Views

Currently, on free sale and in warehouses, you can find gas masks and accessories for them, marked according to two different standards.

Let's consider both of these classifications in more detail.

According to the marking adopted in the EU countries, the filter boxes of industrial gas masks are of the following types:

- A (brown) - designed to filter vapors of substances boiling at temperatures below 65 ° C, as well as gases of organic origin;

- AX (brown) - this composition of the charge provides filtration of vapors of substances with a boiling point of more than 65 ° C;

- B (gray) - provides air purification from most inorganic gases (with the exception of carbon monoxide);

- E (yellow) - used to protect against acid vapors and gases;

- CO (purple) - special grade for protection against carbon monoxide (carbon monoxide);

- K (green) - filters ammonia;

- NO (blue) - the filler consists of substances that remove nitrogen oxides;

- P (white) - designed for biological protection against aerosols of viruses and bacteria suspended in the air;

- Hg (red) - protects against mercury vapor and its hazardous compounds;

- SX (purple) - Provides protection against chemical weapons of mass destruction;

- Reactor (orange) - protects against radioactive isotopes of iodine and their compounds, and also reduces the amount of alpha particles entering the respiratory system.

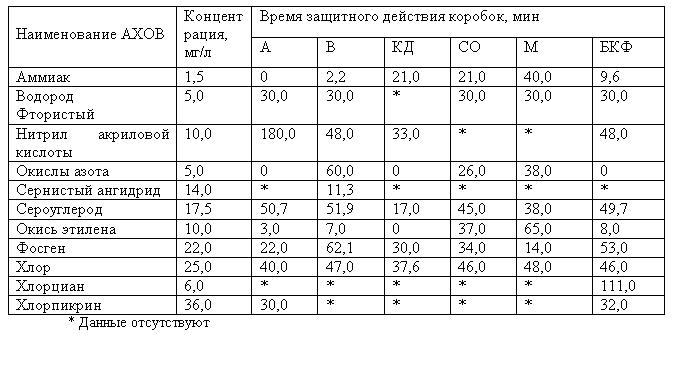

In the USSR, GOST 12.4.235-2012 established the following brands of boxes:

- A (brown) - the technical characteristics of the filler of such boxes allowed them to purify the air from vapors of kerosene and gasoline, acetone, benzene, toluene, xylene, various alcohols and ethers, aniline, tetraethyl lead, organochlorine and organophosphorus compounds, nitrogen-containing aromatic substances and organohalogen substances;

- B (yellow marking) - protects against chlorine, sulfur dioxide, hydrogen chloride, hydrogen sulfide, phosgene, hydrogen cyanide and nitrogen oxides;

- Г (marked with a combination of black and yellow colors) - used to filter mercury vapors;

- KD (gray) - protects against ammonia, hydrogen sulfide and mixtures containing these substances;

- E (black) - used to filter gaseous phosphorus and arsenic hydrides;

- M (red) - a semi-universal option that provides sufficient protection against carbon monoxide (which may contain minor impurities of organic substances), ammonia, gases of acid origin, phosphorus and arsenic hydrides;

- CO (white) - a special grade of boxes for protection against carbon monoxide;

- BKF (the box is marked with a vertical white stripe) is another semi-universal model that provides protection against gases of acid origin, organic vapors, aerosols of solid substances, arsenic hydrides and gaseous phosphorus.

The presence of a filter is indicated by a vertical white stripe or white color of the bottom. Such boxes are used together with outdated models of gas masks (for example, GP-5) and may not fit newer versions, on the valve boxes and hoses of which a different design of the connecting unit can be used.

When is replacement required?

Information about the duration of the boxes will serve as a guideline for the operation of the filter for gas masks. Storage times may vary, it all depends on the device model. There are several detection methods to determine if filters need to be replaced. This procedure is required when toxic gas is felt under the mask. The method is dangerous in that a high concentration of gases is clearly felt.

Replacing the filter is required when the weight of the device changes. This option is suitable for boxes that capture CO. They function at a low level of air humidity, and do not work at a high level.Due to the absorption and binding of moisture, the weight of the device becomes heavier.

Replacement may be required after some time of use. The option is suitable for brand G gas masks. If the device has been used for about 100 hours, then the box must be replaced. Each gas mask may have its own shelf life

It is important to observe them, since human safety depends on it.

The installation of a new filter can be performed on a schedule. In this case, the boxes must be changed often if there are a lot of harmful components in the air. The procedures are also carried out after laboratory tests. Then the expiration date of the filter is established by experiment. Computer simulation of the period of operation of the filters allows you to determine the negative factors, including temperature and humidity. The replacement time is determined by the elements - sensors. Timely installation of the filter allows you to use the device without harm to health.

How to choose?

When purchasing gas masks and accessories for them, you should first of all pay attention to their expiration date. Even such reliable devices tend to fail, especially after long-term storage in unsuitable conditions.

Saturated with dust and impurities from the surrounding storage air, fillers largely lose their filtering properties. In addition, the state of the charge has an important role in the activity of absorption of impurities - the larger the specific surface area of its particles, the more actively it will filter the air. The charge that has accumulated after long-term storage will not only become a bad filter, but also noticeably complicate the passage of air through the box.

When choosing between different brands of boxes, consider the most likely emergencies at your facility. For example, if an ammonia pipeline passes nearby, then the most suitable brand of boxes for you will be K (according to the EU classification) or CD (according to the Soviet standard), and if you purchase gas masks for a warehouse where mercury is stored, then you need to purchase Hg brand boxes in a new or G by old standards.

See below for what is inside the filter box.

TEST METHODS

4.1. The appearance of the boxes is checked visually.

4.2. Compliance with the size of the thread of the neck is determined by smooth and threaded gauges in accordance with GOST 8762-75.

4.3. The tightness of the boxes is determined according to GOST 23223-78. The place of seaming the bottom of boxes of all brands except M and CO is not checked for tightness.

4.4. The weight of boxes of grades M and CO is determined on a scale with a weighing error of no more than 5 g. The weight of boxes of other brands is not checked.

4.5. The oil mist permeability coefficient of boxes is determined in accordance with GOST 12.4.156-75.

4.6. The resistance of the boxes is determined according to GOST 10188-74.

4.7. To determine the time of protective action for each control hazardous substance, as well as to check the correctness of the equipment and control the emission of dust through the neck, 2 boxes are selected from among those selected from the boxes. In this case, before checking the time of protective action, one of the 2 boxes is subjected to a 4-hour shaking. The emission of dust through the throat is determined on 2 boxes after 4 hours of shaking. The manufacturer is allowed to shake before packing.

(Modified edition, Amendment No. 1).

4.8. The time of protective action for vaporous harmful impurities is determined in accordance with GOST 12.4.158-90.

4.9. The time of protective action for gaseous harmful impurities is determined in accordance with GOST 12.4.159-90.

4.10. The time of protective action for carbon monoxide is determined in accordance with GOST 12.4.160-90 when the outlet concentration of carbon monoxide reaches 0.62 g / m3 behind the box.

4.11. The time of protective action of boxes of grade G is controlled by benzene in accordance with GOST 12.4.158-90 with the following addition: the time of protective action must be at least 30 minutes with an initial concentration of benzene of 25 g / m3. Boxes are not tested until breakthrough, the test time is limited to 30 minutes.

In cases of disagreement in assessing the quality, the time of protective action for mercury vapor is determined in accordance with GOST 12.4.161-75.

(Modified edition, Amendment No. 1).

4.12. The correctness of the equipment is determined by the normative and technical documentation.

4.13.The emission of dust through the neck of the box is determined in accordance with the normative and technical documentation.

4.14. The presence and correctness of the marking on the box is checked for compliance with the requirements of this standard.

What it is?

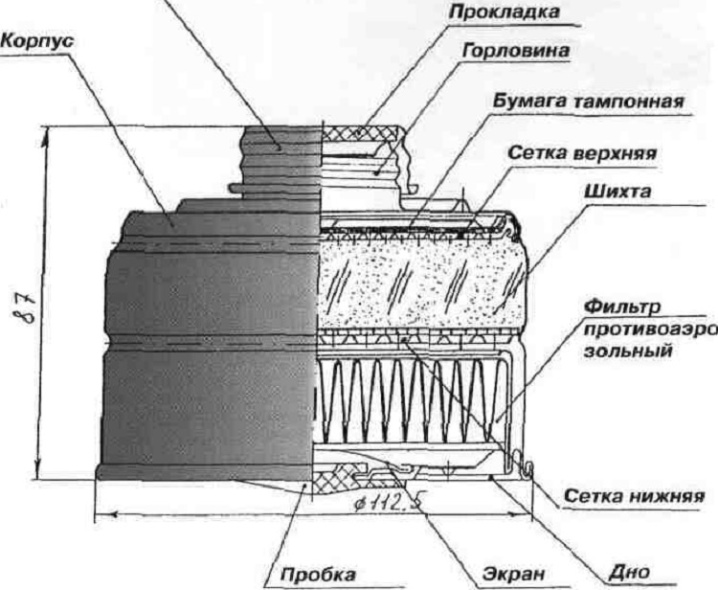

The filter-absorbing box for gas masks is a cylindrical protective device that is attached to a connecting tube (a corrugated hose connected to a rubber mask). These devices are designed for direct filtration of the air entering the gas mask from the external environment from harmful impurities: gaseous poisons, dust, radioactive substances, dangerous bacteria and other gases, aerosols and vapors that threaten human life and health.

In most models, the absorber is divided into two segments, namely anti-aerosol and anti-dust. Activated carbon, hopcalite, aerosol filters, cotton wool and special absorbing materials are used as filtering materials, depending on the brand of the box. Usually a layer of activated carbon is present in all models, regardless of their purpose. It is always located at the very top, playing the role of the last protective barrier. Between the layers of the absorbing charge, there are grids separating them.

The upper (closest to the tube) mesh is additionally equipped with a layer of tampon cardboard, which prevents activated carbon dust from entering the respiratory system of a person using a gas mask.

RULES OF ACCEPTANCE

3.1. Boxes are accepted in batches. For a batch, boxes of the same type and of the same brand are taken, decorated with one quality document containing:

batch number; the type and brand of the box; the number of boxes in the batch; date of manufacture; designation of the standard; the number of boxes in the batch; the number of boxes in a box; box test results;

designation of normative and technical documentation for components and semi-finished products.

The number of boxes in a batch should not be more than 6000 pcs.

3.2. To check that the quality of the boxes meets the requirements of pi. 2.2; 2.3; 2.4; 2.5; 2.6; 2.7; 2.8; 2.9; 2.10; 5.2; 5.3; 5.5; 5.6; 5.7; 5.8 3 boxes are selected from the lot, from which 1% of the boxes from the lot are selected by random sampling, but not less than 10.

(Modified edition, Amendment No. 1).

3.3. When receiving unsatisfactory results of tests for compliance with pi. 2.6 and 2.8 the batch is rejected. If unsatisfactory results are obtained for at least one indicator of the remaining items, repeated checks are carried out on it on a doubled sample. The results of repeated tests are valid for the entire batch.

LABELING, PACKAGING, TRANSPORTATION AND STORAGE

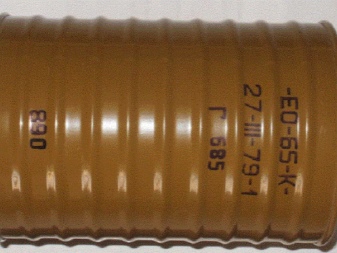

5.1. Each box must be marked with indelible paint.

5.2. Marking of boxes of all brands (except M and CO) includes:

the conditional name of the manufacturer, the date of manufacture (month, year) and the batch number - between the first and second ridge, counting from the neck;

the designation of the gas mask in accordance with GOST 12.4.034-2001 and the brand of the box (gas mask) - between the second and third zigs.

5.3. Marking of boxes of grades M and CO includes:

a directional arrow indicating "to the mask" - between the first and second ziggles, counting from the upper neck;

the conditional name of the manufacturer, date of manufacture (month, year), batch number - between the second and third zigs;

gas mask symbol in accordance with GOST 12.4.034-2001, box brand (gas mask) - between the third and fourth zigs;

the weight of the box with caps and rubber gaskets is between the fourth and fifth zigs.

5.4. Transport marking is carried out in accordance with GOST 14192-96, indicating the manipulation signs "Top" and "Protect from moisture".

5.5. Labeling of containers with packaged products is carried out by typographic method on paper labels or applied with water-indelible paint on containers in accordance with the requirements of GOST 14192-96.

The marking includes:

product name (filter-absorbing boxes); product brand; batch number; box number;

number of items in a box, pcs; the conditional name of the manufacturer; month and year of manufacture; designation of this standard.

(Modified edition, Rev.No. 1).

5.6. Before packing, boxes of all brands, except for M and CO brands, must be tightly closed from the bottom with corks, and the necks - with metal caps with a rubber gasket.

For boxes of grades M and CO, both necks must be tightly closed with metal caps with rubber gaskets.

5.7. Boxes are packed in boxes in accordance with GOST 11142-78 or other normative and technical documentation.

The gross weight of boxes with boxes must not exceed 80 kg, the overall dimensions of boxes must not exceed 1100x650x480 mm.

Packing should be done in the following sequence.

The bottom and walls of the box are lined with paper in accordance with GOST 8273-75 or TU 13-0248643-788-89. At the bottom of the box, a lattice made of cardboard with a thickness of at least 2 mm is installed in accordance with GOST 7950-77 or GOST 7933-89. It is allowed to make a grid from cardboard of a different thickness with a total thickness of the cardboard layer not less than 2 mm. The boxes are installed in the cells with the neck up. Boxes of brands M and CO are installed in one row, boxes of other brands - in two rows. The first row of boxes is covered with a sheet of cardboard at least 2 mm thick. Similar to the first, the second row of boxes should be installed. The gaps between the grate and the walls of the box are sealed with waste filter material or wrapping paper. From above, the boxes are covered with paper and a sheet of cardboard.

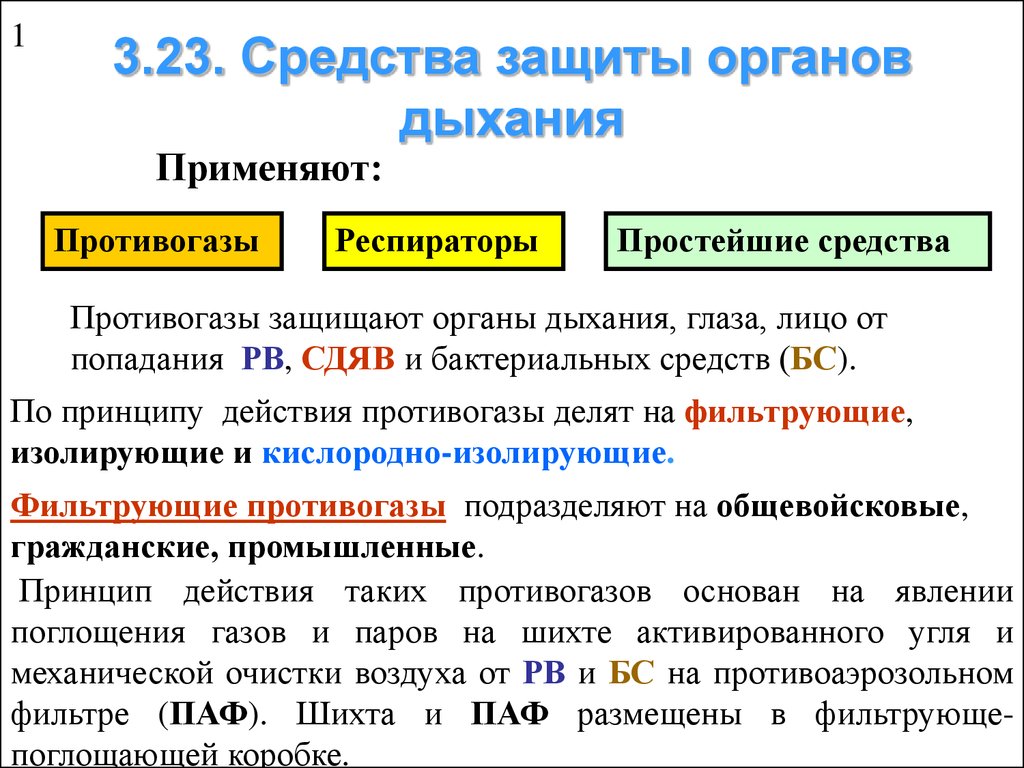

Respiratory protection

Respirators are lightweight respiratory protection against harmful gases, vapors, aerosols and dust.

Respirators are divided into two types:

The first is respirators, in which a half mask and a filter element simultaneously serve as a front part;

The second is a respirator that cleans the inhaled air in filter cartridges attached to the half mask.

By appointment, they are subdivided into anti-dust, anti-gas and gas-dust protection. Anti-dust protects the respiratory system from aerosols of various types, gas masks from harmful vapors and gases, and gas and dust protectors from gases, vapors and aerosols with their simultaneous presence in the air.

A gas mask is used both as an independent means of personal protection, and in a set with other means (for example, withcombined arms protective kit).

Gas masks differ in the types of protection:

- filtering - from specific types of emergency chemical poisonous substances, filtering the ambient air, it is usually possible to replace the filter element;

- isolating - the generation of a breathing mixture, that is, the respiratory organs do not breathe the surrounding air, but the air generated by the regenerative cartridge and the oxygen enrichment system;

- hose - supply of air mixture from some distance (10-40 meters), usually used when working in containers.

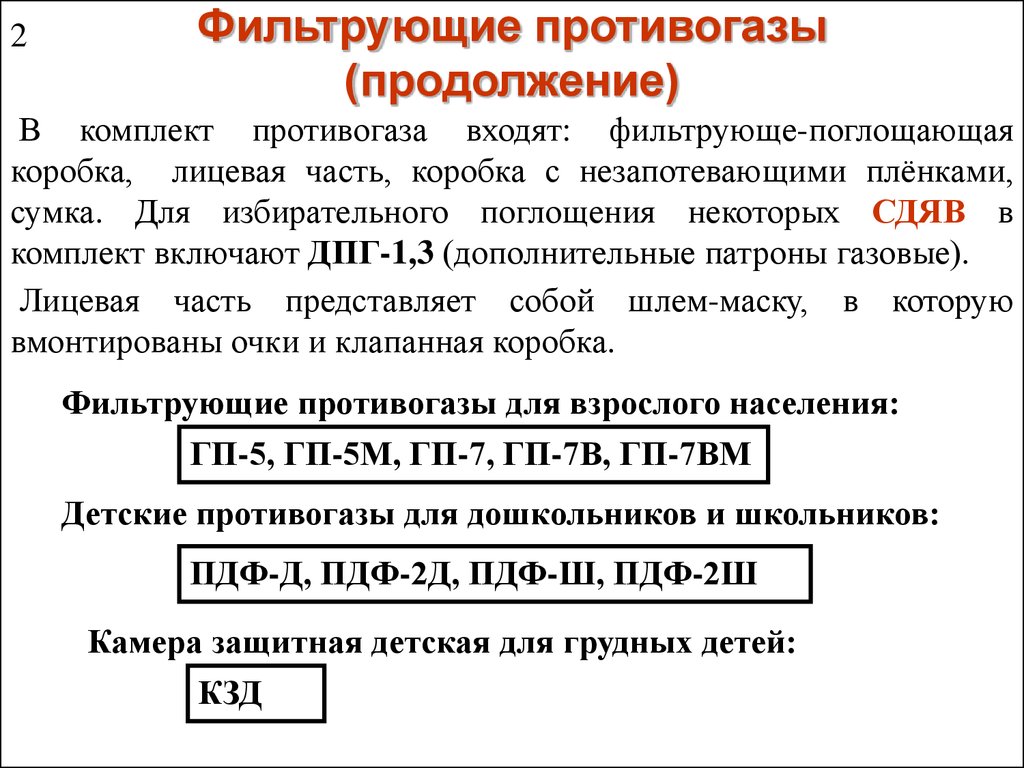

The gas mask consists of a front part (mask, helmet-mask), filtering-absorbing boxes, which are connected to each other directly or using a connecting tube.

The gas mask set includes a bag and anti-fog films, and, depending on the type of gas mask, there may be intercom membranes, a knitted cover. The filtering-absorbing (gas) box is designed to clean the air inhaled by a person from vapors and aerosols of poisonous, potent poisonous and radioactive substances, as well as bacterial agents.

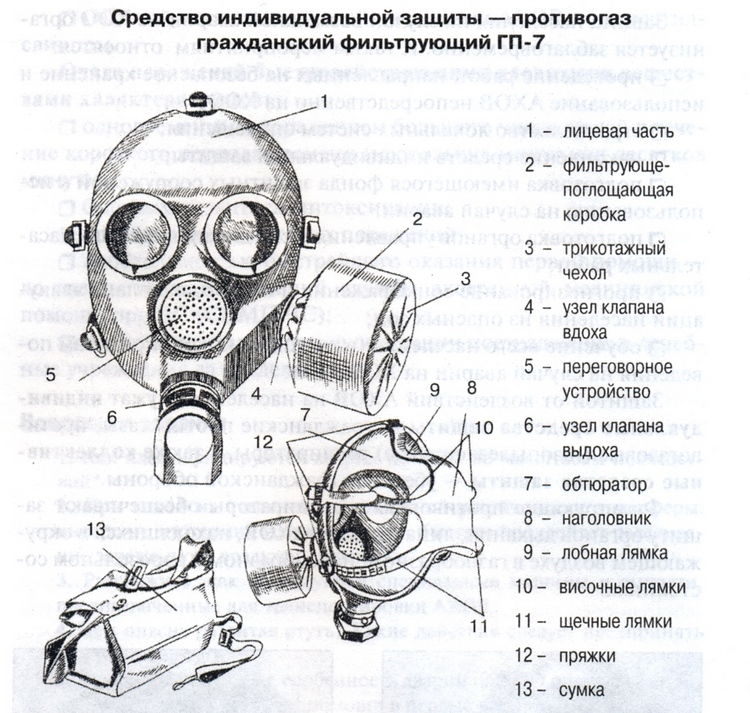

To protect the population, the most widely used filtering civilian gas masks GP-7 (GP-7V), which looks as follows:

| Gas mask GP-7: 1 - front part; 2 - filtering and absorbing box; 3 - knitted cover; 4 - inspiratory valve assembly; 5 - intercom; 6 - a node of exhalation valves; 7 - obturator; 8 - headgear (occipital plate); 9 - frontal strap; 10 - temporal straps; 11 - cheek straps; 12 - buckles; 13 - bag; 14 - spectacle knot with anti-fog films. |

How to put on a gas mask

- At the command of "Gaza!" hold your breath without inhaling air.

- Close eyes.

- Get the gas mask out of the gas mask bag, taking out the gas mask with your left hand, and holding the bag from below with your right hand.

- Pull the valve out of the filter.

- Before putting on the gas mask, place your thumbs on the outside and the rest on the inside.

- Place the lower part of the helmet-mask on the chin.

- Pull the gas mask sharply over your head from the bottom up.

- Exhale.

- It is necessary that after folds do not form, the spectacle knot should be located at eye level.

- Move the bag to its side.

Gas mask removal procedure

- At the command "Hang up!" take it with index fingers under the ears and pull it upwards.

- Put the gas mask in the gas mask bag.

- Fasten the buttons.

Anti-dust fabric masks are among the simplest means of protection; they are used to protect the respiratory system from radioactive dust and bacterial aerosols. The anti-dust sheet mask consists of a body and an attachment (the body is made of four to five layers of fabric).

For protection against emergency chemically hazardous substances, the simplest respiratory protection means are not suitable.

Gas masks: types and purpose

Studying gas masks, the types and purposes of these protective equipment, you need to highlight the following types of gas masks:

Studying gas masks, the types and purposes of these protective equipment, you need to highlight the following types of gas masks:

- civil;

- military;

- industrial

Civilian gas masks are placed in crowded areas so that in the event of a chemical attack, the civilian population can use them and escape the poisonous and contaminated air. Civilian gas masks consist of the simplest elements, allowing even an unknowing person to easily use them.

Military gas masks are equipped with additional special attributes, such as a hose for air suction and quality treatment. It is assumed that a soldier, even during a chemical attack, can carry out assigned tasks and attack the enemy.

Industrial gas masks are made using a special technology that involves multiple processing of poisonous air. Industrial gas masks are usually built into a protective suit or OZK.

Gas masks are divided into 2 types according to the method of protection and type of construction:

- Filtering;

- Insulating

Filtering gas masks consist of a filter box that protects the respiratory system from chemical attack by purifying the air inhaled by a person. Thus, using a filtering gas mask, a person breathes air purified with a filter. The need to replace the filter box makes it difficult to use a gas mask. This is the only drawback of filtering gas masks. The service life of the filter can range from several tens of minutes to several days.

Isolating masks are completely universal and have a higher degree of protection for a person from exposure to chemicals. Isolating gas masks are used in conditions of a lack of oxygen. The main feature and advantage of this type of gas masks is that a person does not breathe with purified air, inhaled from the outside, but with pre-prepared clean air from a pre-prepared source.

Isolating gas masks are divided into two types:

- self-contained breathing apparatus - include a compressor box with a compressed air cylinder placed in it;

- hose respirators - air is supplied through a hose from an external source, for example, a compressed air line

The disadvantage of insulating gas masks is that its use is limited by the amount of compressed air in the cylinder. Most often, this is no more than 3 hours. In addition, the weight of a complete set of an insulating gas mask can reach 5 kg, which makes it difficult for a person to move.

Marking

Filter boxes for a gas mask may have the following markings:

- A (brown): protects against gasoline, kerosene, acetone, benzene, toluene.

- B (yellow): does not allow chlorine, sulfur dioxide, hydrogen chloride, hydrogen sulfide, phosgene to pass through.

- G (yellow-black): protects against mercury and organic matter.

- KD (gray): does not allow ammonia, hydrogen sulphide to pass through.

- E (black): protects against the penetration of arsenic, phosphorus hydrides.

- M (red): does not allow carbon monoxide with organic matter, ammonia, acid gases to pass through.

- CO (white): protects a person from carbon monoxide.

- BKF: protects against acid gases, organic vapors, aerosols, arsenic hydrides, phosphorus.

The boxes come in large, medium and small sizes, which determines the duration of protection from contaminated air. If they have aerosol filters, the downtime is reduced. It can be detected by the presence of a white vertical stripe, and on small boxes - by the white color of the bottom. Boxes А, В, КД, Г, Е without anti-aerosol filters are designated by number 3. Therefore, their marking can be represented as - A3B3Reactor2. In this case, the filter for the gas mask has type 3 protection class A. The warranty of such parts can be within 3-5 years.

Filters for completing PPF-5M, PPF-5S, PPF-5B

Depending on the time of protective action, the filters are marked with letters indicating the protection classes in numbers (for example, A1, B2, K3, etc.). Now the choice of filters is extremely simplified, since the new letter marking contains complete information about the purpose and protective properties of the filter. The time of protective action depends on the brand and class of the filter and must comply with the requirements of GOST R 12.4.193-99. The real time of the protective action may differ from the time specified in GOST R 12.4.193-99, both upward and downward, depending on the operating conditions and the concentration of the harmful substance.

All combined filters are equipped with an anti-aerosol filter "P" and protect against various aerosols (dust, smoke, fog). The use of filters of other brands that do not correspond to the specific hazardous substance is unacceptable.

Special filters (CO, NO-P3, Hg-P3, AX) are not subdivided into classes. The protective action time meets the requirements of GOST R 12.4.231-2001 and GOST R 12.4.232-2007.

One of the most important and, perhaps, unique properties of the new filters is the universal protection of the respiratory system from several types of harmful substances at once. This advantage of multifunctional filters is especially significant for different divisions of industrial facilities, where harmful substances of different concentration and composition are often used. If earlier, when moving an employee from one department to another, it became necessary to replace one brand of filter with another, now the use of a new universal filter completely eliminates the need for this. This became possible due to the use of the latest high-efficiency absorbers in the design of the filters.

DOT Filters

GOST R 12.4.193-99, GOST R 12.4.194-99

Compliance with new GOSTs, harmonized with European standards EN141, EN143. Much more effective in comparison with gas mask boxes produced according to the old GOST due to unique absorbers. An excellent combination of protective and performance characteristics. A wide range of simple and compound brands. Versatile protection against a wide range of hazardous substances

Simplified selection of grades and performance classes with the required properties. Use when the concentration of harmful substances in the air is up to 1.0 percent by volume

DOT 220 m.А1В1Е1Р3D

Filter DOT 220 m.A1B1E1P3D

Article: 187-254

Check the price with the operator

Add to cart

DOT 250 m.A1

Filter DOT 250 m.A1

Article: 187-255

Check the price with the operator

Add to cart

DOT 250 m.A1 with P2 filter FP

Filter DOT 250 m.A1 with filter P2 FP

Article: 187-256

Check the price with the operator

Add to cart

DOT 250 m.А1В1Е1

Filter DOT 250 m.A1B1E1

Article: 187-257

Check the price with the operator

Add to cart

DOT 250 m.A1B1E1 with filter P2 FP

Filter DOT 250 m.A1B1E1 with filter P2 FP

Article: 187-258

Check the price with the operator

Add to cart

DOT 250 m.А1В1Е1К1

Filter DOT 250 m.A1B1E1K1

Article: 187-259

Check the price with the operator

Add to cart

DOT 250 m.A1B1E1K1 with filter P2 FP

Filter DOT 250 m.A1B1E1K1 with filter P2 FP

Article: 187-260

Check the price with the operator

Add to cart

DOT 320 m.A2, B2E2, K2

Filter DOT 250 m.A1B1E1K1 with filter P2 FP

Article: 187-261

Check the price with the operator

Add to cart

DOT 320 m А2В2Е2Р3D

Filter DOT 320 m А2В2Е2Р3D

Article: 187-262

Check the price with the operator

Add to cart

DOT 320 m А2В1Е1К1Р3D

Filter DOT 320 m А2В1Е1К1Р3D

Article: 187-263

Check the price with the operator

Add to cart

Pillbox 320 m HgР3D

Filter DOT 320 m HgP3D

Article: 187-264

Check the price with the operator

Add to cart

DOT М 460 m.А1В1Е1К2СО15SX

Filter DOT M 460 m.A1B1E1K2CO15SX

Article: 187-265

Check the price with the operator

Add to cart

Pillbox 460 m.K2

Filter DOT 460 m.K2

Article: 187-266

Check the price with the operator

Add to cart

DOT 460 m.K2 with P2 filter FP

Filter DOT 460 m.K2 with filter P2 FP

Article: 187-267

Check the price with the operator

Add to cart

DOT 460 m.А2В2Е2

Filter DOT 460 m.A2B2E2

Article: 187-268

Check the price with the operator

Add to cart

DOT 460 m.A2V2E2 with filter P2 FP

Filter DOT 460 m.A2B2E2 with filter P2 FP

Article: 187-269

Check the price with the operator

Add to cart

DOT 460 m.А2В2Е2АХ

Filter DOT 460 m. А2В2Е2АХ

Article: 187-270

Check the price with the operator

Add to cart

DOT 460 m. А2В2Е2АХ with P2 filter FP

Filter DOT 460 m.A2V2E2AX with filter P2 FP

Article: 187-271

Check the price with the operator

Add to cart

DOT B 600 m В1Е2Р3D

Filter DOT B 600 m В1Е2Р3D

Article: 187-272

Check the price with the operator

Add to cart

DOT М 600 m В2Е2К2СО20SX

Filter DOT M 600 m В2Е2К2СО20SX

Article: 187-273

Check the price with the operator

Add to cart

Bunker М 600 m В2Е2К2СО20SX with Bunker P3

Filter DOT M 600 m B2E2K2CO20SX with DOT P3

Article: 187-274

Check the price with the operator

Add to cart

M 600 m B1E1K2NOP3D

Filter M 600 m B1E1K2NOP3D

Article: 187-275

Check the price with the operator

Add to cart

600M A1B2E2K2NOP3D

Filter M 600 m B1E1K2NOP3D

Article: 187-276

Check the price with the operator

Add to cart

DOT 600 m.K3R3D

Filter DOT 600 m.K3R3D

Article: 187-277

Check the price with the operator

Add to cart

DOT 600 m.А2В3Е3Р3D

Filter DOT 600 m. А2В3Е3Р3D

Article: 187-278

Check the price with the operator

Add to cart

DOT 600 m А2В3Е3Р3D (n)

Filter DOT 600 m А2В3Е3Р3D (n)

Article: 187-279

Check the price with the operator

Add to cart

DOT 600 m.А2В2Е2К2Р3D

Filter DOT 600 m. А2В2Е2К2Р3D

Article: 187-280

Check the price with the operator

Add to cart

DOT 600 m.А2В2Е2К2Р3D (n)

Filter DOT 600 m.A2V2E2K2R3D (n)

Article: 187-281

Check the price with the operator

Add to cart

DOT 600 m.А2В2Е2К1АХР3D

Filter DOT 600 m. А2В2Е2К1АХР3D

Article: 187-282

Check the price with the operator

Add to cart

DOT 600 m.А2В3Е3АХР3D

Filter DOT 600 m. А2В3Е3АХР3D

Article: 187-283

Check the price with the operator

Add to cart

FOS DOT 780 m А2В2Е2АХ

Filter FOS DOT 780 m.A2V2E2AX

Article: 187-284

Check the price with the operator

Add to cart

Bunker 780 m А2В2Е2Р3 (expanded charge)

Filter DOT 780 m А2В2Е2Р3 (expanded charge)

Article: 187-285

Check the price with the operator

Add to cart

DOT P3

DOT P3 filter

Article: 187-286

Check the price with the operator

Add to cart

DOT А2В2Е2К2

Small size filter А2В2Е2К2

Article: 187-287

Check the price with the operator

Add to cart