Advantages and disadvantages

The main advantage of conductors is that not even highly qualified specialists can work with them, but “ordinary” people at home. And they will have clear and precise holes (both perpendicular and oblique).

You will not need to perform any calculations and markup, and this reduces how

labor intensity and time of work.

The following advantages of using this type of device can be distinguished:

- The drill jig is capable of providing perfect precision for both straight and oblique drilling.

- To use them, you do not need markup, as well as preliminary scrupulous calculations.

- Acceleration of assembly of pieces of furniture, other structures.

- Possibility to drill several holes at a time without preliminary marking.

The disadvantages of drilling jigs are much less, to be more specific, there is only one: the rather high price of this device. That is why some carpenters make their own conductors.

How to make a jig with your own hands

Since there are many varieties of conductors, thanks to this, we will begin to consider an unusual design and an analogue based on this. And so we begin.

Jig for perpendicular drilling

Its main purpose is to produce holes in thick workpieces, at an angle of 90. In essence, it is a set of bushings connected in one body. In most cases, these are overhead conductors, which are commonly used in furniture assembly.

It is worth attaching the device to the surface and proceeding immediately to drilling, without punching. There is one drawback, the device should be held firmly, and even more so at the beginning of work. Due to vibration, the device may move.

This type of conductors can be made with your own hands.

- In the form of a base, you can use a block of wood, a piece of PCB, reinforcement with a square section of 10 x ten millimeters.

- We finish the surface perfectly, clean it up and proceed to the marking.

- It must be borne in mind that the center of the holes must be 8 mm. from the edge of the workpiece. This is due to the fact that 8 mm. this is half the thickness of the chipboard sheet.

- According to the standards, there should be exactly 32 mm between the centers of the holes.

- Then in these centers we make holes with a diameter of 5 mm.

Handicraft conductor can be used, however, for more comfortable use, an emphasis should be built, in order to do this, metal with a width of 23-25 mm is used. and a thickness of 1 mm., after that the sheet is bent at an angle of 90 and attached to the jig. Also, bushings of different diameters can be inserted into the base of the jig.

Conductor for pipes and cylindrical blanks

Everyone knows that making a hole in a sloping surface is problematic, the end of the drill regularly jumps off. This type of jigs is fixed in a predetermined position and makes it possible to work very accurately.

This type of jigs can be done quickly and on your own.

- For this we need a block of hardwood, immoral along the diagonal. And we fix a piece of plywood to the edge of the bar with screws.

- After that we make holes of the required diameter in a bar of wood.

Now everything can be said conductor ready for work. In order for the holes to break less, they can be improved with iron sleeves, which are made from round pipes of various diameters.

Jig for drilling holes at an angle

This type of drilling is used in few places.

Suitable when it is usually impossible to hold a drill or screwdriver at the required angle.

It must be said here that in metal products, this type of hole is made only with a cutter. And as for wood products, that is, ready-made solutions in the form of sets.

It is easy to use these conductors, we press the workpiece tightly to the base, set the specified height and, as a result, we get even and beautiful oblique holes at an angle. Yes, if we do not need a through hole, then it is unforgettable to put a stop ring on the drill itself.

It is difficult and problematic to make this type of device on our own. There are quite simple methods and options, but they do not stand out for their accuracy. So, for example, a drill is placed on a prepared inclined surface and our workpiece is drilled at the obtained angle, as we understand the accuracy suffers too much.

Conductor for drilling holes under dowels

Their main purpose is to fulfill the alignment of the holes, in the future, into which the dowels will be installed. In other words, when you apply, conductor to both sides of the product, you get a wonderful seam.

As you can imagine, this type of conductors can be done by hand. If you have a stream of workpieces with the same geometry, you will be comfortable using an overlay template. It is best to use hardboard or other light-transmitting material (plastic) as a template.

We apply the markings and drill the holes. It will be better to drive brass or copper pipes into the holes so that the drill does not break the calibration hole.

Universal device

When you use blanks of different sizes and shapes, then you need a universal device. The most curious thing is that this device can be made from materials that are always at hand.

- For this we need plywood, about 15 mm thick.

- We make three equal blanks.

- We make holes along the edges, into which the dowels are installed as legs.

- We make one hole in the middle, which we reinforce with an iron tube.

- We make three metal slats with symmetrically placed holes, they will act as a shoulder. These shoulders are responsible for the linearity of the holes of the upcoming conductor.

- We make cuts in plywood blanks and install iron shoulders, we fasten everything. Our multifunctional self-centering jig is ready.

Scope of use

Furniture conductors are devices that no furniture maker can do without during work. Such devices avoid the main problem in furniture production, namely, the entry of the drill at the wrong angle. If you make such a mistake, then it is very difficult or impossible to correct it later. Such a device not only makes it possible to correctly guide the drill during operation, but also allows the tool to constantly keep the desired path (even, perpendicular or at an angle).

Furniture conductors are devices that no furniture maker can do without during work. Such devices avoid the main problem in furniture production, namely, the entry of the drill at the wrong angle. If you make such a mistake, then it is very difficult or impossible to correct it later. Such a device not only makes it possible to correctly guide the drill during operation, but also allows the tool to constantly keep the desired path (even, perpendicular or at an angle).

Such devices are used both in the design and manufacture of furniture, and in assembly, when there is a need to make holes for attaching elements to each other. Often, for such actions, conductors are used for companies or dowels, without which it is impossible to make even holes.

Also, this device cannot be dispensed with if it is necessary to make holes at an angle or at the end of a thin plate (it is especially important to use a device when working with chipboard slabs)

When drilling holes with this design, the process itself is quick and easy. The fasteners allow you to work at any distance from the edge of the slab, as well as regardless of its width.

In the furniture industry, dowels are very often used as fasteners. But at the same time, this option has already existed for a long time, and their use requires the mandatory presence of a drilling jig when working. The only condition and at the same time a problem is the factor that the parts to be joined together must have a right angle during operation.Therefore, such elements must be located exactly perpendicular to each other. When making holes for dowels and adding parts, it will be very difficult to do without a jig.

Furniture production is not the only area of application for such devices. They can often be used to make holes in pipes and other round parts. Special devices make it possible to make quality holes even in the smallest tubes.

Applications

Conductors are considered especially in demand, with the help of which furniture is made.

When creating any object for a strong fixation of furniture boards and panels, it is very important to hit the part at the correct angle, and the conductors help to ensure this accuracy. Any modern furniture manufacturing industry is not complete without additional high-precision drilling equipment, since wood, MDF, chipboard and other types of products can be damaged when drilling

The jig for furniture dowels allows you to achieve straightness of the drill entry and eliminates defects.

Common use cases:

- installation of structures with obligatory perforation for fasteners and fittings - in these cases, the confirmation and the conductor for the dowels are relevant;

- drilling at a certain angle, when the work is carried out with thin sheets and panels of such finishing, furniture materials as particle board and fine dispersion board made of wood fibers;

- the device is in demand in the serial production of furniture - the use of templates speeds up and simplifies the production of holes, regardless of their location and size of the part.

Perhaps it will seem to someone that dowels, these insertable threadless thorns or rods are outdated fasteners, but they are still considered the most reliable fixators in the production of various furniture structures.

In addition to being used in the manufacture of furniture products, conductors are used in other industries, moreover, with the help of this important part, perforation is possible even in pipes with a minimum inner diameter. Ease of use and versatility allow these useful devices to be used in the following areas:

- construction industry - many structures require precise holes for reliable fastening;

- the area of creating various communication systems for public and home use, mainly for the installation of pipelines for various purposes;

- machine-building sphere - here conductors are used for workpieces made of any materials of all possible dimensions.

Drilling templates are of various sizes, simple and complex in design. In some cases, it is better to buy ready-made models, but it is also possible to make simple modifications with your own hands. This is quite justified when the required conductor has a high price.

Description

The most common type of fasteners for the installation of elements of modular furniture made of chipboard, MDF and other wood-based materials are confirmed (euro screws, euro screws). These fasteners involve preliminary drilling of 2 holes of different diameters: a blind hole from the end of one connected element for the Euro screw thread and a through hole in the face (plane) of another element. It is almost impossible to do this with a conventional drill, because the hole breaks, and it is rarely possible to create a right angle. In this regard, for such work, it is necessary to have a toolkit called a conductor.

In fact, the jig is an ordinary template with holes of the required diameter.

For comfort, it can be equipped with a regulator and a locking device.

The jig guarantees the necessary direction of the cutting tool at right angles to the surface, preventing the possibility of sideways

This is especially important when working with narrow component parts of cabinet furniture, such as the end surfaces of doors or walls. Without this device, it is rather difficult to maintain the required angle, which can lead to a defect, since sometimes a slight deviation in the direction of the hole for fasteners can make it impossible to assemble individual parts into an integral structure

The devices are endowed with the following advantages:

- thanks to them, it is possible to obtain accurate holes for additives for confirms (euro screws);

- the toolkit does not need to be marked for a drill;

- any piece of furniture will be assembled much faster;

- you can make a specific number of holes without prior marking.

Benefits of using

In fact, such a jig acts as a template for making holes so that they are made as accurately as possible. They can be used for those holes whose axis is perpendicular to the surface of the workpiece, as well as for working at an angle.

This tool is a great alternative to sketching and hand measurements. You can place the drill exactly at the desired angle in relation to the workpiece and do not allow any deviation. The result will be especially noticeable when it comes to making deep holes.

If you use such a device of high quality for work with chipboard, then it must have the following characteristics:

- facilitate the quick assembly of furniture without the need to use complex tools;

- make it possible to make several holes at the same time without manual marking;

- significantly improve the quality of work with the drill.

Conductors are made on the basis of different materials, there are models based on plastic or organic glass. However, the best option is considered to be made of steel, which has such advantages as:

- minimal likelihood of deformation;

- the drill is directed as clearly as possible;

- lack of heating during operation.

Very often, overhead models based on lightweight materials that are easy to manipulate are used in the role of furniture conductors. Many people use factory or homemade tools.

And the most qualified and experienced craftsmen no longer use the conductor, since they can independently easily make a hole in the structures as accurately as possible. But not everyone can do it.

The key advantage of such a device is that the work can be performed as accurately and efficiently as possible even by a person who does not have the proper experience. You do not have to carry out markings and complex preliminary calculations. You will save a lot of time and make furniture much faster.

Classification

According to the features of use, conductors are classified into the following types:

- Overhead. These are simple and mobile devices that do not require fixation, but are held by hand. In view of this, drilling using these jigs has to be carried out with one hand. They are used mainly in the processing of chipboard and MDF boards. The devices in question are easy to create yourself.

- Swivel. These conductors are equipped with brackets. Designed for drilling in two adjacent planes with one pass.

- Sliding. These devices are designed to create multiple holes without changing settings. They are professional equipment that requires appropriate skills.

- Corner (angled). Presented by highly specialized options designed to make holes at different angles. Often made according to the invoice scheme.

Homemade conductors

First of all, it should be noted that the simplest models of conductors are very inexpensive, therefore, it is not always advisable to make a template for dowels with your own hands. In addition, it should be borne in mind that models for confirmations are the easiest to make. The dowel options are more complex.

For self-creation of such a device, drawings are required, which are easy to find in open sources. There are also instructions in different forms. They describe the creation of various types and variants of templates for dowels: with one and several holes, from different materials, etc. The starting materials can be represented by improvised raw materials such as wooden blocks, fragments of reinforcement and plates, etc. So, a square reinforcement 10x10 mm. In addition, you will need locksmith tools and equipment such as a drill and grinder. To create more complex jigs, a welding machine is required.

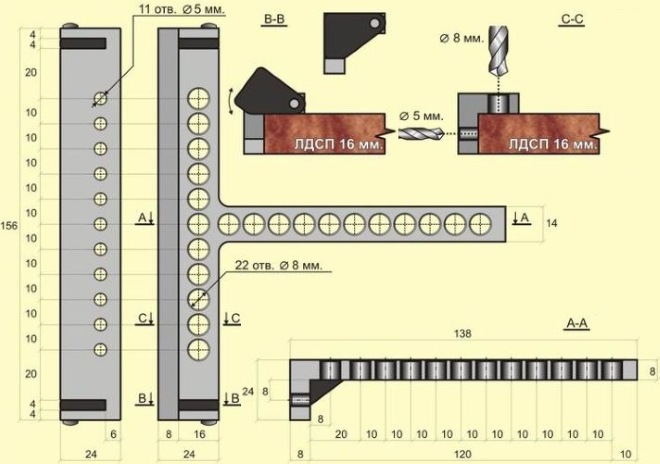

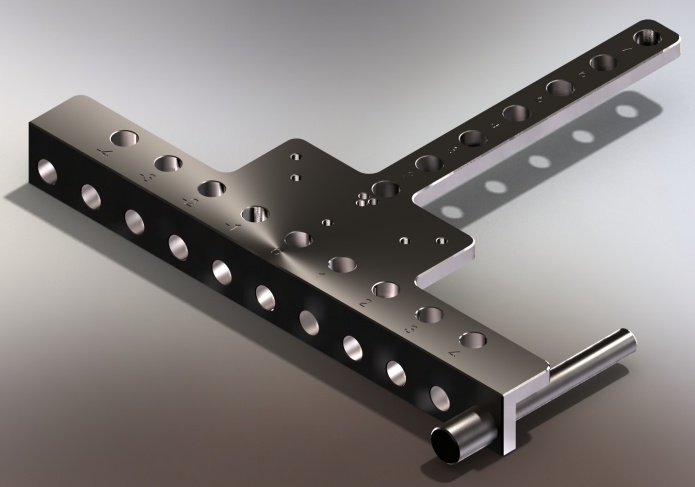

Self-creation of a template for dowels includes several stages. On the first, the reinforcement is cut into fragments, the length of which is determined by the dimensions of the product. Next, holes are made for drilling, for which it is necessary to know their parameters. They have a diameter of 5 mm and are located 8 mm from the edge of the conductor and 32 mm from each other. To increase the ease of use, it is possible to equip with a stop. In the form of it, a plate bent at a right angle, fixed to the product, can protrude. The parts are fixed using a clamp and fastened with threaded connections. In addition, sometimes self-made conductors are equipped with pallets for chips in the form of fragments of plastic bottles.

Drilling in two parts at the same time

This option is considered the most accurate and, moreover, the fastest. But in order to make a hole in two parts at the same time, you will need to fix them before drilling. This may require special clamps, clamps and other devices.

Hole drilling attachments

In order not to mark each time 8 mm from the edge both into the layer and along the end, you can use a special device, which, by the way, is easy to make yourself.

It is a kind of wooden template with a metal drill sleeve inside.

It looks like this, see the photo:

And this is a more professional thing:

Watch a short video on accurate drilling of holes in chipboard for confirmation and assembly of furniture parts:

What is it used for

In the manufacture and assembly of elements of furniture structures, specialists have to carry out many of the same type of actions associated with both marking locations and drilling future holes. The furniture jig allows you to optimize both of these processes.

According to their functional purpose, furniture conductors can be marking and drilling. The first, as their name implies, are intended to simplify the marking of the locations of future holes. Drilling jigs used in the manufacture of furniture structures exclude the use of marking devices.

Drilling jig for confirmation

The furniture template, designed for preliminary marking of the places of future holes, is purchased by many in the factory. However, you can make a do-it-yourself jig for assembling furniture. The easiest way is to make a furniture jig from a metal ruler, to which a crossbar is screwed strictly perpendicularly. Such a furniture template is a multipurpose marking device that is easy to manufacture and use. The holes through which the drilling locations will be marked are made in a metal ruler at a certain distance. So, if the holes are drilled for the minifix, then the distance between them will correspond to 32 mm, and for shelf supports - 100, 200 or 300 mm.

You can make the simplest furniture marking template using a regular carpenter's square as a basis, in which holes are also drilled at the required distance. Such a marking device, although more functional, is less stable on the surface of the workpiece being processed. This is its most significant drawback.

The simplest furniture template for handles is a plate with calibrated holes, on the back of which a stop bar is fixed

According to a similar principle, using available materials, it is possible to make highly specialized marking devices (for example, a jig for furniture hinges or for marking holes for fixing furniture handles or any other furniture accessories).

Of course, if you have your own serious furniture production and the volume of assembly operations performed is large enough, you should pay attention to professional devices for assembling furniture. However, the cost of such furniture conductors and templates, especially if they are produced under well-known brands, is quite high.

Classification of instruments

Before you buy a ready-made conductor or make it yourself, you need to decide what tasks you will solve with it, and only then you need to select the appropriate option in terms of design and function.

There are a number of categories of devices that differ in their performance and functional features. Here is some of them:

- overhead - such devices are superimposed on a part that can be processed, then they are attached to it or simply fixed by hand. With their help, holes are made in various flat parts, MDF plates or chipboard;

- rotary - these templates are used when processing cylindrical parts. They are equipped with horizontal and vertical pivot points, so that holes can be made at different angles;

- universal - such devices are suitable for small serial furniture manufacturers, where sometimes a quick changeover of the equipment used is required, they have all the functions necessary for this;

- overturned - used when the technological procedure is carried out in several planes at once;

- sliding - such conductors do not need to be fastened. Just attach them to the section of the workpiece surface where you want to make a hole;

- fixed - they are more convenient to use, but they limit freedom of action, which is very critical when working with machines where there is only one spindle.