Metal colors

Each individual drill has a different color scheme. Experienced craftsmen know that technical indicators depend on the color of the product. For example, a steel color is an indication that the cutting tool has not been exposed to high temperatures.

Steel-colored drills do not have an increased level of strength, which means that they wear out much faster. Experts advise using steel-colored cutting elements to create holes in thin metal sheets, plastic, drywall and wood.

The presence of black color on the surface of the drill indicates that it has undergone heat treatment, after which the product received additional strength, respectively, its service life increased.

Varieties

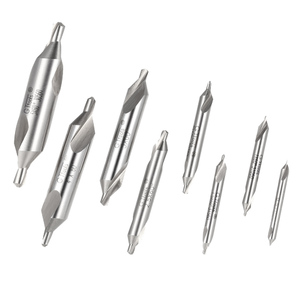

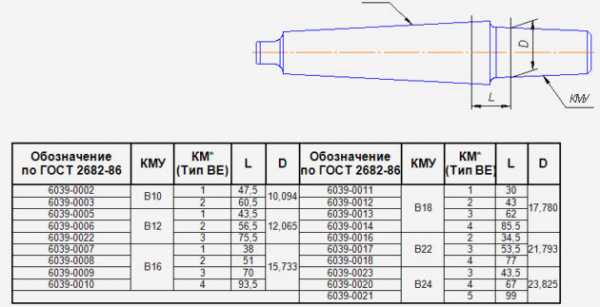

The taper shank or Morse taper is available in several versions.

-

Instrumental

- the most common, as they are designed for quick automatic change when working on the machine. The parameters of the product are regulated by GOST. -

Shortened

e - the tail part of the drill is reduced due to the thickened part of the taper. It is marked as follows: B7 - shortened to 14 mm, B10 - to 18, and to B24 - shortened to 55 mm. This option is used when a hole requires a certain diameter but shallow depth. -

Elongated

- used for drilling deep holes in several stages. -

Metric

- shanks, in which the ratio to the working part is 1:20, and the angle is more than 1 degree.

The photo shows the varieties of drills with a tapered tail

The purpose of the drill is determined by the sharpening: apex angle, clearance angle, etc. Sharpening and grinding is carried out on special machines or manually.

Conical GOST

GOST 10903-77 regulates a tool with a tapered shank - with a Morse taper, and a version with a neck.

-

Possible product diameter

- 5-10 mm. -

Cone lengths

- 58–85 mm. -

Tail section

- 6-12 mm.

Elongated

Drills with an extended tail section are regulated by GOST 2092-77. They are used in the production of deep holes.

The size of the diameter ranges from 6 to 30 mm. The length of the tail section is 145–275 mm.

Products are produced in two accuracy classes:

-

A1 and A

- with increased accuracy; -

B1 and B

- with normal accuracy.

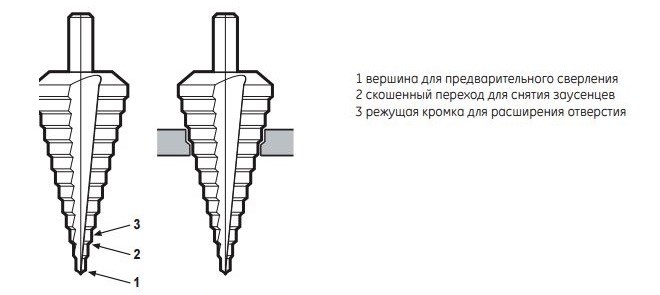

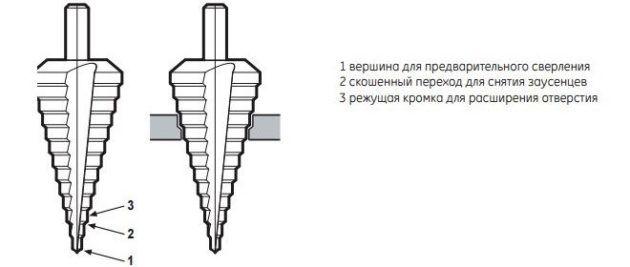

Conical stepped

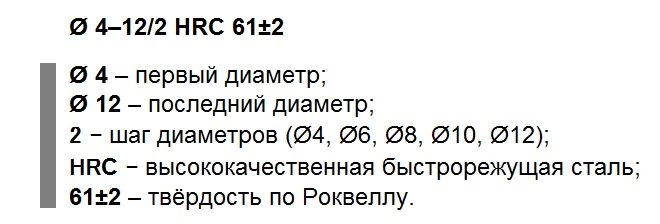

The cone in this case looks like a pyramid, where each "step" is responsible for the formation of a hole of a certain diameter. This design allows you to drill holes of different sizes without changing tools. In its marking, a number of values are indicated at once.

The same feature allows you to chamfer with the same drill that made the hole. The drilling speed is relatively low - up to 1000 rpm, which makes the tool very suitable for working with plexiglass.

Centering is problem-free due to the tapered shape, but the sensitivity to misalignment is higher than that of the instrumental version.

They use tools for processing steel, aluminum, duralumin and non-metallic materials - plastics, plexiglass, ebonite.

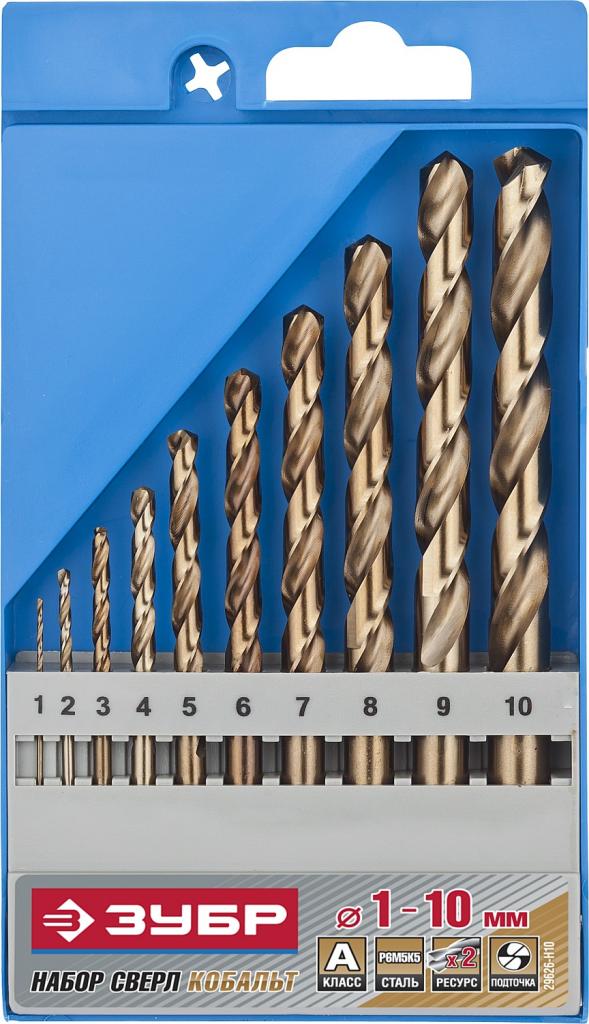

Cobalt Taper Shank

To improve the strength properties and heat dissipation, the products are subjected to additional processing.

- HSS-G - undergo additional grinding;

- HSS-Co - steel contains cobalt, drills of this class are designed to work in severe temperature conditions;

- HSS-R - rolled products;

- HSS-Tin - the tool is treated with titanium nitride, the coating reduces friction, and, therefore, heating of the tool and material.

You can tell how the drills were treated by their color: a bright gold color indicates the deposition of titanium nitride, black - heat treatment was used, and so on.

Self sharpening rules

A few simple recommendations will allow you to sharpen the drill quickly and efficiently:

- First of all, the preparation of a grinding device and a container with a liquid for cooling is carried out;

- Sharpening is carried out with the maximum pressure of the drill against the grinding wheel. If the effort is weakened, a marriage may result;

- An individual sharpening angle is selected for each type of metal: steel - 140 degrees; copper alloys - 120 degrees; copper - 100 degrees;

- The grinder processes all the edges of the drill without exception.

The cone drill is a versatile tool. It is recommended to have it both at the production site and in your home kit for minor repairs.

Design and types

The device consists of:

- the actual working part, which has a conical shape;

- shank, with which the tool is attached to the drill;

- sharp tip that can handle the densest metal.

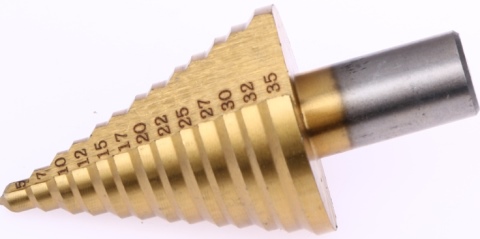

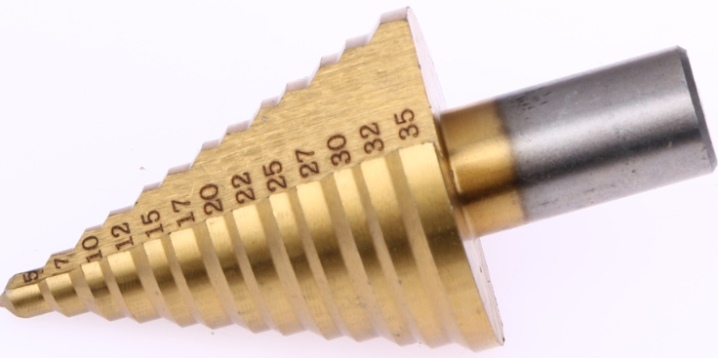

The cutting edge of the step drill is either straight or spiral type. Each of them has its own advantages. The straight edge sharpens more easily and faster, while the spiral edge allows for smoother, smoother drilling for a smoother ride. When using a spiral edge, the efficiency of processing thin sheet metal is especially increased. There are varieties of tools designed for different materials - wood or plastic. But all step drills are designed in the same way.

There are round or hex shanks, which are considered to be more reliable in use. The tool is made of high quality stainless steel, and a durable coating of titanium nitrogen or diamond grit extends its service life and reduces the need for frequent sharpening. In this case, it must be remembered that observance of the operating rules and the value of the permissible load is required.

There are two types of step drill shanks - hex and round

There are two types of step drill shanks - hex and round

Self sharpening

Drills, which are called stepped or conical, allow you to create holes with a diameter of 4 to 32 mm and are available in two versions: with the possibility of sharpening or with a design that does not imply this technological operation. The high cost of products belonging to the second type is justified by their durability.

Their cutting edge (subject to all operating rules) does not become dull for a long time. It should be borne in mind that sharpening them without appropriate experience can only lead to the fact that they become unsuitable for further use.

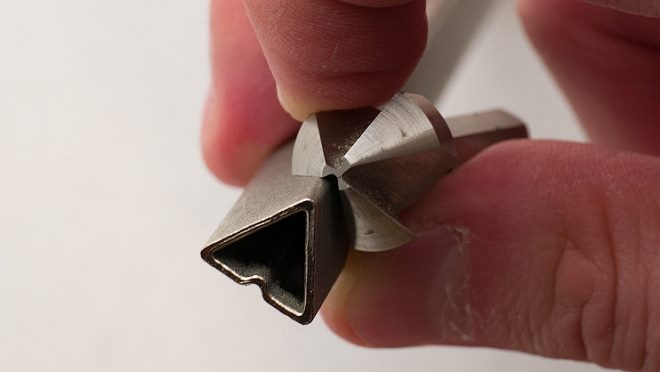

Conical drills with a specific configuration can be sharpened with a triangular abrasive bar

In order to properly sharpen a stepped drill, it is enough to watch the training video and adhere to the recommendations of qualified specialists. To perform this procedure, you can not even be guided by the drawing, but simply restore the original geometric parameters of the product.

Also, in some cases, it is permissible to use thin abrasive diamond stones for these purposes, intended for sharpening knives, scissors and other tools.

Sharpening such a tool, like twist drills with a taper shank, can be done using a special machine equipped with a working surface that can be covered with ordinary sandpaper.

What to look for when choosing a tapered drill

You should make a choice of such a tool as a conical drill for metal only after you become familiar with its characteristics. Color can tell a lot about a step drill.

- The steel-gray color of the material of manufacture indicates that the drill has not undergone any heat treatment, therefore, you should not count on its high quality.

- The cone tool, which has a black surface, has been hot steam treated to increase its strength.

- The golden color of the steel indicates that all internal stresses in the metal were previously eliminated, which improved its quality characteristics.

- If the surface of a step drill has a bright golden hue, it is highly wear resistant. This provides the titanium nitride contained in the metal. The rather high cost of such products is fully compensated by their long service life.

The marking of the stepped drill indicates its characteristics.

For the production of cone drills, various grades of steel are used, which are determined by the marking. If the abbreviation HSS is present in the marking, it means that with the help of this product you can perform high-speed processing without worrying that it will deform or lose its strength characteristics during intense heating.

When choosing a stepped drill, pay attention to the basic dimensions

When choosing conical drills, you must also consider the following parameters:

- the diameter that the cavity depends on the characteristics of the holes to be obtained;

- trade mark (this parameter largely determines not only the quality of the product, but also its cost);

- compliance of the purchased conical drill and the material from which it is made to all the requirements of GOST;

- the possibility of multiple sharpening (here you should be guided only by your own preferences and experience in sharpening spiral and conical drills in accordance with the requirements of GOST).

Terms of use

The operation of tapered cutting elements, in contrast to conventional twist drills, has certain features. They are simpler and more convenient to use. No wonder they say that novice craftsmen should work with a tapered tool.

But before starting work, you need to study the instruction manual of the product and remember the drilling technology. During the work, the master must follow a clearly drawn up algorithm. Even the slightest indentation can lead to serious problems.

First of all, you need to prepare the tools, namely the tapered drill, drill and base, where you want to drill a hole. The drill size depends on the desired hole diameter. The drill must be powerful and pick up the required speed in seconds. Experts, in turn, recommend fixing an additional handle on the drill. As for the workpiece, it can be any metal or synthetic surface.

By putting together the required tools, you can get to work.

To begin with, you need to fix the cutting tool in the drill chuck and apply the appropriate designation to the drilling site.

The drill inserted into the drill is applied to the work point and the tool is activated

It is important that the cutting element is perpendicular to the workpiece being machined.

The drill gradually deepens into the workpiece with a constant increase in the rotational speed of the drill .. The final result will be a smooth hole that does not have burrs and other defects at the edges.

The final result will be a smooth hole that does not have burrs and other defects at the edges.

The following video provides an overview of the cone drill.