Laying rules

Planking of an engineered board is carried out indoors at a temperature background of +18 degrees and a humidity level of about 65%. In the room, you should turn on the heating in advance, as well as the ventilation system, since the material must lie down in this room for at least a day. The engineered board is placed on a carefully leveled surface, the base should not have any defects and protruding fragments.

Installation can be carried out in three ways, such as:

- on glue;

- for concrete mortar;

- on a synthetic backing.

The most rational and practical is the option with the use of a special synthetic pillow. This material creates conditions for maintaining full air circulation and thus eliminates the occurrence of fungus and dampness. Installation directly on concrete is the cheapest, and besides, it is performed rather quickly. However, user experience has shown that laying on concrete without a backing will significantly shorten the life of the coating.

Let's dwell in more detail on the features of laying on a synthetic pillow, for this you need to follow the steps below:

- the screed is cleaned of sand particles, small debris and other types of contamination;

- the surface is treated with a primer for porous substrates, after which a perforated pillow is laid, fixing it along the edges with glue;

- then proceed directly to the installation - the rows are laid, starting from the wall, while the perforated holes in the substrate must be filled with glue.

Thus, the entire finish is laid, the glue must be applied to the surface right before fixing the board.

When designing the very last row, additional adjustment of the panels may be necessary. At this stage, small irregularities may appear at the junction of the slabs and the wall, they are masked with a plinth. After the glue has completely hardened, the floor can be used without any restrictions.

English herringbone or Herringbone

Laying of parquet with an English herringbone consists of planks located at right angles to each other. Distinguish between one-, two- and three-row English herringbone. Planks can be made of oak, walnut, ash, as well as exotic merbau, wenge and other tree species.

The drawing has a long history that begins in France. The oldest floor that has survived to this day was made in 1539 in the palace of Fontainebleau for Francis I. Ancient documents say that the parquet, now called the English Christmas tree, was laid by Italian craftsmen. It also indicated that the technique and drawing were called Italian. However, in Italy there were no such monuments, although, in fairness, it must be said that there are also more ancient buildings, in which bricks and ceramic tiles were laid in a "herringbone" pattern.

Zig-zag Herringbone gives the interior a certain identity, simple, non-flashy appeal. Natural finish looks great in both classic and modern interiors, in perfect harmony with almost any type of finish.

The analogue of the English Christmas tree is the Hungarian one. In this case, during installation, planks of different types of wood are used, due to which the coating looks more expressive. This layout is suitable for spacious rooms with high ceilings, it can visually make cramped rooms even smaller.

What and in what case is better to choose

Under the electric and infrared "warm floor", it is still better to lay the flooring made of a laminate that has a special marking (about the nuances of choosing a laminate under a warm floor, see the article "Which laminate to choose for a warm floor?"). It conducts heat better. On a water "warm floor" with its sharp jumps in temperature, a parquet board is more suitable, which levels out temperature drops - it warms up for a long time and cools down just as long.However, it is recommended to lay the board only when the entire floor surface is heated evenly.

By design, the parquet board looks great in a study, a living room, a hall in a private house and a library. In the bedroom, nursery and hallway, experts advise laying laminate flooring. In the bathroom, it is best to refrain from using any of these coatings. There are other materials for her.

In the kitchen, in the work area, it is best to use tiles, and in the rest of the space, moisture-resistant laminate. On a glazed balcony or in a loggia, only moisture-resistant laminate can be laid from compared materials.

Care

Natural wood is highly sensitive to external influences such as temperature fluctuations and moisture. This is not surprising, since the materials are of natural origin - in their natural environment, trees always obey natural phenomena, react to temperature, the movement of the sun, as well as humidity. That is why the surface of the finished floor must certainly be protected, usually oil or varnish is used.

The oil coating is environmentally friendly, safe, it has the ability to deeply penetrate the wood structure and create a high level of protection. The coating acquires high wear resistance, easily tolerates temperature fluctuations and high levels of humidity. In case of damage to the surface, it is not difficult to restore the appearance of the engineering board - you just need to grind the area and re-impregnate it. The oil does not form a film, so the wood retains its natural color and texture.

Varnishes are mostly water-based, so they do not contain toxic substances. This composition does not penetrate into the structure of the wood, therefore, there is no interference with the material; over time, the varnish can always be replaced with an oil coating. This treatment will last from 5 to 10 years under standard operating conditions.

However, it is important to treat the varnished board with care, as it reacts very strongly to any point damage. You do not need to ride on it on rollers or defile on heels, and it is advisable to stick soft rubberized pads on the furniture legs

Both types of coatings provide a good protective and decorative effect, but the oil should be preferred in the following situations:

- when the floor is laid in a room with a high level of humidity or long periods of unheated periods are planned;

- when installing the "warm floor" system;

- to create accents on the natural texture of wood.

Any contamination must be removed as soon as possible, otherwise they will be completely absorbed, it will be almost impossible to remove them.

It is important to dry clean every day and remove all hard particles of street dirt and sand, the best option would be to use a vacuum cleaner with soft pads. For wet cleaning, use soft textiles soaked in a concentrated soap solution and carefully wrung out

Chemical means for washing are not recommended, since the coating may dissolve, the lamellas will be defenseless against aggressive external factors.

If the pollution is small, then you can always do with plain water without any impurities. Traces of berries must be washed off with hot water, and blood only with cold water. It is better to rub old fat with acetone, but too frequent use of it will destroy the decorative coating

Freezing helps to get rid of traces of adhering gum, rubber shoes and bicycle wheels - the ice must be wrapped in a bag and put on a contaminated area, and after a while the frozen particles must be carefully scraped off with a knife

Which one to choose?

The engineering board is presented in three categories.

- Rustic. To create the outer layer, veneer is used, obtained by sawing at different angles. At the exit, the boards may differ in texture and colors, slight defects are allowed.Such products are cheaper than others.

- Natures. Lamellas are formed by the tangential (tangential) or radial (along) sawing method. Of the defects, there may be a slight difference in shade and texture. This product belongs to the average value group.

- Select. In this case, the veneer is used, obtained by sawing along the direction of the fibers. Boards of this type are identical in texture to each other and have no flaws. This variety is the most expensive.

Colors and texture

Modern technologies for the production of natural and laminated parquet allow the most advantageous way to present the fibrous structure of wood, to give it the desired shade. The color of the parquet should be in harmony with the decoration of the walls and furniture. In the parquet flooring, it is worth using the pink tones of the cut of the tree if the walls are finished with pink marble or the wall decoration has a warm palette of colors.

The oak floor has a rich palette of colors - from light greenish texture to dark noble shades. Oak lends itself very well to tint with various stain colors. You can give the flooring the desired color for a more harmonious interior decoration.

Aged parquet looks very interesting. Today's fashionable shebi-chic or Provence will become a worthy background for such a floor finish. The technique of toning wood in white or black colors is popular, the combination of which creates an exquisite floor pattern.

White parquet is one of the luxurious tools for decorating state halls and living rooms in a vintage style. Wooden parquet can be given different colors. Some combinations, for example, black, gray and pink dots, look very stylish and sophisticated.

The parquet flooring can have a silky textured surface. Such processing of the dies reveals the tenderness of the wood fibers, the beauty of natural natural material. This texture is achieved by treating the wood with oil or wax. The matte surface, however, has sufficient fragility before mechanical stress, is sensitive to moisture and requires some effort to maintain.

Polishing and glossy varnish add shine to the room, splendor, add light and space. The parquet pattern gets great decorativeness and stylization. Polishing improves the performance of the floor covering. Traces of mechanical damage can be easily removed by filling them with varnish. Such parquet is indispensable in halls with high traffic of people, large halls, ballrooms, rooms for receiving guests.

Advantages and disadvantages

Any finishing material has its own advantages and disadvantages, therefore, before choosing a floor covering, it is necessary to scrupulously study its main features. The tree looks elegant and beautiful, but with the wrong choice of boards or mistakes during maintenance, it will not last long. Among the main advantages of the finishing floor under consideration, the following can be distinguished:

- durability - the material is characterized by resistance to abrasion, even with prolonged use, scuffs and scratches do not appear on it, it can be mounted in rooms with the highest traffic;

- resistance to adverse environmental factors - with temperature fluctuations, contact with moisture, as well as under the influence of ultraviolet radiation, aesthetic and technical and operational properties are fully preserved;

- good maintainability - the veneer is represented by a rather thick layer, therefore, when the coating wears out, it is possible to remove 1–2 mm and carry out scraping, as a result, the wood returns its aesthetic appearance, and the density of the coating does not suffer;

- high insulating parameters - the multilayer structure of durable plywood layers dampens noise much better than laminate boards and solid wood parquet strips;

- engineering plates of various shapes and sizes are on sale; they can have a small or large pattern.

Among the disadvantages of the board, the following should be noted:

- the difficulty of installation in the absence of finishing skills;

- high material price.

The cost of one square meter of varnished board starts at 2 thousand rubles. To this you will have to add the purchase of glue and payment for the installation of the coating.

Materials and sizes

Inlaid parquet made of piece blocks is a truly valuable finishing material. For its manufacture, hard tree species are used: beech, oak, walnut. The dies are 25 to 45 centimeters long, 4 to 7 centimeters wide and 1-2 centimeters thick. To decorate monochrome parquet, black ebony dies, chocolate details from African wenge wood and bright accents of white ash wood are used. Ebony and wenge wood are rare and expensive types of wood, maple does not have sufficient strength, so they are good as contrasting details of the floor pattern.

In a more democratic price segment, there is a massive parquet board made of natural wood, its dimensions vary considerably: width - from 0.8 meters, length - up to several meters, thickness - 1.5 centimeters. Such parquet creates a more coarse brutal floor pattern, which is very fond of designers for its practical properties, high resistance to mechanical stress and the beauty of large cuts of wood. Perfect for interiors in ethnic styles, African, Mediterranean, Scandinavian. In a special treatment, aged massive parquet acquires a rustic look.

And finally, manufacturers offer a huge selection of laminated parquet flooring with a rich palette of colors and textures. The aesthetic possibilities of laminated parquet are even wider than natural, it can be given the texture of any, even very rare wood. And the technical characteristics of the laminate exceed natural parquet in terms of wear resistance and the degree of resistance to moisture.

Comparison with parquet and laminate

Inexperienced users often confuse engineered planks and parquet floors. Visually, they are similar to each other; they differ significantly in operational parameters and structure. The material made of plywood is much cheaper than its analogue made of wood dice, although in terms of user characteristics it wins in many ways. Engineering board, in contrast to traditional parquet, is characterized by greater moisture resistance, it is much less susceptible to damage by fungus, mold, as well as warping, swelling and other types of deformation. In terms of resistance to scratches and mechanical damage, both coatings are approximately the same.

The parquet board is quite thick, so it can be looped many times. Engineering is inferior in this parameter, so it can be restored no more than 1-2 times. If you compare an engineered board with a laminate, the difference is obvious. The first is more practical and durable, and it looks more respectable. But the laminate is easier to install and wins in terms of maintainability.

What it is?

Any engineering board has a multi-layer structure consisting of a plywood base veneered with durable wood species. The product can be varnished or sold without it - in the latter version, sanding and subsequent varnishing is performed on the spot during the installation of the parquet. The composition of such a board includes such three layers as:

- the first layer is a protective coating based on paintwork materials or wax impregnation; its main task is to protect the tree from the adverse effects of dust, dirt and moisture;

- the second layer is represented by natural veneer - it is he who provides a decorative look to the dies, it is thanks to him that the floor covering looks expensive and presentable;

- the third layer is multilayer plywood; it is responsible for the deformation stability of the base, is not subject to decay, therefore it is optimal for creating a substrate.

The use of plywood sheets in the manufacture of boards significantly reduces the cost of production in terms of each square meter. Such a covering is much cheaper than traditional block parquet. Product design largely depends on the manufacturer and the characteristics of a particular collection. In the factory, a variety of veneer processing methods can be used, due to which the products acquire the texture of an expensive solid wood.

Peculiarities

Herringbone parquet began to be used by old masters in England several centuries ago for decorating floors in castles and mansions. Such a finish required painstaking work of cabinetmakers, each die was carefully adjusted to one another to create a smooth finish. The slots were unacceptable in order to protect the wood from moisture ingress, because heating in those days was episodic. The cost of such a floor was very high, but the service life was calculated for decades and even centuries. Parquet flooring serves as a good insulation from noise and cold. A certain system of locks between the dies creates strength and resistance to external influences. Wood grain pattern is used for interior decoration in various colors and stylistic solutions.

English

The oldest type of styling is called the "English Christmas tree". Its essence is that each die is laid perpendicular to the other, the narrow end of one parquet board adjoins the beginning of the long side of the neighboring one. A pattern is formed, similar to the trunk of a Christmas tree with branching branches. The dies are tied by the interweaving of each plank at an angle of 90 degrees.

Such weaving provides high wear resistance, uniform load distribution, which avoids the formation of gaps between the dies. This makes the flooring more durable, does not require frequent repairs and becomes a beautiful floor pattern.

The English "herringbone" can be used to cover the entire floor surface. The main emphasis in this case is on the play of wood texture. The dies can be selected in one tone and one type of wood to create a single canvas. For an accent floor, combine different types of wood or different colors of wood. This is how unique patterns are obtained with alternating textures.

Often they use the technique of simultaneous laying of two or three dies in a row on one side, then the same number of parts on the other side of the "Christmas tree". The drawing gets variety and flavor. Sometimes planks of different lengths are combined, a picture of the multi-row space of the floor is obtained. The English "Christmas tree" can be used as a decorative element for a variety of interior design styles - from the classic Empire style to ultramodern trends. Finally, the English "Christmas tree" is the most economical installation option, during which there is almost no waste.

French

On the basis of the Christmas tree floor pattern, a variety of laying in the "French herringbone" appeared. This pattern is more decorative, but also more difficult to execute, compared to the traditional English tree. The material consumption also comes out more, since the edge of each plank is cut off at an angle of 30 to 60 degrees. The resulting dies are in the form of a trapezoid, which are glued end-to-end. There is no weave in this pattern.

However, this layout does not have such high performance characteristics as in the first version. Due to the refusal of a bundle of dies among themselves, the load when walking is distributed unevenly, crevices may form or the edges of the planks can rise, which will require more frequent repairs. Other qualities, such as sound insulation, heat capacity, remain unchanged. The high decorative value of such parquet invariably attracts designers to create a unique floor pattern.

Hungarian

On the basis of these two options for laying, the craftsmen began to combine various types and colors of wood, and gradually an independent type of laying was formed - the Hungarian "Christmas tree".The method of laying out wooden dies is used perpendicular or angular, but each side of the joint is laid out in a contrasting color of wood. A clear geometric floor pattern appears. This option is indispensable for large areas to give the floor space a certain flavor. The brushing technique is popular for the Hungarian "Christmas tree" - it favorably emphasizes the texture of the wood, making it versatile.

This is the most expressive type of flooring. The unique wood cut pattern is combined in an exclusive range, forming an original interior. With the help of a certain direction of the stripes, you can influence the visual perception of the space, make it narrower or wider, depending on the needs of the layout.

Accommodation options

The Christmas tree pattern has a clear linear direction. By their location, the stripes on the floor are a visual reference point. The longitudinal arrangement of the stripes stretches the space, making it longer. A parquet pattern laid across the room will visually expand it. These properties of herringbone parquet should be taken into account at the planning stage. You can mitigate the flaws in the layout or add certain properties, for example, in a large hall, a Hungarian "Christmas tree" lined with longitudinal lines from the threshold will create a feeling of infinity.

The diagonal arrangement of the herringbone parquet pattern greatly decorates the interior, gives it uniqueness and charm. It can be used both as an independent floor covering and as a border for artistic parquet or become a part of it.

Pros and cons of laminate

Analyzing the strengths and weaknesses of the laminate, it is necessary to dwell on some points separately.

1. Strength. Sellers and manufacturers of laminated panels note the high strength of their products. The buyer does not have the opportunity to check this indicator in a laboratory way. But this can be done empirically: by holding the laminate board in your hand. After all, the strength of MDF depends on the density of the material. And denser substances, as is known from school physics lessons, are heavier.

So it was until recently, until the Chinese companies, and after them the Russian ones, did not add heavy additives to the MDF composition. As a result, only products from Europe (Germany, Belgium) are marked with the declared class. Therefore, lamella of the 33 class of a little-known manufacturer may turn out to be with the level of strength of the laminate for walls.

2. The use of various research methods for wear resistance and, therefore, for durability does not allow us to unambiguously believe the manufacturers' statements about the service life. The consequence of this approach was the situation when the declared 15 years of operation turn into real 7, and the 10 years indicated on the packaging turn into 20 or more years of impeccable service.

From the above, the following conclusions can be drawn:

- high strength and wear resistance is guaranteed only for products from Europe from the upper price sector;

- in the average price sector, the probability of buying a fake is close to 50%;

- it is better to refuse to buy cheap brands of laminate flooring, since Chinese companies dominate here.

And now we will consider the advantages of the laminate, confirmed by practice:

In addition to the listed advantages, in the literature you can find several statements that do not correspond to reality.

- Laminate flooring has a high level of sound absorption. Here, exactly the opposite is true: the floor covering is the most "sonorous".

- It is a good insulation, which is not confirmed by the indicator of thermal conductivity: it is high.

Among the disadvantages:

the presence of 20% formaldehyde resins (НСНО) in the material at comfortable temperatures does not affect human health in any way

Everything changes when the floor temperature rises to 28 ° and higher, which is often observed when installing underfloor heating, when they do not pay attention to the marking and lay a regular laminate.The active release of formaldehyde into the air has an extremely negative effect on the owners of an apartment or house;

low moisture resistance

Active absorption of moisture from the air leads to swelling of individual panels, the replacement of which requires complete or partial disassembly of the floor. In direct contact with water, even for a short time, a complete replacement may be required. And this is significant finance;

The laminate has risen due to water ingress.

The laminate has risen due to water ingress.

an almost ideal surface is needed for laminate flooring: strong, dry and, most importantly, even, which places increased demands on the floor screed: a height difference of no more than 3 mm and without a slope. All this significantly increases the cost of preparatory work;

the ability of the laminate to amplify intra-apartment sounds (resonate) does not bring pleasure to either the owners or neighbors

Attempts to solve the problem of soundproofing with a thicker substrate lead to another trouble: a thick substrate increases the amplitude of vibrations when walking, which leads to rapid destruction of locks;

the material of the protective film accumulates static voltage from working electronic devices: TV, personal computer, laptop, which leads to dust accumulation and unpleasant sensations when walking with bare feet;

it is difficult to remove ink, oil paint and grease spilled on the floor surface, and therefore experts do not recommend this type of floor in the nursery and in the kitchen;

wet cleaning increases the likelihood of injury, which few people know about, but trauma surgeons are well aware;

in the autumn-winter period, walking on a laminate flooring without slippers is extremely unpleasant because of the cold;

care must be taken when installing heavy furniture. Placing 2 legs on one panel will quickly break the locks.

Styling technique

Herringbone parquet layout with a perpendicular bond between the dies is quite simple, but the French herringbone technique is more complicated. Modern manufacturers offer complete ready-made sets of any configuration of the parquet pattern. Having such a kit, even a not very experienced master can do the styling on his own, knowing the basic technological methods.

The design can be seamless or have clear seams that give geometry to the pattern. Parts of wooden dies, processed on technological equipment, have a very accurate cut of the edge, which allows you to make a continuous abutment of the dies to each other. The absence of gaps increases the life of the floor covering.

In the middle of the room, pull the lace in the right direction. Collect the first pair of dies with a groove-ridge lock. The grooves are pre-coated with special glue. Lay in the center of the cord on plywood coated with glue. Each strip is fastened with special self-tapping screws in the grooves of the dies. In this way, the first Christmas tree is collected along the lace. The rest of the pattern is arranged to the right and left of the central stripe.

After laying, natural parquet is sanded, putty and varnished or waxed; laminated parquet does not require these operations. After laying, it remains to follow simple rules for caring for the decorative floor covering so that it will decorate the house for many years.

You can learn more about the technique of laying herringbone parquet in the next video.

French herringbone or Chevron

When laying parquet with a French Christmas tree, the dies are joined not perpendicularly, but at an angle of 30 to 60 degrees. The most common variant with a 45-degree cut is the easiest for this drawing. Fern, rays or rhombuses are all variants of the French herringbone, characterized by elegance and presentability.

The first documented mention of this method of laying parquet dates back to 1690. The French herringbone parquet was laid in the Palace of Versailles, where you can admire it to this day, in the Louvre, in the castles of Monsoreau, Blois and many others. It should be noted that this pattern was the beginning of the development of a wide variety of types of artistic parquet.

Chevron is more labor intensive and technologically complex drawing than Herringbone. Making perfect oblique cuts, especially at that distant time, was quite problematic. Only at the end of the 19th century, when there was a leap in woodworking in Europe, the French herringbone ceased to be the result of painstaking manual cutting.

Today on sale you can find dies, cut and completely ready for laying. Among them you will find "right" and "left" plaques. The exquisite French herringbone is strongly associated with ancient palaces and castles, as well as with chalets - cozy provincial houses in the Swiss style.

Description of parquet, parquet board and laminate

Parquet is understood as a hardwood floor covering in the form of planks (rivets) with locks for fastening, which consist of a ridge and a groove. The dimensions of the planks vary in thickness within the range of 14-22 mm, length - from 20 to 70 cm, width from 50 to 90 mm (for more information on this type of floor, see the work "Block parquet").

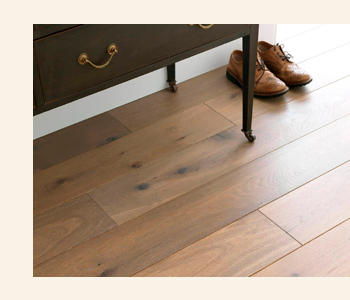

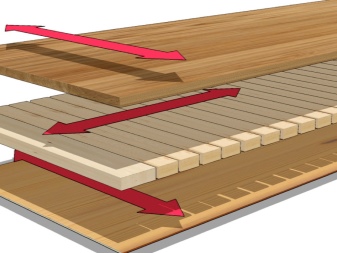

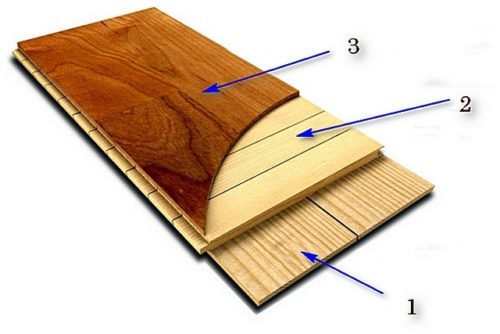

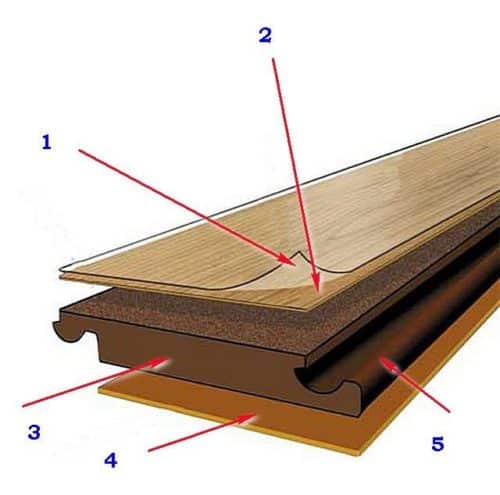

Parquet board is a three-layer floor covering, glued from wooden segments, the fibers of which are located perpendicular to each other.

The transverse arrangement of the layers allows to increase the strength of the board, resistance to moisture and temperature fluctuations (less linear expansion). On the sides of the board there are locks, like a block parquet.

The top layer (in photo 1) is glued from valuable types of wood (oak, ash, beech, cherry, etc.).

The middle layer (in photo 2) is a load-bearing one, it is assembled from wood of technical varieties (mainly birch) spliced under the press.

The lower, stabilizing layer (in photo 3) is made from conifers, mainly from pine in Russia and spruce in Europe.

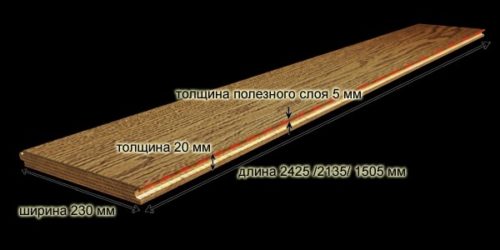

Almost all manufacturers cover their products with a wax-oil composition or varnish, which reduces the time and resources for impregnating the flooring with parquet varnish and polishing it. The dimensions of the board are less variable than that of block parquet: the width (230 mm) and thickness (20 mm) are fixed, the length ranges from 1505 mm to 2425 mm (see photo).

Laminate is a structure glued together from several layers of different materials. The top of the "sandwich" is covered with a transparent film made of acrylic or melamine resin (in Fig. 1). It has two functions:

- protects the decorative layer from mechanical damage and ultraviolet rays (sunburn);

- serves as the basis for applying wood texture, resulting in a textured surface that imitates natural wood.

The second, decorative layer (in Fig. 2) consists of paper impregnated with paraffin, or vinyl, with a printed pattern imitating wood, stone or other material. The overwhelming majority is wood.

The body of the laminate board (in Fig. 3) is made from wood fibers. It can be fiberboard of a dry method of medium or high density (the latter material is called HDF, in English transcription HDF). This part of the structure is responsible for the main functions of the flooring:

- withstands mechanical stress;

- responsible for the connection between the lamellas - it is here that the locks are cut (in Fig. 5);

- serves as a heater.

The consumer properties of the laminate (moisture resistance) depend on the carrier layer, or rather on its density and the degree of impregnation with moisture-resistant compounds.

The bottom layer (in Fig. 4), which is also stabilizing, protects the laminate board from deformation. Some manufacturers also add a fifth layer by gluing a soundproofing underlay.

Concluding the description of flooring materials, we note that in the literature, including Wikipedia, you can find the expression "laminated parquet". We clarify that laminated parquet and laminated flooring are one and the same material. Laminate.

Conclusion

Having considered how the parquet differs from the laminate, or rather, how the parquet board differs from the laminate, we can draw brief conclusions.

- Laminate flooring is significantly cheaper in all respects: the cost of materials, the cost of installation and the amount of maintenance costs.

- Parquet board is at least 3 times more durable.

- Laminate is stronger: it can withstand significant dynamic and static loads.

- Both materials are safe for human health, but only when purchasing products from trusted brands.

- There are no significant restrictions, with the exception of the bathroom, for installation in the premises of the apartment.

What exactly to choose should be decided by the consumer, since it is difficult to give advice in such a situation without knowing the nuances.