How to make a snow shovel

Prices for snow removal tools can be different: democratic and very significant.

Prices for snow removal tools can be different: democratic and very significant.

If you have free time and desire, you can make this necessary equipment yourself. A wooden homemade tool will turn out no worse than purchased at a retail outlet. To create a snow removal tool, you can use the material at hand, which can be easily found in the country shed. In order for a snow shovel to be useful with your own hands, it will take only 3-4 hours.

Required materials and tools

The following tools are required for manufacturing:

- plywood sheet;

- a bar for obtaining a cutting, 1.5 meters, 30 * 40 cm;

- edged board, 40 cm long and 3 cm thick;

- galvanized iron (tape) of the same width as plywood, at least 5 cm thick;

- nails (15 mm), wood screws (3 cm).

Step-by-step manufacturing instructions

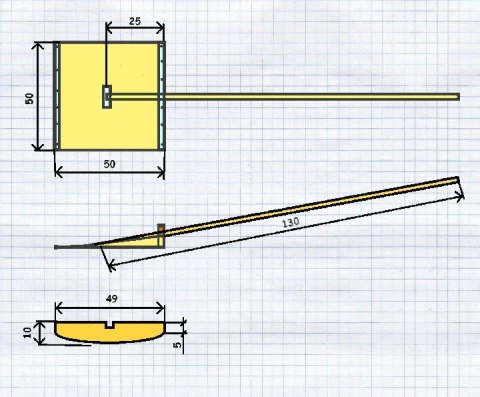

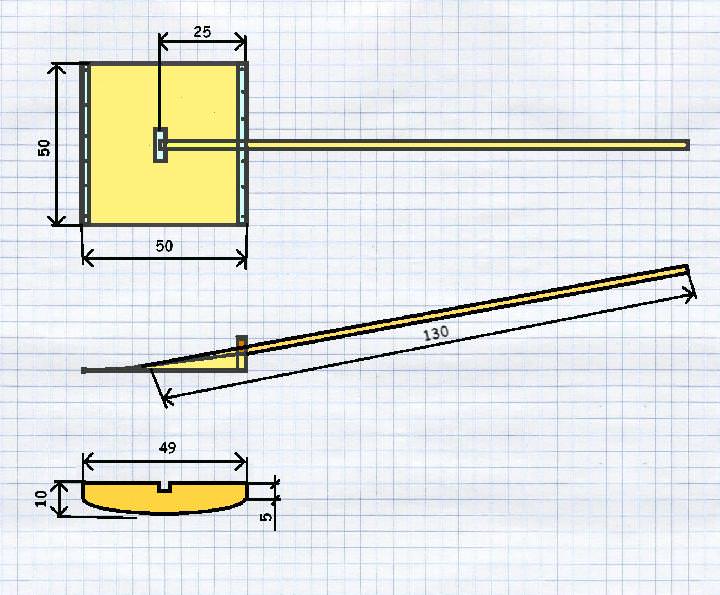

First, cut a piece of plywood to the desired size.

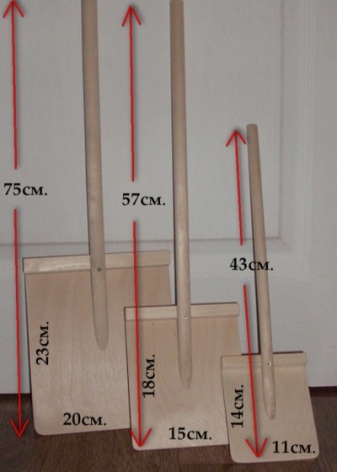

For an adult man, a sheet of plywood with a size of at least 50-50 cm is required.If the snow needs to be removed by a woman or a teenager, then these dimensions should be reduced to 30 * 30 cm.Children's snow-removing equipment will need to be made even smaller and must be made of plastic or plywood. so that its weight is insignificant.

For an adult man, a sheet of plywood with a size of at least 50-50 cm is required.If the snow needs to be removed by a woman or a teenager, then these dimensions should be reduced to 30 * 30 cm.Children's snow-removing equipment will need to be made even smaller and must be made of plastic or plywood. so that its weight is insignificant.

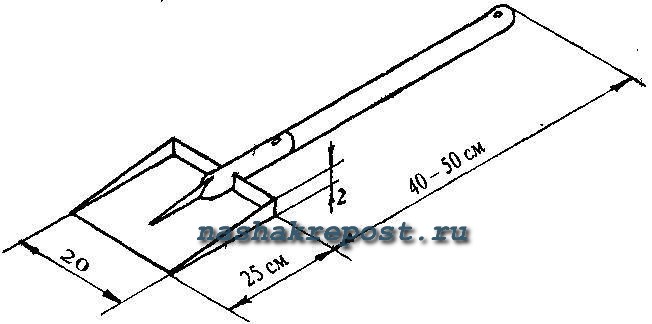

Next, proceed to the rear wall of the future bucket. It is obtained from a piece of edged board. An arc is drawn on the board evenly from one edge, and then a cut is made along this border. You need to get slightly rounded edges on the board to give the bucket a semicircular shape.

In the center of the back wall, draw a place for the holder to pass with a pencil.

The shape of the cut will depend on the shape of the cutting. If a rectangular bar is used as a holder, then the hole will need to be made of the same shape and size around the perimeter. For a round shank, it is necessary to make a round hole of the same diameter as the shank. You can make this hole with a jigsaw. If such a tool is not at hand, then you will have to use a hacksaw and a chisel.

At the end of the cutting, an oblique cut is made for it to fit snugly against the face of the plywood. The finished wall of the future bucket is attached to the plywood sheet with nails.

And it is also recommended to equip this tool, which is necessary in the household, with edging boards. This will require a beam that is the same length as the plywood and the width of the transverse wall that was recently attached longitudinally to the plywood. For the sides, it is necessary to cut the beam in half diagonally, in order to obtain two long triangles as a result, which will play the role of side walls.

Such a shovel will allow you to remove fluffy and loose snow.

You can give plywood strength using galvanized tape. This material may remain after roofing work. And also this tape can be obtained from a regular tin can. It is necessary, putting on protective gloves, take metal scissors and cut the tape of the desired width.

You can give plywood strength using galvanized tape. This material may remain after roofing work. And also this tape can be obtained from a regular tin can. It is necessary, putting on protective gloves, take metal scissors and cut the tape of the desired width.

The galvanized material is bent in half and hugs the edge of the plywood, which will be subject to the greatest wear. With the tapping movements of the hammer, the maximum permissible adhesion to the plywood sheet is obtained and the tape is fixed with nails.

When the bucket is ready, a handle is attached to it. One edge of the holder, where the oblique cut is made, is passed into the hole in the front wall of the bucket and fixed with wood screws: clearly in the center of the plywood from the front side.

To create more comfortable operation of the tool, you can build a handle at the end of the holder. This additional accessory can be temporarily removed from the shovel, which is used in the spring and summer season.

To create more comfortable operation of the tool, you can build a handle at the end of the holder. This additional accessory can be temporarily removed from the shovel, which is used in the spring and summer season.

A shovel for snow removal with your own hands can be made of galvanized sheet, at least 5-6 mm thick. It is carried out on the same basis, only a metal sheet is used as plywood. By the way, an old baking sheet can be used as a material for making a bucket of a snow blower tool. In this case, a super drawing for marking a piece of plywood or metal is not required. Which tool is the best to make for cleaning snow, you decide.

Characteristics of types of snow shovels

Mechanical shovels do not have a motor, so they can easily be made by yourself. Shovels for cleaning the area from snow in winter differ not only in the materials from which they are made, but also in their purpose. A metal snow shovel is made from the lightest, but rather reliable metals or alloys, therefore, it is currently the leader in the market for snow removal hand tools.

The most popular are aluminum models, which, however, are not reliable enough if they are used to remove a large amount of ice. The advantages of aluminum can be considered the relative lightness of the shovel. The steel tool is quite heavy, but as strong and reliable as possible, especially if a galvanized surface is present. Modern metal alloys keep the tool weight low and give it maximum strength.

Modern markets offer the domestic consumer a fairly wide selection of working tools made of modern plastics. Plastic snow plowing tools are very easy to use. The presence of a smooth surface does not allow the snow mass to stick, which greatly facilitates the work. Among other things, the tool is available in a wide range of colors and sizes. Sizes can be different, and it is from this material that the classic children's shoulder blade is made. The main and most significant advantage is the light weight of plastic shovels and their high wear resistance. The disadvantages include fragility.

A wooden or plywood snow plow is by far the most inexpensive option. Wooden shovels for cleaning snow from the local area can be easily made even with your own hands, but this type is short-lived and can only be used when it is necessary to clean up freshly fallen snow. The accumulation of snow on a wooden surface makes it difficult to work with such a tool, and high humidity often causes plywood to split. The best proven scrapers are those fitted with a protective metal edge on the tray. Among other things, such cleaning equipment requires careful storage and mandatory drying.

The principle of operation and features of operation of a benzene blower for snow

The category of metal snow blowers includes interesting mechanical models with a built-in auger. Such a tool allows you to perfectly cope not only with loose and shallow snow, but also with a wet snow mass.

It is important to remember that any metal snow blower can damage the cleaned surfaces, including expensive ceramic tiles in the local area. Such modern mechanisms do not depend on gasoline or electricity.

In recent years, snow benzopaths have been increasingly used. The components of such models are represented by an engine, a fuel tank, a starter motor, a wheel and auger drive system, as well as a shovel-bucket for capturing the snow mass.Among other things, the mandatory elements are represented by auger or rotor-milling mechanisms, an impeller for ejection of the collected and crushed snow mass, a guide pipe for ejection, a handle for controlling movement, as well as buttons for switching on and regulating the operation.

The principle of operation is represented by the ability of the bucket of the machine, when moving, to capture snow from the surface to be cleaned and direct it into the ejection pipe, which is located in the central part of the bucket. The tool class influences the characteristics of the ejection system, which can be one-stage, two-stage or three-stage. The first version of the design involves ejection of snow with the help of the auger itself, without the use of additional devices.

In two-stage systems, an impeller is provided, which prevents the pipe from filling with snow, and also increases the throw distance. Three-stage models are able to break up the largest pieces and effectively grind into small chips by means of an additional special auger, which is located in the central bucket part, made of high-quality and high-strength plastics or metal. The auger blades have rubber or metal parts with rubber pads, which provide a gentle effect on the surface to be cleaned.

Selection recommendations

In order not to be disappointed after purchasing a snow shovel, it is recommended that you familiarize yourself with some important criteria for choosing this tool. With the help of them, the owner will not only be able to choose an option that will cope with the task at hand and will meet his requirements, but will also save a significant amount. Since, having chosen a high-quality shovel, she will not have to look for a replacement after some time.

The dimensions of the tray are an important characteristic when choosing a shovel.

First of all, you need to take into account your physical capabilities. Having given preference to a shovel with a wide tray, which, although it will allow you to collect a fairly large amount of snow, will still exert a very serious load on the owner's back and shoulder joints

However, this disadvantage can be solved thanks to the small wheels. This type of shovel can be purchased ready-made or made yourself. It should be noted that the standard tray size is 40 centimeters.

- The slope angle affects the comfort when working with a wooden shovel. The tilt of the implement base can be used as a lever. This will greatly facilitate and speed up snow removal. The best option is a shovel with an angle of inclination not exceeding 20-25 degrees.

- The length and weight of the cutting will affect how quickly the owner gets tired of cleaning the snow. The fact is that the comfort of this process ensures that there is no need for a person to constantly bend over and unbend. Therefore, it is recommended to give preference to a long and light cuttings. When buying, it is advisable to carry out several strokes with a shovel in order to get an idea of which product you will have to work with.

- The sides are an equally important criterion for a snow shovel. Their presence will allow you to keep a large amount of snow when clearing it. Thus, maximum precipitation will remain on the surface of the tray, and the process will take less time. It is advisable to give preference to wooden shovels with deep sides.