Screwdriver bits: general information, basic tip types

Like removable attachments for drills, screwdriver bits belong to the category of devices that are aimed at expanding functionality. Thanks to them, this tool can be turned into a universal screwdriver or a compact machine for cutting sheet metal. The range of handpieces offered by manufacturers is very wide. With their help, you can carry out construction work of any complexity at home, which made the screwdriver so popular.

To choose the right bits, you need to know the classification of products in this group.

Some buyers don't see the difference between a drill and a screwdriver, but there is one. Moreover, these differences must be taken into account when choosing removable nozzles for performing certain jobs. First, the rotational speed of a screwdriver is much lower than that of a drill. Secondly, it lacks a moment of inertia. In other words, if you press the shutdown button, the screwdriver will instantly stop, unlike a drill, which will rotate for some time.

All screwdrivers have a release clutch. It is designed to adjust the tightening force. Some models do not have a cartridge. Instead, a hex socket is installed in which the bits are fixed.

There are several varieties of the tool, each of which can provide specific benefits:

- Small screwdrivers - used as a miniature electric screwdriver for repairing watches, telephones and small appliances.

- Folding screwdrivers - these models are designed to work in a confined space that a regular tool cannot reach. If the handle interferes with work, you can simply remove it.

- Drill drivers are designs that are hybrids. They combine the best properties of each instrument.

Working attachments for a screwdriver can be purchased in sets or individually

Varieties of screwdrivers

Cordless screwdrivers

The screwdriver models on the market are of two types:

- Cordless screwdrivers.

- Network screwdrivers.

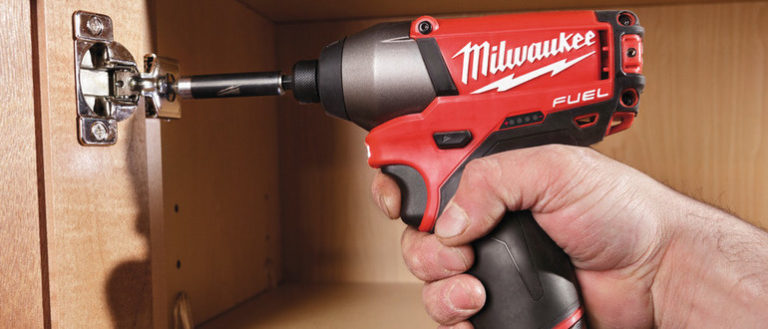

Cordless screwdriver with lithium-ion battery

Each of these varieties has its own characteristics, and in order to make the right choice, you should carefully study them before purchasing.

- Cordless screwdrivers have one significant advantage, namely mobility. They do not depend on the presence of voltage in the mains, therefore, such a screwdriver can be used almost everywhere.

- The most commonly used power source in cordless screwdrivers is lithium-ion batteries. As a rule, the battery is located at the bottom of the handle and additionally serves as a kind of balancer.

- Most cordless screwdriver models are lightweight and compact. This is also an indisputable advantage, since it is a dubious pleasure to mount gypsum plasterboards on the ceiling while holding a heavy tool in weight.

- The most common cordless screwdrivers are designed without a chuck. The bit for tightening the self-tapping screws is inserted directly into the spindle, into a socket with an internal hexagon.

Network screwdrivers

Unlike cordless models, drywall corded screwdrivers are mainly used by professionals. Accordingly, the price of such instruments is much higher.

TEMP DE-1000 network screwdriver: one of the budget models

Corded models of screwdrivers are not equipped with rechargeable batteries, as their power would require a too large and heavy battery. Such screwdrivers are equipped with a sufficiently long (5 meters or more) power cord, which must be connected to an outlet.

In addition to the method of generating energy, cordless screwdrivers differ from cordless ones in the following:

- Instead of a torque regulating clutch, corded screwdriver models are equipped with a torque clutch. At the same time, when the fastener reaches the specified depth, the spindle is automatically disengaged - so there is no risk of “overtightening the screw.

- As a rule, such screwdrivers are characterized by a high operating speed - up to 6 thousand revolutions per minute. This allows you to perform cladding as quickly as possible, which is very convenient for large volumes of work.

Useful gadgets

In fact, the screwdriver is a fairly versatile tool, and working with plasterboard sheathing is just one of its many purposes (see also how to sheathe the ceiling with plasterboard). But today there are quite a few devices that are designed to optimize the operation of a screwdriver with gypsum plasterboards.

Among such devices, mention should be made of:

Store-type attachments with a clip or tape, which allow you to screw screws in series, without the distraction of removing the next screw from the bag and putting it on the cue ball. Such devices are produced for almost all brand models of screwdrivers, and can significantly save your time. The appearance of the store attachment is shown in the photo.

Hilti SD 5000 screwdriver with magazine attachment

# 1. What is a screwdriver for?

We will not go into the details of the structure of screwdrivers - our material is not a bit about that. The scope of this tool is quite wide:

- screwing and unscrewing various fasteners, including bolts, screws, screws and screws. This is the main function of the screwdriver, which allows you to use it during the assembly and disassembly of all kinds of furniture, installation of skirting boards and in other works;

- firm tightening of anchors and dowels;

- professional screwdrivers can be used to drill holes in soft materials, here the scope of use is similar to household drills;

- threading;

- some use screwdrivers to stir slurries and even to create holes in ice during winter fishing.

Surely, craftsmen from the people came up with a dozen more interesting options for using the screwdriver, but screwing in and out of fasteners is still the main one.

Often the question arises, which is better to choose, a screwdriver or a drill, or a two-in-one tool. If you work with furniture many times more often than drilling holes in metal, brick, concrete and wood, it is better to take a separate screwdriver. If you need the most versatile tool, then a drill-screwdriver would be a good option, where you can change the attachments and adjust the speed of revolutions. On the other hand, there are advanced screwdrivers, the design and power of which allow you to cope with drilling wood, and sometimes even metal, but their drilling function is still secondary and is intended for infrequent use.

The design feature of the screwdriver is such that the inertial moment during operation is completely absent. This means that as soon as the master removes his finger from the switch, the tool stops working, and the drill, if it does not have a brake function (found only in expensive models), will continue to function for a few more seconds. Not only is it inconvenient, but it also risks getting damaged. The screwdriver mechanism stops the chuck when the rotation resistance reaches its maximum, i.e. when, for example, a screw is completely screwed in.

An ordinary household screwdriver has a rather low maximum rotation speed, since a rotation frequency of more than 500-600 rpm is not used to tighten the fasteners. With drills, the maximum rotational speed is much higher, and an impact mechanism may be present for more efficient drilling in hard materials. However, some craftsmen manage to tighten screws and screws with an ordinary drill, but this is not a trick for beginners.

With the same power, the screwdriver will be stronger than the drill in the sense that it has a higher tightening torque and torque. In addition, the torque in the screwdriver can be adjusted. In general, a screwdriver and a drill are completely different tools, and it is better to take two separate independent devices to perform serious repair work. In everyday life, drills and screwdrivers and screwdrivers with a drill function show themselves well, but you will not be able to drill with the latter often and you will not be able to do a lot - this is an option for small and rare home repairs.

The best special purpose corded screwdrivers

If universal devices can do everything and at an acceptable level, then tools from this category are created to perform specific tasks, but cope with them as quickly and efficiently as possible.

| Bosch GSR 6-45 TE + MA 55 Professional | Makita 6844 | Metabo DWSE 6.3 | |

| Power, W | 701 | 470 | 550 |

| Chuck diameter, mm | 6,35 | — | 6,35 |

| Chuck size, mm | 6,35 | — | 6,35 |

| Chuck type | hex | — | hex |

| Max. screw diameter, mm | 6 | 4 | — |

| Number of stages of torque | — | — | 10 |

| Max. torque, Nm | 12 | — | 18 |

| Number of speeds | 1 | 1 | 1 |

| Speed control | |||

| Spindle speed, rpm | 0-4500 | 3000 | 0-2100 |

| Screwing depth adjustment | |||

| Reverse | — | ||

| Cable length, m | 3,9 | 2,5 | 4 |

| Weight, kg | 1,8 | 2,1 | 2,1 |

Tape screwdriver Bosch GSR 6-45 TE + MA 55 Professional

Professional tool designed for frequent and prolonged work requiring a large number of screws. An electric motor with a power of 700 watts produces up to 4500 rpm, the number of which is regulated by a trigger. The magazine tape nozzle allows you not to be distracted by driving the screw onto the bit and is equipped with depth adjustment - the screws are screwed exactly flush to the surface.

+ Pros of Bosch GSR 6-45 TE

- The screw strap attachment allows one-handed operation.

- The nozzle can be removed without additional tools.

- Possibility to use tapes from other manufacturers.

- Clamp on the body for securing the screwdriver to the mounting belt.

- Small, for a device of this class, weight - 1.8 kg.

- The trigger can be locked and not held during operation.

- Cons Bosch GSR 6-45 TE

- If the tape is used only halfway, it is inconvenient to attach the screwdriver to the belt.

- There is no illumination of the working area.

- It is not always convenient to screw the screws into a profile attached to a wall.

Tape screwdriver Makita 6844

A highly specialized professional device for working on drywall. Its design is designed for comfortable use, even when driving screws at a distance of 15 mm from the wall. The speed of work is provided by an electric motor with a power of 470 watts, issuing 3000 rpm. Small and medium-sized screws up to 4 mm in diameter are used.

+ Pros of Makita 6844

- Good ergonomics - the device is comfortable to hold, and all buttons and switches can be pressed with one hand.

- Motor position and D-handle ensure good balance.

- Separate attachment for mounting belt or strap.

- Manual setting of the depth of sinking screws into drywall.

- Standard consumables - you don't have to look for branded ones.

- Cons of Makita 6844

- A short power cable - 2.5 meters is not always enough for comfortable work.

- The magazine mechanism is built into the screwdriver - you can only tighten screws from the tape.

Roof and wall screwdriver Metabo DWSE 6.3

It is positioned as a universal tool for tightening / unscrewing screws and nuts in vertical and horizontal planes.The spindle does not rotate directly from the motor, but through a gearbox, which provides a smooth ride and additional power and allows it to deliver torque up to 18 Nm at 2100 rpm with variable speed.

+ Pros of Metabo DWSE 6.3

- Versatility - there is a 10-step power adjustment for working with different materials.

- Secure bit attachment with retaining rings.

- The 4 meter power cord allows you not to carry the carrier with you during operation.

- Quality engine cooling for continuous operation.

- Cons of Metabo DWSE 6.3

- Overheating may deactivate torque control.

- It is necessary to adapt to the power and weight of the device when working with small screws and soft materials. The screwdriver's weight of 2.1 kg helps to drive the screws into the metal, but with prolonged work with wood and drywall it may be excessive.

Selection by technical characteristics

Having come to a specialized store for a screwdriver, you should not pay attention only to the price category of the device. It is necessary to study the passports of those models that you liked the most.

The document indicates the technical characteristics of the tool, which should be considered in detail, since they affect the performance of the screwdriver. In order to choose the right tool, you need to pay attention to the following characteristics.

Power

This is one of the parameters of paramount importance. The average value of the power of the device is from 0.5 to 0.7 kW

Such a tool will easily perform chores. The professional has a power of 0.85 kW.

Torque

The indicator is measured in newtons per meter. For home use, minor repairs, a screwdriver with a torque of 10 to 15 Nm is suitable. To perform professional work, you will need a device that develops a torque of up to 130 Nm.

The indicator is easily adjusted using a special ring located at the chuck.

Manufacturer

An important aspect that needs to be paid attention to is the manufacturer of the device. It is worth examining the warranty period for the product

The official guarantee for the operation of the screwdriver should be from 1 to 3 years. It is recommended to purchase the product from a specialized store. Recommended brands are given below in the article.

Battery voltage and other parameters

The performance of the device depends on the supply voltage. The instruments are equipped with batteries with a voltage of 9 - 36 W. The low voltage screwdriver is capable of small accomplishments. For example, screw a fiberboard sheet to a metal profile. Choose high voltage models if you need to do voluminous work. A device with a supply voltage of 13 to 16 W is quite suitable for home use.

Power sources are:

- Ni-Cd - nickel-cadmium. You can do about 1000 charges. In addition, they have a memory effect - when the battery capacity of the device decreases due to the fact that it was not fully charged. A screwdriver with this type of battery ensures uninterrupted operation at low temperatures;

- Ni-MH - nickel metal hydride. They can be charged up to five hundred times. Also have a memory effect. This type of battery is not designed to work in frosty weather;

- Li-Ion - lithium-ion. The most capacious type of battery. Moreover, they do not suffer from the memory effect, they are considered ecological. However, the device does not withstand subzero temperatures.

Rotation frequency

The tool can have several speeds. The number depends on the parameters of the screwdriver gearbox. If the device has two speeds, then the first will allow the tool to rotate up to 450 rpm, and the second up to 1400 rpm.

Cartridge

This part of the device is important for the quality of the tool. There are two types of screwdriver chucks:

- key. It is necessary to have a special key, by means of which the screwdriver nozzle is replaced;

- quick-clamping. This type allows you to instantly change attachments.In addition, nozzles of any thickness can be installed.

Keyless chucks are preferred by most buyers because they are easy to use and do not require special attachments to change the tool bit.

Reverse

Almost all good screwdriver models are equipped with a reversing tool for easy operation. This is a switch that allows you to change the rotation of the chuck. In this way, you can instantly switch from screwing out the screw to tightening it.

The weight

The lower the mass of the instrument, the less effort a person applies. The weight of a screwdriver can vary from 300 grams to 3 kilograms. On average, a handy device weighs 1 kilogram or more. It is more comfortable to work with such a tool.

Additional features and capabilities

When choosing a device, pay attention to the position of the handle. There are models with an additional handle in the center. Such screwdrivers are more convenient, since they require less physical effort from a person. There are impact devices that can be used to drill brick, concrete. A special adjusting ring allows you to select the desired operating mode of the screwdriver.

The tool can be equipped with a function of stepless speed adjustment. In this case, the button is pressed gradually. For battery devices, there is an additional function of displaying the state of charge. Expensive models include a second battery and a fast charger.

Technical specifications

After you have decided on the type of screwdriver and power supply, you need to focus on the technical specifications. They determine what kind of screws and what material you can screw into.

An example of the technical characteristics of a screwdriver

Rotational speed and torque

The torque with which the screwdriver can turn the screw is determined by the torque. It can be quite small for household models - 10-15 Nm, and can reach 130-140 Nm for professional ones. Therefore, pro screwdrivers can easily and quickly tighten large self-tapping screws and work with hard materials.

But a large torque is not always necessary and not with all materials; therefore, screwdrivers provide the ability to adjust the applied force. There is a limiter for this. It is designed as a movable ring, which is located behind the chuck.

The higher the RPM, the stronger the torque

There is a mark on the ring, placing it opposite a certain number, you set the maximum force that the tool can develop. Upon reaching this value, the chuck will scroll to idle - the screw will no longer be tightened. The achievement of this value can be clearly tracked - the ratchet is turned on.

Many models of screwdrivers can work in two modes: the actual tightening of the fasteners and drilling. Such models are called a screwdriver-drill, but they are now the majority. To switch to drill mode, the switch is set to the extreme position (after replacing the nozzle first). At the same time, the maximum speed is turned on, which allows you to drill even rather hard materials.

Screwdriver power

And the boiling moment and rotation speed are a consequence of the power of the electric motor. Therefore, we must also look at this parameter. But here it is necessary to track three values at once: so that the power of the screwdriver corresponds to the speed parameters. Powerful models with good parameters can be found from many manufacturers, but such as Metabo (Metabo), Bosch (Bosch) and Makita (Makita) and other well-known prices for them are very high. There are other brands with similar characteristics, but more affordable prices. For example, RYOBI. The brand is still little-known, but according to reviews it is no worse than the aforementioned famous brands. In order to be able to compare the main characteristics and the price of models of approximately the same power, but of different brands, we will summarize them in a table.

It is worth saying a few more words about the number of work speeds.Not to be confused with the number of rotation speeds. These are two modes of operation that are used when working with different sizes of screws or drills. When working with small screws / drills, you can select a higher speed, when screwing in large screws or drilling large holes, a lower one.

Battery parameters

To choose the right screwdriver with batteries, in addition to the type of batteries, you must select their operating parameters:

- Capacity. Reflects the amount of energy that can be stored. It is clear that the larger this parameter, the better (but also more expensive).

- Voltage. There is a rechargeable battery for a screwdriver for 10 V, 12 V, 14.4 V. Household models usually go with such parameters. A more serious tool works with 18 V and 24 V.

What characteristics to choose a screwdriver with? - The ratio of the current strength to the charging time (A / hour). The higher this indicator, the longer the battery will work before discharging.

To choose a screwdriver for home or professional use and do not regret it, you must view these parameters. If you have picked up several models, compare them according to these characteristics, because it depends on them how long the interval between the charges of the screwdriver batteries will be.

The choice of a screwdriver, adjusted for the peculiarities of working with drywall

When choosing screwdrivers, you need to rely on the complexity of the work ahead. The rechargeable battery is well suited for simple tasks, since it is easy to move with it to different parts of the room in which work is carried out.

Always have a spare battery on hand in case of a discharge. Due to the fact that in the market of building materials and equipment, new models are steadily replacing old samples, after a while, purchasing a new charger for him may become an impossible task.

Before purchasing a new tool, you need to pay attention to the build quality and the list of main functions:

- The recommended cord length should be more than 7.5 m;

- For tasks using GCR, the rotation frequency should be from 300 to 500 revolutions per second.

- If you have the necessary experience in making drywall structures, you can purchase an automatic screwdriver with self-tapping screws.

- The device should fit comfortably in the hand of the technician and have the appropriate weight.

- It should be compact, allowing it to perform tasks in hard-to-reach places.

- The ability to attach to a mounting belt is more often used when working with gypsum board on ceilings.

When performing processes with drywall, tape screwdrivers can often be found. Using such a unit, a specialist can wrap dozens of self-tapping screws without interruptions for recharging.