Criterias of choice

When choosing the optimal vise model, several important points should be clarified.

- The dimensions of the parts that are planned to be processed using the machine. This indicator directly affects the size of the precision vise. However, as professionals note, large machines are more practical than small ones. They break less often and serve for a very long time.

- The presence of ball bearings. This important detail allows the vise to be tightened much more comfortably and reduces the amount of physical force used.

- The presence of a lifting mechanism. This is a very convenient function that allows you to perform any work at a given height.

- Correspondence of the main parameters of the precision vise and the surface on which they are planned to be installed.

In order to get the most out of the precision vise, models with replaceable clamping plates should be preferred. This will allow you to process a variety of materials, as well as quickly change sponges if necessary.

Guided by these recommendations, you can choose the best option for precision vise, which means that it will be possible not only to simplify the work and reduce the physical load on the workers, but also to expand the production capabilities.

All about the vice of machine tool precision MVN-150, see the following video.

Types and purpose

Precision machine tools come in several varieties.

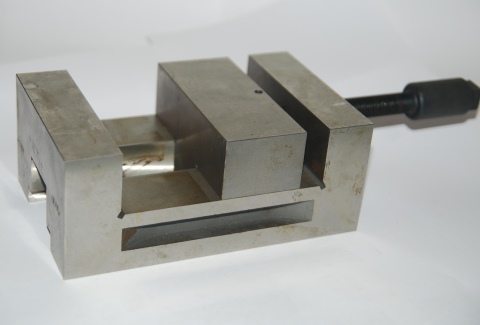

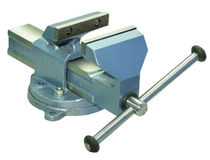

- Stationary (non-rotating). They make it possible to fix the part in relation to the jaws only at right angles.

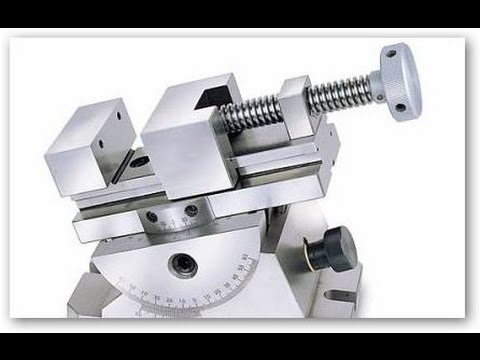

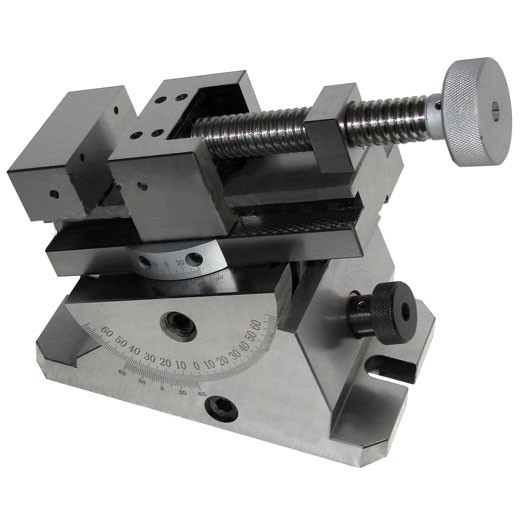

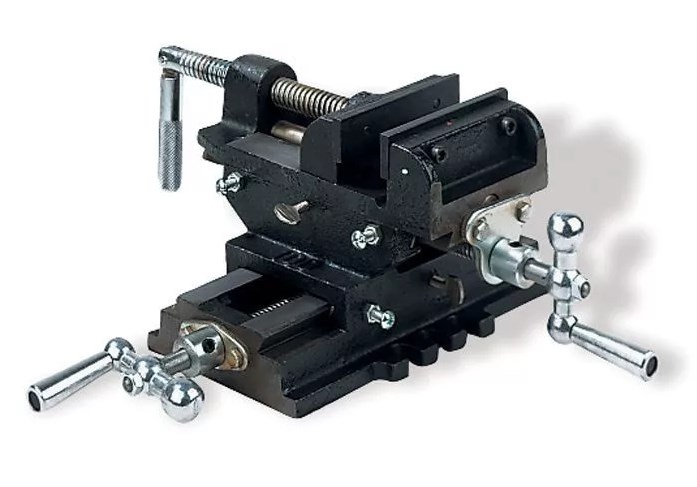

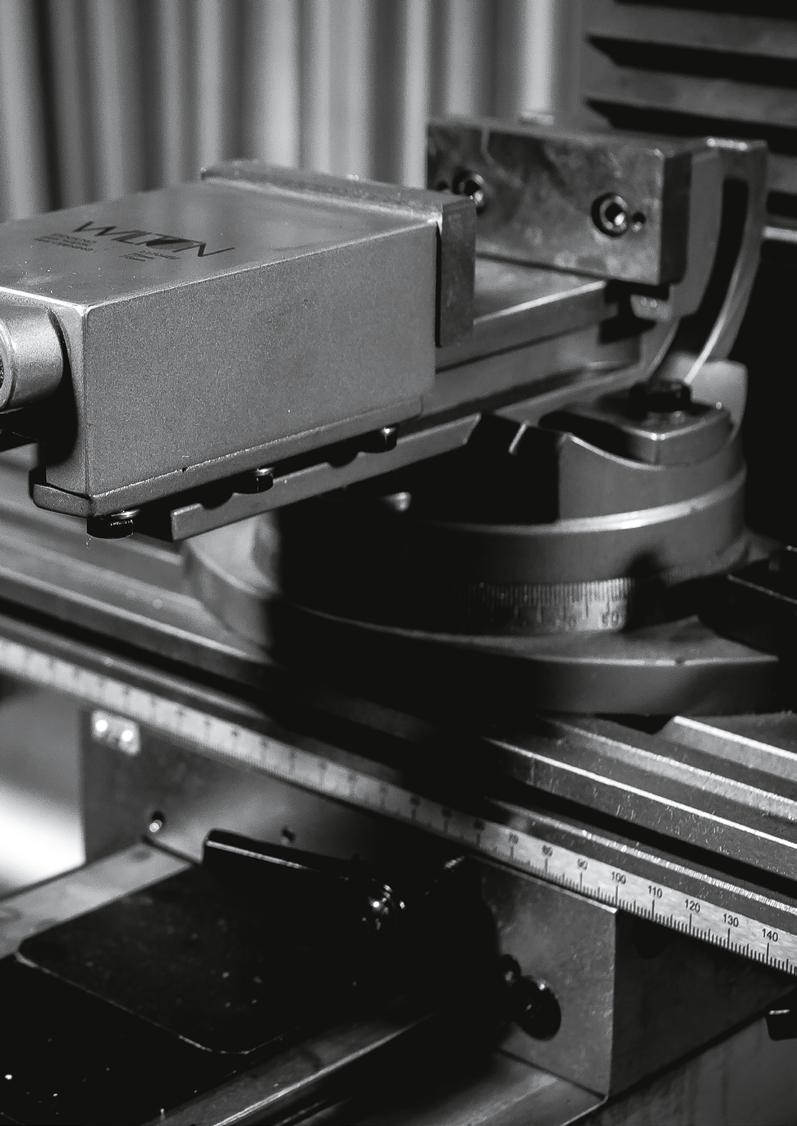

- Multi-axis. They have the ability to rotate along different coordinate axes.

- Sinus. It is possible to process the part at any angle necessary for the convenience of work.

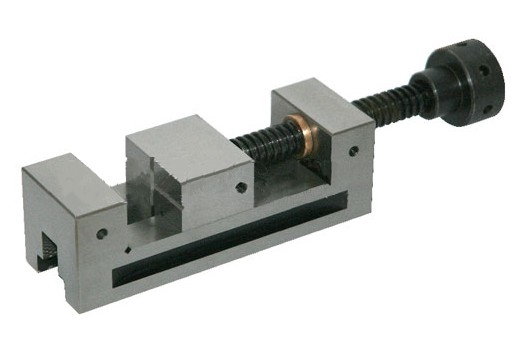

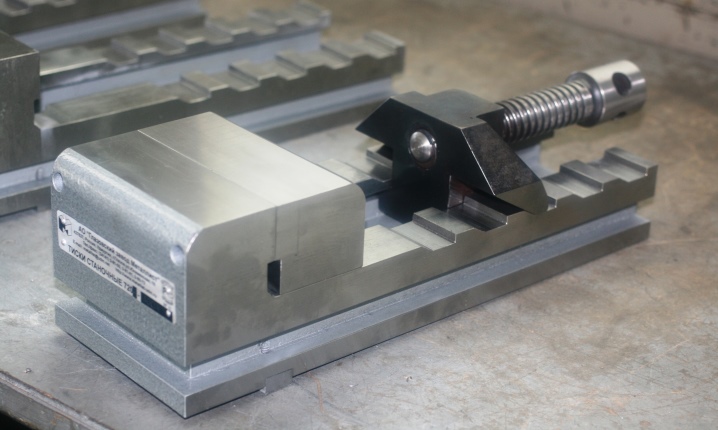

The precision vise has a variety of drive designs and is also equipped with extra strong hardened metal jaws. The equipment is used for milling, grinding and other very precise work. Stationary (non-rotating) precision vices necessarily complement the operations that are performed on CNC machines and processing devices.

Features and working principle

Curve vise is a special device that belongs to high-precision equipment. There are several differences from conventional devices. The differences are as follows.

- Manufacturing precision.

- Possibility of tilting.

- The base of the case has threaded holes for attaching to all kinds of devices.

- Smaller dimensions.

- High-quality execution of some details.

They are used for various types of work: weaving, drilling, planing and other processing. The main purpose is reliable fixing the workpiece.

The vise consists of three main parts: a clamping screw with a rotary handle, a jaw and a base with a base plate. The principle of operation of the device is as follows - with the help of a screw, the movable platforms are unclenched, the workpiece is placed between two platforms (jaws) and again tightened with a screw.

Criterias of choice

When choosing a manual vise, you should pay attention to a number of important points.

First of all, you need to decide on the dimensions, which are selected based on what parts are planned to be processed. The most versatile are models with a jaw width of 50-60 mm.

They are perfect for fixing not only small, but also medium-sized workpieces, which greatly expands the scope of their application.

You should also pay attention to the presence of backlash

And although it is practically absent in a hand grip, it is still necessary to check the tool for possible defects.

It is also necessary to look at the working gap, the choice of which depends on the specifics of the work to be done and the size of the workpieces being processed.

You should also pay attention to the inner surface of the sponges, and if you plan to work with workpieces made of low-hardness metal, it is better to purchase a model with a small height of the teeth, since more embossed sponges will leave a mark on soft parts.

It is important to look at the manufacturer of the instrument and not buy too cheap models from dubious firms.

So, saving a couple of hundred rubles in the future can result in damage to parts, a quick breakdown of the vise itself and injury to the hands. Among the most popular models are the products of the Taiwanese company Jonnesway and the German brand Stayer, whose production facilities are located in China.

Another important selection criterion is the temperature resistance of the tool.

So, if a vice is supposed to be used to fix hot workpieces, then the best option would be to purchase models made of high-alloy steel with the addition of vanadium, chromium and molybdenum.

If a vice is chosen for a jewelry workshop, then it would be right to purchase several tools at once, with the help of which it will be possible not only to clamp blanks made of precious metals, but also to engage in grinding and cutting of precious stones.

An overview of the hand vise is presented in the following video.

Model overview

Fans of Russian products should pay attention to the Bochka jewelry vise. Delivery set includes plastic collets

The collet is complemented by a bottom clamp. This model has 96% positive reviews.

It is helpful to look at the MicroBlock when you are familiar with the ball vise. The manufacturer promises the optimal combination of small size and secure fit

The clamping jaw system will center itself in the most rational way. The manufacturer also promises:

-

reliable system of internal stoppers;

-

suitability for setting stones;

-

low profile, ideal for working under a microscope;

-

opening up to 50 mm;

-

total net weight 1.8 kg;

-

ball diameter 79 mm;

-

the height of the clamping jaws is 46 mm;

-

clamping jaw width 22 mm;

-

a hex wrench and a number of other auxiliary tools included.

The T-16 model turns out to be a true "classic" of jewelry making. It was made back in the USSR. The vise itself is made of metal, but equipped with a wooden handle. The divorce limit is 10 mm. Other specifications are as follows:

-

length 130 mm;

-

width 16 mm;

-

own weight 0.165 kg.

Model overview

There are many varieties of curved vices. The most high-quality and demanded models are as follows.

An inexpensive, but excellent quality option is the QKG-25 precision molds. The device has a jaw with a width of 25 mm and a maximum opening of 22 mm. The cost is about 3 thousand rubles.

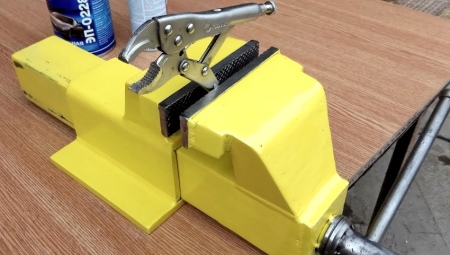

There are also more expensive models, but they are recommended for purchase by professionals, and for home use it is quite possible to get by with one of the above options. An alternative to each model presented is a homemade vise.

What it is?

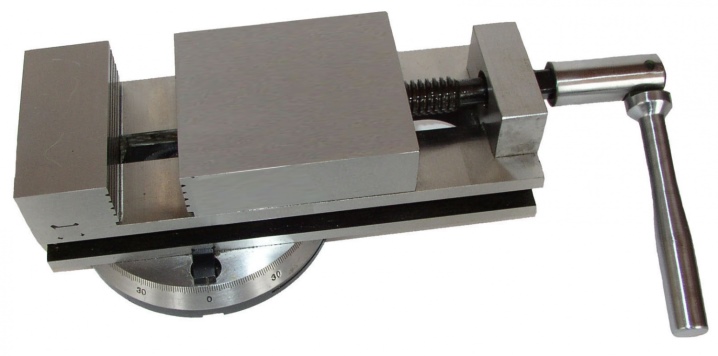

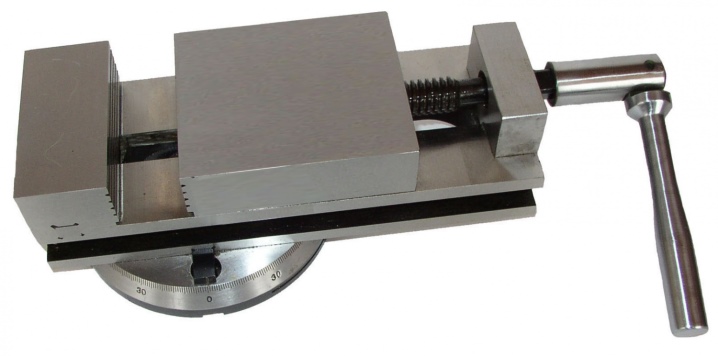

Precision machines are a device that allows you to ensure the most accurate position of the part and its minimum deviation relative to the jaws.

The advantages of these machines include:

- quick installation of the vise on the work surface;

- 100% alignment of equipment relative to the required plane;

- high positioning accuracy of the part, as well as its minimum displacement;

- guides of increased hardness;

- constant clamping force, without loosening;

- increasing the speed of cutting and material removal.

Precision vices are widely used not only in large industries, but also in small companies engaged in milling and other processing of metal, wood and other materials.

How to choose?

Of course, the choice of jewelry vise is made taking into account the work to be performed.

In this case, you should definitely pay attention to the reviews that give a particular model

Important: these reviews should be taken from different sites in order to eliminate any problems or misunderstandings. It is categorically impossible to take a metalwork curved vice for jewelry and other fine work.

Using them is sheer anguish

It is categorically impossible to take a metalwork curved vice for jewelry and other fine work. Using them is sheer torment.

Quite a few experts believe that it is necessary to use the "gravity" model. When creating it, they tried to take into account all the shortcomings of the previously existing options. Such a device is different:

-

rigidity like a good plumbing tool;

-

reliable tilt adjustment using wedges;

-

thoughtful fixation of various movements;

-

low availability (new copies are no longer made even to order, and the old ones cost 30,000 rubles);

-

large (about 30 kg) own weight.

The key in any case is the width to which the sponges are bred. It is she who determines which parts can be successfully processed.

Important: it should be checked that the vice works smoothly and without jamming. It is useful to have a fuse on the lead screw, otherwise it will easily fall out

You can watch an overview of jewelry vices from China in the video below.