Briggs & Stratton I / C engine design

- Cylinder

- Piston

- Connecting rod

- Crank and crankshaft

- Valves

- Flywheel

- Carter

- Crankshaft. A crank is a lever that is pinned to the end of the connecting rod with the other end rigidly connected to a shaft called the crankshaft.

- Valves are devices that control the flow of intake and exhaust gases into and out of an engine cylinder.

- Flywheel - A heavy wheel mounted on the crankshaft to ensure that it rotates evenly.

- The crankcase is the lower part of the engine that serves as a housing for the shaft and a sump for lube oil.

Four-stroke I / C gasoline engine:

- Fuel suction

- Compression

- Working stroke (combustion)

- Exhaust

Most popular gasoline engines

Honda engine classification is represented by such series as GC, GX, GP, IGX.

The main features of Honda engines are air cooling and manual start, the weight of the extremely productive units is 25 kilograms, the balanced fuel consumption is 2.5 liters.

The most popular of all Honda engines are the GX engines. This series of engines undergoes regular revision, which increases their efficiency in terms of fuel consumption, as well as increases their environmental friendliness.

The GX series engines are high-quality, universal components designed for long-term continuous operation in extremely demanding conditions. With regard to power, in most cases it does not exceed 15 horsepower.

In the spring of 2010, Honda launched the GX-240, GX-270, GX-340, GX-390 line. These units comply with strict EPA 3 Phase emission standards.

Noteworthy are the improved models GX130, GX-160, GX-200.

The following improvements have been introduced: variable ignition timing, higher compression ratio, improved carburetor performance, and a lighter piston. They contribute to increased power and torque, improved fuel efficiency, and reduced vibration and noise. In contrast to the characteristics, the dimensions and external outlines have remained practically unchanged. This has led to the fact that the engines of this series are easily replaceable, this process does not cause any special difficulties. It is also worth noting the CG springs introduced into this series and distinguished by their special reliability.

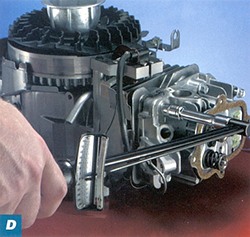

general information

The Briggs & Stratton I / C 6.5 general-purpose gasoline engine offers easy starting, quieter operation and longer life. Thanks to OHV technology in combination with a Lo-Tone muffler, these engines save fuel with optimal power and high torque.

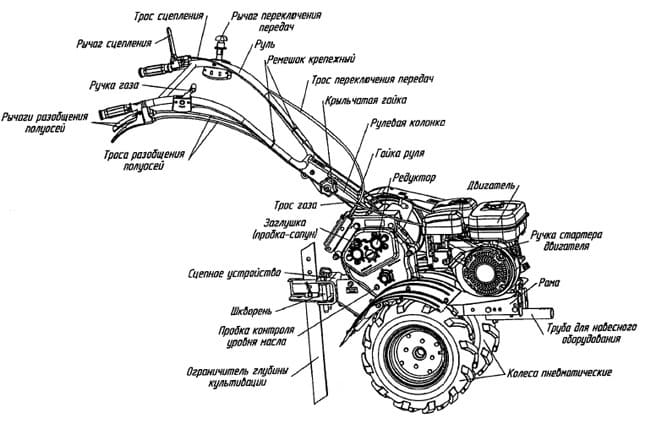

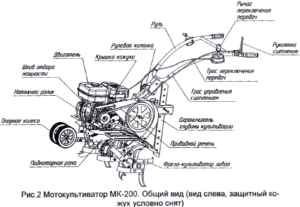

208cc Briggs Stratton IC cm are installed on:

- walk-behind tractors

- motor cultivators

- vibrating plates

- pressure washers

- other power equipment

To install the engine on some models of walk-behind tractors, an adapter plate may be required.

B&S I / C 6.5 features:

- Dura-Bore Cast Iron Liner Cylinder: Resists wear and misuse while providing improved oil control.

- Float carburetor for consistent easy starting.

- Maintenance-free Magnetron electronic ignition for fast and reliable starting.

- High Capacity Dual-Clean Air Cleaner: Pleated paper filter, foam pre-filter and debris ejection slots provide superior protection.

- Overhead valve (OHV) design for no overheating and longer valve life.

Intek I / C 6.5

There is a variation of this model - Intek I / C 6.5 - with some improvements.

Features of Briggs & Stratton Intek I / C 6.5:

- Compact overhead valve: Cleaner and cooler - Provides more power, longer engine life and improved fuel economy.

- High efficiency cylinder head: 20% more power than conventional engines, improved fuel efficiency and significantly reduced emissions.

- One-Start Carburetor: Fast fuel delivery for first-try start and smooth operation.

- Heavy Duty Bearing: Self-lubricating ball bearing made of bronze coated steel to resist loads and reduce wear.

- Large fuel tank: allows you to refuel the engine less frequently.

- Mechanical governor: controls the throttle to provide more power for demanding tasks.

- Fuel shut-off valve: Easily shut off the gasoline supply for safe transportation.

- Lo-Tone Silencer: Provides quieter, quieter operation.

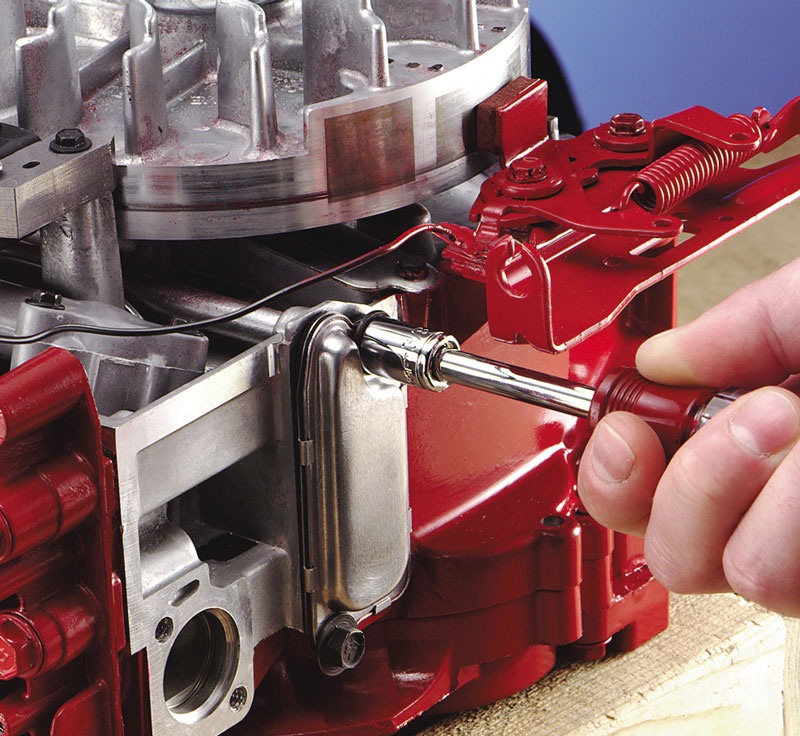

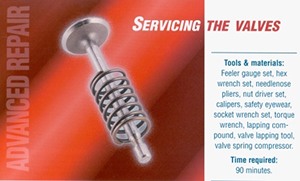

How to adjust the pusher clearances

During operation, the valves rub in, removing some of the outer coating, therefore, after lapping or reinstalling, it is recommended to adjust the pusher clearances.

Description of the procedure.

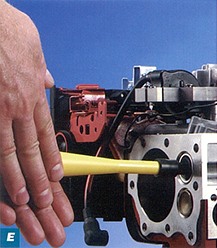

- Having installed the valves, it is necessary to turn the crankshaft clockwise up to the stop. Make sure the installed parts are tightly closed. Now we turn the same shaft beyond the top point - let the piston move a quarter from the cylinder head.

- Using a dipstick, we check the gap. To increase it, you can grind the tip of the square of the rod, before removing the pusher. Experts advise to constantly check the length so as not to cut off excess metal.

- Clean the individual parts well. Then it is necessary to thoroughly lubricate the stem, the valve guide - for this, a special lubricant is used. At the end of the procedure, check for any lubricant at the ends of the pusher.

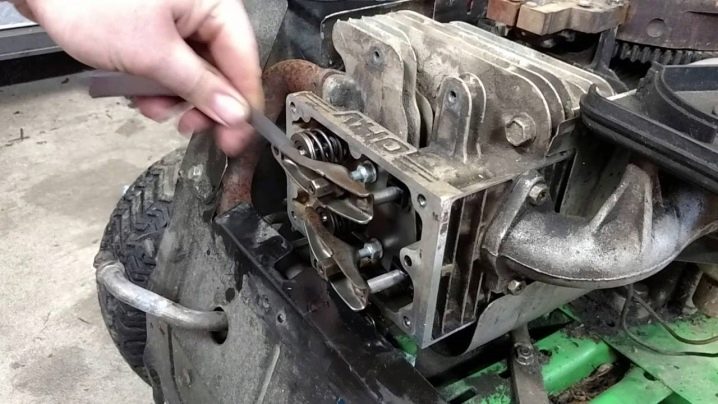

Adjusting the top valves is as simple as the previous one. The main thing is to follow the following guidelines:

- release the brake spring;

- turns the handwheel to close both pushers;

- insert a narrow screwdriver into the spark plug hole - you need to get to the piston;

- turn the flywheel clockwise - the piston should drop below the top dead center by one fourth;

- measure the range of motion with a screwdriver;

- experts advise to carry out such a procedure to all owners of V-shaped carburetors;

- it is necessary to check the clearance using a feeler gauge, placing it between the rocker arm and the valve head. Keep in mind, both gaps are different sizes: 0.002-0.004 and 0.005-0.007;

- when turning the rocker screw, we proceed to the very adjustment of the clearances - do it at our discretion;

- at the end, do not forget to tighten the nut;

- when installing the cover, you can replace the gaskets (in case of wear), and then check the reliability of fastening.

The American company Briggs & Stratton is a durable, wear-resistant, efficient engine for motoblocks for various purposes. Thus, the equipment is equipped with the latest technologies that greatly facilitate the work process as a whole: it reduces noise levels, protects against wear, and reduces fuel consumption

When buying a device of this brand, it is important to decide on the type of household or construction work. The specialist will select for you the optimal model, which, among other things, comes with a guarantee in the event of a malfunction of the mechanism after the first or second start.

For more information on the features of Briggs & Stratton engines for a walk-behind tractor, see the video below.

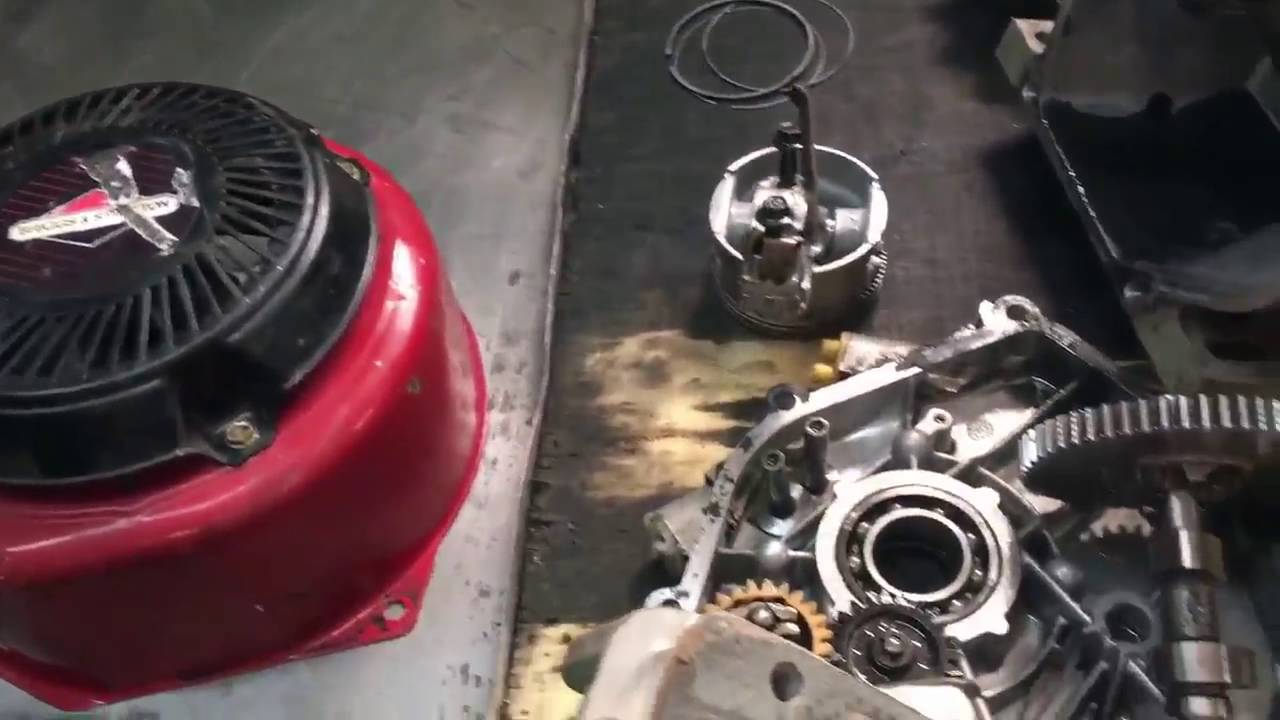

Major problems with Briggs & Stratton engines

Briggs & Stratton engines are known to have some common problems such as overheating or fuming, inability to start, poor engine performance during use. These problems are usually repaired by the owner and not by specialists.

- Overheating of a Briggs & Stratton engine can occur for a number of reasons. The motor may be dirty, the solution is to remove dirt and debris during a thorough cleaning. Also, the engine may have a low oil level or the air / fuel mixture needs to be increased. Replacing a loose gasket can also prevent further overheating problems.

- Repairing a smoking engine is largely dependent on the color of the smoke. White or blue smoke indicates oil is burning, and black smoke indicates carburetor adjustment. Cleaning or replacing the air filter can also help.

- If the engine won't start, it could be due to old fuel, dirt and debris. Changing the fuel and cleaning the carburetor and spark plugs can often fix the problem. Otherwise, it could be the engine valves and compression system, which may require professional repair.

Conclusion

The walk-behind tractor can perform a very wide scope of work, but this requires certain efforts on the part of the owner of this unit. It is not only about replacing failed parts and components, but also about the timely adjustment of some units of the device.

In particular, the correct operation of the walk-behind tractor engine will depend on how correctly and on time the valves are adjusted.

And it doesn't matter if we are talking about a Honda walk-behind tractor, or a Vityaz 8 hp walk-behind tractor is being considered and its correct adjustment, we are talking about adjusting the valves on a diesel walk-behind tractor, or adjusting the valves on the forte walk-behind tractor is required ...

It is advisable to do this after each season, but there are times when such an adjustment is required at least twice during a given period of work. The main indications for this are atypical noise in the carburetor area, tapping - in general, uncharacteristic sounds during the operation of the walk-behind tractor.

If this is found, and if the valves do not keep the dz adjustment in the walk-behind tractor, then you need to immediately inspect and decide on the actions, especially since this procedure is quite simple and doable at home.

The cart for the walk-behind tractor is a useful device that you can assemble with your own hands.