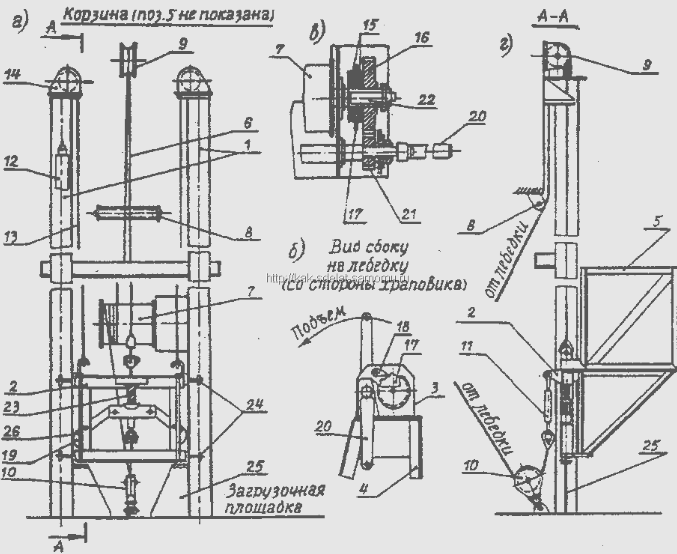

DIY pneumatic jack

As an example, also consider the pneumatic device, which is the easiest to make. So, you will need:

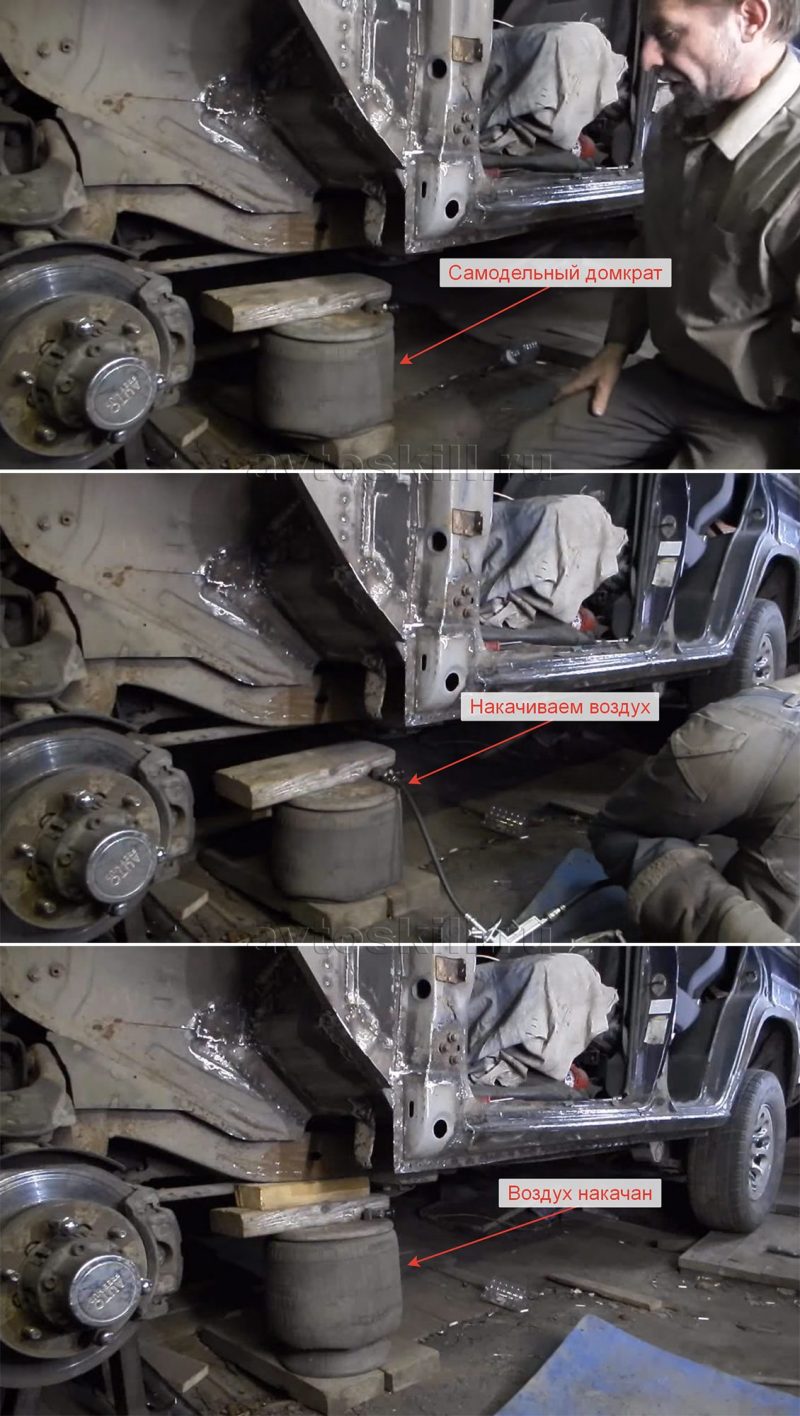

- Air bag. The main working part that can be found on disassembly or on the market. An ordinary rubber cylinder from the air suspension of a car can act in its role. It is best suited from a cargo area, as it is much stronger and can withstand strong pressure, which increases the lifting moment. But it has a great height, so it is not always possible to substitute such a jack under a car with low ground clearance;

- Two bolts. They will be needed to make the valve in the pillow. In general, it initially has a factory threaded hole into which a high-pressure pipe was screwed. Now, instead of it, we need to select the same diameter bolt, and then find another one that will serve as the top cover. They need to be drilled so that when they are connected to each other, a cavity is obtained inside them. Then we put a ball from the bearing and a strong connection for pumping inside the upper bolt. Now the whole structure can be welded and screwed into the hole in the pillow.

In principle, any passenger car can be easily lifted with such a home-made device. It is enough to place a pneumatic cylinder under the platform on the bottom and connect a high pressure hose to the fitting. By supplying compressed air, the pillow will begin to rise with the machine.

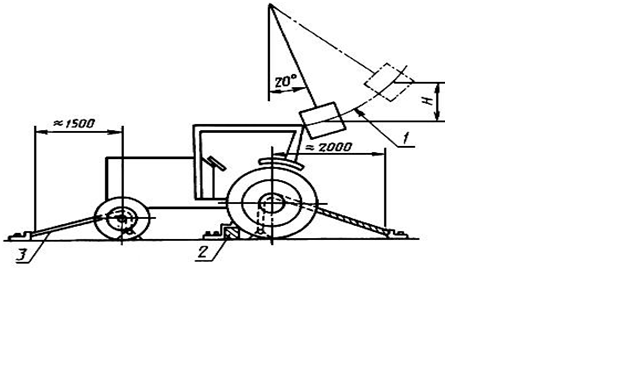

The principle of operation of a homemade pneumatic jack

For convenience, such a jack can be completed by inventing a reliable platform with wheels. Thus, if the cylinder is taken for disassembly, then the device of its own manufacture goes almost for a penny.

Improved pneumatic jack on wheels

You can also watch a few videos on how to make a pneumatic jack with your own hands:

Device and principle of operation

Electric lifting devices are the result of a synthesis in one design of mechanically moving elements and an electric drive from a motor with a gearbox. The carrying capacity of such devices is at most 2 tons.

The main drive is structured as follows: a small device based on electrical and mechanical action, includes an electric motor and a gearbox, which drive a lifting screw-like structure. For operation, the device should be installed in the required place and connected to the power supply. For this, along with an adapter for interfacing with the power supply, the jack is equipped with two cables for connecting to the car battery. The work of the lift is coordinated by means of the remote control.

The principle of operation of the electric jack is quite simple:

- the lift is connected to the network (usually by means of a cigarette lighter);

- the connection signal is fed through the wires to the jack microprocessor;

- a signal is sent to the engine of the device;

- using the control panel, the car owner sets the required height to which the car needs to be lifted;

- the microprocessor and the hoist motor receive this information and execute the operation.

How to choose a quality tool: comparison of manufacturers and models

Despite the fact that electric jacks have already taken one of the leading positions on the market, there are several brands that are especially popular among both experienced and novice car enthusiasts.

The most popular manufacturers include the German company Varta and the American company Turbo.

Electric jack of the American company "Turbo"

For the manufacture of a known modification of the diamond-shaped electric jack V-CJ2.02, a steel alloy that does not rust is used. Due to the fact that the one-piece construction consists of parts that can be detached separately, these jacks have high reliability and excellent stability. In the instructions, the manufacturer indicates that the design can be used even if it is snowing or raining outside.

Important!

The main disadvantage of an electric jack for a car is the relatively low carrying capacity, which is no more than 2 tons, as well as the large weight of the assembled Kraftool jack - up to 6 kg. When reading the reviews of motorists, we can conclude that there are practically no problems during the operation of such a mechanism.

Features of the design of an electric jack

Before buying an electric jack for your car, it is recommended that you familiarize yourself with all existing models and varieties of such structures. Familiarization with the existing advantages and disadvantages of the Kraft hydraulic trolley jack 3 t will help to avoid buying a fake unit. So, as for the types of car lifts, they are divided into the following groups:

Electric jack

Electric jack

- mechanical;

- hydraulic;

- electrical;

- pneumatic or inflatable.

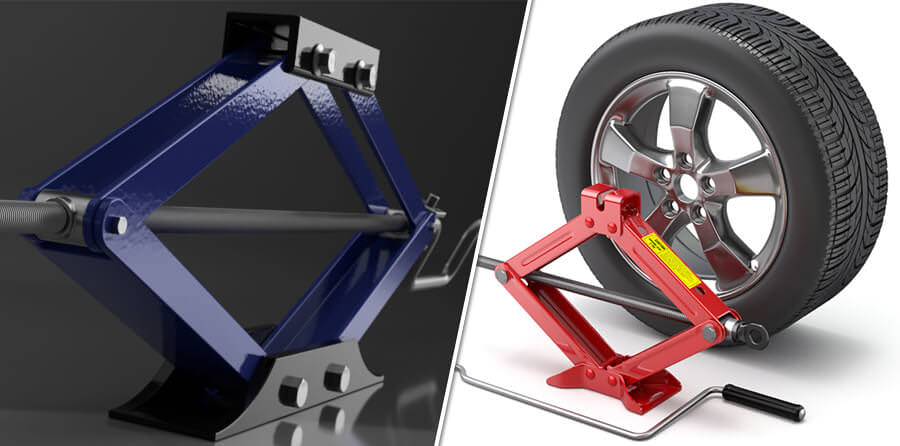

The simplest and most reliable design is a mechanical jack. But the low carrying capacity allows the use of mechanical lifts only for the repair of passenger cars. The design of a mechanical automotive device is characterized by the presence of a screw or rack and pinion mechanism.

The operation of the hydraulic unit is carried out due to the effect of the pressure of a special oil, which, in turn, increases the carrying capacity and transmission of the pressing forces of the mechanism several times.

The main disadvantage of hydraulic pumps is the constant need for maintenance.

Rhombic jack 2 tons Kraft KT 800025 is represented by an inflatable pillow, for the manufacture of which a strong material is used. Due to the fact that the air in the cylinder acts on the chamber, it gradually begins to swell, as a result of which the vehicle is lifted. The advantages of such tools include ease of operation and good lifting capacity, but even so, pneumatic jacks are extremely rare. This fact can be explained by the fact that the use of such a device is possible only with the help of a special compressor.

Even though electrical structures in most cases require electricity to operate, their autonomous operation is also possible.

Experienced motorists say that there is no need to regularly plug the Kraft KT 820003 jack into a power outlet.

Often, in order to supply the structure with electricity, it is enough just to connect the jack to the on-board electrical network in the vehicle. In this case, the engine can be switched off. To bring the electric jack into working condition, you need to perform a number of the following functions:

- Using the cigarette lighter, you need to connect the device to the network.

- The signal that the unit has been connected enters the microcircuit through the wires.

- After that, the microcircuit passes the signal to the working cylinder of the jack.

Electric jack in action

Note!

The required height for raising the car is set by the driver using the control panel, which sends data to the microcircuit and the engine, as a result of which the structure begins to work.

Most popular models

Despite the fact that electronic devices have appeared not so long ago, both leaders and outsiders have already appeared among them. The most popular among users of such products is the products of the German company Varta. Nevertheless, the American firm Turbo does not lag behind its competitor.

Jacks from the Varta company

The main drawback is not too outstanding carrying capacity - up to 2 tons. To some extent, a large weight can also be attributed to the disadvantages - 6 kg. However, this is a kind of "side effect" of the one-piece construction, which gives the jack excellent stability.

According to the drivers, there are no problems with the installation or operation of this model. There are no difficulties with the installation or lifting of the car. However, if the engine is off, the device operates more noisily due to the reduced battery voltage.

In addition to the jack described above, many drivers like another model from the same company - V-CJ2.11W. The whole mechanism is also one-piece and made of stainless alloys. By analogy with the previous device, this product also has a special remote control with only 2 buttons for raising and lowering the machine. However, if power cannot be provided, a lever is provided on the unit for lowering.

The V-CJ2.11W also does not have a large payload. The maximum weight is 2 tons. In addition, some drivers have problems during installation, since this device must be located on a level surface.

Turbo electric jack

model Jack GB-A20

Drivers praise this product for its ease of use, excellent quality and lack of strict requirements for a flat surface. In addition, even with the engine off, this unit runs quietly.

Electric jacks for cars are quite specific devices that have not yet passed the "test of time". Nevertheless, a fairly large number of drivers are happy to use these products. Maybe it's time for you to join them?

Electric jacks

Construction management

An electric jack is a device for lifting a load, powered by a vehicle's cigarette lighter or its own battery. To power the jack electric 12 volts will be enough. Such a lift can work even when the car engine is running, which is especially appreciated by car owners. This makes it possible to charge the jack battery from the mains of the lifted machine.

An electric jack is a device for lifting a load, powered by a vehicle's cigarette lighter or its own battery. To power the jack electric 12 volts will be enough. Such a lift can work even when the car engine is running, which is especially appreciated by car owners. This makes it possible to charge the jack battery from the mains of the lifted machine.

The main drive is a small electromechanical device consisting of an electric motor and a gearbox driving a lifting screw structure. To work, it must be installed in the right place and connected to the power supply. For this, in addition to the adapter for connection to the on-board network, the jack is equipped with a pair of wires for connection to a car battery. The lift is controlled by the remote control.

An electric jack, like other similar devices, is a unit, when working with which you need to take care of safety. When performing operations related to changing wheels or other lifting operations, the following measures must be taken:

Securely fix the wheels of the vehicle with shoes in order to avoid spontaneous or erroneous movement of the vehicle.

Securely fix the wheels of the vehicle with shoes in order to avoid spontaneous or erroneous movement of the vehicle.

Having raised the body to the required height, special stops are installed under it to secure and prevent the machine from lowering.

It is forbidden to penetrate under a car that is in a raised state without fixing. It is required to take measures to prevent the body from sliding off the lift.

Lifting capacity of the electric jack

You should pay special attention to this characteristic when buying a tool.If you make a mistake in the selection, then other possibilities will become irrelevant, since if the jack could not cope with its main duty, did not raise the intended car, then it does not matter what the quality of the product, the working stroke and stability

A certain model is designed for its maximum lifting weight, which is spelled out in the data sheet and on the nameplate placed directly on the body of the device. Calculating the required lifting capacity of the jack, add 10-15 percent of this figure to the mass of the car. Having made a mistake in the carrying capacity, you can break it, and in the worst case, injure yourself when the car falls.

A certain model is designed for its maximum lifting weight, which is spelled out in the data sheet and on the nameplate placed directly on the body of the device. Calculating the required lifting capacity of the jack, add 10-15 percent of this figure to the mass of the car. Having made a mistake in the carrying capacity, you can break it, and in the worst case, injure yourself when the car falls.

Advantages and disadvantages

Given the main technical characteristics of electric lifts, one can form an opinion about the positive and negative sides of owning such a device. Speaking about the good properties of the electric jack, I would like to highlight its ease of use. This is such a convenient and unpretentious device that a woman driver can also use in an unforeseen situation.

It's not bad when you can control such a device remotely from the remote control. For example, standing away from the car, slightly raise it for a better view of the space under the bottom. The remote control eliminates the need to manipulate all kinds of levers and handles when lifting the body.

It's not bad when you can control such a device remotely from the remote control. For example, standing away from the car, slightly raise it for a better view of the space under the bottom. The remote control eliminates the need to manipulate all kinds of levers and handles when lifting the body.

Power autonomy will also be recorded among the advantages of electric lifts. Such a device will be able to work in the farthest corners.

There are many advantages of owning an electrified lift, but there is no equipment without disadvantages either. If you look at the cost of such equipment, which significantly exceeds the price of comparable devices according to technical data, it can be very high. Electric jacks are a fairly new technique, and new items are always appreciated more expensive.

There are limits on the height of the pickup. For some jacks, it is limited to 15 centimeters, that is, this technique will not work for cars with low ground clearance. A small annoying detail will be the need to lower the vehicle, which has been lifted by an electric lift, manually.

The choice of such products must be approached carefully and carefully. If the high price is not intimidating, and the car is suitable for the carrying capacity requirements, such an electric assistant will be a good purchase. For owners of heavy SUVs and lovers of tourist routes, a rack and pinion jack is suitable, which can be used instead of a winch.

Tools and materials for a homemade jack

In order to make a jack, there must be a suitable tool. The first step is welding, since it will be used for assembly. It is desirable that it be a semi-automatic apparatus with carbon dioxide. Then the seams will turn out much smoother and there will be no excess slag.

The second, and no less important, is the grinder. It is good if the assortment includes both small and large

With their help, you will cut out steel blanks. You will also need a drill, because you have to make more than one hole. To handle iron parts with ease, you need an electric sharpener. It is key in the fitting process. In addition, it is advisable to have hand tools: files, needle files, bars, hammers, screwdrivers, rasps, drills with a set of taps, sledgehammers, vices, etc. The more tools you have at hand, the easier the manufacturing process will seem.

The more tools are available, the easier and better the jack will be.

A lathe is a great helper in any business, but not everyone has one. In principle, you can cope without it, but if you have such a unit in your garage or workshop, it will work out much faster. After all, with the help of a milling unit, it is easy to grind or process any part. For example, a bolt or a rod. In general, your machine will be very useful.

It is also worth talking about the material. You can buy it at the market or at the scrap metal collection point. The second option is much cheaper, since at the scrap reception all the metal is rusty and bruised. It is not suitable for exploitation, but as a donor it is just that. It is desirable, of course, to purchase as much as possible. Indeed, depending on which jack you want, you may need additional mechanisms or fasteners that you cannot make yourself. Therefore, be prepared to purchase some of the components on the market.

Popular brands

We present a small rating of jacks, compiled according to drivers' feedback. The lifting mechanisms of the German company Varta are most in demand among motorists.

Varta V-CJ2.01

The device is made of non-corrosive steel alloy and has a rhomboid configuration in the working position. Due to the integrity of the structure (i.e. no separate detachable elements), the lifting mechanism is endowed with impeccable strength and stability.

The main disadvantage is the extremely small lifting capacity - up to 2 tons... To some extent, the disadvantages include a large mass - 6 kilograms. Be that as it may, this is a specific "undesirable effect" from the solidity of the structure, which gives the jack tremendous stability.

According to the reviews of car owners, there are no difficulties in installing this modification or when lifting the car. However, if the engine is off, the hoist is noisier due to the undervoltage in the battery.

V-CJ2.11W

In addition to the aforementioned jack, many car owners like another modification from the same manufacturer - V-CJ2.11W. The entire structure is also monolithic and made of non-corrosive alloys. Similar to the previous device, this product is equipped with a special remote control with only 2 buttons for raising and lowering the vehicle.

The V-CJ2.11W also does not have a large payload. The maximum weight is 2 tons. In addition, individual car owners have difficulties in the installation process, since this mechanism requires a flat base.

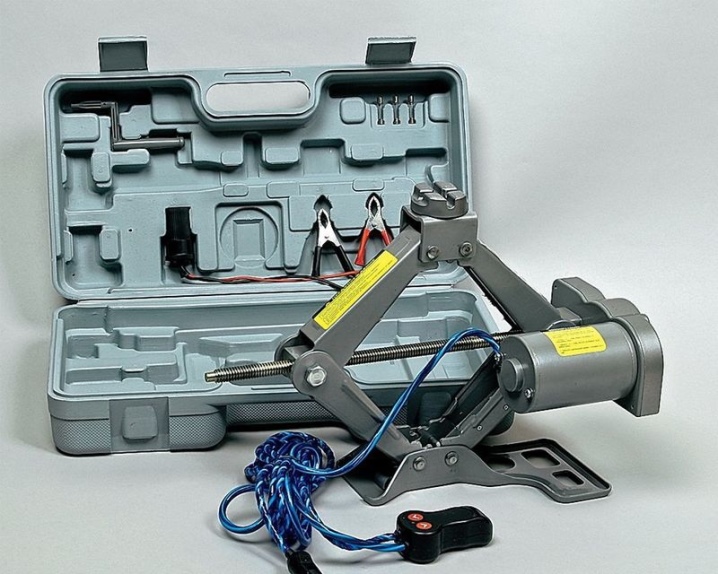

Sorokin 3.562

The 12 V electromechanical jack, in a case, with an impact wrench, is a balanced multi-purpose device equipped with additional accessories.

It combines, in addition to the lifting mechanism, a built-in air compressor with an overpressure measuring device (manometer) and auxiliary lighting equipment (LED main lamp, vertically directed lighting and hazard warning lights).

It will suit even owners of SUVs, since the carrying capacity of this model has been increased to 3 tons. In addition to its standard purpose, it can be used to loosen nuts. It has a universal power supply - both from its own rechargeable battery and from a car generator. This modification is characterized by all the optimal qualities of devices of this type.

The company from the USA Turbo does not lag behind its rivals.

Turbo Jack GB - A20

Another trusted electric jack is the Turbo Jack GB - A20. This model is also not offended by the positive characteristics in the form of carrying capacity - like the previous modification, it is 3 tons, and even minimized to 110 mm of pick-up height... Motorists praise this option for its high quality workmanship and performance on a wide variety of surfaces. This electric jack is characterized by a lower noise level.

Electric jack VARTA V-CJ2.11W

Electric jack VARTA V-CJ2.11W

Designed for vehicles weighing up to 2 tons,

torque wrench 380 Nm

Estimated price - 3500 rubles.

In fact, a whole set of tools for changing wheels: in a plastic box with convenient locks, in addition to the jack itself, there is also an electric impact wrench with an extension cord and heads of 17, 19, 21 and 23 mm! The manufacturer also did not skimp on spare fuses and an adapter for connecting directly to the battery terminals. The cord is long enough to reach any of the wheels. The support platform was made from a bolt by sawing a groove in its head. The minimum threshold height for a car must be at least 160 mm (many cars cannot be raised this way). The head of the bolt is not covered by anything: it will damage the paint on the threshold. With the engine not started, the jack works very loudly, but sluggishly. It seems that the motor is about to jam or burn out. The mechanism should be set almost at the level, otherwise it will turn it inside out. The LED in the control panel will help you not miss in the dark. If the jack suddenly breaks, it can be lowered using the supplied plastic lever, but this is a very slow process. The impact wrench more than exceeds the factory tightening torque standards. We just need to wait for the eighth or tenth blow. Long, but effortless.

Device performance

Any jack is assessed according to individual parameters that determine the area of its application. In order for the instrument to serve for a long time and without frequent repairs, these requirements must be observed. The technical characteristics of the jacks are as follows:

- Lifting capacity - the maximum weight of an object, for which the jack is adapted to lift. It is measured in tons or kilograms.

- Pick-up height - the smallest gap between the floor, the ground, another base on which the lifting device rests, and its part for gripping the car in the lowest position.

- Lift height - the highest position of the gripper in relation to the supporting surface. Working stroke - the difference between the extreme gripping points.

- Stability - the ability of the lift to remain in one plane with any vertical or horizontal efforts aimed at bringing it out of balance.

- Drive Handle Force - Force applied when lifting weights to the desired level. This indicator is related to the mass of the load being lifted and the number of drive cycles for lifting it to the upper position. It is individual for each type of jacks.

- The gear ratio is the ratio of the length of the hydraulic pump plunger to the length of the jack plunger. (The plunger is a special piston that is used in such mechanisms where higher pressure is required compared to conventional piston pumps).

- Versatility - the ability of the lifting mechanism to work with machines of different weights and regardless of their location.

Criterias of choice

The price of electrical products is higher than, for example, mechanical or hydraulic hoists. In this regard, it is recommended to approach the selection of the device with particular responsibility. And you certainly shouldn't get the cheapest modification.

However, if the electric jack is bought for the first time, it is not worth buying especially expensive samples. An electrical device may not be right for you. Therefore, the best option is to make a purchase in the middle price segment.

Thus, when choosing, you should pay attention to the following parameters:

- The first step is the price of the lift.

- Carrying capacity is the most essential characteristic that will be discussed separately.

- Lift Limit - The distance the vehicle can rise above the ground.

- Pick-up height (the distance between the road surface and the lowest point of the central part of the vehicle) is the smallest clearance required for the jack to be mounted under the vehicle. The lower the suspension system of the machine, the lower the lift height will be.

- Stability is a property that provides balance when the vehicle is lifted.

As a bonus feature, the multifunctionality of the lift can be called. This is the characteristic that is responsible for the lifting capability of all types of vehicles.

At the same time, when choosing, it is also advisable to pay attention to the dimensions of the device - its weight and dimensions. However, this condition is not important for all car owners.

The main quality is carrying capacity.

Carrying capacity is an especially important parameter in the selection of an electrical mechanism. In fact, is the size of the jack or the height of its lifting so important when it is not able to lift the car? For this reason, when choosing any type of lift, not necessarily electric, this parameter should be in the first place.

In order to choose the right attachment, you need to find out the weight of your car. You can find out from the data sheet. After that, it is necessary to add 100-150 kilograms to the mass. This will become a kind of insurance in case something weighty "gets lost" in the car or in the trunk.

Under no circumstances should you lose sight of the extra pounds. Otherwise, unsafe situations may arise. The most trivial is if the electric jack cannot withstand the weight of the machine and breaks down, and the vehicle falls to the ground with a crash. It follows from this that the owner broke both the car and the lifting mechanism for his own money.

Despite the importance of the parameter, electrical mechanisms do not have a large carrying capacity. For example, screw jacks are capable of lifting a car weighing up to 15 tons, rack and pinion jacks - up to 20 tons, rolling jacks - 3, 5, 10 and 20 tons, hydraulic jacks - generally up to 200 tons. Electric modifications, like their counterparts - inflatable (pneumatic jacks), are not able to withstand a mass of more than 4 tons.

Therefore, electrical samples must be purchased exclusively for small cars. Pickup trucks, jeeps and other "massive" vehicles are hardly suitable for such a carrying capacity.

You can watch a visual overview of the electric jack in action in the following video.