Advantages and disadvantages of a rolling jack

The main advantages of sliding hydraulic lifts include:

- High efficiency value.

- Good carrying capacity with small dimensions of the device. This is made possible by the horizontal arrangement of the cylinder and the removable handle.

- Smooth movement of the lifting mechanism. The stock moves very neatly, slowly raising the car to a sufficient height. Due to the presence of a shut-off valve, the load is secured at any lifting height.

- Excellent stability due to the large support area.

- The convenience of use.

- Cleanliness of work. There is no need to lie under the car, as is often the case with other types of jacks.

The disadvantages of a hydraulic lifting mechanism are:

- Slow ascent, since it is possible to raise the car to a small height in one cycle. While smooth ascent has been considered a virtue, speed is sometimes necessary.

- The pressure in the main cylinder can be relieved and the load can be lowered.

- In winter, at subzero temperatures, the hydraulics freeze. Although for off-season rubber changes this is not particularly critical, as, indeed, for work in a car service or a garage with heating.

- Expensive repairs and short service life. Without periodic maintenance and with improper operation, the structure becomes insufficiently durable.

- Needs costly ongoing maintenance.

- Low lifting height.

- When operating this kind of mechanisms, a flat solid surface is required: concrete or asphalt.

Peculiarities

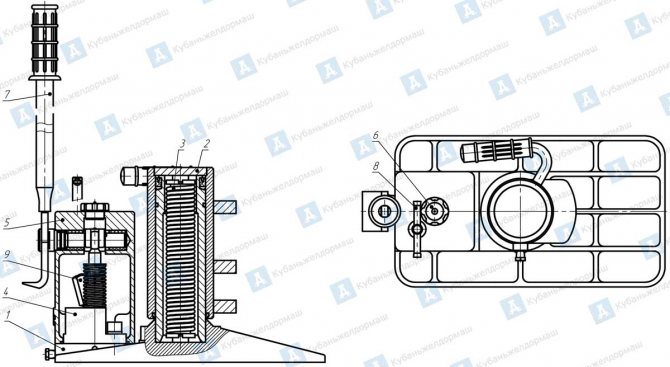

Technical characteristics and working principle rolling jacks are determined primarily by the elements of its design. Lifts belonging to the described category have the following parts.

- Jack body, which can be aluminum or high quality steel. It is worth noting that professional models of lifting equipment have a more massive body, which is due to operating conditions.

- Swivel support platform.

- The rod of the working hydraulic cylinder, which is responsible for the movement of the platform.

- The main hydraulic cylinder, which is the main unit.

- Rotary handle that acts as a pump lever. Most often, to ensure comfortable operating conditions, this element is made removable.

- Plunger acting as a hydraulic pump.

- The screw that controls the function of the drain valve, with which, by gradually decreasing the pressure in the system, the raised vehicle is lowered.

- Spring that returns the piston to its original position when pressure is released.

- Some models can be equipped with a removable or stationary handle for transporting the device.

- A protective cover (cover), the main function of which is to prevent dirt and dust from entering the hydraulic cylinder rod.

- Wheels.

- Scissor arm system.

- Many lifts are equipped with maintenance cuff kits.

A mobile car lift is a hydraulic system, that is, a device whose principle of operation is based on a change in the pressure of the working fluid in the system.

The force applied to the lever is multiplied by the valve system and the presence of communicating chambers. The stem is driven by the appearance of oil in the cylinder, the reverse movement (outflow) of which is prevented by the check valve.To lower the platform, it will be necessary to turn a special screw that opens the valve, with the help of which the pressure of the working fluid in the cylinder is reduced.

It should be noted that for all their advantages, the described lifts have one design feature. They are relatively small in height, but this, in turn, provides the devices with increased stability. A sufficiently large area, among other things, is responsible for the maximum strength of the entire structure.

It is also worth paying attention to the shut-off valve. This element is designed to fix the jack, and therefore the load in a certain position.

Extremely reliable in this context will be models with clamps, which allow you to hold the system at the desired height without much effort.

How to choose a quality tool

It is important to take into account the maximum lifting height: this characteristic shows to what maximum height a given double-rod jack can lift a load. The most common indicator that can be found in the characteristics of rod jacks is 300-500 millimeters. This is enough to effortlessly replace a wheel or handbrake cable.

Double-rod jacks are also capable of lifting to great heights - up to 1 meter - this will be especially appropriate in off-road conditions. On the Russian market, the BelAK BAK.20046 12t model has the highest lifting height (600 mm).

You also need to pay attention to the pickup height: this property indicates the minimum height from which the ascent begins. The smaller it is, the more functional the jack is considered.

The most common limiting range is 60-250 millimeters. This characteristic must be taken into account depending on the vehicle's ground clearance - the distance between the wheel bearing point and the lowest part of the vehicle body.

Note!

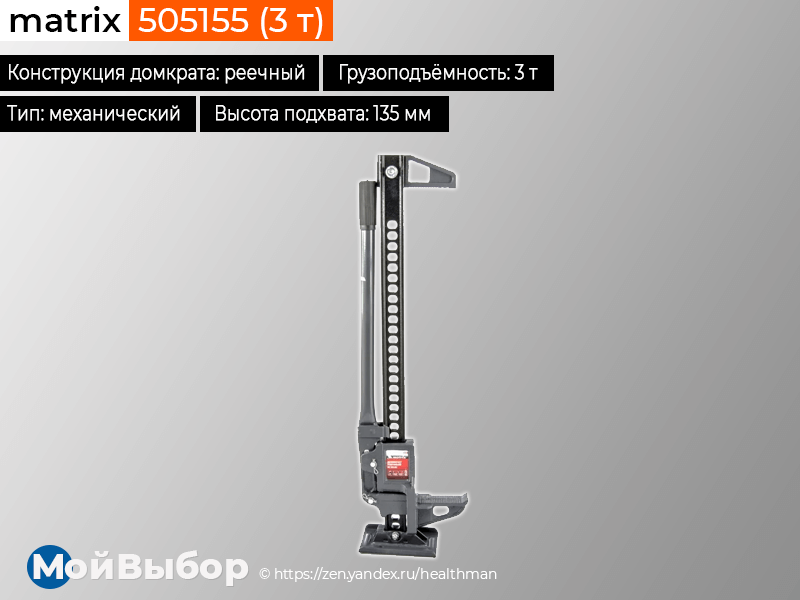

Some models of double-rod jacks can lift from a height of 60-90 millimeters, but most often this parameter starts from 160 mm. The more weight a hydraulic jack can lift, the higher its lifting height is usually. The lowest lifting height among modern double-rod jacks that can be found on sale is the Sorokin 3.560 - 135 mm model.

It also features an electric lifting mechanism.

The lowest lifting height among modern double-rod jacks that can be found on sale is the Sorokin 3.560 - 135 mm model. It also features an electric lifting mechanism.

Sorokin 3.560

Sorokin 3.560

A rather important parameter is the working stroke of the jack - the distance between the pick-up point and the threshold point of lifting. The wider the working stroke, the more versatile the tool is considered. The best choice for this parameter is "BelAK BAK.20049 20t", its working stroke is 360 mm.

It is necessary to decide how often the tool will be used. If a three-rod jack or any other will lie idle in the car, then there is no point in acquiring expensive complex models.

The choice should be made in favor of branded products. Well-known companies (Matrix, BelAK, AE&T, Sorokin) test every manufactured product for strength and reliability, use only high-quality materials, the components are well and reliably fitted. You can get a guarantee for a branded product for a duration of 1-3 years.

Important!

As practice shows, products of unknown manufacturers or fakes become unusable after a couple of uses - threads may break, nuts may crack, oil may leak out.

User manual

The design features of hydraulic, plunger jacks of this category determine their simplest operation. Almost everyone can use such equipment, even without the appropriate experience.This requires the following steps.

- Place the lift under the load (vehicle) so that the base fits snugly against the most level surface. Choosing a solid point of support for the stem is equally important.

- After installing the jack, start lifting the object. It is necessary to tighten the bypass valve and use the special lever that is included with all devices. The pressure of the working fluid is created by the up and down movements of this handle.

- After completing all work, lower the piston with the rod. To do this, the same valve will need to be turned off one turn.

It is highly recommended to check the piston and rod for dirt and water before lowering the load.

It is also important to remember that during the operation of the bottle jack it is prohibited:

- start lifting the vehicle and performing any work on the carriageway (if possible, the car should be removed off the road);

- work under the vehicle body, which is held without stops (supports) by only one jack;

- use the bumper as a stop for the stem;

- lift a car with a trailer;

- start the engine of a jacked-up car;

- leave passengers in the passenger compartment of the vehicle;

- to lift in jerks or too quickly - the movement of the lever should be smooth and uniform;

- use stones and even more bricks as supports for fixing the lifted machine and other loads.

In addition to all of the above, it must be remembered that it is highly undesirable to use the same working fluid for a long time without replacement. Changes in the properties of mineral oil have a negative impact on the performance of the lifting device.

The following rules will help to extend the life of the bottle plunger jack.

- The working fluid should be changed at least 2 times a year. With the active operation of the equipment, this procedure is carried out monthly and always with high-quality flushing of the hydraulic cylinders.

- In winter, it is necessary to fill in synthetics.

- Store the jack in a dry and warm place as much as possible.

- At low temperatures, the operating time of the device must be reduced to a minimum.

It is no secret that competent operation and timely maintenance can significantly reduce costs. High-quality prophylaxis prevents malfunctions, and, consequently, rather expensive repairs or the purchase of new lifting equipment.

How to choose a bottle jack, see below.

Bottle jack characteristics

When choosing a lifting device, you should pay attention to its technical data.

The most important parameters are:

- Maximum lifting capacity. For work with a passenger car, a bottle jack up to 2 tons is enough, for small trucks - 5-8 tons. It is impractical to use more than 20 tons of the lifted weight for personal purposes - such a jack will be heavy and take up a lot of space.

- Minimum lifting height. It is usually equal to the body height if the stem is recessed flush. The minimum height from which the lift can begin is 180-250 mm, depending on the model. This distance is not always sufficient to lift a low car with a flat tire, so the choice of this value should be considered carefully.

- Maximum lifting height. For a single stem design, the height limit is twice the body height. Two-rod ones have a slightly higher lifting height, and some are additionally equipped with a retractable screw rod with a nozzle at the end.

- Bottle jack weight and ease of use. A good unit has a durable cast body, so it cannot weigh little. Normal weight for a 2 tonne is 4-4.5 kg. Many have convenient packaging for storage in the trunk of a car.

The indisputable advantages of hydraulic devices are: compact size, stability, high lifting capacity, ease of operation, reliability, all-weather resistance.

Interesting!

They can be used not only for their intended purpose, but also for locksmith and bodywork, as a load-bearing element in pipe benders and presses.

How to choose?

There are a lot of modifications to hydraulic jacks, so you need to carefully choose the device, first of all, starting from your own needs. So, for heavy-duty trucks, the bottle device may be the best choice. It is also possible to use other constructions, but only when there is a clear understanding of exactly why they are needed. It is worth considering that the lifting height of the bottle lift does not exceed 0.5 m.

A rolling jack can be a fairly convenient solution. True, it is quite cumbersome. The mass of such models sometimes reaches 10-40 kg. They can only be placed on flat, solid areas. Therefore, such products are in demand mainly in car services and official repair services.

It is imperative to take into account the carrying capacity. Its optimal value is determined simply: 100-300 kg are added to the passport curb weight to compensate for the additional load. If you need to change the wheel, a lift of 0.3-0.5 m is sufficient. For more serious pit work, the height should be higher. A very low pickup height is needed for low-slung machines with a ground clearance of less than 0.1 m.

If you plan to work at a summer cottage, you can limit yourself to a bottle hydraulic jack with a bearing capacity of up to 10,000 kg. More powerful options are needed for professional construction crews. But you can also choose a rolling hydraulic device with the same limitation in terms of carrying capacity.

Types, properties and characteristics of a hydraulic bottle jack

Jacks are divided into several types, the first division is according to the number of rods (half-pistons):

- Single-stem bottle, the most common type Fig 2.

- Double-stock bottle Rice 3.

Fig 2. Single-pin jack

Fig 2. Single-pin jack

Fig 3. Double-rod jack

Fig 3. Double-rod jack

There is also a division according to the principle of operation of a pump that pumps a liquid:

- Manual, operated by user pressure on the lever

- Large pumps designed to lift enormous masses are driven by a separate drive, hydraulic pump or hydraulic station.

Properties:

Lifting capacity, an important parameter that determines the maximum lifting weight. The parameter depends on the volume of the working chamber and strength characteristics. Bottle-type devices have a lifting capacity from 2 to 100 tons.

The minimum lifting height, otherwise it is called the minimum pickup height. This is the height at which the load should already be located in order to be able to substitute a jack under it

Pay attention to the minimum height when choosing a device for a car. If you have a low ground clearance (ground clearance), then the bottle-type device, due to its high design, will not suit you

Maximum lifting height. The height to which it is possible to lift the load. The bottle has a feature, on the support platform there is a telescopic screw that increases the minimum and maximum lifting height.