Double row hiller

The advantage is the ability to process two rows at once. With such an improvement, you can: speed up site maintenance, save work time, save fuel. To create a double structure, the following steps are taken:

- Prepare homemade hillers with racks.

- They are mounted on a square, horizontal bar. Such metal elements are easy to find.

The fastening process looks like this.

- It is necessary to cut out, cut out a strip of steel 2 mm thick.

- At each tip, rectangular slits are made.

- The canvas is bent in the middle so that this part can go around the square bar from the back at a right angle.

- A front, double eyelet is formed.

- The rack of the hinged device is threaded into it.

- A hole must be drilled in the mount in advance to fit the bolt.

- Holes are drilled in the cavity of the rod on the left, right side. The same distance is maintained between them.

- The threads should be cut by hand. It is advisable to work with a tap and a knob.

- In the back of the mount, through the thread made in the rod, the bolt is screwed in until it stops.

Note! The stand of the hiller, threaded into the eyelet, will gradually move. The element will be correctly fixed .. In the middle of the bar, a small stand is welded to ensure a rigid, reliable fastening of the suspended and walk-behind tractor

By moving the structure along the bar, the width of the rows is selected, carrying out double hilling. Due to the sliding wings, the dump mode is set

In the middle of the bar, a small stand is welded to provide a rigid, reliable fastening of the suspended and walk-behind tractor. By moving the structure along the bar, the width of the rows is selected, carrying out double hilling. Due to the sliding wings, the dump mode is set.

Potato processing

Weeding

A week after planting, you should loosen the soil. During this time, a dense crust formed on the ground, which interferes with the germination of plant stems and the access of oxygen. Weeding is carried out weekly. This helps to control weeds that negatively affect root crops.

For weeding work, a rotary or mesh harrow, tines and a weeding machine are used.

Hilling

Seedlings appear in 3-4 weeks. Now, after planting, you need to spud the potatoes. The walk-behind tractor will help with this. For hilling, one, two or three-row hiller is suitable. If desired, you can apply fertilizer by installing an additional nozzle.

Harvesting potatoes

The tiller is used not only for planting, but also for harvesting potatoes. By the fall, the potato tops dry up, and everything is ready for harvesting. You need to dig potatoes in August - September, in dry weather. For digging with a walk-behind tractor, a mounted plow or potato digger is installed.

But you can get by with a single-row hiller, which will raise the ground and the potatoes will lie along the edge of the ridge. It remains to go through and collect the potatoes. Planting and processing potatoes with a walk-behind tractor are far from all areas of its application. Technical innovations have greatly facilitated the work of summer residents.

The motoblock has now become a necessary tool for the cultivation of a land plot. The unit is well worth the investment. How you can use motoblocks, in addition to planting potatoes, you can see on the sites "Tips of the old plowman".

The choice of attachments depends on the requests of the owner.The example of planting, hilling, weeding and harvesting potatoes shows how the use of a walk-behind tractor simplifies life for gardeners.

Hilling with disc hiller

For motoblocks of the Neva, Centaur, Oka, Sich or any other models, there are several types of hillers. Their design completely solves the question of how to properly huddle potatoes in a short time and without much physical effort. They are:

- fixed grip when fixed width is set;

- with adjustable working width;

- with disc elements;

- with propeller attachments.

Among the listed modifications, the hiller with disc elements is especially popular. It is ideal for any models of walk-behind tractors.

Installing and configuring the hiller

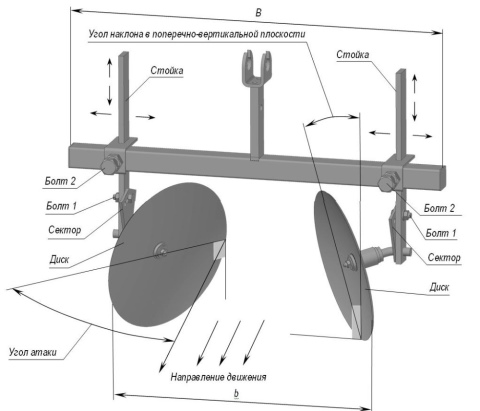

The hiller with disc elements has a simple design. It consists of the following devices:

- T-shaped leash;

- screw adjusters (with their help, the angle of inclination of the discs is regulated by a circle of the vertical rod);

- racks in the amount of two pieces;

- two disc elements.

The distance between the discs is regulated by means of stands. This makes it possible to set them to the required width of 30-70 cm and to hilling rows with different distances from each other. The disc elements are tilted using screw fixtures called turnbuckles.

An important point: in order for the hilling to be of high quality, it is necessary to install wheels of the required size on the walk-behind tractor. Their diameter should be 70 cm and a width of 10-14 cm. This will allow work to be carried out without damaging the plants, which reduces the level of crop losses.

The disc hiller is installed directly on the hitch bracket using a locking element, flat washers and two bolts. During operation, the walk-behind tractor should work at a reduced speed.

How to huddle with a disc hiller

The technology of adding soil under potato bushes using a hiller with disc elements is simple. The tiller is placed in the furrows so that the rows of potatoes are between the lugs, and is inserted exactly along them so as not to damage the plants. The discs pull together the earth and leave a roller behind them. Their rotation additionally breaks up clods and loosens the soil.

In practice, during the season, they make three hilling of potatoes using a disk unit based on a walk-behind tractor:

- 1st - when the plant grows up to 15 cm after planting;

- 2nd - when the height of the potato stalks reaches 25-30 cm;

- 3rd - when the plant has finished blooming (more soil must be poured onto the stems).

The main advantage of this type of hiller is that the soil embankment turns out to be a high slide. In comparison with other modifications, it is easy to use and gives a minimum load on the walk-behind tractor. This feature significantly reduces energy consumption.

Of course, you have to pay for comfort in work and savings. Such a unit is much more expensive in comparison with other modifications. But in the future, such an investment of money will fully justify itself 100%.

What walk-behind tractors can be used

Today, various models of walk-behind tractors can be used for planting potatoes. Each of them has its own distinctive features. Often, summer residents use the Neva walk-behind tractor. This is a reliable and unpretentious unit that is perfect for working at a summer cottage. Using such a walk-behind tractor, you can carry out various works in the country.

A similar principle is observed for the Bison and MTZ units. This is explained by the fact that the design schemes are the same and differ little. This suggests that planting potato tubers with the help of Bison can occur in two ways. MTZ walk-behind tractors remain no less popular today.

But how to get rid of the wireworm in potatoes using folk remedies, and what means should be used, this information will help to understand.

In the video - Bison walk-behind tractor for planting potatoes:

They are distinguished by reliable and durable parts. Such a technique rarely fails, since it uses high quality materials during its assembly.In addition, the unit is economical as it consumes little fuel. It remains a powerful species in its class. But how the vibrating potato digger is used for the Neva walk-behind tractor, this information will help to understand.

The following characteristics are characteristic of the MTZ walk-behind tractor:

- slight vibration;

- work is carried out with low noise;

- easy start;

- Ease of controls;

- environmental Safety.

MTZ is distinguished by its ease of operation. In addition, it is so easy to operate that even an inexperienced person can perform all the work. And its maintenance can be done quickly and easily, even with your own hands, thanks to which you can save money.

For planting potatoes, the Salute walk-behind tractor can also be used. This is a multifunctional unit, in which the cutter grip will be 80-105 cm. Salute is produced with several variants of gasoline 4-stroke engines from different manufacturers.

It will also be interesting to know if you can plant tomatoes after onions.

Planting potatoes is an important event in the life of every summer resident. You need to properly prepare for it.

Then it will be possible to get a high-quality high yield. To simplify your task, you can use a walk-behind tractor for these purposes. This unit allows you to do everything quickly, simply and efficiently.

How to get a good harvest of potatoes, how to plant them correctly

Types of potato ridgers

Types of potato ridgers to the tractor

Cultivator Mantis - a means of cultivating the land in the country

Video compilation

Planting potatoes with a walk-behind tractor greatly simplifies the work, greatly reduces the cost of physical labor. Additional devices - a potato planter, a hilling mechanism - are very useful and necessary if the potatoes are planted on a large area. But does the potato planter add tubers too often? And the depth of the furrow must be regulated. How will the potatoes sprout? And hilling is not of the same quality as manual. There is nothing to be done - the areas are large, you cannot do without the shown unit! The disc hiller is generally good. With a new furrow, the previous one is filled up. I think the walk-behind tractor shown is popular in the countryside.

The walk-behind tractor greatly facilitates work on personal plots, we plant potatoes in our garden under a plow, it turns out very quickly and well.

We constantly planted potatoes by hand under a shovel, and how much easier it is to work with equipment. Now we plant it into the comb using a disc hiller. The ridges warm up faster, seedlings appear earlier, and it is easier to huddle in the future. At the summer cottage, the walk-behind tractor does not stand idle.

If you have planted potatoes at least once, then you know how difficult and tedious it is. And planting with a walk-behind tractor, with the help of a mounted potato planter, turns into, one cannot say, pleasure, but at least not hard labor anymore. Easy and fast.

Variety of models

On the market of products for agriculture, you can find a manual hiller "Druzhba". It is equipped with adjustable fenders that allow you to change the working width, and the addition of a front iron support wheel. The equipment is operated by two operators. Product dimensions are 55 cm wide and 48 cm high. Unit weight - 17 kg. It is produced in the city of Cheboksary, and its cost varies from 3000 to 4000 rubles.

Another version of the hiller is "Tiani-Push", which is popularly called a manual plow. It is unregulated. The design of the tool allows them to cut furrows, weed weeds, and spud the planted potatoes. The product is 45 cm wide and 90 cm high (including handle). The unit has a weight of 7 kg. It is lightened by rubberized handles. The price of the instrument is from 1,500 rubles. It was produced in Kiev.

A popular hand-held tool is the "Hairdryer". The design provides for the ability to work with both two and one operator.The hiller is adjustable both in the height of the handles and in the width of the cultivated ridge. As an additional tool to the hiller, a flat cutter is offered, which is connected by a handle with ordinary bolts. Product dimensions - 16x40x40 cm, and weight - 10 kg.

Modern manufacturers offer flat cutters. This tool is a bent plate with sharpened edges. With the help of the equipment, you can remove weeds and loosen the soil. To weed several row spacings at the same time, several plane cutters are combined on a special hitch. On the market, it is called the wide row weeder.

The Tornado cultivator became famous among hand tools for loosening. It features a simple design with curved teeth connected to the handle. In relation to the base, they are turned counterclockwise. To work with the tool, it is enough to rotate it around the axis in a vertical position.

Instructions

I would like to start by considering the process of making a disc hiller, because this type of device is the most in demand today.

By setting disc sizes of different diameters, it is possible to huddle potato bushes of various lengths.

Disc hiller

Many people ask the question - how to make a hiller for a walk-behind tractor with their own hands? At home, this is quite possible if you follow certain recommendations. So, we will describe the manufacturing process in stages (for example, take a disk hiller for the Neva walk-behind tractor):

- For manufacturing, we need cutters from an old seeder, or metal sheets 2 mm thick. They are fastened using bearings with oil seals.

- You need to put them at an angle to each other. The distance between the lower parts of the discs must correspond to the track width of the walk-behind tractor. They are connected by welding, or using ordinary bolts.

- Here you need to follow a strict recommendation - the disks should be symmetrical to each other. Otherwise, the walk-behind tractor with a hiller will move to the side, which will significantly complicate the whole process of work.

- In addition to the discs themselves, the design of the hiller includes screw lanyards, a T-type leash and stands. Lanyards, in this case, perform the adjusting function of turning the discs along the vertical axis.

- A do-it-yourself hiller for a walk-behind tractor, the drawings and photos of which you see below, must be made in strict accordance with the dimensions. Of course there will be improvisation, but at the first assembly experience it is best to use other people's developments.

- Depending on the possibilities, it is possible to make a fixed and adjustable working width. The second method is more convenient, because you can change the disc spacing by simply rearranging the racks.

- To aggregate the hiller with the walk-behind tractor, you need to use the hitch bracket, on which there is no bead. The hiller leash is attached to the hitch with a stopper, connected with bolts and washers. The stopper itself is inserted into the square tube and then tightened.

Active hiller

To make such a hiller, we need exactly the same list of materials and tools that we used in the manufacture of a disk hiller:

- welding machine;

- sheet metal;

- Bulgarian;

- fastening connections.

Using a similar toolkit, you can make an active hiller for the MTZ walk-behind tractor, Plowman, Champion, Carver, Husqvarna, Lifan. The manufacturing principle is in many ways similar to the disk version:

- The axles also need to be adjusted to the parameters of the walk-behind tractor, and the parts themselves are welded using a welding machine.

- As previously reported, this type of hiller makes certain requirements for the walk-behind tractor. It should have two forward gears, as well as a PTO - a power take-off shaft. Many sellers of walk-behind tractors, speaking of the fact that a walk-behind tractor has two gears, mean one rear and one front.

- So when buying, you need to clarify this point.

- It would be expedient to manufacture several bushings with brackets, as well as additional blades made of metal.

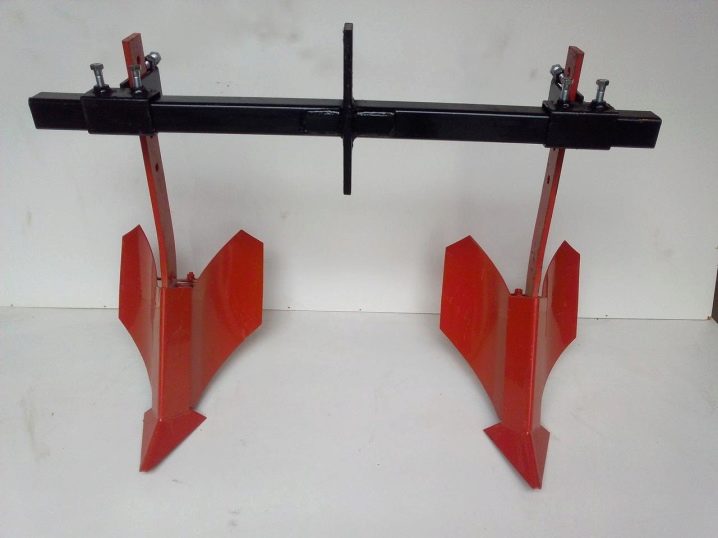

Double row hiller

A double-row hiller is the same lister type of a hiller, but in a double volume. Let's consider the whole process of work in stages:

- For work, we need a sheet of metal about 3 mm thick. From this material it is necessary to weld the base of the hiller.

- A 4 mm steel strip can be used as a bracket. The field board is made from a 5 mm thick sheet of steel.

- The stand of the hiller takes the brunt of the work. Therefore, you need to make sure that it is the most stable and reliable in comparison with the rest of the hiller.

- The hiller wings can be made from a sheet of steel with a thickness of 2 mm. They need to be bent slightly using a pipe of the desired diameter.

Otherwise, the manufacturing principle is completely identical to that of the fixed Lister version.

Potato planting instructions

Before proceeding with planting, it is necessary to prepare the soil. The site should be plowed with a plow or cutter and then harrowed with the same walk-behind tractor or manually with a rake. However, if the plowing depth reaches 20 cm, then it is not necessary to harrow.

The next stage of preparation is the marking of the rows: their width should be about 60-65 cm and is determined by the type of potato. Next, the holes are prepared for laying the planting material, and you can start planting.

You can plant potatoes using two attachments - a potato planter and a hiller. The principles of their work are very different, however, no matter what equipment is used, it must be remembered that the distance between the tubers should be at least 20-30 cm, and the depth should be 10-15 cm.

If planting with an adjustable hiller, move the blades before planting to maximize the grasp. The track should be at least 60 cm wide. Furrows are cut, then planting material is laid out in the holes. Having completed this stage, you need to install wheels on the walk-behind tractor, but leave the same track width. The tubers are covered with earth by the return passage.

If the land plot is large enough, it is more productive to use a potato planter for planting potatoes. This device includes a furrower, a conveyor, a planting material distributor and a disc hiller. Thanks to this, one pass is enough for planting - the unit prepares the holes, after the specified distances it puts the tubers into the ground and immediately fills them up.

Let's consider the features of each of them.

They have a fixed width of the soil execution and are used on very light motor-cultivators with a power of up to 4 horsepower. They are able to cultivate beds measuring 25-30 centimeters in width, equipped with two side wings and a thin stand. The stand protects the equipment from overloading and mechanical damage.

This implement can only be used on dry soils, as the adhering soil will interfere with the movement of the moving parts. Lister attachments are available with adjustable soil working width. They are installed on motor vehicles of greater power - from 4 horsepower. Similar aggregates can be used fearlessly on wet ground.

Double (2-row)

Carries out cutting of two furrows before planting crops, and is also used for hilling and loosening the soil. Includes a frame on which 2 hillers are fixed. When cultivating the land, it significantly saves time, since it has two working elements. It is mounted on a walk-behind tractor by means of a hitch. Due to the fact that such a device requires great resistance to operate, it is used in conjunction with lugs.

Rotary active

Instead of wheels, this tool is equipped with rotors with helical teeth.Demonstrates high productivity when creating, loosening and hilling potatoes. Suitable for use with 3-speed units (two forward and one reverse). In the first gear, the implement spills the landings, and in the second gear it also throws the soil out of the space between the rows of landings.

Single row

Planting methods for potatoes

There are two planting methods. They differ in the tools used:

- Hiller with a regulator

- Mounted potato planter.

Both options are equally popular with summer residents. It's just that the first option is used for a small area, and the second for a large one. But the first option is also cheaper. Well suited for those who like to save. So, let's take a look at each of them.

Motoblock with hiller

Its design consists of the following elements:

- Conveyor - a conveyor that delivers seed.

- Furrower - creates furrows.

- Distributor - with its help, the tubers are planted in a strictly specified period of time.

- Hiller - loosens the soil and covers the crop with earth.

This tool works according to the following principle. Before starting work, metal wheels and a special hopper are installed on the tool. The wheels create furrows. They should be even, then the growing process will be simplified.

Potatoes are placed in the bunker, which, when moving, will fall out into the holes. After that, the wheels are replaced from grouted to rubber ones and they are installed along the track width. This will prevent damage to the root crop.

Further, the hiller covers the potatoes with earth, simultaneously tamping it down. In addition to manually adding tubers to the hopper, the entire planting process takes place automatically.

Mounted potato planter

Before using the potato planter, you will have to carry out a preparatory stage for planting. First you need to plow the land. Then harrow so that the crop receives the required amount of water and oxygen. After that, you need to moisten the soil (if possible).

This type of walk-behind tractor has the following design:

- furrow makers;

- special bunker;

- disc device for backfilling potatoes with soil.

The structure of the motoblock-hiller allows you to plant potatoes in one approach, since the tool simultaneously makes furrows, pours out the tubers and covers them with earth. Before use, you need to attach special wheels for grabbing the soil and an additional attachment - a potato planter.