Do it yourself

Now let's talk about how you can make a homemade conductor. Let's dwell on a simple model, since something complicated to do with your own hands is not worth it. It is better to immediately buy a quality tool from a trusted manufacturer.

Conductors are made from pieces of reinforcement, plastic and metal bars. You can take wood, but it is less durable.

From the tools you need to prepare a set consisting of:

As you understand, a ruler and pencil are required for marking. The task is not the most difficult, therefore you will probably be able to cope with it. In addition, watch a visual video.

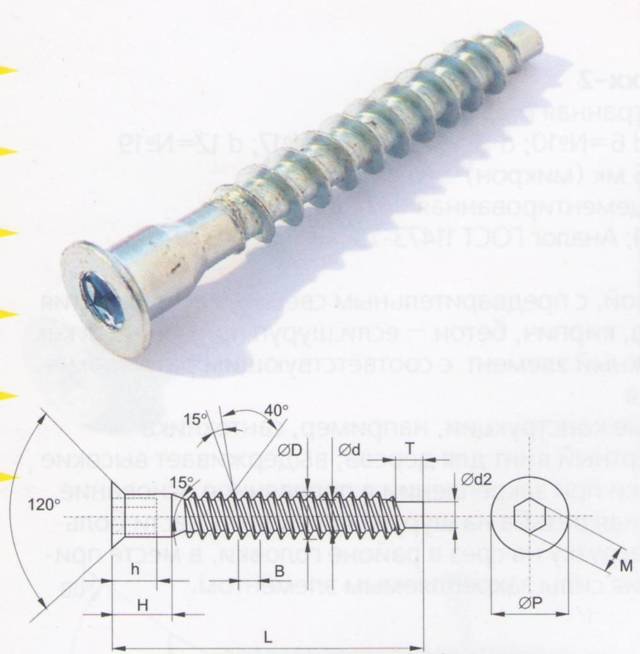

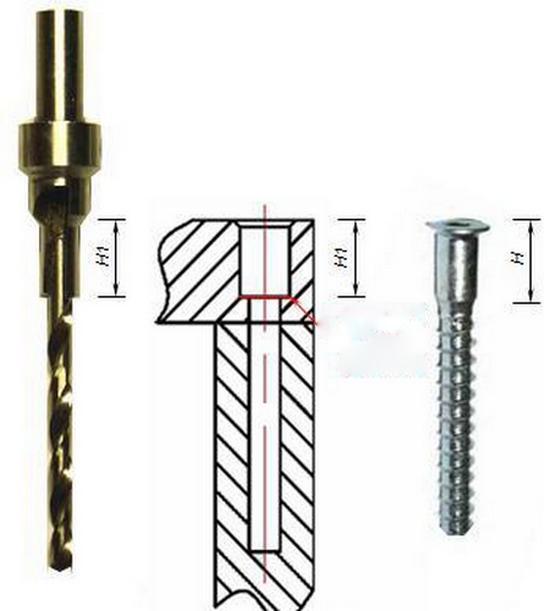

We will take a piece of metal as a basis and will make a conductor for confirmations or furniture euro screws.

- take a piece of metal with a cross section of about 10x10 mm;

- cut the element of the required length with a grinder or jigsaw;

- smooth out all irregularities and roughness with a file;

- mark the future holes in the conductor;

- the center of the hole should be 8 mm from the side edge;

- retreat 32 mm from the end;

- between each subsequent hole is also 32 mm;

- make holes with a 5 mm drill;

- clean the edges with sandpaper;

- make an emphasis from the metal plate;

- bend the workpiece in a vice, keeping a right angle;

- fix the details with clamps;

- from the side of the metal plate, make holes for the size of the screws;

- cut the thread;

- connect the components;

- process the edges, cut off the excess parts.

I cannot say that the task is extremely simple. There are difficulties and nuances here. Plus the eternal problem of self-made conductors is that not everyone succeeds in maintaining a right angle of the hole in them.

Therefore, I am of the opinion that it is better to buy a conductor. This is an inexpensive pleasure, but very useful, with verified dimensions and convenient configuration.

Subscribe, ask questions, leave reviews and tell your friends about our project!

What it is

In talking about what tools a furniture maker needs, I missed such an important point as a conductor. I can't say that this is an essential element, but without it, solving some tasks is much easier and faster.

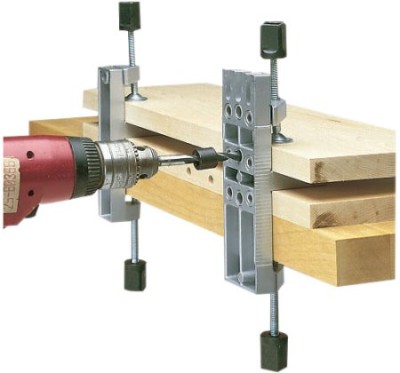

Furniture conductors are fairly simple mechanical devices. They are needed in order to simplify and speed up the process of drilling various holes. Using such an object, you can make a hole according to the marking and with optimal accuracy and the required angle of inclination. It is actively used in the process of assembling furniture, when performing various carpentry tasks. The jig is perfect for domestic use, since you can always do it yourself or buy a small tool for personal use.

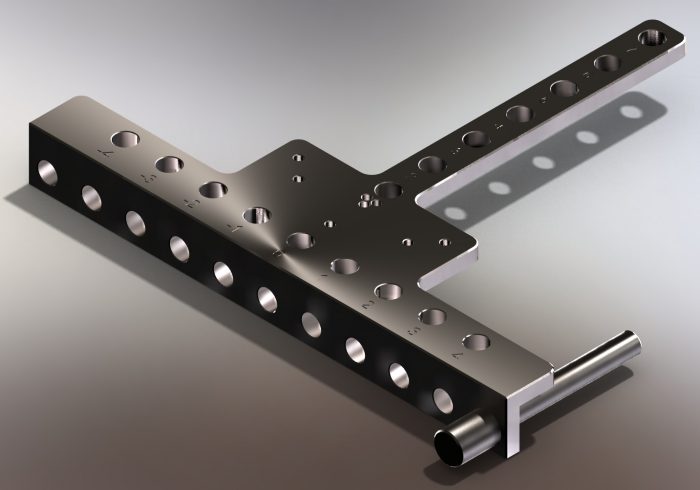

In fact, we are talking about a template for holes with different diameters. The main part of the tool is presented in the form of a rectangular bar made of durable material. There are holes on the block.

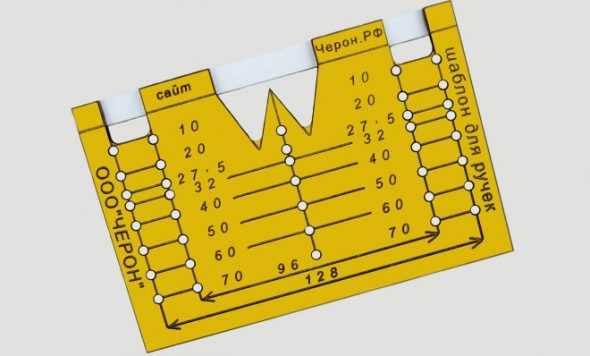

To simplify the work with the jig, many models are equipped with additional adjustment and fixing mechanisms. If you want or need, you can make a tool with your own hands... And sometimes the result is no worse than Cheron.

With the help of the jig, the drill moves in a given direction and creates a hole of the required size. In this case, the material is drilled strictly at a right angle of 90 degrees. Some models allow you to adjust the angle or in them initially tasks a certain slope

It is extremely important to exclude deviations when processing thin materials, end parts of doors and walls.Manually maintaining the correct angle is difficult

Often there is a lot of marriage, you have to spend extra material.

If you need to make many of the same holes on different parts, or ideally make them evenly along one line, the jig will become simply an indispensable device.

Applications

It must be said that the use of a jig for holes is practiced almost everywhere where there is a need to constantly drill holes. These areas may include the following.

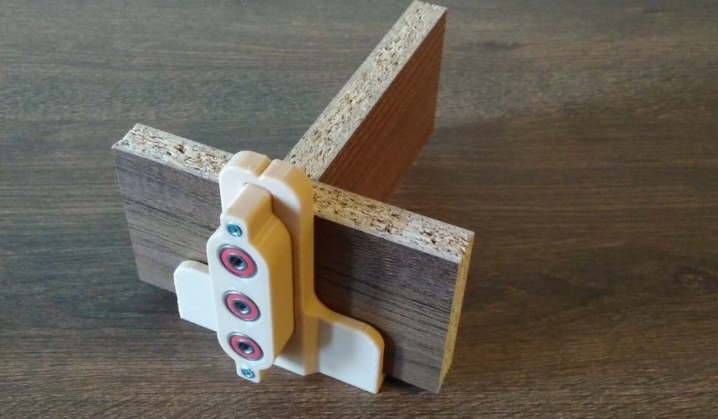

Furniture manufacturing. They are used both in the manufacture and in the assembly of pieces of furniture, when it is required to make holes in the mating elements for the installation of fasteners. In such episodes, a jig for spikes or a jig for confirms (Euro screws) is often used, without which it is impossible to produce high-quality mounting sockets for fasteners. For example, a U-shaped jig for confirmations with a stop simplifies drilling holes for euro screws and facilitates the assembly of cabinets and cabinets. Such a tool is extremely necessary when you need to drill holes (including at an angle) in thin sheets of chipboard or MDF.

With the use of a jig, the assembly of pieces of furniture is quick and easy. Even a simple device such as a bar with an emphasis greatly simplifies the procedure for making holes of the same type.

They are often used to make holes in pipes and other cylindrical workpieces.

For drilling pipes and cylindrical parts

In modern furniture, not only chipboard, fiberboard, MDF and wood are used. Steel pipes of various diameters can be used as additional elements. Plated with chrome or stainless steel, they perfectly complement the overall furniture ensemble.

In modern furniture, not only chipboard, fiberboard, MDF and wood are used. Steel pipes of various diameters can be used as additional elements. Plated with chrome or stainless steel, they perfectly complement the overall furniture ensemble.

It is very difficult to drill a spherical surface - the drill strives to slip to the side. And it's not so easy to mark when there are a lot of holes and they are located in several rows.

So that the notorious colander does not turn out from the pipe, but the correct part with precisely made holes, you will need a conductor - this is the ideal solution in this situation.

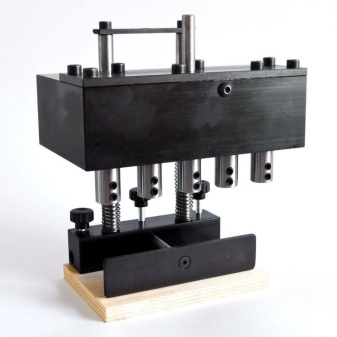

There are steel conductors made in the form of an adjustable clamp. This design feature allows you to clamp pipes of different diameters in them and drill holes in them with high accuracy.

There are steel conductors made in the form of an adjustable clamp. This design feature allows you to clamp pipes of different diameters in them and drill holes in them with high accuracy.

Unable to make such a device, you can use junk materials by making an even simpler device using a block and a strip of plywood. So, a block cut along a diagonal on a circular saw can be nailed or screwed with self-tapping screws at an angle of 90 ° to the plywood. The resulting device is superimposed on top of the pipe, and a strip of plywood, resting against a table or workbench, does not allow the given angle to be violated. Pre-drilled holes in the bar of the required diameter are placed taking into account the required distances between future holes, which will allow you to quickly and accurately drill the pipe exactly according to the drawings.

How to do it yourself

The simplest designs are cheap, and professional furniture makers are not puzzled by homemade production, but prefer to buy factory models. But there are also such masters who want to make such a device with their own hands.

The simplest designs are cheap, and professional furniture makers are not puzzled by homemade production, but prefer to buy factory models. But there are also such masters who want to make such a device with their own hands.

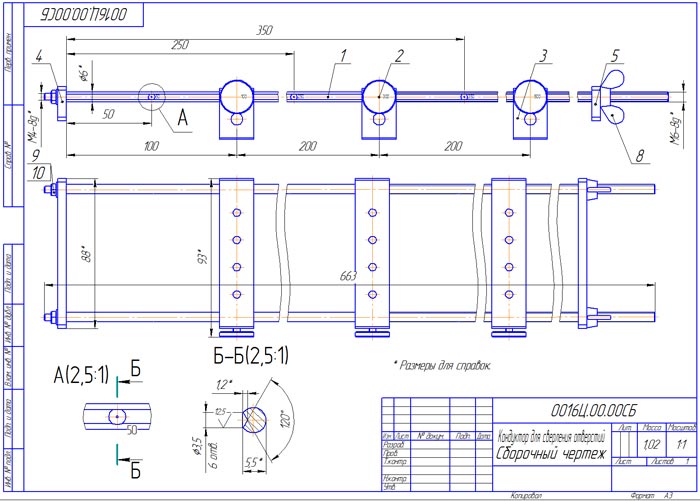

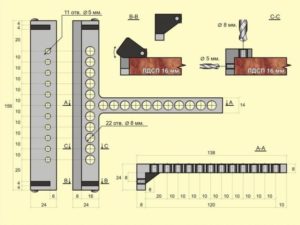

To create a conductor yourself, you need to use the drawings, of which there are a lot on the Internet. With your own hands, you can make simple designs for confirmations and more complex ones for dowels.

For production, you need to prepare a tool:

- drill;

- classic set of tools for the locksmith;

- welding;

- Bulgarian.

The simplest conductor can be made from improvised means, which are mainly found in any household, in a workshop in a country house or garage. For its creation, the simplest materials are suitable, such as fittings, metal sheets and wooden blocks, etc.They can significantly save money in the production of such a device.

The manufacture of such a device should be carried out in several stages:

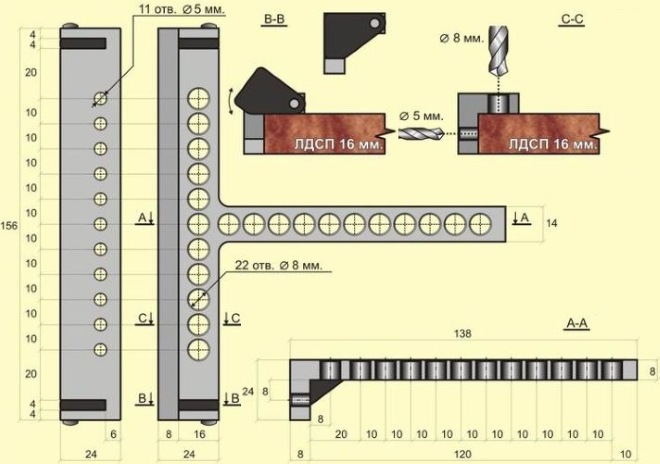

- From square reinforcement 10x10 millimeters, it is necessary to make several segments of the desired length.

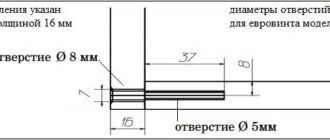

- The holes through which the drill will pass should be at a distance of 8 millimeters from the edge of the reinforcement.

- According to generally accepted standards, the distance between the holes should be 3.2 centimeters, and the hole diameter should be 5 millimeters. This creates a loop of holes.

- When you also make additional stops, it will be much easier to use such a device. To create it, you need a metal plate 1 millimeter thick and 20 millimeters wide. The plate should be bent at an angle of 90 degrees, then attached to the overall structure. After fixing all the elements with a clamp, they must be securely bolted together.

Originally posted 2018-04-06 09:10:15.

Design features and types of conductors

The drilling jig is actually a pattern of holes that allows you to make them with maximum accuracy. They can be divided into two types:

- when the drilling axis is at right angles to the material surface;

- when the axis is at an acute or obtuse angle with respect to the plane.

Conductor device

The tool has such versatility that it is used in different areas of the industry. For several decades, it has been very actively used in the engineering and construction industries. After all, it allows you not only to drill holes in the required workpieces at different angles and excellent accuracy with different configuration features. With its help, holes are easily drilled in various building structures, as well as pipes made of any material, etc. The jig is often used in the furniture industry, as it greatly simplifies the process of fastening fittings and the assembly of its various parts. In fact, this is only a small front of tasks that the conductor is able to solve.

What is and its purpose

In fact, a furniture jig is a regular template with holes of the required diameter. The working part of the device is a rectangular block of solid material with holes located according to the required marking. For convenience, it can be equipped with adjusting and locking mechanisms. Based on the simplicity of the design, you can quickly make stencils for furniture with your own hands from improvised means.

The jig ensures the correct direction of the drill at an angle of 90 degrees to the surface, eliminating the possibility of deflection

This is especially important when working with narrow pieces of furniture such as the ends of walls or doors. Without this device, it is quite difficult to maintain the desired angle, which can lead to rejection, because even a slight deviation in the direction of the mounting hole can make it impossible to assemble individual elements into a single structure

For the perfect fit of furniture elements to each other, the exact location of the holes for the fasteners is also of great importance. Those who make furniture with their own hands are often faced with the need to create a series of identical holes at a certain distance from each other. To make the work easier, to make it faster, it is easier not to do the markup every time, but to apply a template.