Operation and storage rules

When you need to remove the chuck from the electric drill for the first time, be sure to read the instructions. This requirement seems to be self-evident, but a lot of drilling machines were damaged due to too rough efforts, "because they cannot be removed in any way."

Regardless of the modification of the chuck and drilling device, the replacement of chucks is carried out only after disconnecting from the mains. It is advisable to place the drill on a table or other flat surface so that it does not fall or break. Hold the drill with both hands during operation.

The power cord must not touch the drill or even the accessory. Before starting work, you should make sure that there is no hidden wiring in the walls and partitions. If it is still there, you need to have a clear idea of the wire routes.

When you have to drill often and for a long time, you should definitely use earplugs. When drilling in metal, protective goggles are required. When handling dusty materials, it is imperative to use a respirator or at least a regularly changed gauze bandage.

It is forbidden to store the drill in damp, cold rooms and in rooms with an unstable climate, especially on the street. It can be moved to the right place only in a special case, other containers are not suitable.

How to choose?

Having dealt with the main types of drilling machines, you now need to figure out how to buy the right model. This information, it is worth noting, does not only apply to Makita brand products. First of all, you need to decide where exactly to buy the drill. Each option has its own strengths and weaknesses. So, when buying on the secondary market (through advertisements or from friends), you can find out as much information as possible about a particular car, but there is a great danger of deception. In addition, there is definitely no guarantee for the tool. If it has been actively used for a long time or stored in improper conditions, breakdown will be inevitable in the near future.

It makes sense to contact large construction supermarkets and department stores if you need quality assurance first of all. However, in the absence of special knowledge, one does not have to rely on professional advice - for the most part “amateurs of a wide profile” work there. Professionals usually go to power tool shops that are well known to them. The salespeople working there can provide meaningful recommendations.

Having dealt with a suitable place of sale, it is now necessary to inquire about the configuration of the device. Along with drills, bits are often purchased that allow you to solve specific problems.

Most often, the kit should include the following items:

- stops that support the specified drilling angle and drill entry depth automatically;

- collet chucks that allow you to work with miniature drills;

- sawdust blowing devices.

Several models of drills under the Makita brand are worth considering.

- The 6501 version is capable of developing high revs (up to 4500 in 60 seconds). The hull is relatively small and weighs only 900 g. Depth gauge is provided. Steel structures can be drilled 6.5 mm and wood structures 9 mm.

- Of the corner drills, the DA6301 deserves attention. In addition, this design can also play the role of a mixer. Low rotation speed and solid torque make it safe to use when drilling "difficult" materials. And also the product manifests itself well when mixing a thick liquid. During continuous operation, 0.81 kW is consumed per hour.

If you need a drill with a diamond core bit, it is pertinent to pay attention to the DBM131. This machine is optimized for wet processing of concrete and natural stone.

The built-in motor develops power up to 1700 W. The device is designed in such a way that even under load the speed does not change. The diameter of the holes to be prepared can vary from 70 to 132 mm.

The 6300-4 drill is deservedly considered a universal device. It can be operated at 4 different speeds to handle a wide variety of materials. The parts that change the speed of rotation are very well thought out. Wooden structures can be drilled to a diameter of 30 mm. For steel, this figure is 13 mm.

How to remove the chuck from the drill (video)

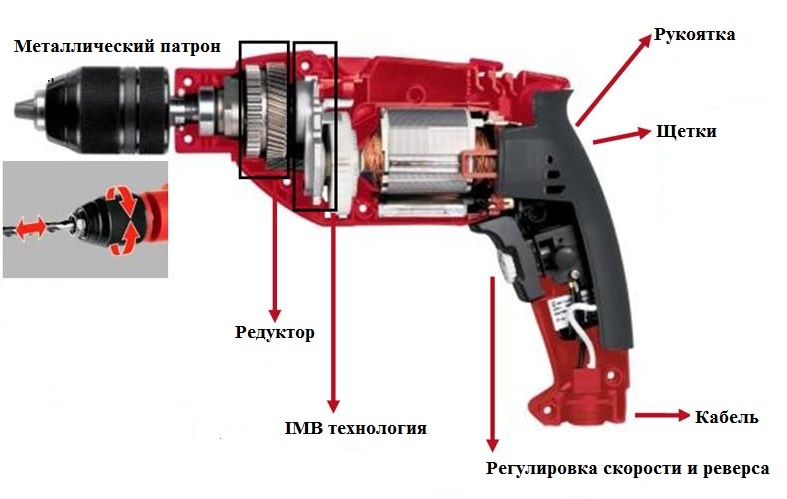

When choosing a drill in a store, pay special attention to the cartridge - it depends on which attachments you can use during the operation of the tool

It is also important to remember that with frequent work, a situation will arise when it is necessary to remove the cartridge, and it needs to be cleaned, lubricated. do it yourself and replacement... Therefore, in order to prevent problems with removal in the future, it is advisable to unscrew the new drill, and lubricate all parts with grease.

Therefore, to prevent problems with removal in the future, it is advisable to unscrew the new drill and lubricate all parts with grease.

Parsing a drill with a Morse taper

There are drill models in which the chuck is not used with jaws (jaw chuck), but with a threaded connection (or Morse taper). You can choose an adapter for it, or continue to work with such a cone - it all depends on your preferences.

In order to repair a drill or screwdriver, it is important to decide which cartridge. Their appearance is similar, so you need to look at the markings that are embossed on the surface of the part

If the chuck is marked with the letter B, this is a device with a Morse taper. In this case, you can remove the cartridge using a punch and a metalwork hammer.

Not everyone can disassemble a drill with a Morse taper

Not everyone can disassemble a drill with a Morse taper

In every Soviet electric drill, screwdriver there is a chuck with a left-hand thread, sometimes disassembly is needed if the self-clamping tapered shaft is jammed, or you need to get the machine head, change the screw, repair or the fastener is stuck. The drill also needs proper use and timely prevention.

With this tool, you can drill:

- Plastic;

- Tile;

- Wood;

- Concrete;

- Metal;

- Brick and other materials.

Most often, in a domestic environment, they use a rotary percussion drill. It includes a cartridge for the SDS system, which was invented by Bosch. Such a system is not particularly accurate. For more precise drilling, there are adapters that consist of jaw chucks.

Advantages

The Makita power tool, as practice shows, performs many works that are inaccessible to products of other brands. The reason for this superiority is not a simple increase in power (this is a dead-end path, as the size of the tool and its weight increase).

Makita developers prefer to achieve their goals through the use of modern technologies and original design solutions. They managed to achieve a high speed of basic manipulations. Thanks to the efforts of the engineers, it was possible to increase the torque, therefore, productivity increases significantly.