Design features

Metabo angle grinders have a number of patented design features.

- VibraTech handle, which reduces vibration felt by the person working with the device by 60%. This allows you to use the device quite comfortably for a long time.

- Metabo S-automatic clutch, which ensures safety during operation. This design will prevent dangerous jerks in the operation of the tool if you suddenly have a jammed disc.

- Clamping nut Quick, which allows you to change the grinder circle without using a wrench. This device is not installed on all Metabo LBM models.

- The disc brake allows the grinder to completely lock the disc within the first few seconds after turning off the device. Installed on WB series machines.

- The power button is well sealed and prevents any electrical flashover. In addition, it is equipped with a safety fuse that prevents unauthorized switching on of the device.

- Technological slots in the housing provide excellent ventilation of the engine, thereby preventing it from overheating during prolonged operation.

- The gearbox in Metabo grinders is made entirely of metal, which allows you to quickly dissipate heat, which means it prolongs the life of the entire mechanism.

Advantages and disadvantages

The Metabo grinder is designed for grinding, cutting, cleaning products from various materials, be it stone, wood, metal or plastic.

This power tool has several advantages.

- High quality. The product is certified and complies with the regulatory documents developed in Russia and Europe.

- Dimensions. The devices are compact in size, while delivering quite a lot of power.

- The lineup. The manufacturer offers a huge selection of grinders with a different set of functions. Here you will find the device with the characteristics you need.

- Guarantee period. The manufacturer gives a 3-year warranty for its tools, including batteries.

The disadvantages of the Metabo grinder include only their price, which is quite high. But the quality of the device fully justifies it.

Views

Metabo grinders can be divided into several types.

By type of food

Both mains powered tools and cordless models are presented here. The Metabo company directed its developments to freeing the construction site from network wires, therefore many models of angle grinders of this manufacturer operate on battery power. Although for conservative builders, there are networked devices in the Metabo range.

Pneumatic grinders are also produced under this brand. There is no motor in their device, and the device is started by supplying compressed air, which acts on the blades inside the device and makes the circle rotate.

By application

Metabo grinders are produced both in a household version, where the power of the device is low, and in a professional one with wider functionality and increased power and torque.

By disc size

The manufacturer produces angle grinders with different diameters of cutting wheels. So, compact models for household use have a diameter of the installed circle of 10-15 cm.For professional tools, this size reaches 23 cm.

There is an assortment of grinders TM Metabo and angle grinders with a flat gear.

Tool required for repair

To repair a Bosch grinder, you cannot do without a tool. Let's make a reservation right away, if you have a screwdriver, then this will significantly speed up the process of disassembling and assembling the tool.

But you can get by with a set of screwdrivers, preferably with a ratchet. You cannot do without an open-end wrench with which you will unscrew the nut that secures the leading helical gear.

It is better to have a special puller for dismantling the bearings.

Diagnostics of the electrical part can be carried out using a tester or a device for determining the short circuit of the turns.

It is especially useful in that it allows you to determine the malfunction of a rotor or stator without removing the assembly.

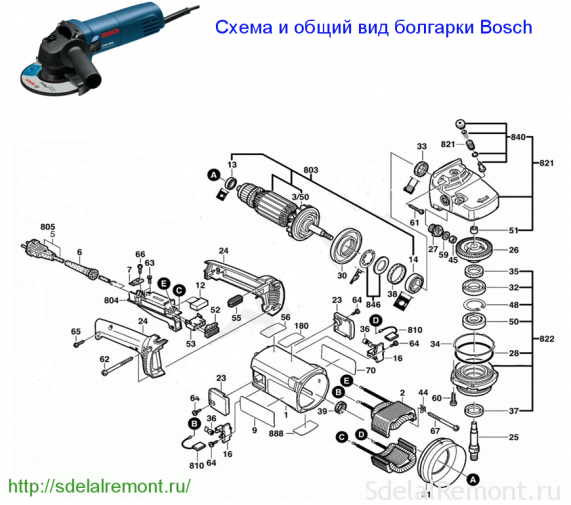

The Bosch grinder diagram will help you carry out the repair yourself, and this instruction will help you to cope with any problem with dignity.

Dismantling the Bosch grinder with your own hands

For the owner of a power tool, knowledge of its device and the ability to disassemble is a must.

Knowing the procedure for disassembling the grinder allows you to independently perform such work as changing lubricants, changing bearings and carbon brushes.

To disconnect the gearbox housing poz.821 from the stator housing poz.888, it is necessary to disassemble (remove) the housing of the grinder handle poz.24.

This operation must be performed in order to get the carbon brushes pos. 810 holding the rotor collector.

At the second stage, unscrew the 4 (four) screws, pos. 61, securing the gearbox and stator housings.

Having pulled out the rotor together with the gearbox, proceed to dismantle the gearbox.

Repair of the Bosch grinder begins with the disassembly of the gearbox pos. 821. Disassembly of the gearbox begins with unscrewing 4 (four) screws, pos. 60. As a rule, the screws are screwed into the sealant at the factory. You will have to make some effort.

Let's note right away! Low-power Bosch grinders use spur gears in the gearbox. For grinders with a power of over 1000 W, helical gears are used in gearboxes.

How to remove the driven gear

After removing the gear cover, you can get the helical gear assembly, pos. 26.

To remove the gear, you need to use a press or a puller. But using a puller is difficult, since it requires the use of special thin jaws.

Before removing the helical gear, check the backlash of the gear connection, the integrity of the teeth, the contact patch.

On the shaft of the spindle, pos. 26, a bearing, pos. 50, is pressed. If the bearing has a large play, makes noises when rotating, the lubricant has dried out, it is preferable to replace it.

To remove the bearing, it is necessary to remove the gear, circlip and dismantle the bearing. If, when removing the rotor shaft assembly, the bearing remains in the gear housing, the bearing is removed using a hammer and a soft tip.

How to remove the drive gear of a Bosch grinder

The drive gear, pos. 27, is removed from the rotor shaft in the following sequence:

- clamp the rotor by hand and, using an open-end wrench, unscrew the nut pos. 45 counterclockwise .;

- remove the washer pos. 59 .;

- pull out the leading helical gear pos. 27.

Visually check the integrity of the gear teeth, contact patch.

If the gears are badly worn (licked), there are chipped teeth, then they must be replaced. Moreover, the replacement of gears is always done in pairs.

If the gears are badly worn (licked), there are chipped teeth, then they must be replaced. Moreover, the replacement of gears is always done in pairs.

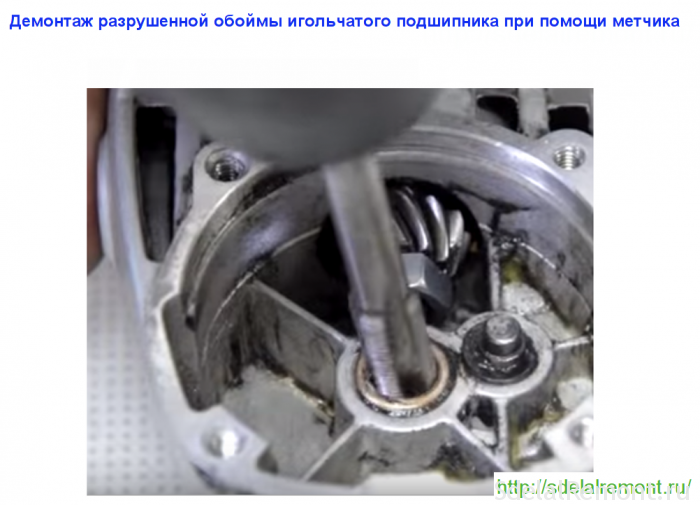

In low-power Bosch grinders, a needle bearing is used as a support bearing in the gearbox.

Do-it-yourself bosch grinder repair follow the instructions strictly provided. If you need to remove the needle bearing from the housing, you can't do without some quick wits. Its dismantling is performed only upon destruction.

To get a destroyed bearing race, you can use a proven method.

A tap is selected with a diameter slightly larger than the inner diameter of the destroyed needle bearing holder

The tap is fixed in the chuck of the screwdriver and screwed carefully at low speeds into the holder. When the tap reaches the bottom of the gear case, it will begin to lift the clip.

In addition to the needle bearing of the spindle shaft, Bosch grinders use two more bearings installed on the rotor shaft.

How to remove bearings from a Bosch grinder rotor

It is recommended to use pullers to dismantle the bearings from the rotor pos. 803 of the Bosch grinder.

The bearing pos. 15 near the collector can be easily removed, but to remove the bearing pos. 14 from the impeller side it is complicated by the fact that a number of preparatory operations must be performed.

Bearing pos. 15 is closed with a soft rubber seat. A similar rubber protection pos. 33 also covers the bearing pos. 14.

To dismantle the bearing, pos. 14, unscrew the nut, pos. 45, remove the spur gear, pos. 17, and the plastic protection, pos. 33. Using a puller, you can easily dismantle the bearing from the rotor shaft.

And if there is no puller? A vice, two metal strips and a hammer with a soft metal guide will come to the rescue.

Dismantling the Bosch grinder

How to use?

Any device ever fails. And to delay this, you need to properly handle the Metabo grinder. When working with the device, you should periodically carry out a technical inspection, clean and lubricate the grinder inside. If during the operation of the tool there are interruptions in work, you should stop the machine and identify the cause. Before disassembling it, check the integrity of the power cord, if your grinder has one. It often bends and breaks inside.

If the wire is intact, then you should pay attention to the trigger mechanism itself. Often the start button becomes greasy and clogged with dirt.

It can be simply removed and washed, and in extreme cases replaced with a new one.

But it is not always possible to fix the device yourself. There are some breakdowns that only a professional can handle, for example, your device needed to change the gearbox bearing or the gear in the head needs to be replaced. In this case, it is better to hand over the angle grinder to a service center, where highly qualified specialists will carry out a complete diagnosis of the device and replace worn parts, especially since the authorized Metabo services have a fairly developed network in our country.

Safety precautions should also be followed when working with this tool.

- Work in overalls and glasses. Sparks and abrasive particles can bounce off and injure you, so protection should not be neglected.

- Do not remove the cover from the grinder without special need during operation. It will also protect you from serious injury in the event that the disc explodes.

- Do not cut the chipboard with this tool. Use a saw or hacksaw for this material.

- Hold the device firmly during operation. If the disc is jammed, the tool may fall out of your hands and harm your health.

- When working, do not under any circumstances speed up the process by pressing on the processing material. You only need to apply force to the instrument itself, and even then it is insignificant.

Take good care of the instrument, then it will delight you with continuous work for many years.

See the next video for more details.