Description

This agitator attachment is designed for two purposes:

- tedding hay;

- shoveling it to one side.

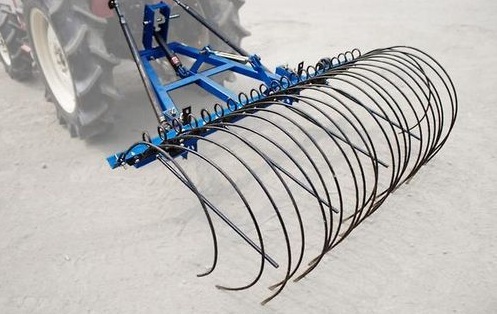

The working part of this type of mounted tractor equipment (Russian, Finnish, Polish or Turkish) in most cases consists of four or five wheels. They all rotate in the same direction in a plane that is perpendicular to the direction of movement of the minitractor.

In this case, the extreme wheel is slightly ahead of the others, the second is slightly behind, the third is even further, then the fourth and fifth. They all rotate in the same direction.

In each wheel, there are many metal rods around the perimeter, which are slightly curved at the edge in the form of a hook.

Tedder rake

In raking mode, the work is as follows.

The wheels, according to the instructions, rotate in such a way that the very first wheel located on the right (if you face in the direction of travel) picks up hay scattered on the ground with metal rods and throws it aside so that it falls under the second wheel. That in exactly the same way throws it under the third, then under the fourth, then under the fifth. The last wheel throws the hay to the left, where it, being collected from the entire working strip of the rake-tedder, is folded into one row.

There are several options for working:

- You can make one pass, then in the opposite direction, so that all the hay falls into one row, where it will be much easier to collect.

- You can make three passes in the same direction, gradually moving the collected hay in one direction. In this case, you will have to collect three times more hay from one row.

Other schemes of work are possible, which can be followed on a tedder rake in this mode.

In tedding mode, the tractor driver rotates the frame with impellers 180 degrees. In this case, the rightmost wheel will be located at the back. The hay he picks up will not fall on the other wheels. The same can be said for each of the wheels.

Tedder rake at work

Technical and operational characteristics of the project

| Index | unit of measurement | The quantity |

| Mechanism type | mounted rake-tedder of tooth type for a single-axle walk-behind tractor of 8-13 liters. with. | |

| Power point | walk-behind tractor | |

| Work items | garden fork blades | |

| Tedding strip width | m | 1,4 |

| Performance | Ha / h | not installed |

| Weight limit | Kg | 50 |

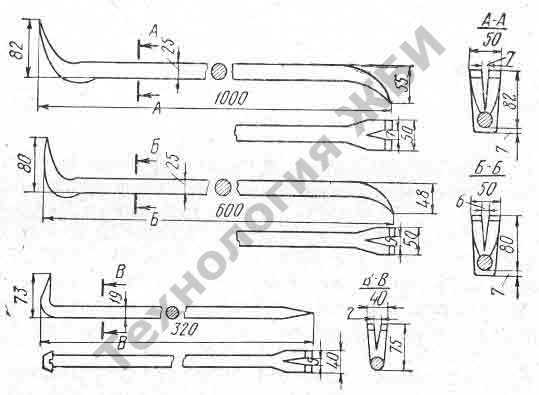

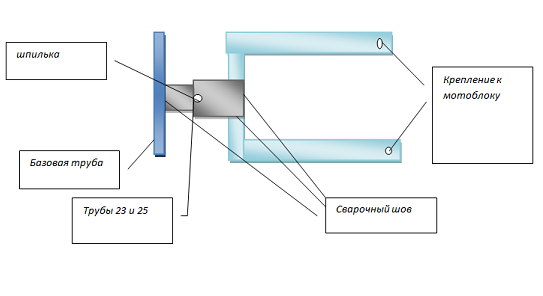

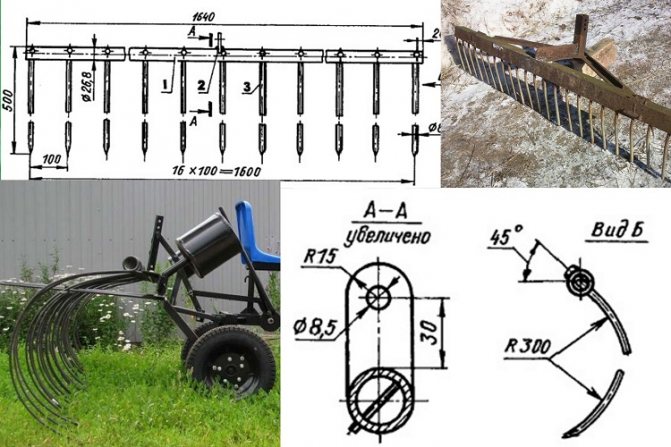

A thick-walled steel pipe with a diameter of 25 mm and a length of 1.4 m is the basic part of a tedder.

For 6 garden 3-tine forks, the tubular attachments to the handle are cut. The workpieces are evenly distributed along the length of the base pipe and welded to it.

The support shoes (can be replaced with wheels) are bent from the steel strip and, through the assembly, which provides a change in the height of the installation and fixation, are attached to the base pipe.

To swing within 10 ° of the tedder relative to the walk-behind tractor, a through hole is drilled for the cotter pin at the end of the larger diameter pipe, and slots for the cotter pin are formed on the other pipe.

Fork pins and track shoes

The design is extremely simplified, home craftsmen can criticize it, modify it and improve it. Home-made tedders, mowers for walk-behind tractors greatly simplify the hay harvesting technology and reduce time costs.

For the mechanization of heavy manual labor on personal plots, in private farms and agricultural farms, in summer cottages, many useful machines and mechanisms have been developed for performing a wide variety of work: plowing the soil, sowing crops and planting seedlings, mowing and mowing grass, harvesting hay, ennobling lawns, transportation of crops.

Experienced and zealous owners have long come to the conclusion: instead of purchasing special equipment for each type of work, it is much more expedient to use a walk-behind tractor or a motor-cultivator in aggregation with various additional devices as a traction force.

After all, by installing various attachments on the walk-behind tractor, like on a food processor, you can perform almost the entire range of agricultural work, while saving a significant amount. Agree, not every owner can afford to purchase a whole fleet of special equipment, often expensive.

Let's figure out with which attachments motoblocks for mowing grass and hay preparation are optimally aggregated: mowers, lawn mowers, rakes, tedders, various balers, hay pick-ups, trimmers, etc. And for what type of gardening and agricultural work is this or that type of equipment most suitable - mowing lawns, harvesting hay, laying grass in swaths, mowing weeds and chopping.

How to operate and maintain a tedder

Since the design of a rake for a walk-behind tractor is quite simple, it does not require constant personal care. If a hitch is installed on the tedder, the device will serve for a very long time. The farmer will have to lubricate periodically, affecting all rotating and docking points. This will ensure a smooth and smooth ride. It is also worth keeping a close eye on the chain drive. The chain should not constantly fly off, so that this does not provoke blocking of the rotating elements.

If over time one of the parts of the structure becomes unusable, it can be easily replaced with a new one. If the farmer wants to provide additional safety to the tedder, he can equip this mechanism with special protective screens. In the course of work, you should also not forget about safety precautions, which it is better to familiarize yourself with even before picking up the tools.

2 DIY tedders

You can do it yourself with a mounted tedder rake. This option is suitable for those who own small plots and mini tractors. A rake for a mini tractor, made by yourself, will have 5 raking wheels (you can install more, but for small farms, a 5-wheel base is enough). If a walk-behind tractor is used as a driving means, then it is enough to make 3 wheels of metal.

To make a finger rake of the Solnyshko tedder, you will need the following materials:

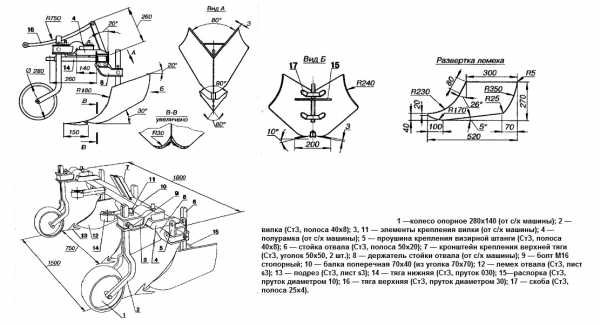

Diagram of the construction of a rake tedder Solnyshko

- a metal tube (you can take a frame from an old motorcycle) for the production of a frame;

- brackets to secure the wheels;

- steel wire 4-8 mm thick, from which raking springs are made;

- steel sheets 4 mm thick for the manufacture of impeller disks;

- two bearings that are mounted in the hubs for mounting each of the wheels;

- parts for the manufacture of a hinge, which is designed so that the tedder can be attached to the transporting vehicle.

As hubs, the best option would be to install hubs from a VAZ car, since they have tapered-type bearings built into them. This increases the wear resistance and durability of the equipment undercarriage.

The do-it-yourself tedder rake is made easily and fairly quickly. Such equipment will greatly simplify the life of an agricultural worker.

2.2 Benefits of using tedders

To clear your plot of dry or freshly cut grass, a mini tractor rake will become an indispensable assistant.

Tractor-operated tedders deliver the highest productivity rates while working at increased speeds. The greatest indicators can be recorded on a long straight distance. But the performance of such tools is slightly degraded if corner areas appear. A big plus of such devices is the way they are attached to the driving vehicle.No power take-off is required for connection.

Many landowners find that with rotary rake tractors, the loss of foliage and hay during raking is minimized. The fingers located on the wheels of the agitator, in addition to whipping the cut grass, also turn it over, as a result of which the ventilation of the hay swaths increases.

2 795

Tedder rake for walk-behind tractor

This type of equipment is also called "Sun". Due to their structural features, they allow not only to remove hay or leaves on the site, but also to turn it over. This ensures uniform drying of the hay, which provides it with a long shelf life. Also with the help of the "Sun" you can move the piles of hay from place to place.

For harvesting significant stocks of hay, multifunctional tedders are one of the main assistants of the farmer, as they allow to complete the volume of work in a few minutes, which requires several hours or even a day without the use of special equipment. "The Sun" is produced in several modifications, from two to four-wheeled. All have the same principle of operation, but differ in their dimensions and performance. Large diameter tedders can rake hay in a heap of 2 m or more, turning it over if necessary. Such indicators make it possible to remove hay from an area of more than 1 hectare in one working hour, which would take a day without using a walk-behind tractor.

Equipment manufacturing drawing

Note that on sale you can find models of the rake "Sun", which have increased power, which allows you to effectively remove sawn branches of trees, and even stir up clods of earth. The main thing is to purchase high-quality equipment, since the design of the tedders consists of several elements, it is necessary that all of them are made of durable material. Only in this case the rake will have an unlimited period of operation. A video of their work can be found on the Internet.

The principle of operation of various models

The principle of operation of various models

The main working element of all types of tractor rakes is teeth, which are melted from high quality steel, so they are not afraid of falling stones or other debris.

Models from different manufacturers have their own characteristics, such as, for example, how the wheel hub is fastened: on roller bearings or nylon bushings; option of installation on a tractor of one model or another.

By design nuances, tractor rakes are divided into three subgroups:

- rotary (rotary) ones are constructed from replaceable raking elements mounted on the right and left rotors, while some of them perform raking and turning functions, the second - turn and scatter the resulting rolls; rotors can work in pairs or one at a time, these are one of the most expensive models of this type of agricultural machinery;

- wheel-finger rakes have as a working mechanism - rotating discs with inclined (45 degrees) spring "fingers" (spokes), which grab hay when the rake moves; the number of spokes on the rake tedders for tractors and mini tractors is 4 dozen; the movement of the wheels is carried out due to the adhesion of the apparatus to the surface of the field; very productive due to a well-thought-out design, however, they can only roll dry grass;

- the simplest design of a tractor transverse rake - they are not intended for tedding, they only rake the raw material into rolls, which are formed across the tractor stroke; the wider the cultivated area and the more powerful the tractor, the better the tractor transverse rake works; sections and teeth are hinged.

Homemade equipment

For the manufacture of homemade equipment for a walk-behind tractor at home, which helps to quickly and efficiently remove hay, the following parts are used:

- 2 wheels with a diameter of 30 to 50 cm (you can take car wheels);

- a rod or pipe for metal (an axis is made from it);

- drawbar (made from a profile pipe);

- rods, with a diameter of about 6-8 mm (go to the teeth);

- springs;

- pipes with a diameter of 3 cm for the axle and 4 cm for fastening.

The entire homemade mechanism consists of:

- drawbar;

- lever;

- traction that raises and lowers the rake;

- brace;

- racks;

- pitchfork or rake with teeth;

- hubs;

- axles;

- wheels.

The following tools should be used:

- hacksaw;

- hammer;

- welding machine;

- puncher.

Gardeners recommend choosing a folding rake model. They are more convenient and mobile for transportation. It is from homemade rakes that you can achieve speed and mobility in hay harvesting.

Important! All work should be carried out only in compliance with the drawing. You can compose it yourself. When manufacturing, pipe sections are welded into one piece

If the size allows, then they can be very firmly inserted (one pipe into another). Traction mechanism - rotation of the walk-behind tractor. In this case, bearings do not need to be inserted into the wheels. Any rake grab diameter can be selected

When manufacturing, pipe sections are welded into one piece. If the size allows, then they can be very firmly inserted (one pipe into another). Traction mechanism - rotation of the walk-behind tractor. In this case, bearings do not need to be inserted into the wheels. You can choose any diameter of the rake grab.

The first step is to build the base. For this, wheels are put on the axle. Pads are welded onto the axle to strengthen the fastening of the mechanism. Hard steel strips are suitable as platforms, they are fixed at a distance of about 12 cm from the wheel.

Important! The drawbar is fixed exactly in the center of the wheel axle. The working mechanism is made as follows. Racks are welded to the wheel axle, to which 2 pieces of pipe with a diameter of 4 cm are also welded

The rake axis is inserted into it, which should rotate freely. Retaining rings are made on both sides so that the rake does not move to the sides. After performing these operations, the rake is supplied with a lever necessary to change the vertical position of the teeth.

Racks are welded onto the wheel axle, to which 2 pieces of pipe with a diameter of 4 cm are also welded. The rake axis is inserted into it, which should rotate freely. Retaining rings are made on both sides so that the rake does not move to the sides. After performing these operations, the rake is equipped with a lever necessary to change the vertical position of the teeth.

The working mechanism is made as follows. Racks are welded onto the wheel axle, to which 2 pieces of pipe with a diameter of 4 cm are also welded. The rake axis is inserted into it, which should rotate freely. Retaining rings are made on both sides so that the rake does not move to the sides. After completing these operations, the rake is equipped with a lever necessary to change the vertical position of the teeth.

Homemade rake for walk-behind tractor

The teeth are attached to the rake axis. It is recommended to make them from wire with a diameter of at least 6 mm. They are best attached by welding. A rack is attached to the drawbar along with the seat.

Important! It is better to equip the lever with an additional spring so as not to waste force on holding it with your hands. After testing the homemade nozzle for the walk-behind tractor, it will be clear whether it is worth correcting possible imperfections in it. To make it last longer, all parts subject to strong friction should be lubricated with grease

To make it last longer, all parts subject to strong friction should be lubricated with grease

After testing the home-made attachment for the walk-behind tractor, it will be clear whether it is worth correcting possible imperfections in it. To make it last longer, you should lubricate all parts subject to strong friction with grease.

A rake for a walk-behind tractor is a device that greatly facilitates any agricultural work. Models existing on the market are suitable for almost all types of motoblocks.An amateur gardener can easily make a high-quality model of a rake for a walk-behind tractor with his own hands, having simple improvised means.

Description of tractor rakes

Tractor rakes are designed for raking into shafts and then turning over meadow grasses and hay mowed during the harvest, as well as for collecting straw after harvesting grain. These operations ensure the yield of a quality feed product, the duration of their storage and protection from the winds.

Tractor rake

This unit consists of:

- several sections - a rake with curved spring teeth, which are interconnected by a system of hinges and are located at an angle of 45 degrees in the direction of travel;

- lifting mechanism, it shifts the hay / grass forward and to the side, forming a loose swath;

- support wheels.

For your information. During the movement of the rake across the field, the teeth, which rotate the drive wheel, rake up all the raw materials lying on the ground. After filling the space between them, the operator starts the automatic tine lifter, and the stripping rods push the formed swath out of the hay into the field.

After that, the working unit (teeth) come to their original state. In areas of a small area, the main work is done by the middle section, the side ones are used for swaths.

Any kind of rake of this type, as the name suggests, can only be operated with tractors, mini-tractors or monoblocks - they do not have their own course. The rake is mounted on the frame, where there is a spoke with a trailer, with which the rake is attached to the tractor. The rake bar can be raised or lowered using a hydraulic cylinder, depending on the desired size of the hay rolls.

The tedder rake is equipped with a floating suspension, which perfectly absorbs it when hitting any uneven ground. The wheels of the units are interchangeable and are mounted on a pair of bearings, which makes maintenance and maintenance work easier.

Varieties of tedders

The most commonly used hay rake. To harvest it, you need a tool that performs tasks such as raking grass, turning and collecting hay into swaths. Turners became this universal tool, which are divided into groups:

- by the nature of the manufacturing of the working part;

- by type of traction;

- by the way wolves are formed;

- by type of attachment.

By type, such devices for a tractor can be divided into two parts:

Tedders Sun to a mini tractor

- wheeled-mounted (for example, the Solnyshko tedder rake);

- rotary.

Wheeled wheels usually have 3-5 wheels located obliquely from each other. This increases overall labor productivity. Using the mounted tedder rake, both the gripping area and the thoroughness of raking the grass, and, accordingly, the speed of work in general, increase. A simplified repair of the wheelbase is noted in the Sun - tractor rake tedders have interchangeable wheels fixed by two bearings. The most popular among the Sun tedders arerake tedders GVKallowing to rake swaths from both sides at once and stir up hay.

Among the advantages of the Sun tedders are:

- low level of labor costs for maintenance of the mechanism;

- mounted rake tedders provide a longer service life;

- have a powerful drawbar and frame (more factory-made);

- convenient implementation of the transfer of the installation to the working or transport position, which is realized by means of the hydraulic system by the tractor operator;

- convenience of adjusting the pressure of the driving wheels.

Tedders to the walk-behind tractor

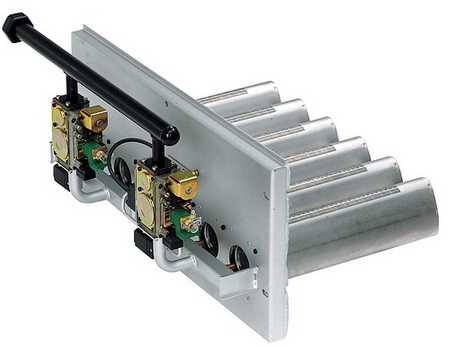

Rotary rake tedders include horizontally positioned discs (rotors), which are connected to the engine and rotate under the influence of the PTO. Metal pipes with fingers made of iron rods are attached to the rotors.As a tractor rake, rotary tedders do their job well, but they also have a specialization. Their specific direction is the collection of hay into compact windrows.

There are also cross tractor rakes. They belong to the mounted type of tedders. Cross devices are intended for raking freshly cut grass with a wide grip. On average, the capture of such tools is 12-15 meters. to the menu

Varieties of nozzles

Various attachments can be useful on the farm. Therefore, the more of them the walk-behind tractor has, the better. The rake is belt, transverse or with tedders, the choice depends on the purpose for which the walk-behind tractor will be used (for example, for collecting hay, foliage or garbage) and the model of equipment. Some types can even be used to collect snow and clear paths.

Specialty stores offer a huge variety of models. Here you can find any attachments for a walk-behind tractor at quite affordable prices. Making a rake with your own hands will be much cheaper.

The nozzle is adjustable in width. Its working part is almost 1.5 m. This makes cleaning the site as fast and efficient as possible. At the same time, such a width allows you to conveniently work both in large spaces and in small areas.

A feature of the rake on the "Neva" walk-behind tractor is that they are made on a spring basis. As a result of this approach, they are not in one position, but somewhat change their amplitude during movement. This allows for better collection of garbage, hay, leaves, etc. Moreover, such attachments are not afraid of stones, so their teeth will not break off. They can be lowered and raised using a special lever.

Important! Some attachment models are great for collecting snow and cleaning yard paths. In specialized stores you can find a huge selection of attachments for walk-behind tractors. The range of products is selected taking into account the requirements of the most fastidious customers

The range of products is selected taking into account the requirements of the most fastidious customers

In specialized stores you can find a huge selection of attachments for walk-behind tractors. The assortment of products has been selected taking into account the requirements of the most fastidious customers.

A feature of this walk-behind tractor is the presence of a special adapter for different types of attachments. It is suitable for all types of equipment, because the adapter adjusts to any size of attachments. The width of the working part of the rake is about 1.5 m. This makes it possible to carry out high-quality agricultural work in territories of different sizes.

The design of the rake is spring-loaded. Due to this, they easily walk along the ground and change the amplitude. The rake is flexible enough to work without breakage. The user does not need to frequently change the tines. The nozzle is lowered and raised with an easily integrated hand mechanism.

Motoblock Neva

Thanks to the well-chosen design of the tedder rake for the Neva walk-behind tractor, you can effectively turn hay, remove straw and leaves. The attachment turns this walk-behind tractor into a productive equipment for solving many important tasks.

With this rake you can:

- to cultivate and prepare the soil in small areas (0.2-0.3 ha);

- harvest and harvest grass;

- effectively clean household plots.

Homemade hay rake

To make a wooden hay rake, you need several types of wood. Usually the cutting is made from conifers. The block and teeth must be made of hard hardwood: birch, elm, ash, mountain ash. It is better to take wood without knots.

Homemade hay rake

The main characteristics of wood species:

- Pine has hardness, lightness, moisture resistance, biostability, strength.

- Birch wood is lightweight, durable and easy to work with.

- Elm has a strength, hardness and resilience comparable to that of oak. Waterproof, but difficult to cut with cutting tools.

- Ash is superior in strength to oak, resistant to deformation.

Block

The hay rake is started from the block. The bark is removed from the birch block, and then dried in a dark and dry place. The shape of the last can be straight or curved. Pad parameters:

- length - 50-60 cm;

- width - 5 cm;

- height - 3 cm.

On a note! With a sharp 10 mm drill, holes are drilled in the block for the teeth. The roughness of the walls of the holes will allow the teeth to hold more securely in the grooves. The diameter is from 10 to 15 mm, the pitch is 40 mm.

A pair of square or round holes for the future handle fork are made between the holes for the teeth. In this case, perpendicularity must be observed.

Teeth

The same wood is used for the teeth as for the last. You can take a birch stump with a length of 135 mm. The end side of the chocks is drawn into squares with a side of 13-15 mm. With the help of a hatchet, the chock is split according to the markings. Using a sharp knife, each of the blanks is brought to the desired tooth shape.

Rake teeth

Each tooth consists of a working part and a head. The length of the head is determined by the thickness of the pad. Its diameter should exceed the diameter of the hole in the block by 1-2 mm. This will provide a firm, snug fit. Sharp edges must be dulled to avoid scuffing the walls of the hole when seating the tooth. The working part of the tooth is from 95 to 100 mm in length. The ends of the teeth are formed with a knife.

To avoid splitting the pads, a wedge-shaped clamp is used during the seating of the teeth into the holes. The teeth are driven into the holes with a hammer or mallet. To avoid falling out and losing the teeth, you can secure them with nails.

Stalk

The handle for homemade products must be made of spruce or pine. Its length is 170-180 cm, diameter is from 30 to 35 mm. If a tree that has just been felled is used, then it must be peeled from the bark, dried in an upright position and given a smooth surface.

At the end of the cutting, a cut is made for a fork with a depth of about 25 cm. This is easy to do with a longitudinal hacksaw.

Important! When spreading the ends of the fork to the sides, the handle may split. To prevent this from happening, at the junction of the handle with the plug, it is necessary to install a metal sleeve, securing it with 2 nails

The ends of the fork are moved apart in different directions at a distance of about 10 cm.

Rake cuttings

Round or square spikes are made at the ends of the resulting fork, in shape and size they must correspond to the holes cut in the block. After that, you can put a block with teeth on the spikes of the cutting fork. Wooden wedges are used to secure the structure.

The final stage

The rake handle should be sanded so as not to injure your hands during operation. The shoe and the fork should be coated with protective agents: oil paint or waterproof varnish. The hay rake is ready.

The hay rake has served gardeners for many years, being an indispensable element of gardening tools.

Interesting fact. Residents of Japan on New Year's Eve give each other a rake to rake in happiness.

vote

Article Rating

Range

In case of difficulties with the manufacture of harvesting equipment with their own hands, professional farmers recommend purchasing ready-made machines. The modern tedder market is represented by a fairly large number of manufacturers and sellers. The range of mechanical rakes is also quite wide. Depending on the complexity of the design, the quality of the materials produced, the availability of component parts, the price of the tedders can be from 5 thousand to over 500 thousand rubles.

The most expensive are the rotary rakes. For example, the manufacturer “Belrusagrotekhnika” offers its customers the rotary models “GR-700 P” and “GVR-630”. The main advantages of this technique include indicators such as:

- Increasing the working width up to 7.3 m;

- Possibility of forming a roll from 14 meters in just 2 passes by a working "shuttle";

- Increase in productivity by 18% when tedding, by 35.6% when raking, by 70% when forming a double swath;

- Reducing the consumption of fuel used during work by approximately 1.2 - 1.4 times;

- Elimination of unnecessary rake pass;

- Improved maneuverability;

- Possibility of switching the tedders from transport to working mode directly from the tractor cab.

Of course, expensive equipment is purchased mainly by large farms with an industrial scale of work. But even with a smaller budget, you can purchase quite high-quality tedders. For example, the rake of the Polish company "Samash" does an excellent job with mowing and turning. Technique with solid construction and rotary bearing elements. Samash tedders are ideal for low-power tractors. Thanks to the hinge connection on the individual support elements, the technique is suitable for cleaning in difficult terrain. Such a rake costs from 5,500 rubles.

Of course, expensive equipment is purchased mainly by large farms with an industrial scale of work. But even with a smaller budget, you can purchase quite high-quality tedders. For example, the rake of the Polish company "Samash" does an excellent job with mowing and turning. Technique with solid construction and rotary bearing elements. Samash tedders are ideal for low-power tractors. Thanks to the hinge connection on the individual support elements, the technique is suitable for cleaning in difficult terrain. Such a rake costs from 5,500 rubles.

Equipment with a ring structure - models of PZ-240 and PZ-250 tedders with 4 and 5 wheels, respectively. The main function of the machines is to rake grass or hay into neat swaths from the swaths. Such rakes work on interchangeable raking wheels mounted on bearings. The cost of the equipment is approximately 26 thousand rubles.

The range of tedders is quite large and it is quite easy to choose the right model. High-quality equipment will not only facilitate harvesting work on any site, but will also increase productivity, which, of course, will affect the volume of the harvest.