Modernization of children's vehicles

And of course, all the best for children. On the basis of a screwdriver, you can make the modernization of many children's vehicles. For example, convert a children's pedal car into an electric car.

Electric car

To make an electric car you will need:

- Frame made of steel profile tube. You can make it yourself.

- The wheels can be used from a rubber-tipped garden cart.

- The body can be taken from an old pedal car or come up with some creative solution. For example, solder from plastic pipes.

- As an electric drive, you must use two motors from screwdrivers and a gearbox from the same power tool. Separate housings are made for them, in which the output shaft is mounted on 201 bearings.

- Battery. You can use a regular car 6ST60.

After all the components are prepared, it remains to assemble the electric car. This process is simple and within the power of every man who has even a superficial understanding of plumbing.

Electric scooter and electric bike

Another use of a screwdriver in the creation of vehicles can be called an electric scooter or an electric bike. The principle of such modernization is based on the installation of a chain drive between the wheel sprocket and the sprocket of an electric motor with a screwdriver gearbox. This device is powered by the hand tool rechargeable battery. This solution is not expensive. As a result of the improvement, a vehicle with a travel speed of 5 to 15 km / h is obtained.

Electric snowmobile

With the help of a screwdriver, you can make not only transport on wheels, but also a real snowmobile. You need to use an electric car for this, having carried out a number of appropriate upgrades. It is necessary to improve the frame of the electric vehicle to install the drive wheel on it. Instead of driven wheels, you need to install skis, replace the plastic steering wheel of the car with a metal bicycle handlebar. The drive wheel is driven through a chain drive from a screwdriver.

Assembling such a miracle technology will not take much time, and most importantly, money. All costs will pay off with the joy of the child, for whom an electric vehicle will be a real gift.

Cool ideas and life facts for using a screwdriver in the household

In addition to the listed mechanisms, the screwdriver can be used to implement other ideas on the farm. This handheld power tool will help automate gate opening, car winch or metal shears. If you attach to it a nozzle for cutting tin, you can turn an ordinary rubber boat into a motor boat, modernize the process of drilling holes when ice fishing. In addition, everyone knows that a screwdriver is used as a drive for a mixer, meat grinder or juicer.

After reading the article, the reader gained knowledge about the unconventional use of a screwdriver. Now he can use this hand tool to create carpentry equipment, improve children's vehicles and other useful things in the household.

Carpentry equipment

A few more interesting suggestions on how to make equipment for home carpentry based on a conventional screwdriver.

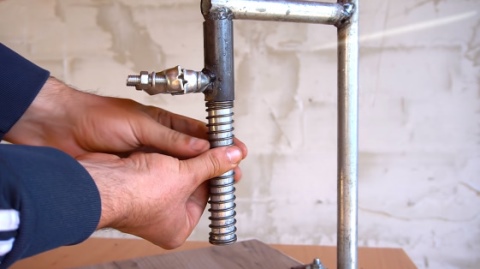

Wood lathe

When making wood products, it is difficult to do without a lathe. You can build it yourself. A flat wooden workbench is ideal for the bed. A screwdriver can be used as a headstock and rotation drive. In a wooden bed made of a bar in the shape of a screwdriver, you need to put the tool and fix it with a clamp. The bar can be fixed with a clamp, and with constant use of the machine, screw it with self-tapping screws. A tooth holder must be inserted into the chuck. The tailstock is made of two bars with an adjusting screw, which is sharpened under the taper. It is installed opposite the fixed screwdriver so that the axis of the tool coincides with the axis of the tailstock adjusting screw. The backgauge structure is secured with a clamp. If you plan to handle large parts, then the fastening should be more reliable. The hand-hand can also be made from a bar by fixing it to the workbench with a clamp. A primitive lathe for a home workshop is ready.

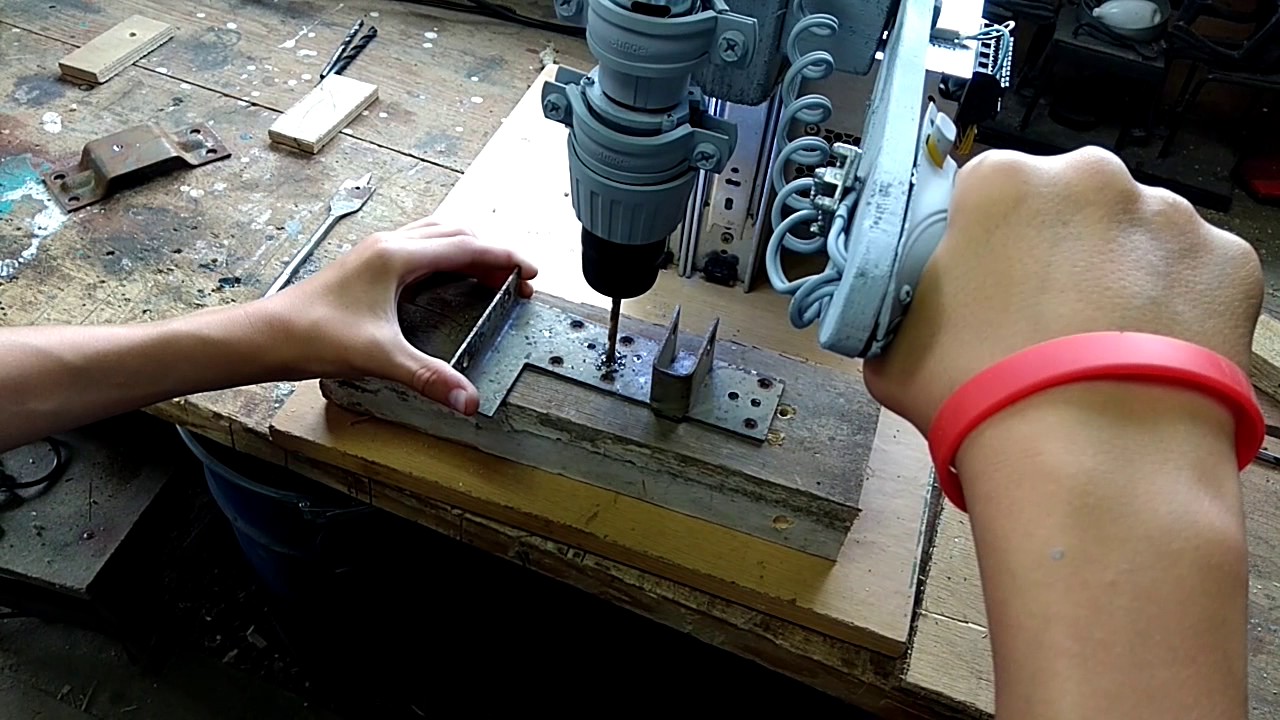

Bench drilling machine

Drilling is another equally important equipment. It can also be made from a screwdriver. To do this, you need a used screwdriver. From it you need to take a motor with a gearbox and a cartridge. Now you need to make two clamps of textolite, which will perform the function of fixing the drilling head of the machine. To achieve maximum alignment of all the holes on the clamps, it is better to process them together, in one set. Then it will be possible to avoid distortions.

Bushings with an internal thread are used as limiting struts. They must be the same size, corresponding to the distance between the clamps. After that, another clamp is made of textolite and two bosses of caprolon. They are drilled off-center to form two eccentric bushings. The clamp is installed on the bar and the backlash is selected with the help of eccentrics. After that, a wooden lever is installed on a spring so that the drilling head returns to its original position. To supply power, you must use a transformer with a capacity of more than 150 watts and an output voltage similar to the used screwdriver. After that, you need to put a diode bridge and a capacitor, install the drilling head on the bed.

Manual router from a screwdriver: step by step instructions

It can be converted into a hand router. You do not need to purchase expensive materials for this. Everything you need can be found in the workshop or garage almost under your feet. To equip a hand router from a screwdriver, you will need pieces of thick plywood or chipboard, a clamp for attaching a tool, fasteners in the form of bolts and self-tapping screws, a locksmith's tool and a feather drill for wood. In the latter case, you can use a drill bit.

Assembling a homemade router is pretty easy. This requires:

- From the pieces of the selected material, cut out the base, the vertical stand, on which the screwdriver, the stop and the gusset will be fixed with the help of a clamp to make the structure rigid. The dimensions of the parts are chosen arbitrarily, in relation to the dimensions of the power tool.

- Drill a Ø 40 mm hole in the base using a feather drill for free access of the cutting tool to the processing area.

- Make a clamp to the diameter of the hand tool.

- Fix the screwdriver on a vertical stand with a clamp so that its cartridge is at a distance of several millimeters from the base.

- Install stiffener.

- Fix the screwdriver on the vertical stand with a stop.

- Insert the cutter into the tool holder.

The screwdriver router is ready to use. Such a machine will not be able to become a full-fledged replacement for a hand-held milling cutter due to its low power and low spindle speed, but it will solve the issue of milling small parts in a home workshop.

Circular Saw

In addition, for your carpentry workshop, you can make a circular from a screwdriver.To do this, you need to make a work surface by applying chipboard sheet or thick plywood. A cut must be made in the table top to exit the circular saw. The screwdriver must be securely fastened to the underside of the work surface using metal or wooden clamps. In the same way, it is necessary to fasten the shaft.

It is important that the saw blade protrudes no more than a third of its diameter above the working surface of the table.

Boat motor

How pleasant it is to ride a boat in warm summer weather. One bad luck - I don't want to take the oars in my hands. Savvy comes to the rescue.

But what if we adapt the motor from a screwdriver to the boat using the tools at hand?

What is easier to apply the following materials for this "idea":

- Screw (rabbit):

- Long metal hairpin;

- Battery-powered screwdriver.

The essence of the idea is as follows. In the rabbit (in this situation, the propeller), drill a hole in diameter equal to the metal hairpin. The screw is mounted on a stud and is securely fastened. The longest pin itself is inserted into a screwdriver, which turns the pin along with the screw. The boat engine is ready!

All that remains is to come up with some kind of metal structure that will allow you to securely fix the screwdriver on the boat itself. But this is too easy a task to discuss. And every amateur will be able to show their inventive abilities in this matter.

We lower the screw on the hairpin into the water and turn on the screwdriver. All that remains is to sail slowly and enjoy the beauties of nature that you see around. There is only one thing - really assess the capabilities of the batteries and "do not swim for the buoys."

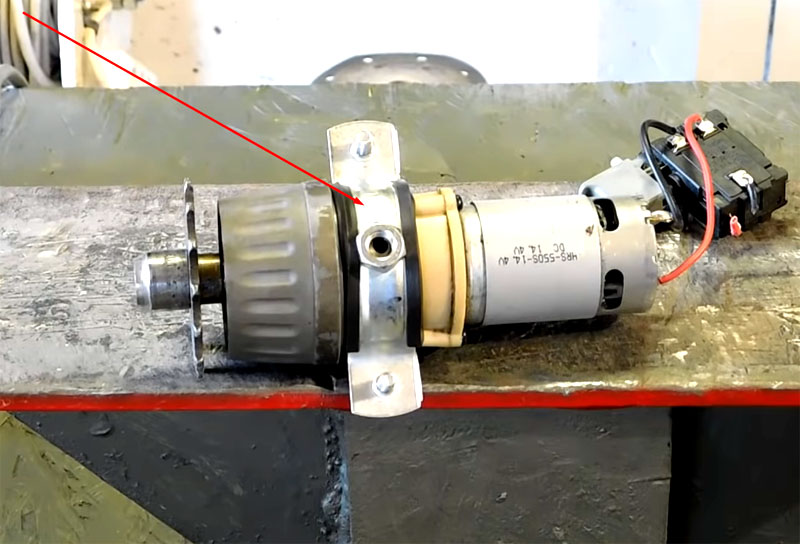

Preparing the electric bike drive

The first step is to dismantle the chuck from the remains of the screwdriver. It is extremely simple to do this, and therefore it makes no sense to describe this action. Then a thrust nut is screwed onto the shaft. It serves to prevent the installed sprocket from touching the body. By the way, it makes sense to immediately rearrange the position of the power regulator to the "drill".

PHOTO: youtube.com An internal thrust nut is installed on the shaft

PHOTO: youtube.com An internal thrust nut is installed on the shaft

Next, you need to put an asterisk on the drive shaft of the engine and fix it with a second nut, which can be removed from the chuck. But if everything is left as it is, the locking nut will loosen when moving. Therefore, at first it is thoroughly pulled, after which a screw with a reverse thread is screwed into the internal thread of the shaft. Such a system will ensure that the sprocket is fully secured and eliminates the risk of the outer nut loosening while driving.

PHOTO: youtube.com The second nut is fixed with a reverse thread screw for reliability

PHOTO: youtube.com The second nut is fixed with a reverse thread screw for reliability

Fastening the engine to the bracket

Now it remains to understand how the electric motor will attach to the bracket that will be installed on the bike. Everything is extremely simple here. For this, an ordinary plumbing clamp will be used, designed for sewer plastic pipes with a diameter of 50 mm. From it, unscrew the stud with the anchor, and put the clamp itself on the motor housing. The photo example below shows how this is done.

PHOTO: youtube.com The plumbing clamp is perfect for attaching to the bracket

PHOTO: youtube.com The plumbing clamp is perfect for attaching to the bracket

This completes the preparation of the electric motor, you can proceed to the manufacture of the bracket.

Epilogue

This is how you can assemble an electric bike at no cost. Of course, additional work is needed here, but the foundation is already there. It's fun to watch people react when they see such an interesting vehicle. Still, it is not clear what is moving along the road. In fact, if you work on a bike for a couple of days, it will not be inferior to expensive factory products in almost anything. Considering that all the work is done “on the knee” in one day, without financial investments, it is safe to say that the idea is very good.

We hope that the material presented today will be useful to the dear reader. If you still have questions about what you have read, you can ask them in the discussions below. HouseChief editors will be happy to answer each of them as soon as possible. There you can also comment on the article, express your opinion about the rework. Tips for improvement, as well as pointing out wizard errors, are welcome. And we have one request. Please do not forget to rate what you have read.

Every opinion, both positive and negative, is very important to us. Enjoy your bike rides!

Use in the garden

We are part of nature. How harmoniously each of us feels in the garden, at the dacha or in the personal plot. An evenly mowed lawn, weeded beds delight our eyes. However, it is very difficult to achieve such a result manually. An aching back, fingers cut by grass can be excluded from your life if you apply ingenuity and use the most primitive tools to design a garden trimmer, or a lawn mower, as we are used to calling this tool.

It is very easy to make such a trimmer. For this you need:

- Cordless screwdriver;

- Body polishing disc;

- Two stationery blades;

- Two screws.

It literally takes a couple of minutes to create a tool. Two clerical blades are screwed onto the body polishing disc with screws. Only they are screwed on not rigidly, but so that they can easily "dangle". This type of connection allows the blades not to break, but to lay when in contact with an obstacle. The disc itself with the blades already attached is installed in the screwdriver, naturally with the cutting tool down. The tool is ready to go!

Such an amateur trimmer will allow you to mow the grass in hard-to-reach, narrow places, in the aisles or where there are partitions. Of course, the undoubted "plus" is the saving of time and effort that you spend on manual weeding. There are only two drawbacks - you still have to bend over and cut the grass in this position, and then pick it up by hand.

There are also specific features. With high grass such a tool, you need to "fight" in a special way. Cut off the top first and then the base, as long grass can get tangled at the base of the disc. Then it must be removed manually.

Assembling an electric bike from an old screwdriver

When all the parts are prepared, you can go directly to the assembly. But first you need to prepare the bike itself.

Some details are removed from it, namely:

- pedals (they are no longer needed);

- trunk (will be rearranged forward);

- chain (you still have to work with it).

Now the bike is ready, and you can start. The bracket is fastened to the "ears" on which the trunk was fixed. In this case, the foot should rest against the frame.

PHOTO: youtube.com The bracket is already in place, it remains to install the engine

PHOTO: youtube.com The bracket is already in place, it remains to install the engine

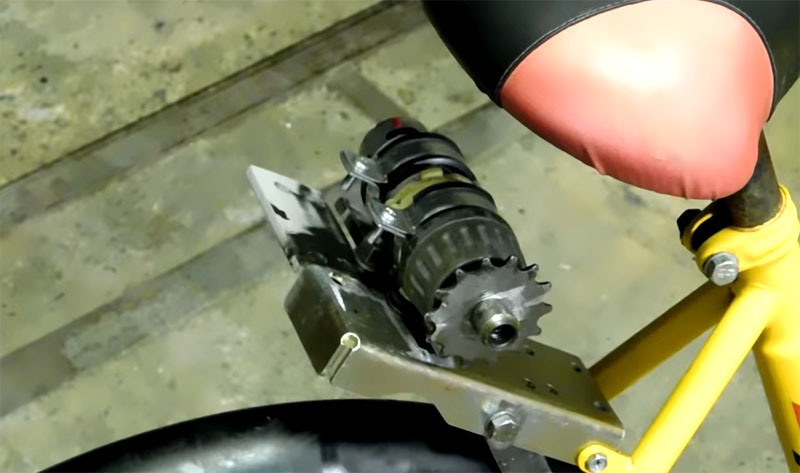

Installing the motor on the bracket

Everything is simple here. The motor is fastened to the platform through the slot with a suitable bolt. You do not need to stretch the connection at this stage.

PHOTO: youtube.com Engine in place, but no connection

PHOTO: youtube.com Engine in place, but no connection

Adjusting the chain to length

The chain removed from the bike will have to be adjusted in length by removing the extra links. Ultimately, it should sag a little for the possibility of improvements.

PHOTO: youtube.com The chain needs to be adjusted in length by removing the extra links

PHOTO: youtube.com The chain needs to be adjusted in length by removing the extra links

Chain tension adjustment

The bracket is movable, so you need to lift it up, move the stop tab and fix all connections in the desired position.

PHOTO: youtube.com The chain is taut, the connections are fixed, now there will be the most interesting

PHOTO: youtube.com The chain is taut, the connections are fixed, now there will be the most interesting

Installation of electrical equipment

The button for turning on the electric motor must be installed on the steering wheel, which means that you will have to lengthen the wires. To do this, you can use a conventional soldering iron. The conductors themselves should be routed in a corrugation for protection.

PHOTO: youtube.com The wires need to be lengthened to be able to install the button on the bicycle handlebars

PHOTO: youtube.com The wires need to be lengthened to be able to install the button on the bicycle handlebars PHOTO: youtube.com The button is conveniently fixed on the steering wheel

PHOTO: youtube.com The button is conveniently fixed on the steering wheel

Along the way, the power wire is also removed, which will go to the battery.

Installing and connecting the battery

It's time to install the trunk. It is needed to house the battery. It is easy to place it over the front wheel, just screw in 4 fixing screws. Almost all bicycles have such a reinstallation.

PHOTO: youtube.com Rear trunk mounted above the front wheel

PHOTO: youtube.com Rear trunk mounted above the front wheel

A car battery is placed on the installed trunk, to which the wires from the button are connected. The battery itself is securely fixed with brackets so that it does not slip while driving.

PHOTO: youtube.com AKB is in place, assembly is complete, it's time to go

PHOTO: youtube.com AKB is in place, assembly is complete, it's time to go

Screwdriver as a generator

The screwdriver can be used as a generator. This is very easy to do. It is necessary to remove the battery, connect the wires to the terminals using crocodiles and connect them to the consumer. Be sure to first check the polarity with a multimeter. Insert and tighten the hex key into the chuck to assemble the furniture. By rotating the spindle, a current will be generated, which will be supplied to the consumer. True, it is worth noting that the voltage generated by this electric machine is only enough to charge a mobile phone or operate a small LED lamp.

Bracket for attaching the electric motor to the bike

For the manufacture of this part, you will need a metal plate and a section of a channel. Finding such parts is not difficult in the garage or at any metal reception.

PHOTO: youtube.com These are the steel parts needed to make the bracket

PHOTO: youtube.com These are the steel parts needed to make the bracket

These parts must be welded together, after which a slot must be made in the plate using a grinder. It will serve to fasten the electric motor with a bolt. A regular hole will not work here, the mount must be movable so that you can align the drive and driven sprockets. If you do not set it up, the chain will fly off, not allowing you to drive even a meter.

PHOTO: youtube.com The details are welded, the groove is cut, there are a couple of little things left

PHOTO: youtube.com The details are welded, the groove is cut, there are a couple of little things left

A persistent foot, and what it is for

The manufacture of the support foot of the bracket is a purely individual process for each model and brand of bicycle. In the photo example, a similar detail will be shown so that the reader understands how it looks. And it will serve to adjust the chain tension. The thrust lug is attached to a bolt with a nut, the connection remains movable until fully tightened.

PHOTO: youtube.com The curved steel strip serves as a stop foot for adjusting the chain tension

PHOTO: youtube.com The curved steel strip serves as a stop foot for adjusting the chain tension