3-650E

The model is intended for use in home workshops, but can also be used for industrial purposes. The only drawback of this jigsaw is the relatively large weight (3.4 kg) for this engine power (650 W).

Jigsaw Fiolent PM3-650E

Jigsaw Fiolent PM3-650E

With this tool, you can make straight and curved cuts, the three-stage pendulum system will help to increase the cutting speed and select the maximum accuracy. The unit has a modern design and an ergonomic body, the motor gearbox is made of cast aluminum. In online stores, the Fiolent PM3-650E jigsaw can be bought for $ 45-50.

Fiolent IE 5202 E2

Currently, this model has been discontinued, but the jigsaw still continues to serve its owners faithfully.The unit has a somewhat outdated design, but it is distinguished by great endurance and high maintainability.

Jigsaw Fiolent IE 5202 E2

Jigsaw Fiolent IE 5202 E2

With it, you can make diametrical and straight cuts in wood, plastic and laminate. The unit is equipped with an engine with a power of 450 W, it is equipped with a three-stage pendulum system and a lock on the power button.

Fiolent PM4-700E

The ergonomic handle provides comfortable control and operator comfort during one-handed operation. The jigsaw is equipped with a 700 W motor. with an efficient ventilation system that prevents overheating of the drive and increases its durability.

Jigsaw Fiolent PM4-700E

Jigsaw Fiolent PM4-700E

Diold jigsaw: a budget option for the household

Another, no less popular manufacturer of domestic power tools, is the Smolensk company Diold. Electric jigsaws are distinguished by their low price and rather decent quality. For homework, this is a perfectly suitable budget option.

Support roller repair

It also has points worth paying attention to. The first is the support roller

Over time, and this is about a year, it begins to lose its round shape. The reason is the material of the video or the technology of its production. It has insufficient hardness.

Its repair is to replace it. Still, it is better not to reinvent the wheel, but to purchase an original video from the manufacturer or take the tool to a service center, especially if it is under warranty.

If this option is not suitable or impracticable, then you can reanimate the jigsaw with the help of improvised means. To do this, you need a regular M5 bolt with a nut. In this case, the bolt will serve as an axis, so you need to grind off the thread on it, and the nut with a roller, in it along the generatrix it is necessary to cut a groove along the thickness of the saw blade.

It is ideal to do this on a lathe, but you can also use a tool that is at hand, such as a drill and an angle grinder disc. The disk needs to be clamped in a vice, the bolt and nut - in a drill and cut into a groove. The repair option is not ideal, but it has the right to life, as it has been tested in practice.

Service trigger button

Another nuance in using the Diold jigsaw is the ingress of wood dust into the start button. This happens due to the lack of tightness, and dust, getting inside the button, prevents the passage of current. The solution to the problem will be periodic, at least once a year, cleaning the contacts.

Jigsaw Interskol: sawing curvature correction

It is worth paying attention to the domestic production of the Interskol jigsaw. It is released in Izhevsk

For domestic use, this is a perfectly acceptable option. It has many positive qualities, and the most impressive is its low cost. But there are also disadvantages.

Replacing the quick-release saw blade mount

This is the curvature of the cut. What is the problem and can you get rid of it? The fault was the quick-release fastening of the file. The fact is that it is designed for the maximum saw blade thickness. All thinner cutting tools in the mount just dangle.

How to get out of this situation? It is necessary to replace the quick-release mount with a simple device with ordinary bolts. It is not difficult to make it. You need to take a square rod, cut off two blanks, drill holes in them and connect with two M5 bolts with nuts. The procedure for attaching the saw blade will be somewhat more complicated, but the tool will produce a smooth cut.

Refinement of the jigsaw design

In addition, you can modify the very design of the tool and limit the movement of the file in the transverse plane.

For this you need:

- take sheet aluminum and cut the plate to the size of the jigsaw sole;

- in the front part of the workpiece, it is necessary to make a cutout according to the size of the working area of the cutting tool.File all edges, make bevels on the inner longitudinal edges of the cutout;

- from plexiglass, you need to cut a plate to the size of the working area of the saw blade. File all sharp edges and make reverse bevels on the outer longitudinal edges;

- the aluminum plate must be marked for its installation on the sole of the jigsaw. Drill holes and chamfer for the installation of countersunk head screws;

- a piece of plexiglass must be inserted into an aluminum plate, after having made a cut at the place of its position.

The saw blade will now be limited in lateral movement almost in the cutting zone during operation, which will give it even more straightness.

User manual

A description of the jigsaw model, the operation manual and technical characteristics can be found on the manufacturer's website: Your browser does not support frames

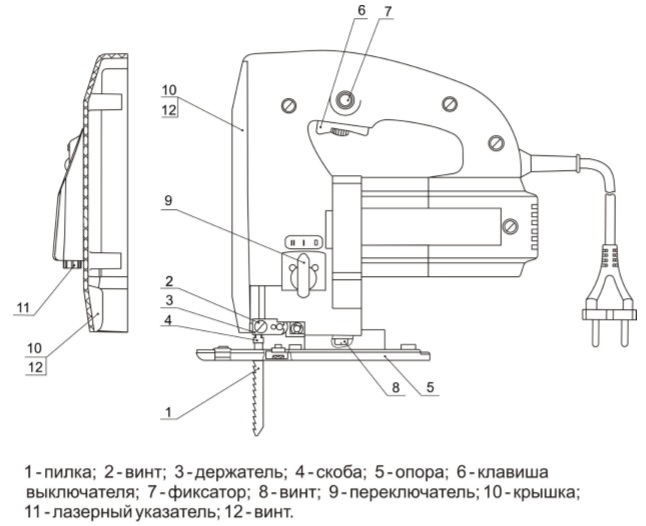

Fiolent jigsaw device

Fiolent jigsaw device

First start

Preparation for work of the Fiolent electric jigsaw:

- When buying an electric jigsaw Fiolent, make sure it is complete and there are no visible faults and defects;

- Ask the seller to carry out a trial run of the jigsaw to make sure it is in good working order and working order;

- Carefully read the manual, familiarize yourself with the device of the product, its technical characteristics and safety rules, when working with electric jigsaws.

- Be careful when choosing a saw blade. Use files that are appropriate for the material being cut and the type of sawing;

- When making long straight cuts, use the pendulum motion;

- When working in closed rooms, you must use a vacuum cleaner;

- Change saw blades frequently. Remember that a blunt file does not cut, but tears the material, causing the engine to overheat and increased wear of the jigsaw;

- When working at low speeds, the Fiolent jigsaw engine can overheat. Consider this circumstance and take frequent breaks if you use the instrument in this mode;

- Use only functional, standard power outlets. Do not repair wall outlets, power cords or extension cords with insulating tape;

- Before installing or replacing the saw blade, make sure the jigsaw is unplugged to avoid accidentally starting the engine;

- Secure the workpiece carefully, especially for small parts;

- At the end of the work, the jigsaw should be cleaned and lubricated.

| Malfunction | Probable causes | Possible remedies |

| When you press the "Start" button, the engine does not start | Defective power outlet or power cord

Broken trigger Low mains voltage No contact between brushes and collector Brushes worn out |

Replace mains lead or socket

Repair the starting device Use a stabilizer Replace brushes |

| When the engine is running, a circular sheaf of fire forms around the manifold | There was a short circuit in the armature winding

Critical brush wear |

Call the service center or an experienced electrician

Replace brushes with new ones |

| When operating the Fiolent jigsaw under load, noises and crackling are heard from the gearbox | The gear wheels of the reducer have become unusable

Critical bearing wear |

Consult a service workshop or an experienced mechanic for assistance |

| Decreased labor productivity and cutting accuracy | Saw blade is dull

The saw blade due to its characteristics is not suitable for cutting this material |

Replace the file with a new one according to the material being processed |

Characteristic

The manufacturer of the instrument in question is the Simferopol plant "Fiolent", created in 1913, named in honor of the Sevastopol cape

An important feature of the power tools produced by the plant, including jigsaws, is their high reliability, achieved through a combination of high-quality materials and thoughtful design solutions that have passed the test of time

Another important advantage of Crimean-made tools is the availability of spare parts on the Russian market and the presence of an extensive network of service centers. Due to this, it is usually possible to repair a damaged instrument within a few days from the moment of breakage.

The entire model range of the company is designed for use both for cutting wood and for processing plastics, ceramics and metal (both aluminum and steel). This versatility is achieved due to the fact that at a similar cost, the company's products are characterized by a significantly higher power than competitors' products.

The cutting speed is controlled by changing the force of pressing the start button, which greatly facilitates the operation of the tool, although it requires a certain skill from the craftsmen. Also, the power button is equipped with a latch that allows you to fix the tool in the on or off state.

How do I detach an old button?

To detach it, you need a thin slotted (straight) screwdriver and a pin. Use a screwdriver to unscrew the existing bolts that clamp the cables coming from the power plug.

The rest of the wires are secured with a spring clip. To disconnect them, you need to thread the tip of the pin into the groove where the terminal is located. Thanks to this action, the terminal is released and the wire is removed along with the pin.

When disconnecting, I advise you to leave in place the wires coming from the capacitor, so as not to forget which pins it is attached to. Since it is not attached anywhere except to the button terminals, they can be removed together and carried in this form to the store to buy a new copy. After purchasing, first of all, plug the capacitor into a new place, after which you can not think about it.

Electric jigsaw Metabo: perfect in quality, but difficult to repair

One of the best jigsaws on the world market are the models of the German company Metabo. Everything is good in him. High power, aluminum body, pendulum device. In addition, the tool is stuffed with electronics, which allows you to customize the jigsaw to individual programs for each type of cut. And the cut is just perfect both in quality and straightness. The Metabo power tool is the best jigsaw to date.

But not eternal. Breakdowns happen here too. The reasons can be very different. But as practice has shown, the weak point is mechanics. After significant loads, and in particular, cutting metal, it may fail.

Typically does not support the axle on the bearing bracket, arm and stem. To restore the tool, it is better to purchase original spare parts, and assemble them at a service center by specialists.

When self-assembling the Metabo jigsaw, it is imperative to apply Castrol LMX grease to all rubbing surfaces with the addition of RiMET grease in a ratio of 3: 1.

Typical Power Tool Failures and Preventive Measures

The jigsaw is designed to perform rough curvilinear cuts, so it's not worth talking about the ideality of sawing. Although in models of hand tools from different manufacturers, this indicator is also different. When using cheap models, they don't pay much attention to this, and the cut turns out to be completely crooked. You need to deal with this in service centers, but you can try to get rid of the curvature at home.

The platter roller can break when using poor quality saw blades or blunt tools. Using the cutting tool in an inappropriate load condition. This can result in jamming or cutting of the support roller.

To avoid such a problem, you need to use well-sharpened cutting blades of acceptable quality, observing the optimal cutting conditions and following the recommendations of the manufacturer.

As a rule, almost all models of jigsaws are equipped with a toolless saw blade fixation unit. This simplifies the process of changing the cutting tool. But the operation of the mechanism in conditions of constant dustiness leads to the ingress of wood chips into it, and this leads to the failure of the device.

In order to exclude a breakdown of the unit, it must be constantly cleaned of dust and lubricated with a special compound such as WD-40. During operation, it is necessary to use a vacuum cleaner by connecting it to the tool.

Failure of the gearbox elements is the result of wood dust entering through the ventilation holes. Here, as in the previous case, you cannot do without a dust collector.

Breakage or bending of the support rod occurs in the process of careless use of the power tool. This can happen when it falls or unintentionally collides with the jigsaw body, directly the support rod with the protruding elements of the machined surfaces.

The destruction of the tooth on the collet of an electric jigsaw can only occur through the fault of the performer. This is the result of an attempt to inadvertently tighten the not fully inserted cutting blade.

The armature worm gear will not last long if you start the cutting process before the tool motor reaches optimum power. To prolong the life of the mechanism, do not start work before reaching full engine speed.

Collector motor malfunctions

So, you have purchased an electric jigsaw and as a common cause for all power tools is the cause of the malfunction, both mechanically and electrically. Basically, such breakdowns can be attributed to various breaks in the electrical circuit, that is, to name the following characteristic causes of jigsaw breakdowns:

- malfunction of the stator windings of the electric motor;

- malfunction of the armature windings of the electric motor;

- capacitor malfunction;

- wear of graphite brushes;

- wear of the electric motor manifold.

In general, there are five main causes of malfunctions of the collector electric motor.

Minor causes of electrical faults include the following:

- wire break in a network cable along its length; mechanical damage to the cable;

- break in the mains cable wire at the base of the plug;

- faulty contact connection in the plug

and other reasons.

The principle of operation of the jigsaw

The moment has come to consider the principle of the tool. There is nothing supernatural here - it is enough to "delve into" the jigsaw device. So, the electric motor generates mechanical energy, which is transmitted through the gearbox to the rod with the file. The rod, moving up / down, moves the jigsaw file, respectively. For better clarity, I bring to your attention a short video in which I tried to demonstrate the work of a jigsaw. By the way, those photographs that were not included in this material were added to the same video.

I hope the article is clear and comprehensive. If you still have questions regarding the jigsaw device, you can ask them in the comment format.

With this article browsing:

- Interskol jigsaws - popular models, reviews

Author -