Hydraulic jack device

To make a calculation of a hydraulic jack for its purchase or self-assembly, it is recommended to find out what scheme, device and design features this device has.

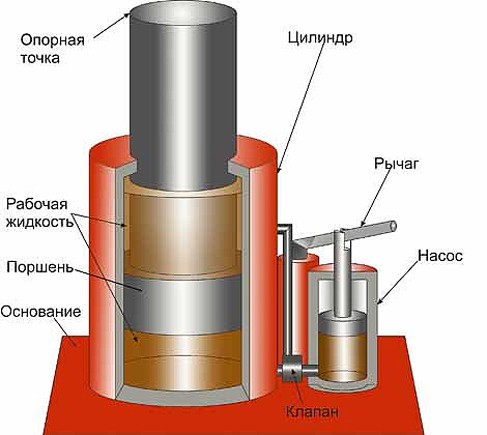

The lifting device consists of three main components:

- Movable piston;

- Housings. It is made of high-strength metal and has the shape of a cylinder. In addition to the functions of the body, it plays the role of a container where the oil is located;

- Liquid environment. It is played by machine oil;

- Levers;

- Valves;

- Plungers.

- Force is applied to the lever, and the use of valves makes it possible to increase it tenfold.

- The plunger allows you to move the piston device by transferring the working fluid, which is the oil, into the container under the plunger.

- The valve prevents the oil from flowing back into the housing.

- Gradually, the plunger transfers more oil under the piston, which contributes to its lifting.

- To lower the load, it is necessary for the oil to return to the housing device. Here you need to open the valve.

This principle of operation is relevant for all hydraulic jacks. Therefore, the diagram, drawings, video guides for the assembly and operation of these devices are approximately the same.

Advantages and disadvantages

If you decide to assemble a bottle-type lifting device, thereby creating a hydraulic jack, or if you want to buy factory equipment, you should first find out about the strengths and weaknesses that characterize the device.

Let's start with the benefits, which include:

- High power ratings;

- Ease of operation;

- High efficiency reaching 80 percent;

- The device works when moving loads weighing up to 200 tons. So the hydraulic jack raises a decent mass.

But this type of jack has its drawbacks. You should know them before you start working on it.

- The device cannot lift a load from a low height.

- Inability to set the level of lowering parts.

- A device of this type requires close attention, periodic service. The service scheme provides for the need to fill in oil, change oil seals, gaskets.

- The hydraulic jack can only be transported and stored when it is upright. Otherwise, oil leaks out and has to be refilled for normal operation. Filling the unit is not difficult, but no one wants to do it all the time.

- The principle of the device does not allow it to quickly perform the lifting and lowering functions.

- The rise is carried out cyclically.

- This type of device is quite expensive.

- Breakdowns for hydraulic jacks are not uncommon, and they are quite expensive to maintain.

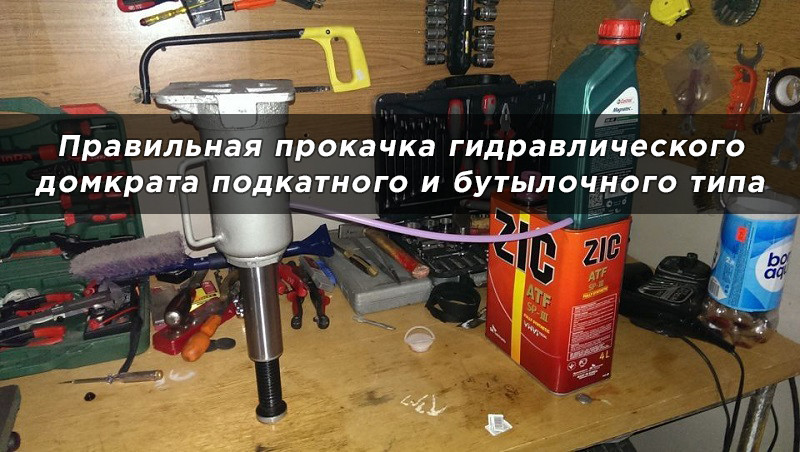

Pumping technology

If the power drops, the rolling jack must be pumped.

Pumping the hydraulic jack begins with the fact that you should open a special bypass valve, a plug from the oil reservoir. This is done so that you can drain the old oil and flush the device. This stage is very important, since during operation the container gradually becomes dirty, debris can get onto other parts of the mechanism, causing serious damage to it. After the oil is drained, it is necessary to fill the container with a special liquid, it can be purchased at a very reasonable price. Maximum effort will cause air to escape completely from the hydraulics. From the container, it is quickly pumped into the oil cavity, this work does not take much time.

When pumping is performed, all traces of air are completely removed from the working cavity. The work must be carried out strictly according to the instructions provided by the manufacturer, since different models of hydraulic jacks may require different actions. As a result of the actions performed, the power of the equipment should not change; during a test run, it works in the same way as in a new state.

A situation may occur when the hydraulic jack starts to operate at the wrong power. This means that not all of the air has been removed from the working cavity. In this case, the procedure is repeated several times until the desired result is achieved. This method is universal, it is great for any model.

The hydraulic jack is indispensable for auto locksmith work.

It so happens that the hydraulic jack starts to work not at 100% of its power, but at a lower value.

Here you should first pay attention to the position of the shut-off needle. It is easy to find it, it should open 2-3 turns

Finding the position of such a needle is not difficult if you look at the proposed instructions. It is always supplied with the equipment. After the needle is found, the screw should be raised to the extreme position, then released. This ensures that the screw is correctly positioned during the work being performed.

After that, it is performed, usually 2-3 times is enough to fix the problem. If there is no result, then the process must be repeated, usually it is enough. In any case, you need to carefully monitor the oil level so that it is at the maximum mark. During pumping, it is topped up until its level remains unchanged. The same method will completely remove the dirt. The head of the body is unscrewed, kerosene is poured into the cavity. The jack is pumped when the needle is unscrewed, which makes it possible to immediately remove all traces of dirt.

Jack pumping

Bleeding the jack is a preventive measure that prevents damage to the device. Prevention should be carried out regularly.

Why do you need pumping?

The number of preventive pumping depends only on the frequency of using the device. In car services, bleeding can be performed once every few weeks, but in a garage or with rare use of the device, you can reduce the number of preventive actions up to 2 times a year.

Prevention will be required for:

- Excessive presence of contaminants in the oil. Foreign matter can reduce the efficiency of the structure and lead to serious damage.

- The appearance of bubbles. Bubbles in the oil indicate that air has entered the system. Although air rarely enters the piston, its condition will also need to be checked.

- Decrease in real carrying capacity. If the jack cannot lift the declared mass, then it is worth carrying out preventive work or taking it to the workshop for the bulkhead of the device.

Modern jacks are of one-piece design, so it's not always possible to sort it out. Even if the device cannot be repaired, then bleeding the system will be an excellent solution.

Work order

Pumping is performed in several stages. First of all, unscrew the valve and remove the plug from the oil reservoir. It is recommended to change the oil before bleeding, therefore the old oil must be drained.

The oil must be drained until only air remains in the device. This manipulation will prevent further damage that may arise from residual contaminants.

Depending on the wishes of the owner, the internal surfaces can be cleaned using special compounds.Special flushing removes various deposits well and helps to extend the life of the jacks.

Next, the grease is poured. There are two types of hydraulic jack oils. Summer oil does its job well in the warm season, but in winter it can lead to a deterioration in performance. If the jack is used constantly in a room where the average temperature does not drop below zero, then you can safely fill in summer oil. When operating a hydraulic jack in difficult operating conditions, it is necessary to take care of the safety of the structures and fill in winter oil.

Oil is poured until the cylinder is completely filled, and the piston at this moment should be at its lowest point.

At this stage, it is considered that the work is completed, but it is better to pump the jack right away. To do this, the oil valve is opened, and the device is intensively pumped using a lever or pedal.

Since faulty cuff gaskets are often the cause of malfunctions that lead to the appearance of air in the system, they should be replaced immediately. Do not rely on their integrity, since small defects on them are almost impossible to notice.

How to change the oil in the jack

Slow lifting and lowering of the device is a sign that the oil in the hydraulic jack needs to be changed. It should be borne in mind that liquid may leak out in case of improper transportation of the device. In a horizontal position in the hydraulic device, fluid flows to the valves, after which it begins to flow out. The place of the working fluid is occupied by air, which significantly reduces the efficiency of the structure.

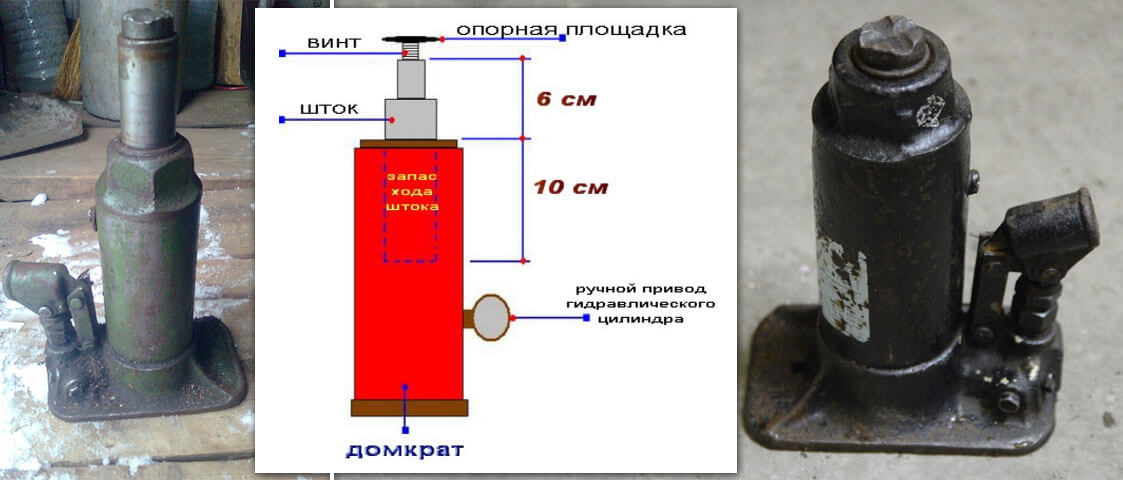

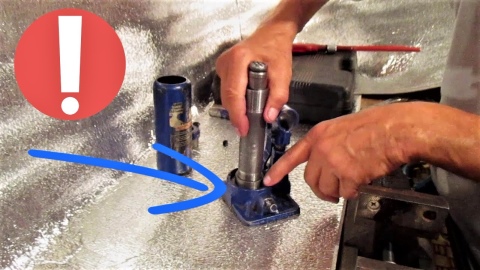

When considering how to refuel a bottle jack, you need to pay attention to the following points:

- It is recommended to disassemble the structure before changing the working fluid. This is due to the fact that you need to thoroughly clean the piston from dirt and corrosion. Such substances can damage the structure. On sale there are hydraulic jacks of a collapsible or non-collapsible type. The first is characterized by the fact that all elements can be disassembled if desired. As a rule, it is enough to get the piston rod

- In some cases, the gasket is replaced. It should be borne in mind that damage to the sealing elements is not always noticeable. An example is the change in the stiffness index. You can meet all the seals on sale or restore the condition of the old ones, provided there is no serious mechanical damage. To do this, you can use ammonia, in which the sealing elements are soaked. After a short treatment, the rubber regains its elasticity and provides the required level of insulation.

- Filling the hydraulic jack with oil is carried out through a special connector. The plug is usually threaded. When replacing the substance, the structure is pumped, since air can significantly reduce the efficiency of the lifting mechanism. It is recommended to carry out the pumping several times, as air bubbles are hardly dislodged.

It should be borne in mind that when draining the oil, there is a chance of losing the metal ball acting as a valve. That is why the procedure in question must be carried out carefully.

In addition to special substances, industrial types can also be used, for example, I12A or I40A. It should be borne in mind that many of them are characterized by high viscosity. That is why, before using industrial oils, you need to check whether they are suitable for a specific hydraulic jack model.

In some cases, brake fluid is used. It should be borne in mind that it is only partially suitable as a working medium for lifting mechanisms. This is due to the high level of hygroscopicity.Some time after the application of the brake fluid, the water that is in the composition leads to the onset of a corrosive process. That is why experts do not recommend using such a fluid for the operation of a hydraulic jack.

The above information indicates that no special equipment is required to change the oil. The level is replenished up to the mark, which is indicated by the manufacturer on the case. Too high or too low a level will prevent the hoist from working properly.

In conclusion, we note that only with the use of special oil can a long service life of the device be ensured. Ordinary substance or processing is much cheaper, but does not provide the required operating conditions.

If you find an error, please select a piece of text and press Ctrl + Enter.

During the repair of a vehicle, on construction sites, during unloading and loading, a device such as a hydraulic bottle jack may come in handy. Due to their versatility, jacks are used everywhere. I am without this contraption at the service station and have no idea what you did.

However, sometimes you have to tinker with the jack. Previously, I did not know how to pour lubricant into it and what substance would be the best solution for this. This is what my next review will be about.

DIY jack repair

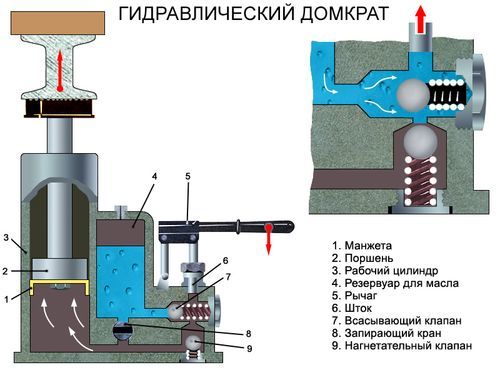

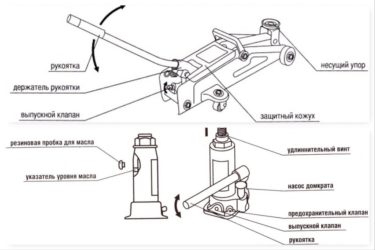

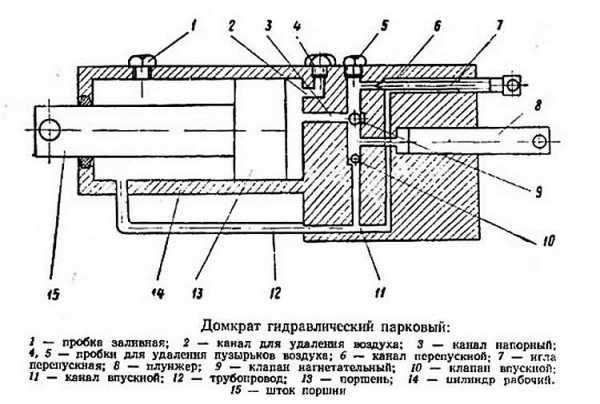

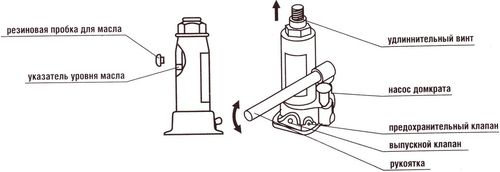

Diagram of a hydraulic jack.

The hydraulic jack is difficult to replace for the purpose of lifting and holding equipment. There are different signs that indicate equipment failure. For example, lifting a load is difficult, and the level of lifting to a height can be significantly reduced.

It is possible that a large number of strokes must be made to mount the device at the required height. If the hydraulic jack does not go down, then this is a clear sign of a breakdown. Knowing some of the breakdowns will help you decide on the choice of the pumping method. This includes:

- The presence of rust inside the device, limiting the process of lowering the mechanism to the desired position.

- The extreme load tested by the device that causes the stem to bend.

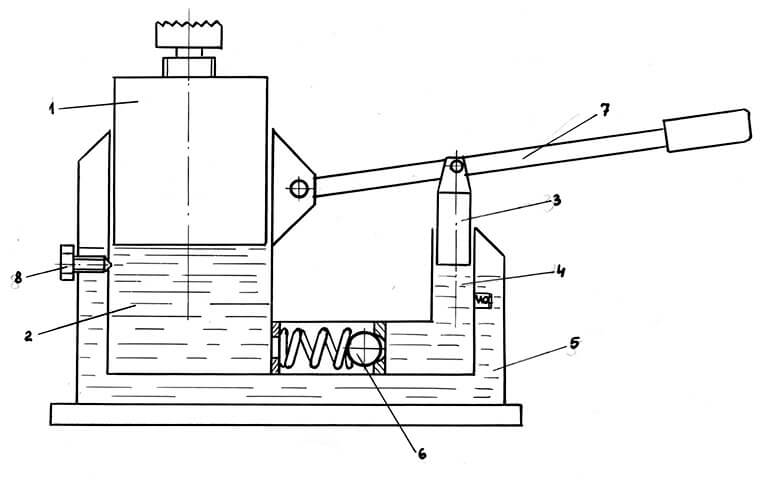

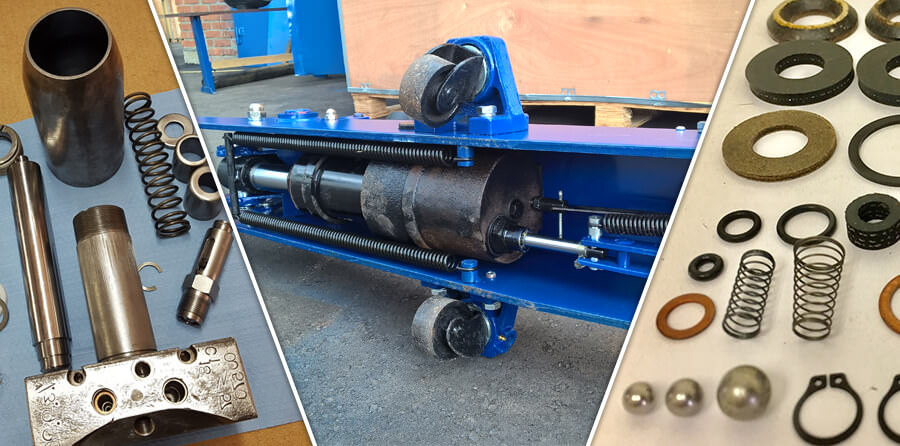

After disassembling the unit, you will notice that the unit has a cylinder containing a piston or rod, which moves inside it when working oil is present. The pressure on the liquid is created during the operation of the cylinder valve. There is a pump that directs fluid into the cylinder.

The device lowers the load at a speed controlled by the hole. It is necessary for the outflow of the incoming fluid from the cylinder. The jack has threads on rods, housings and bases.

Dismantling the jack

Jack repair scheme.

To open the unit, perform the following basic steps:

- The unit is completely disassembled using keys.

- Unscrew the fasteners.

- The valve that bleeds oil is removed from the device, as well as the primary piston.

- A detailed inspection of the unit is carried out to check the quality of the ball of the special valve and gaskets in order to replace them.

- They clean the device from unnecessary elements and flush the system.

- After opening the unit, change the oil.

It must be a high grade or Total LHM + spindle oil. Further, other rubber bands are installed and the used oil is drained.

For complete drainage, the lifting part of the device is moved down and then up. The open chambers allow all of the piston fluid to be released. The pressure spring of the device must be removed. Next, close the valve by bleeding off the oil using a check ball. For accurate oil penetration into the device, it is required to lift the jack up and then lower it down. At the end of the work, the installation of fasteners is carried out: pins and studs.

The device is equipped with two valves - fittings that open under pressure. Each of them has a spring-loaded "plug", which is a stud with a cap. Its tip should fit into a small hole, and the cap will rest against a special spring.

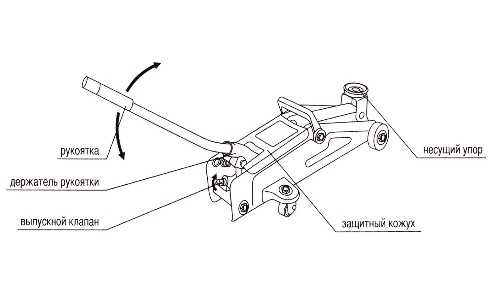

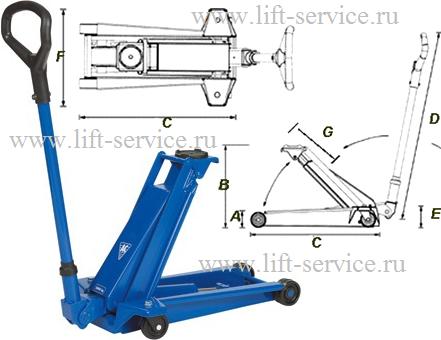

Park hydraulic jack diagram.

The first valve usually opens under pressure from the side of the lever and is unscrewed to release. The oil is launched into the large “holding” cylinder after it has passed the small “rocking” cylinder. When the pressure from the lever drops, the valve begins to hold the oil while being closed. A second valve is required for etching into the reservoir from the large “holding” cylinder under overload conditions.

Before lifting the load, the jack is adjusted to a certain weight of the load so that it cannot burst during pumping, otherwise some parts may simply fly out of the mechanism body. Therefore, pumping the jack requires compliance with safety measures.

Previously, both valves are disassembled to check where the spring with the “nail” is located, whether they have the correct position. Disassemble the device by spreading some material or newspaper. They make sure that not a single trifle can fly out of its place and get lost, since it will be very difficult to find a replacement part later.

In case of malfunctions after pumping the jack, it is required to fill in oil through one of the valves, it is possible through the first one. The jack foot should be slowly raised with your hands, and the fitting is directed upward so that air can escape during the descent, but not completely. This can cause the rubber plug to fly out, which is shaped like a large rivet on the surface of the cylinder.

When the second valve is disassembled, it is re-adjusted for the correct weight. It is not necessary to twist too much, since the air is deflated under load. Carrying out a gradual twisting, the load of the set weight is lifted. After that, pumping stops. Then check the possibility of descent in case of excess weight.

Hydraulic jack pumping technology

Pumping the hydraulic device begins with flushing the mechanism of the hydraulic device.

Flushing the instrument ensures that the instrument operates normally. During operation, dirt penetrates into the device into various parts of the mechanism, which can provoke serious breakdowns, up to the failure of the unit to work.

After draining the working fluid, the container is filled with a special flushing fluid. In the process of flushing with a special fluid, all contaminants are removed from the device. After removing the contaminants, the special flushing fluid is drained and the reservoir is filled with working fluid. In the process of pumping, the working oil passes from the container for filling into the working cavity, this process is carried out quite quickly and does not take much time.

During the procedure, air is gradually displaced from the working cavity. Repeat the pumping operation until all air bubbles have been expelled from the reservoir. All operations for changing the working fluid and flushing the device should be carried out in full accordance with the instructions attached to the device by the manufacturer. The fact is that hydraulic devices of different design have different technology for replacing the working fluid.

After completing the work, close the bypass valve and the oil reservoir opening.

A hydraulic jack is a mechanism that allows an object to be lifted to a specific height. Most often used in maintenance services.

Hydraulic lift device

The main components of the system are the body, the movable piston and the liquid medium (engine oil). The body is made of durable metal in the shape of a cylinder.It serves both as a rod guide and as a reservoir for technical fluid. Additional elements that bring the device into operation:

The use of valves makes it possible to increase the force applied to the lever tenfold. The plunger is required to move the piston by transporting the working fluid into the container below it. The valve prevents the liquid from flowing back into the general container. Gradually, the plunger pumps more and more fluid under the piston, lifting it up. And in order for the load to descend, it is only necessary to allow the oil to return to the common tank by opening the valve.

Application of hydraulic jacks

Lifting devices are used to fix, move and lift heavy loads: building plates, machine tools, cars, columns. Their carrying capacity can be hundreds of tons. Depending on the purpose, the design and dimensions of the machine change. High performance and ease of maintenance have made jacks indispensable in manufacturing, car service stations, in the processing industry, in power plants, warehouses and other manufacturing areas. Car enthusiasts also cannot do without their own compact lifts. And the ability to move loads vertically and horizontally is widely used at construction sites.

Operating tips

The secret of uninterrupted and long-term operation of any tool lies on the surface and is available to everyone who wants to maintain its effectiveness for a long time. Modern safety technology and operating rules are compiled on the basis of a combination of the colossal experience of manufacturers and users of technological equipment. Subject to specific and quite simple recommendations, pumping the jack will not be required very soon, and the ease of use of the tool will always be at its best.

- Exceeding the permissible load in 9 out of 10 cases leads to a breakdown of the device. You should not allow peak values either, but limit the range of the weights being lifted to 95% of the capabilities declared by the manufacturer.

- The jack should be installed exclusively on a flat and solid surface. Lifting loads with an unstable pivot point increases the chance of stalling with unpleasant consequences for the object, tool and operator.

- When lifting a car, you need to make sure that the wheels are fixed with a handbrake or props.

- To lower the jack rod, turn the bypass valve smoothly, no more than 1 turn. Slow opening of the channel will not allow the liquid to quickly flow into another tank and the load will descend without jerking.

- To avoid fluid leakage, the jack should be transported in its working position. Bottle and rhombic ones are transported in an upright position, and trolleys are transported horizontally.

- Do not allow the jack to come into contact with water to avoid corrosion. If dirt or moisture gets in, wipe it off with a dry cloth.

- Moving parts such as the arm mount and pump piston and retractable extension screw should be lubricated periodically. The last two elements should be omitted after work. Storing the hydraulic jack with the screw and pump piston raised can cause corrosion.

Save this page in your social. network and return to it at a convenient time.

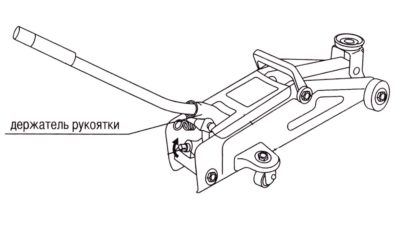

Methods for pumping other types

Pump a bottle-type hydraulic jack with your own hands. Jacks of this type have a very simple structure and principle of operation. They are installed in trucks intended for the transportation of heavy loads. The minimum lifting capacity of the bottle jack is 3 tons, and the maximum is up to 200 tons.

There are 2 types of vertical hydraulic jack: single-rod and double-rod.The first one has a simple design and is very easy to use, it is mainly used for installation work in construction, for car repairs and for other purposes. The principle of operation of the second is based on the installation of two rods, due to which a high lifting capacity is achieved.

As for the pumping technology, the bottle jack is no different from the rolling jack. To pump a bottle hydraulic jack, it is also necessary to clean the mechanism from working fluid and oil. To clean it, you need to unscrew the valve and drain the used fluid, and then the oil by pumping the pump.

If the equipment, even after changing the fluid and oil, continues to work incorrectly, then it is necessary to check the working area again for the presence of air accumulated during operation. To remove it, open the check valve and the plug from the oil container and pump the pump until the air bubbles are completely removed from the working cylinders. And then close the check valve and the cover from the oil container.

It may also be necessary to pump a 5 ton hydraulic jack in case of contamination and air ingress. A jack with a lifting capacity of 5 tons is usually used in car services. Therefore, the car jack needs pumping more than others due to the heavy load. To pump a jack of 5 tons, you need to carry out the same actions as in the above

The main purpose of pumping is to remove accumulated air, and it is important to repeat pumping the pump until it is completely removed from the working mechanism, otherwise the jack will not be able to lift even the lightest load

Every year more and more motorists prefer hydraulic jacks. The equipment is easy to operate and requires minimal effort to lift a large enough weight. Certain types of devices take up little space and will become indispensable travel companions. Knowing how to pump a hydraulic jack, you can service it yourself without contacting a service.

As with any device that operates hydraulically, the jack must be checked periodically and, if necessary, add oil and bleed the system. If air bubbles appear in the hydraulic jack, then it loses its functionality, therefore, it is necessary to carry out pumping in a timely manner. Experts recommend pumping the equipment at least 2 times annually. This frequency will prevent premature wear of the jack and allow it to last for more than one decade. Since it is quite easy to pump a hydraulic jack, any motorist can perform this procedure.